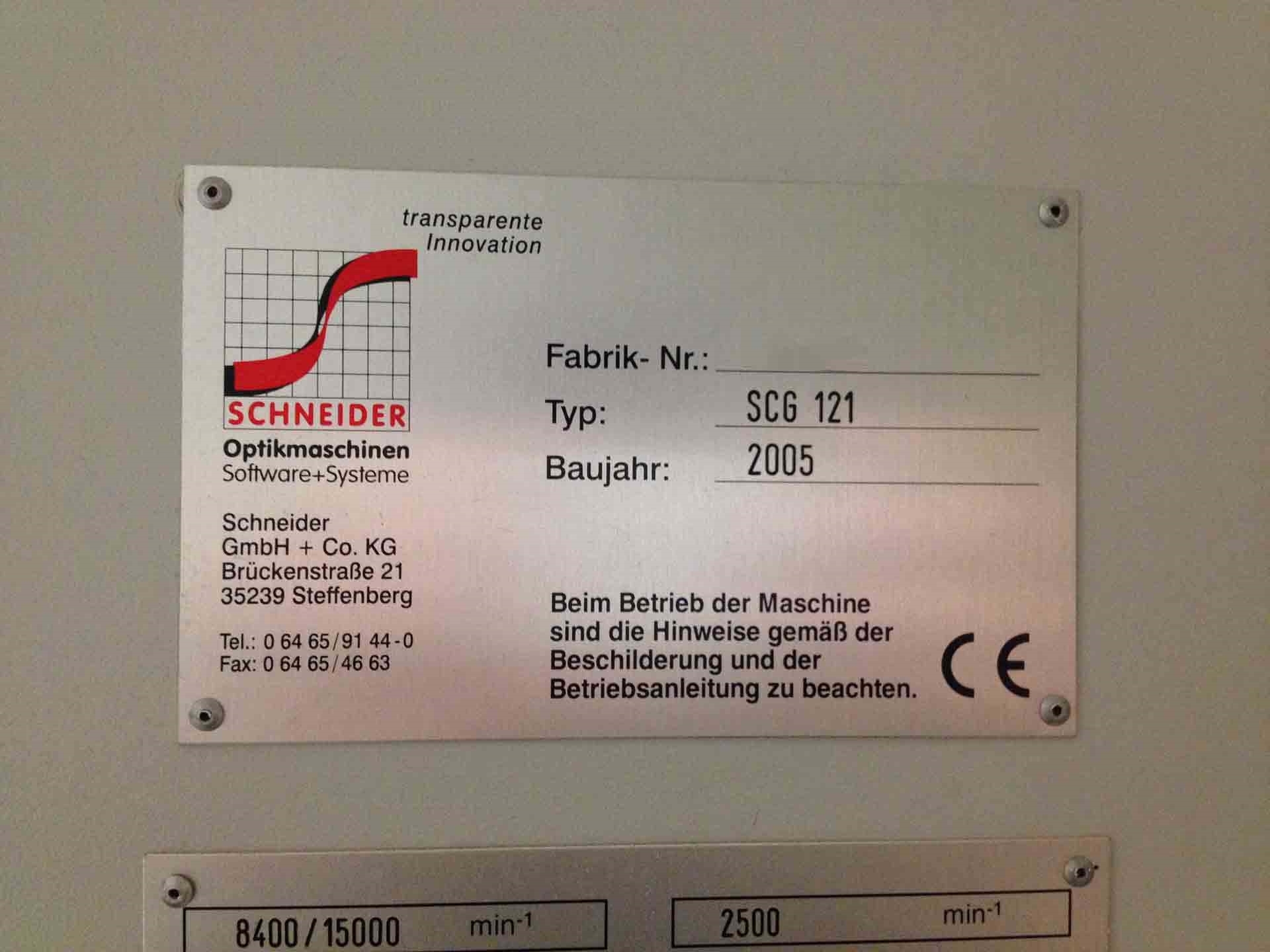

Used SCHNEIDER SCG 121 #9161016 for sale

URL successfully copied!

Tap to zoom

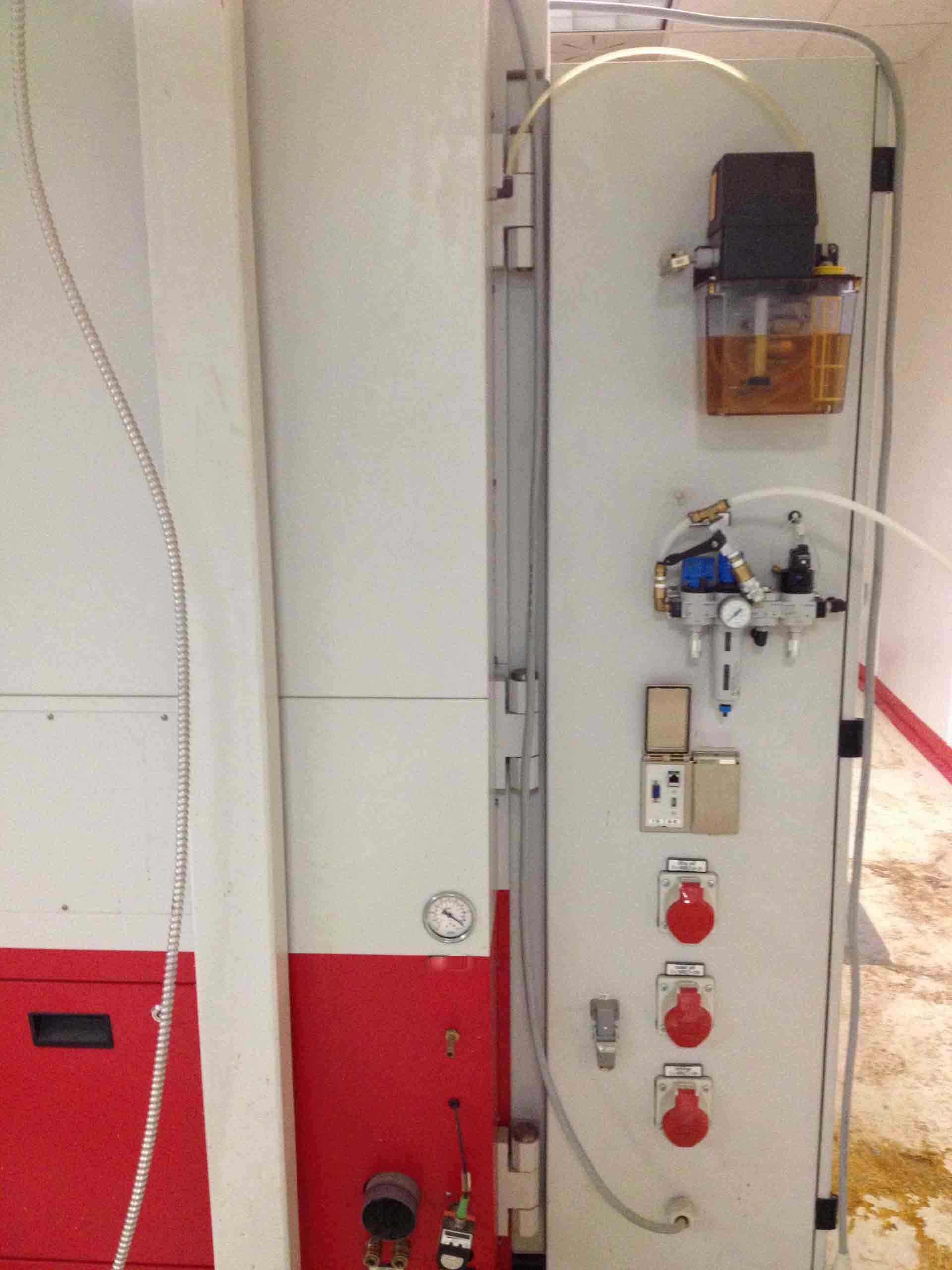

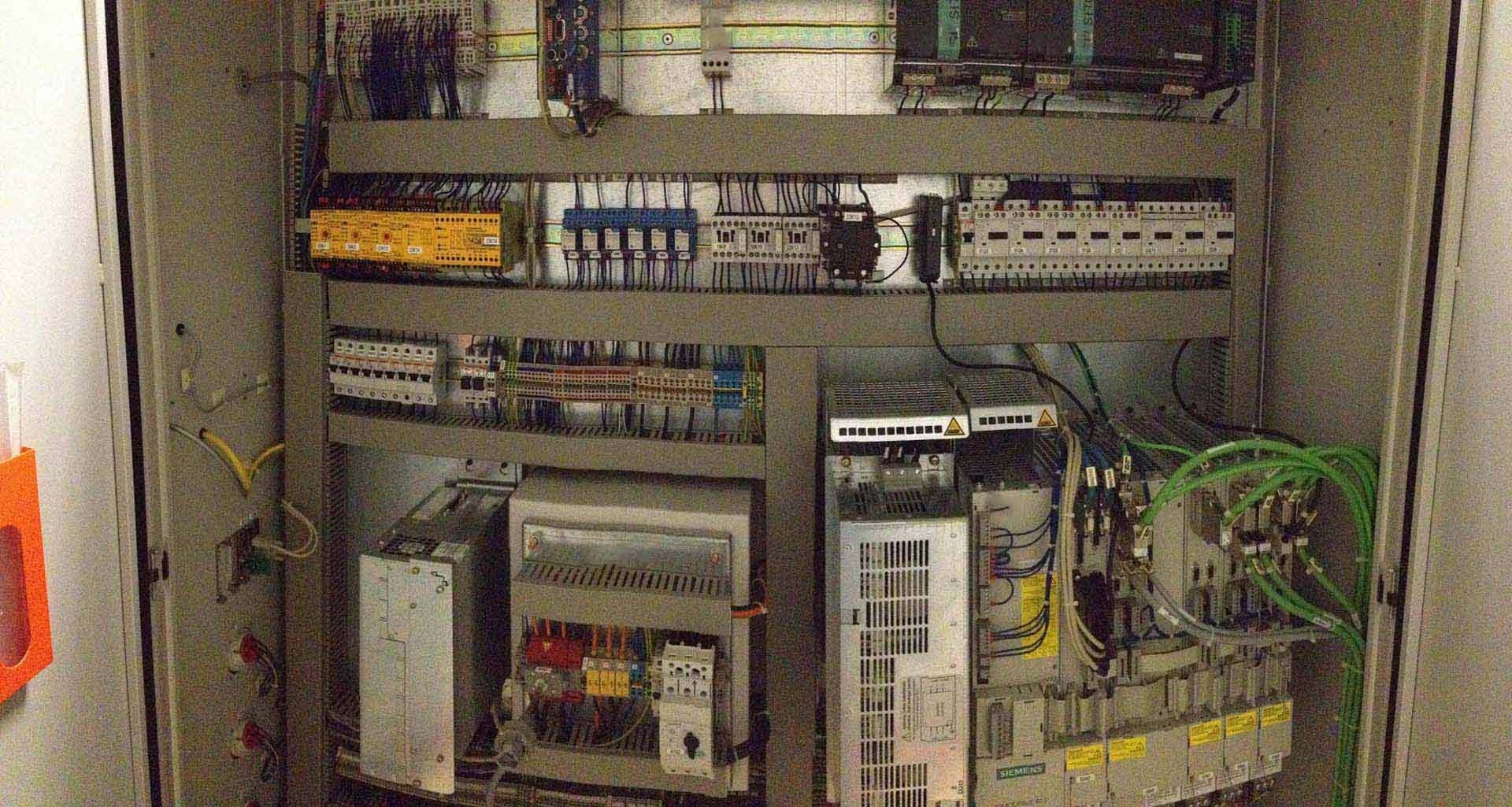

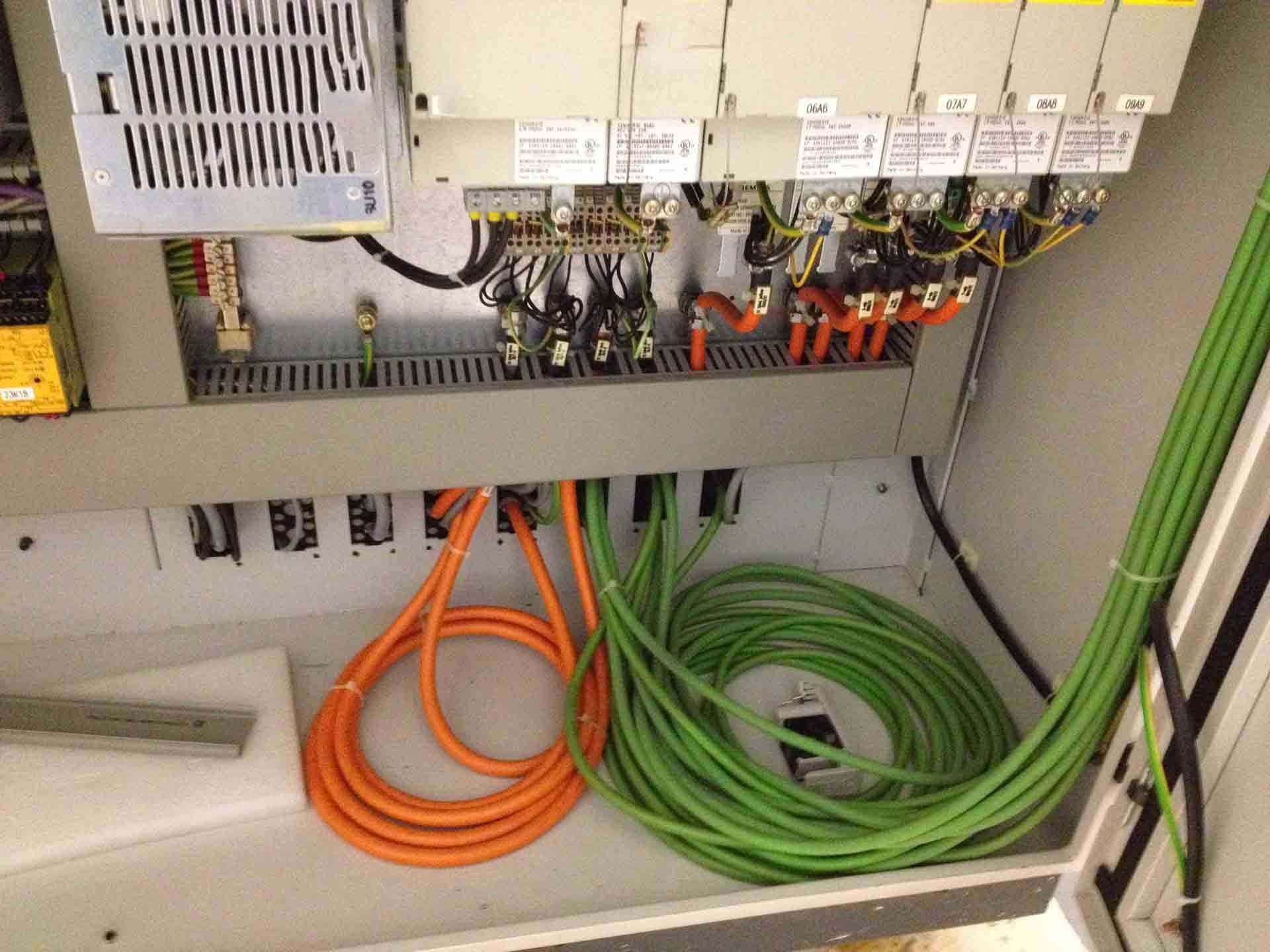

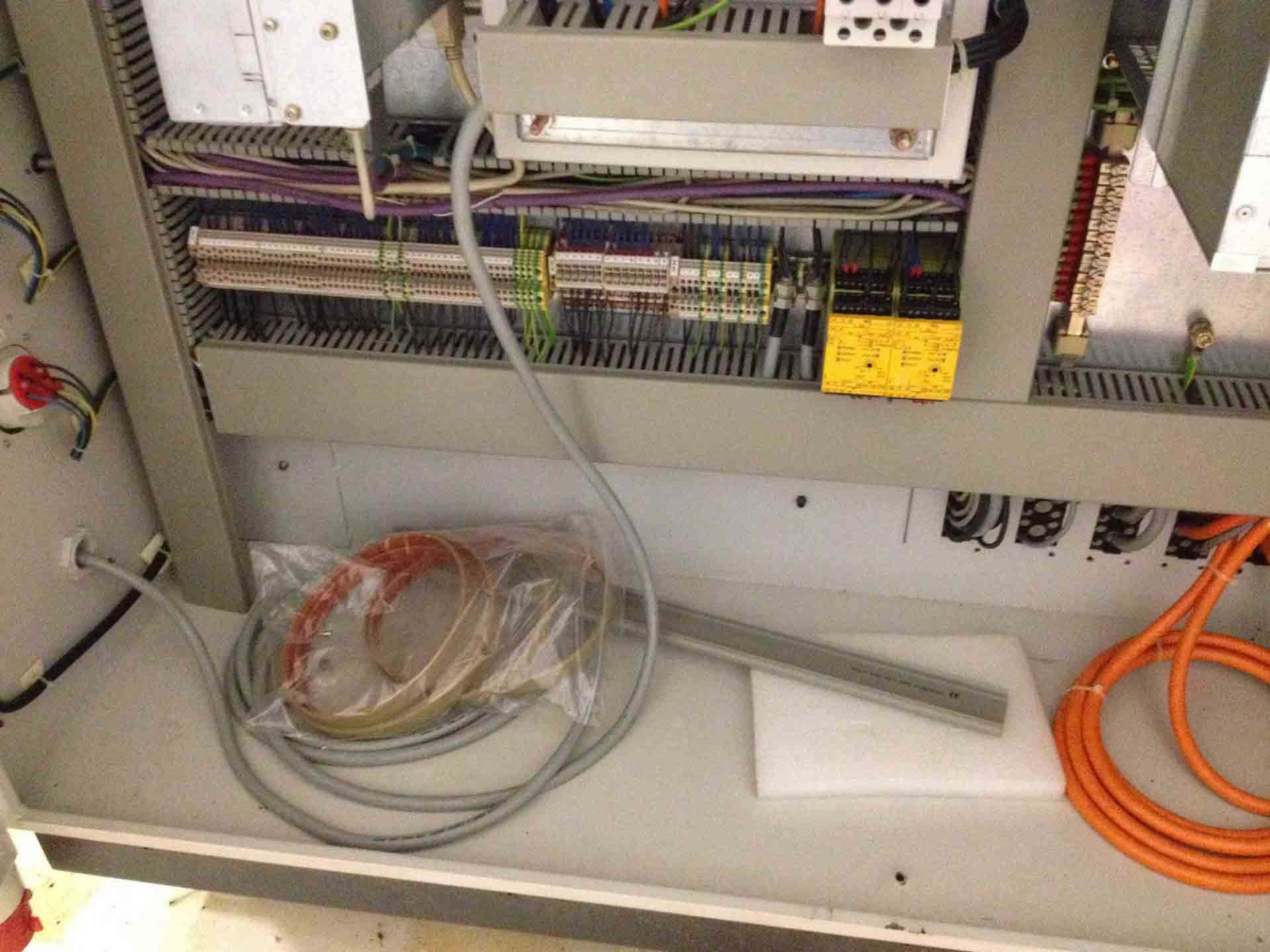

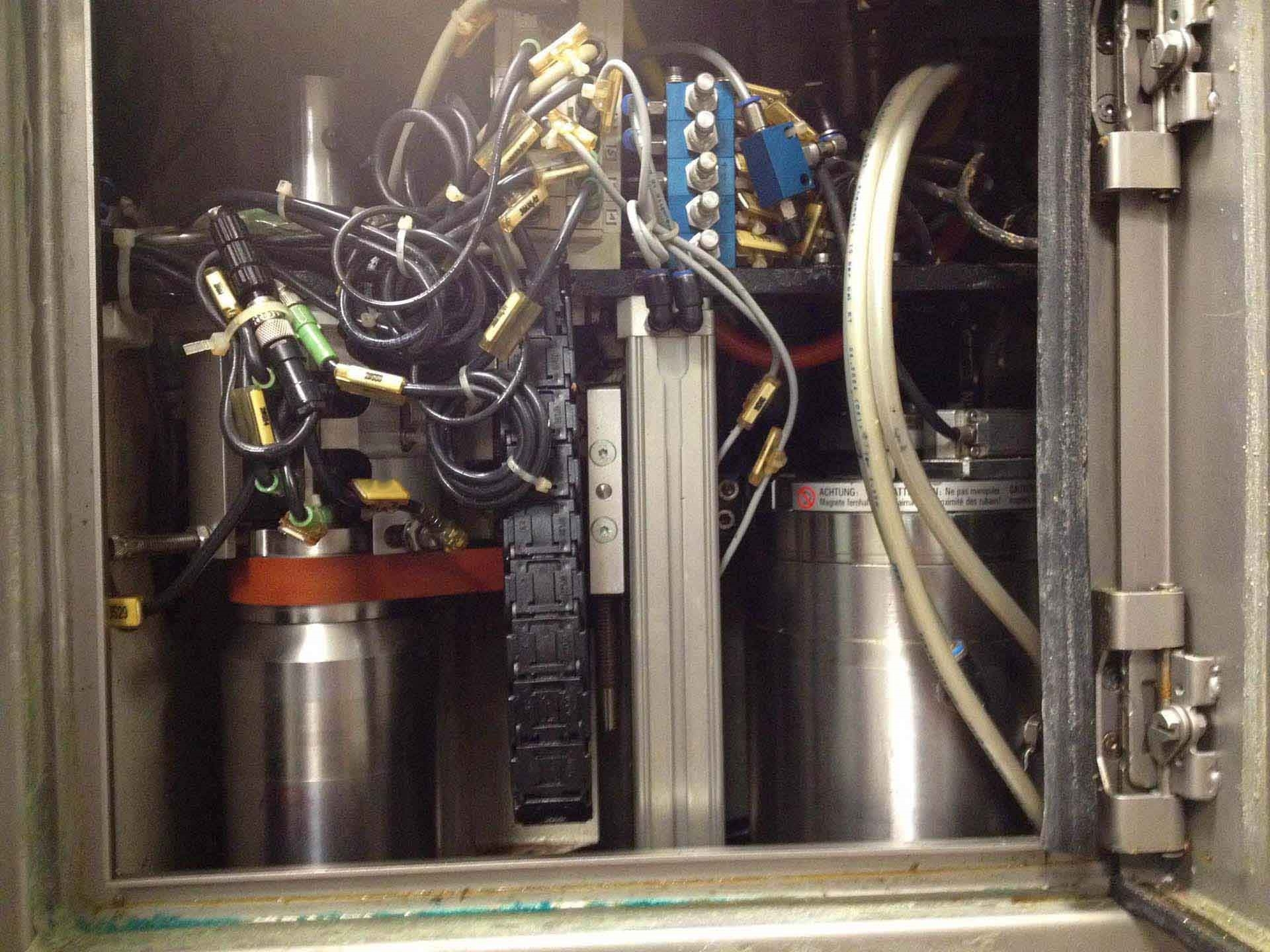

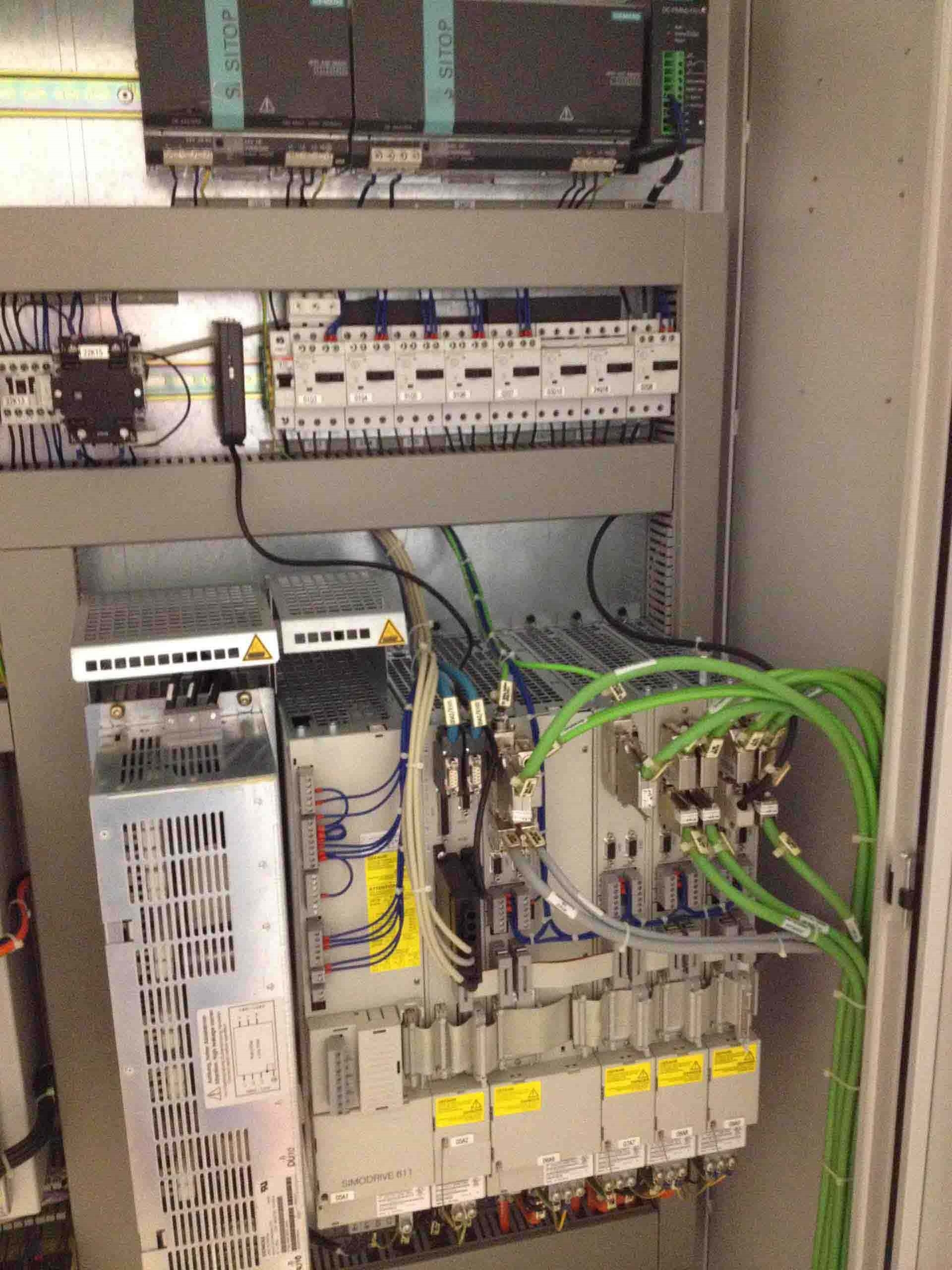

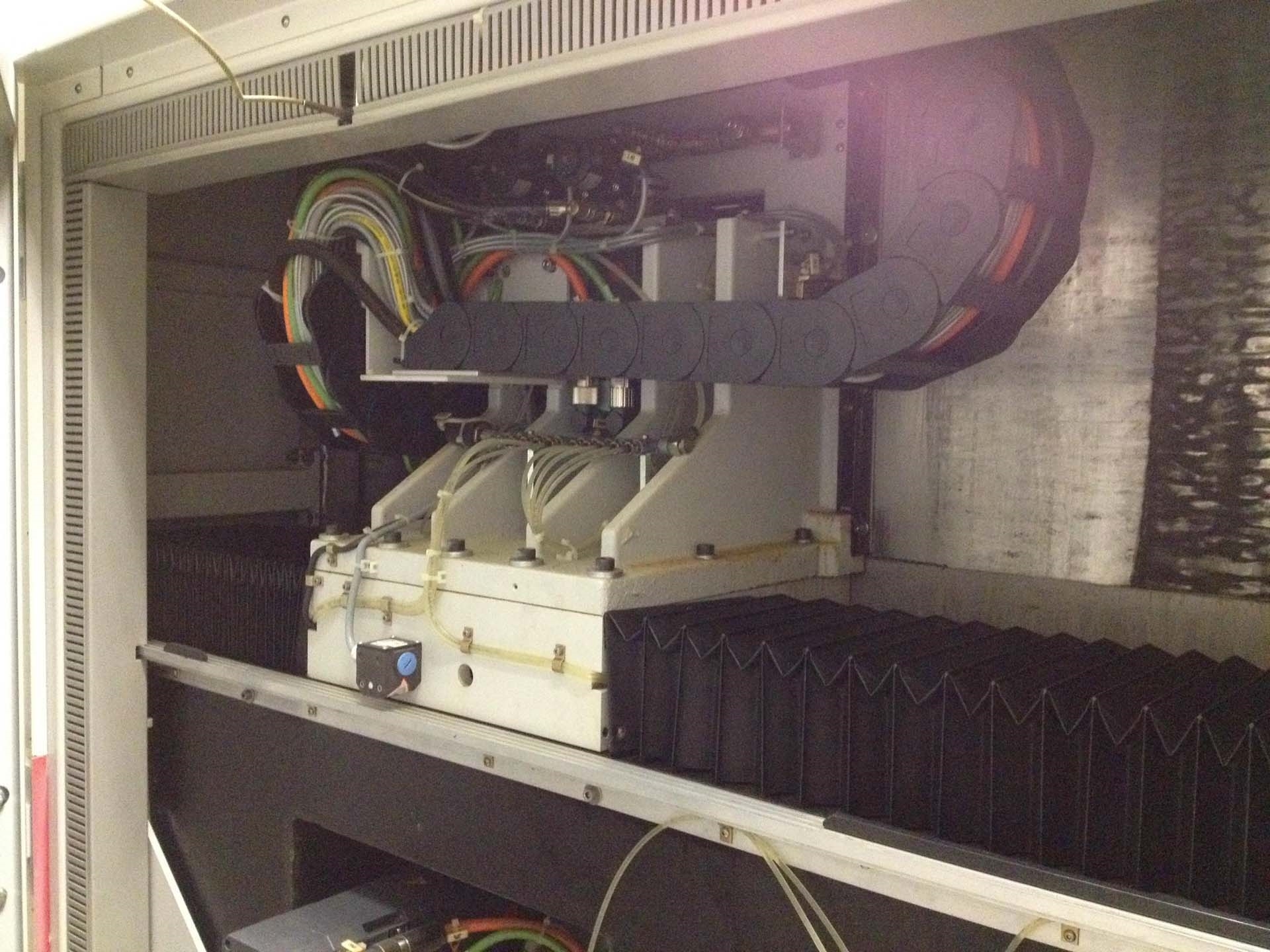

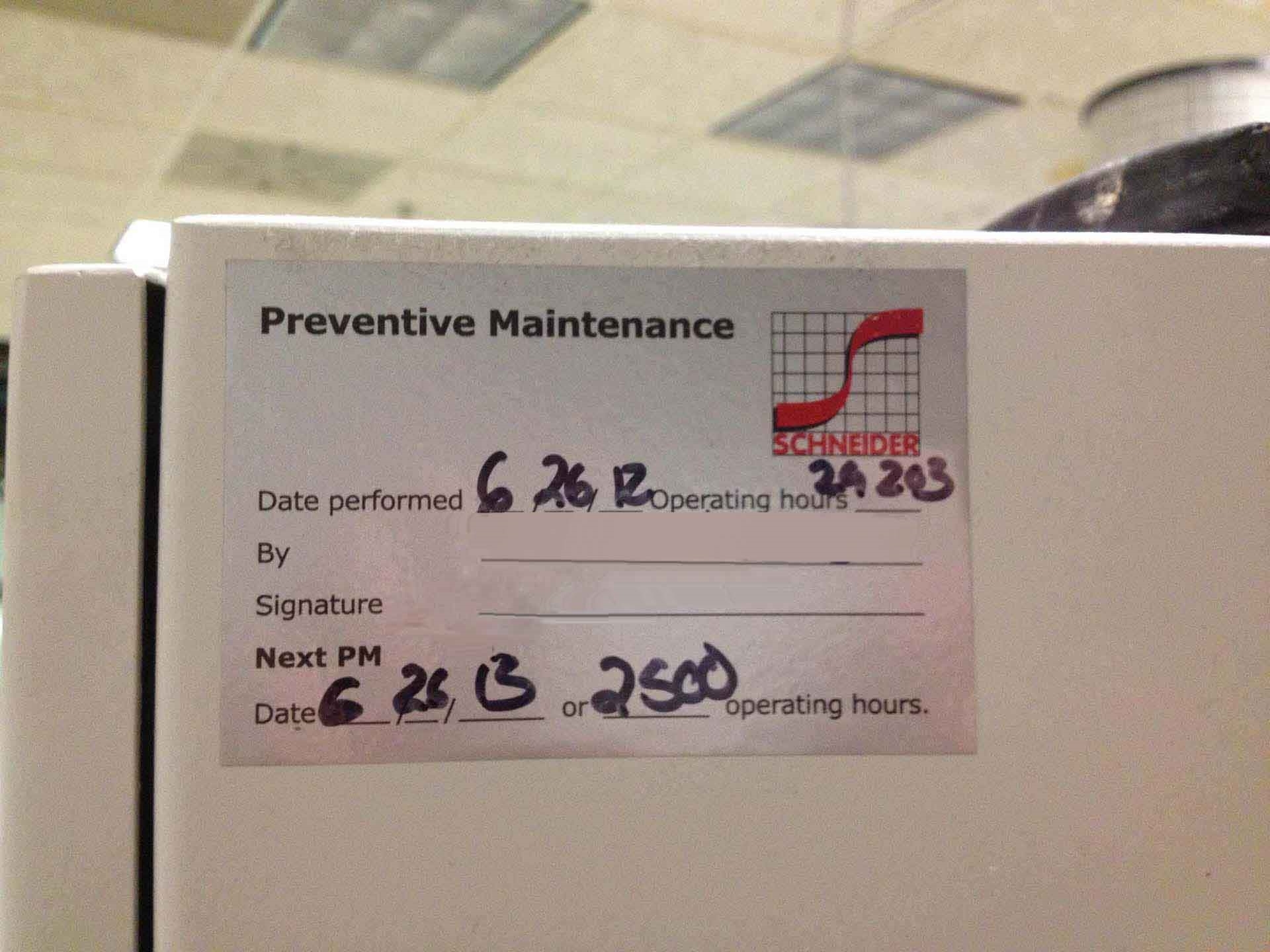

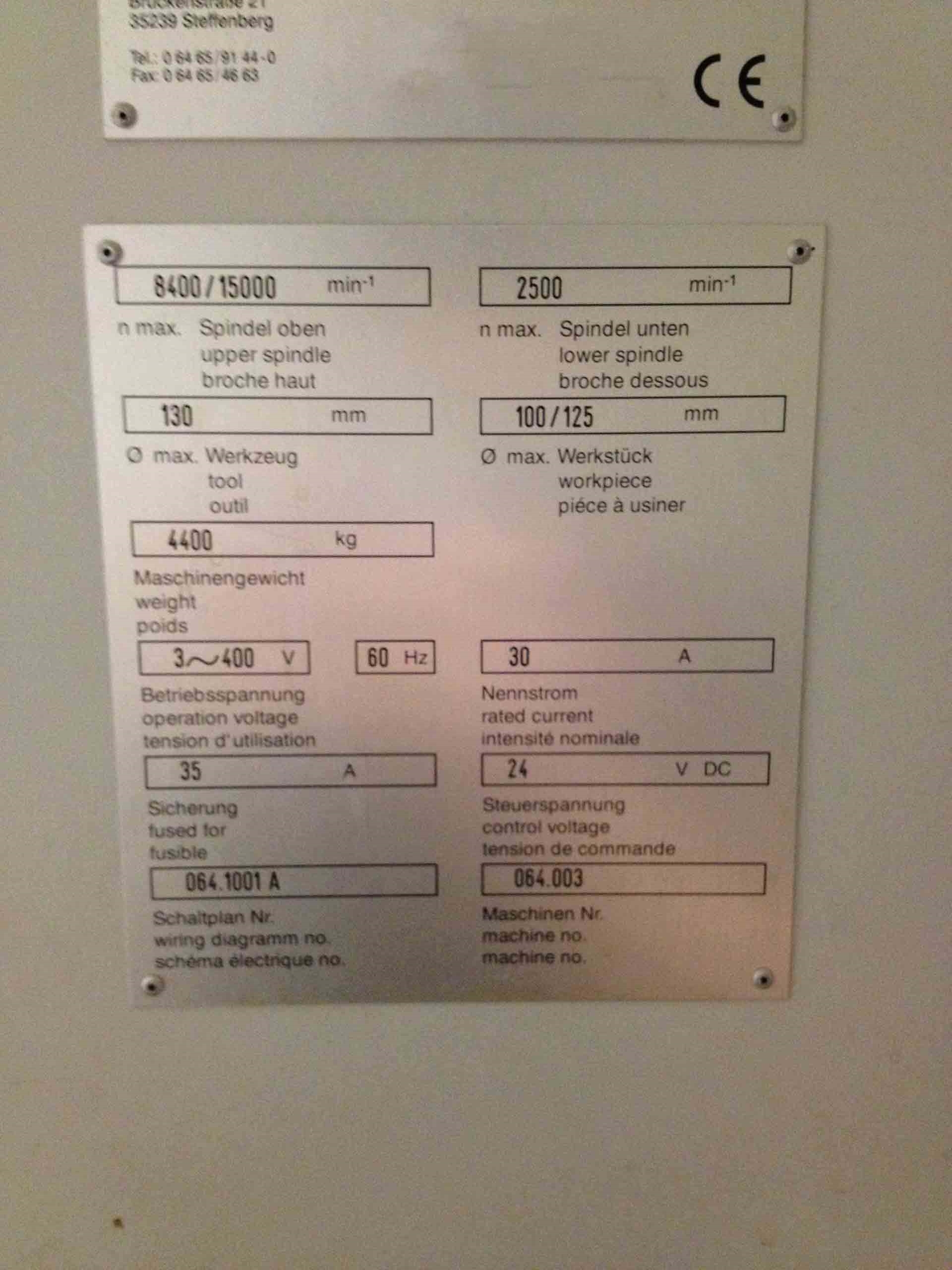

SCHNEIDER SCG 121 is a fully automated wafer grinding, lapping and polishing equipment specifically designed for the fabrication of advanced III-V compound semiconductor devices. It is the first of its kind in the semiconductor industry and offers a completely automated solution for performing complex processes on small wafers at the nanoscale with high precision. SCG 121 consists of three processing components: A manipulator arm for holding the wafer, an air bearing grinding/polishing disc, and a single-axis tilt stage that rotates the wafer relative to the direction of grinding/polishing. The wafer is loaded into the manipulator arm and secured in place. The manipulator arm is then moved to the disc, which can be adjusted for various grinding/polishing angles. The tilt stage can also be adjusted to ensure that the wafer is passing constantly over the same area of the disc. The system also includes a control unit with a graphical user interface for controlling the entire operation, including setting grinding/polishing angles, speeds, and duration of each process. Additionally some models are available with a data logger for logging the process history and parameters. The unit is built with advanced feedback and control technology which helps achieve highly accurate tolerances and extreme process repeatability with minimal variation even over long production runs. Its stability requirements, coupled with the machine's automated operations, makes it ideal for the most demanding high-reliability semiconductor device fabrication processes, such as creating nanoscale gate threshold voltages or the bonding of advanced metallisation layers using full-surface grinding and polishing techniques. SCHNEIDER SCG 121 also allows for the customization of grinding/polishing processes through the selection of different media such as emery cloth, diamond impregnated pads, or lapping films to achieve optimum surface finish quality. Its good mechanical structure design is well-suited for high vibration environment and it also offers efficient tool cooling and heating for superior process stability and long-term reliability. The asset is also designed with safety features to help ensure operator safety. SCG 121 is a cutting-edge model for wafer grinding, lapping and polishing that offers superior flexibility, accuracy, and productivity for semiconductor fabrication. This multi-functional equipment is an ideal choice for making reliable and precise devices with nanoscale features.

There are no reviews yet