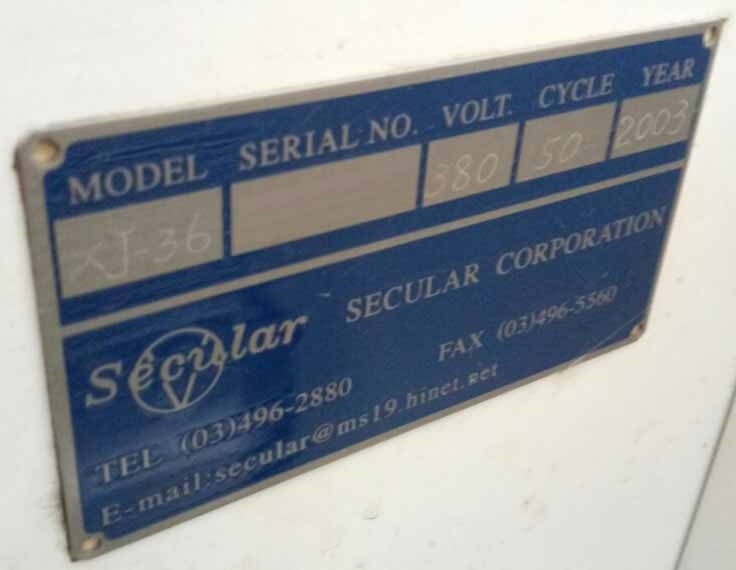

Used SECULAR XJ-36 #9280303 for sale

URL successfully copied!

Tap to zoom

SECULAR XJ-36 is a wafer grinding, lapping and polishing equipment specifically designed for research and production applications. This system is ideal for thin film processes requiring vertical and radial orientation to obtain the best lapping and polishing results. The multiple tilting angle chuck allows for easy material loading and chip loading on the wafer, improving productivity and throughput. The unit can also be used to fabricate intricate shape complex parts, which makes it suitable for a wide range of research applications. XJ-36 grinding machine is composed of two wafer carriers, with a mounted spindle drive motor and grinding spindle. This tool is designed for precise and repeatable grinding across even the toughest materials, allowing users to accurately form and shape components. It also includes a completely integrated digital control interface which provides comprehensive process control, programming, data capture, and analysis. This digital manager is specifically designed to provide users with easy-to-use intuitive operation capabilities. SECULAR XJ-36's grinding and polishing systems feature a robotic arm for handling die boards, a robotic arm that can be used for both die pick and placement back to the original carrier, and a dual lapping plate. This multi-functional robotic asset is designed to provide maximum flexibility for process control and optimization. XJ-36 also includes a fully automated wafer load/unload model which allows for greater flexibility and segmentation of the process. This equipment also includes a wafer edge detection robot for precise edge control, edge deburring, wafer substrate thinning, and edge chamfer. SECULAR XJ-36 has a user-friendly operator interface with stone selection, program storage, parameter setting, and stone management functions. With the automatic vision recognition system, you can easily inspect the wafer's surface, edge, thickness, and radius before and after processing. This unit is also capable of tracking and recording the exact process data for each sample, allowing for easy analysis after the complete process is finished. XJ-36 also features an integrated high-frequency heating facility which enables users to adjust the temperature of the wafer without any downtime. It also supplies a cooling machine to decrease process time and achieve maximum quality results. This tool is further designed with a vacuum chuck that works in combination with the grinding asset to help increase surface cleaning. Finally, this grinding model is equipped with a nanoparticle grinding wheel which is ideal for high-end applications such as MEMS, advanced semiconductor, and photonics.

There are no reviews yet