Used SCHNEIDER SLG 301 #9203345 for sale

URL successfully copied!

Tap to zoom

ID: 9203345

Vintage: 2002

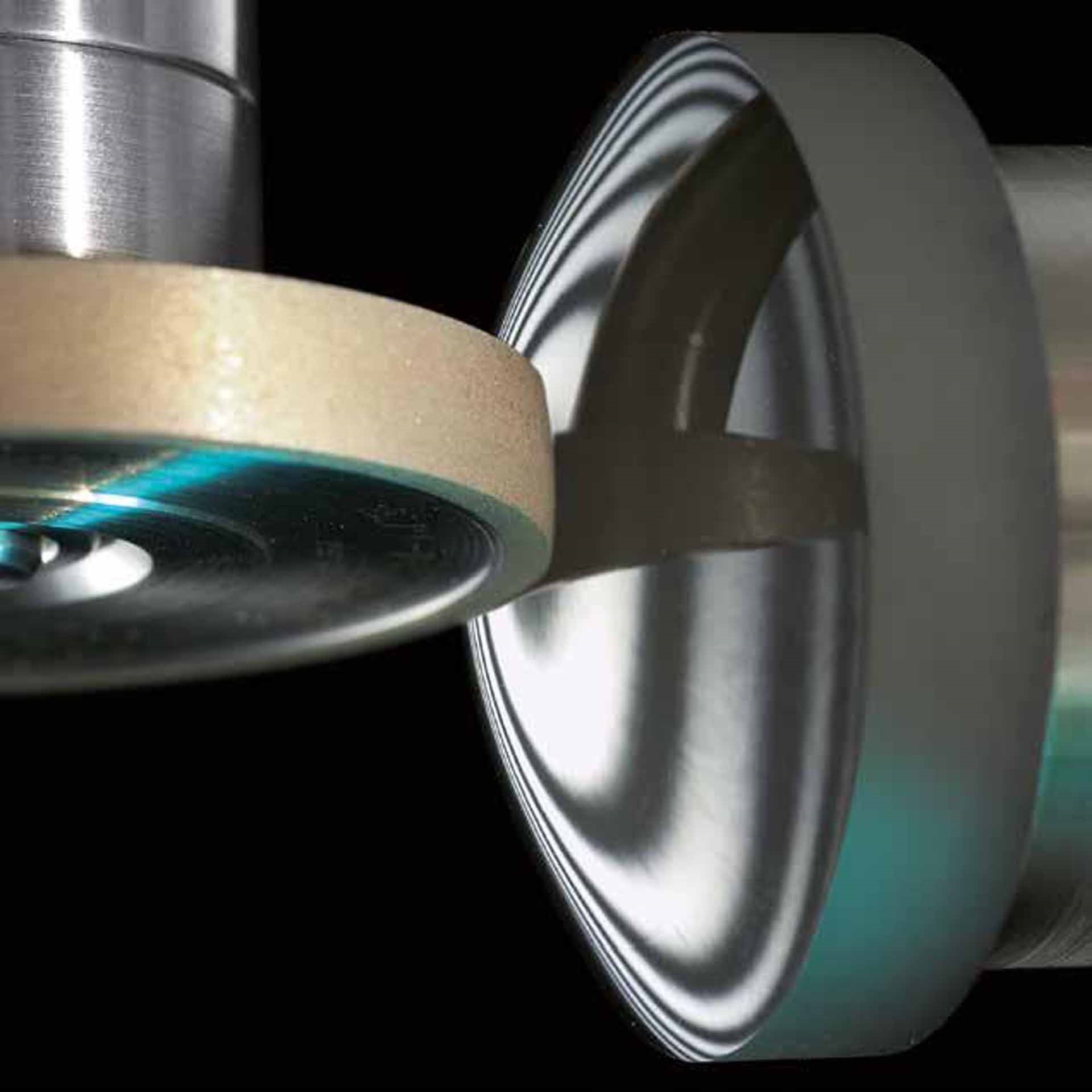

Spherical surface grinder

CPU Has been replaced

Feed control:

Load dependent feed-rate control

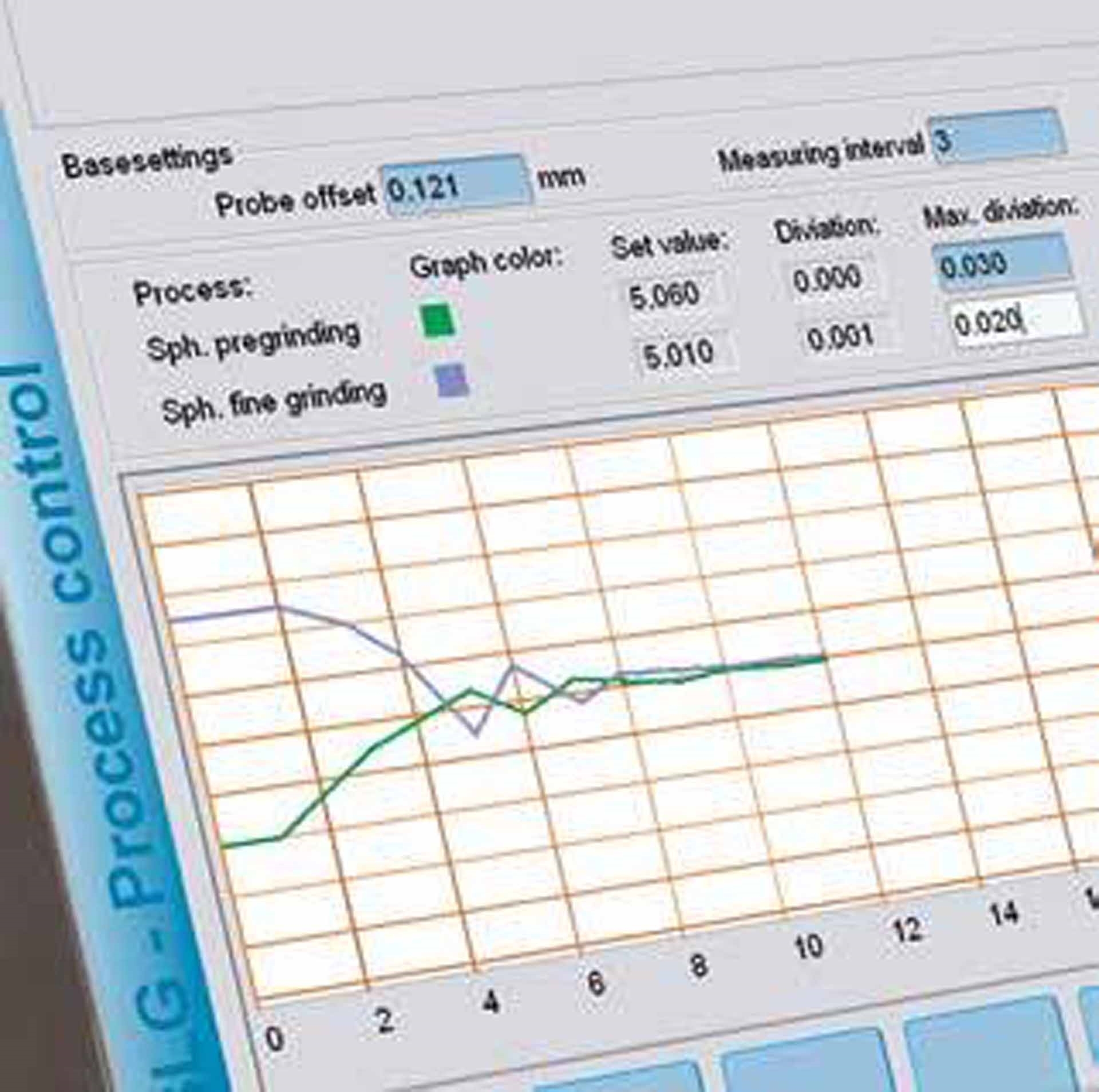

CNC Controlled measurements ensure precise center thickness control:

Reduction of setup times

Process control

Tool control:

CNC Controlled recognition of the grinding tools

Significant reduction of the setup time

Verification of tool settings

Kinematics:

Manufactured on a cast-iron bed

Geo control:

CNC Controlled axis position

Optimization of sphericity

Working range maximum ø: 480 mm

Working range radius: 30 mm flat

Number of axes: 4 (5) + 1 (X, Z, B, C, (Y), Q)

Feed rate:

X-axis: 0.01 15000 mm/min

Z-axis: 0.01 7500 mm/min

Positioning accuracy

Repeat accuracy:

X-axis: +/– 0.001 mm

Z-axis: +/– 0.001 mm

Feed rate b-axis: 0.01 – 2160 °/min

positioning accuracy

Repeat accuracy B-axis: +/– 4"

Tool spindle connection: 40 x 80 HD, HSK-A 50 (TC)

Speed range: 1000 – 7000 min^-1

Workpiece spindle connection flange ø: 120 mm

Speed range workpiece spindle: 25 – 1500 min^-1

Power requirement maximum: 25 kW

Air requirement min: 6 bar (90 psi)

Vacuum min: 0.6 bar (9 psi)

2002 vintage.

SCHNEIDER SLG 301 is a wafer grinding, lapping & polishing equipment designed to address the most demanding requirements for thin wafer processing. It offers a high degree of flexibility due to its modular, open-frame design which allows for ease of access, installation, and maintenance. At the heart of the system is its high-speed, multi-pressure turbine wheel motor that is capable of producing high levels of power that can be precisely controlled regardless of the type of starting material. This powerful motor is paired with adjustable eccentric masses, allowing for maximum speed control and the ability to accurately calculate the contact pressure of the grinding, lapping or polishing process. SLG 301 utilizes a computer-controlled grinding, lapping and polishing tool which ensures repeatable process execution, precision, accuracy, and consistency. The tool which is controlled by the operator is then fitted into the pre-defined grinding, lapping or polishing process and allows for reproducible results. Processes for SCHNEIDER SLG 301 can include grinding, lapping, and polishing of wafers and other materials, including: sapphire, quartz, and optical fibers. Furthermore, the unit is capable of handling wafers with a thickness ranging from 0.5mm to 50mm, as well as materials with a thickness ranging up to 300mm. The safety of process handling is paramount with SCHNEIDER SLG. Thanks to its Sensor Box and Digital Electrics Suite, the machine is equipped with a wide range of safety and monitoring features that include monitoring of the wafer temperature, monitoring the polishing force and operation speed as well as monitoring wear of the lapping or polishing disc. SLG 301 comes with a user-friendly operating machine which enables quick and efficient wafer process set-up and control. The steps which are included in the set-up are: file management, process parameter setting, wafer preparation, wafer fixing, process execution, wafer unloading, and post-processing data analysis. This tool also offers sophisticated process data analysis, such as process parameter history, substrate calculation, and wafer output calculation. SCHNEIDER SLG 301 is the perfect solution for those that need a versatile and reliable wafer grinding, lapping and polishing asset. Thanks to its superior technology and precision control, it can deal with even the most demanding wafer processing requirements.

There are no reviews yet