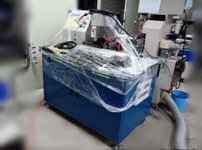

Used SEC GCM-650B #9399476 for sale

URL successfully copied!

Tap to zoom

SEC GCM-650B is an automated wafer grinding, lapping and polishing machine designed to produce precise, uniform thicknesses and flatness of substrates. The machine features a numerical control equipment, built-in measuring system, and automated stacking and clamping to ensure precise processes and superior results. The unit can process semiconductor wafers up to 6" in diameter both with and without a handle. The grinding and lapping process evenly finishes both the surfaces and the subsurface with a high surface quality result. The adjustable feed rate on the feed table and the rotational table speed allow for precision grinding and polishing. The process starts with the feed table picking up the wafer from the stack. The feed table then transfers the wafer onto the rotational table. The polishing media, in the form of abrasive discs, is placed onto the rotational table. The wafer is then set with the corresponding cutting pressure and rotational speed before the grinding and lapping process is started. The cutting pressure can be adjusted and monitored from the numerical control machine. As the grinding lapping is performed, the polishing media is slowly removed and a fresh piece of media is placed on the rotational table. The entire process is repeated until the desired thickness is achieved. GCM-650B measures results using an integrated digital thickness control tool, a measuring asset that continuously monitors the thickness, flatness, and size of the substrates during the process. After each thinning step, the measurement is taken and the difference between the actual thickness and the target thickness is reported. Should any inaccuracies be found, they can be corrected with refinement iterations. Once finished, the parts are removed from the rotational table and transferred to the discharge table. The parts can then be placed in the collection bin for further processing, packaging, or shipment. SEC GCM-650B wafer grinding, lapping, and polishing machine is an automated and precision model with superior results for obtaining uniform thickness and flatness of substrates. The equipment enables users to produce high quality and accurate parts while being controlled by a numerical control system, measuring unit, and automated stacking and clamping. This machine is suitable for a variety of industries including telecommunications, electronics, optoelectronics, and bio-medical companies.

There are no reviews yet