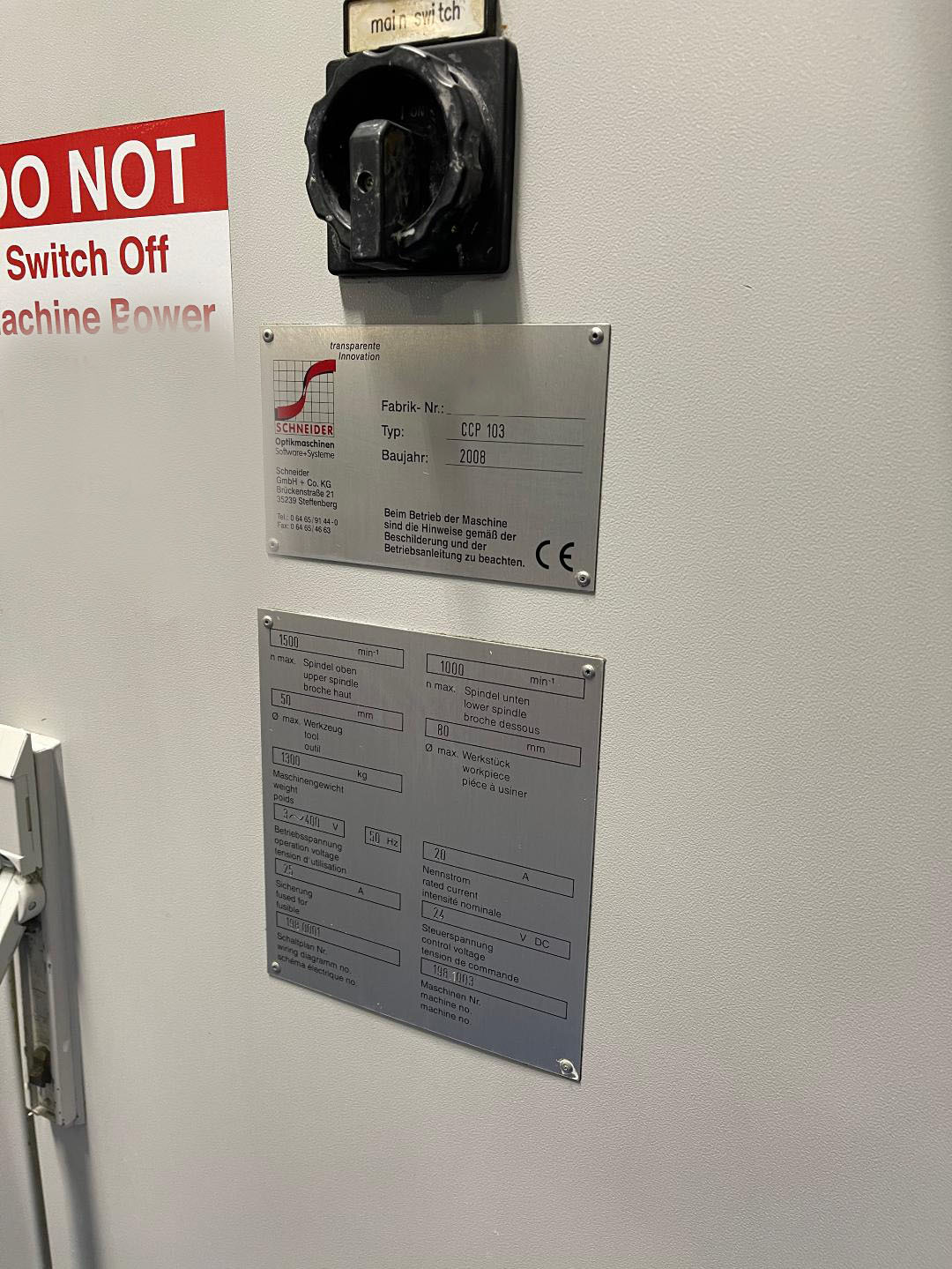

Used SCHNEIDER CCP 103 #9363946 for sale

URL successfully copied!

Tap to zoom

SCHNEIDER CCP 103 is a versatile wafer grinding, lapping, and polishing equipment designed to provide optically flat surfaces with precise shape and parallelism. This system is suitable for testing and processing many types of semi-conductor substrates and device components such as silicon wafers and gallium arsenide wafers. CCP 103 incorporates two-axis traversing in the X-Y plane with a repeatability of 0.1µm. This unit employs a versatile clamping mechanism to secure the mounted substrate. The fixture provides secure clamping using a 1" vacuum vent port, spring loaded aluminum clamp, and adjustable pressure knob. The fixture accepts substrates up to 4" in diameter and features an adjustable ring that allows for precise alignment of the wafer before and during the grinding process. SCHNEIDER CCP 103 wafer grinder consists of a durable granite base, a high-precision linear guide, and a top spindle driven by a DC brushless motor, with a frequency range of 10 to 2000 Hz. A diamond-impregnated grinding wheel is used for removing substrate material. The wheel is diamond abrasive-filled for superior grinding performance, providing unparalleled machining speed and precision. The lapping capabilities of CCP 103 machine provide excellent surface finish. A lapping wheel consisting of an aluminum oxide-filled resin is used to produce an optically flat surface, with precisely controlled concentricity, parallelism, and flatness. The polishing capability of SCHNEIDER CCP 103 is driven by a motion and technology-optimized DC brushless motor with a frequency range of 10 to 2000 Hz. The polisher wheel is diamond-filled for enhanced polishing performance, providing superior surface finish. A wide range of polishing and substrate materials can be processed using this tool, making it highly versatile and suitable for many applications. CCP 103 asset also features an adjustable speed controller, allowing the user to dial-in the optimal processing speed. The accurate linear motion control and motion force monitoring ensures consistent material removal and flatness tolerances, resulting in a superior surface finish. In addition, SCHNEIDER CCP 103 model provides accurate temperature control and feedback, enabling consistent and repeatable processes for precision machining. With its accuracy and ease of use, this equipment is ideal for the most demanding grinding, lapping, and polishing tasks.

There are no reviews yet