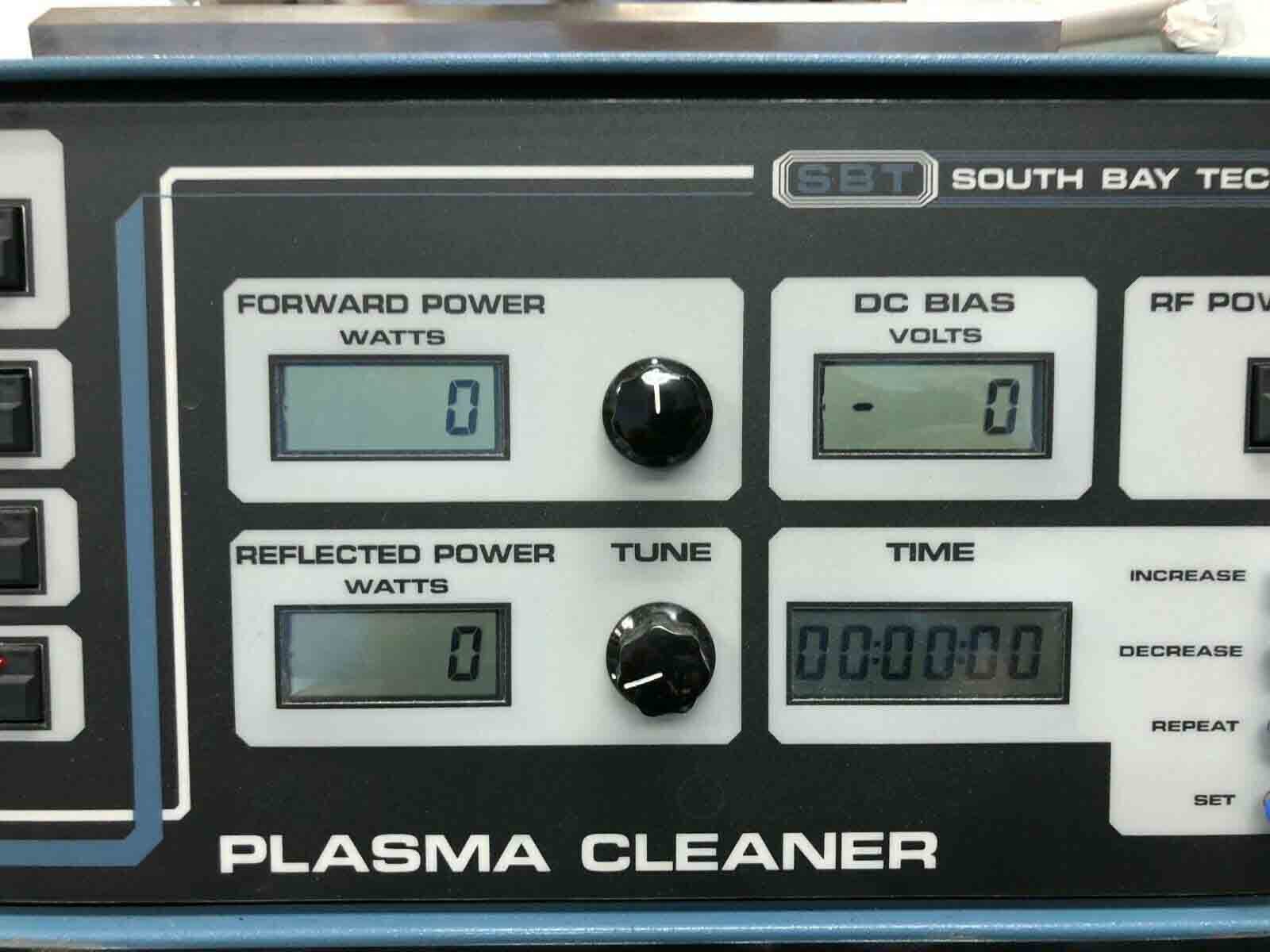

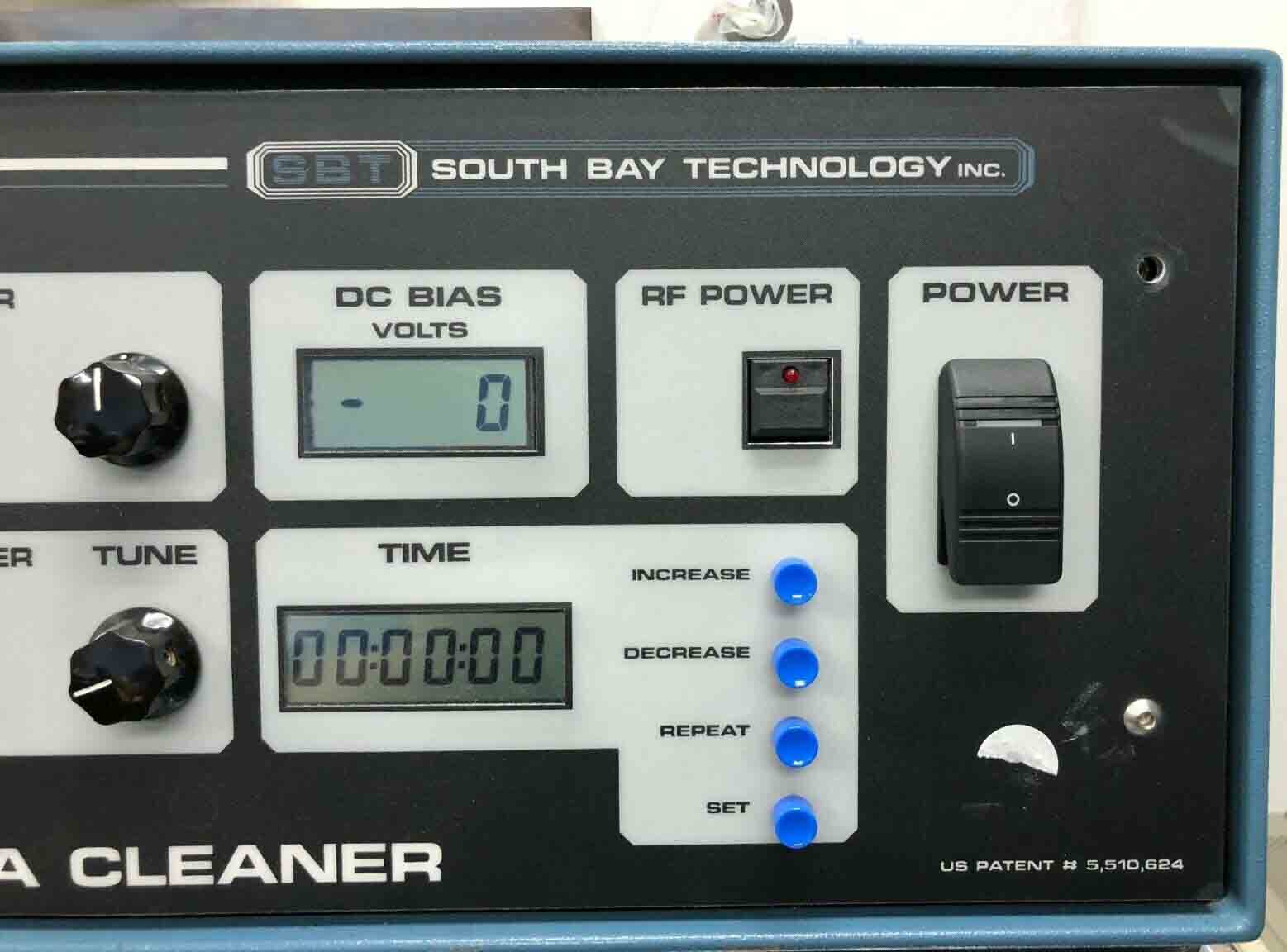

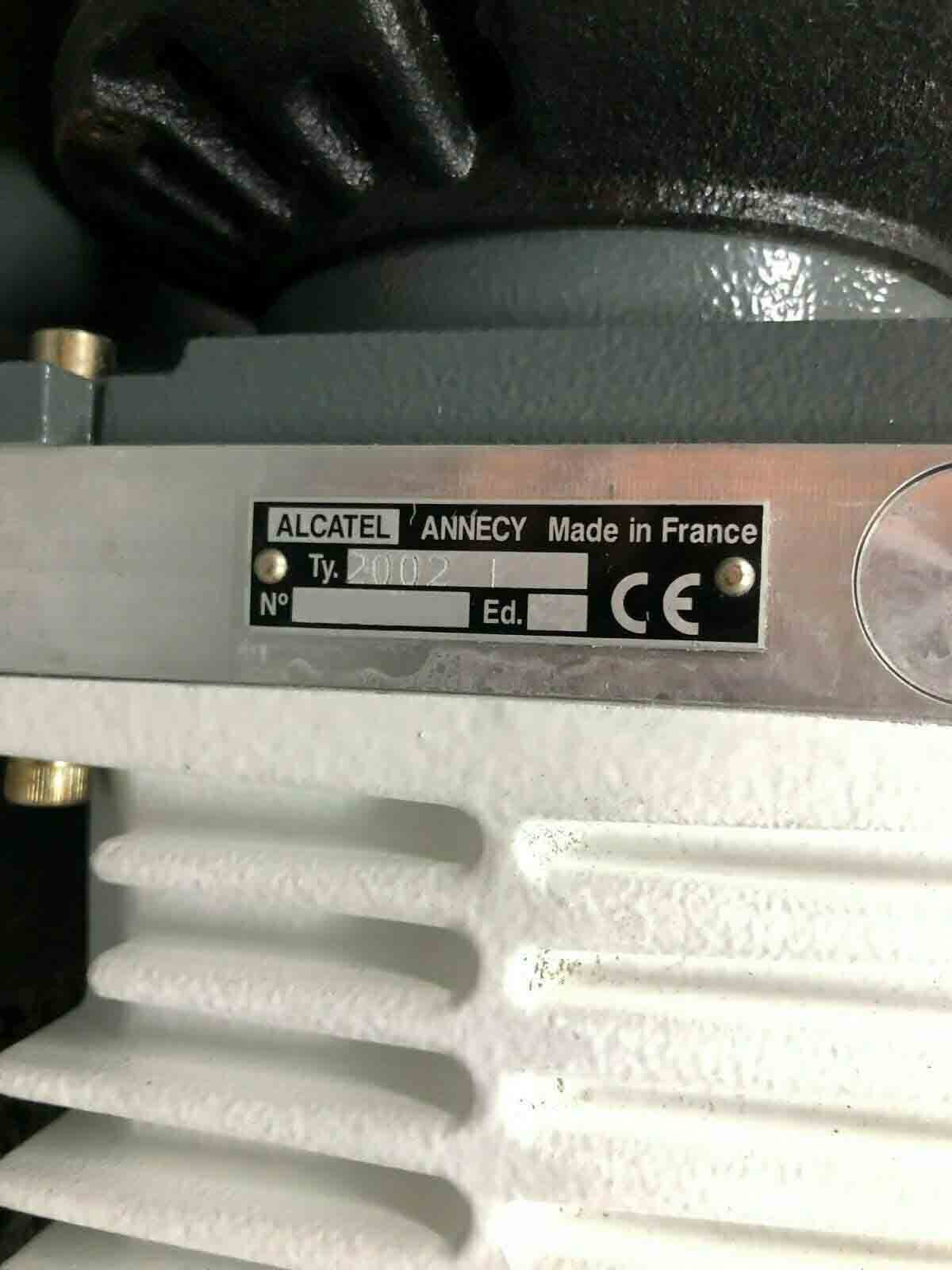

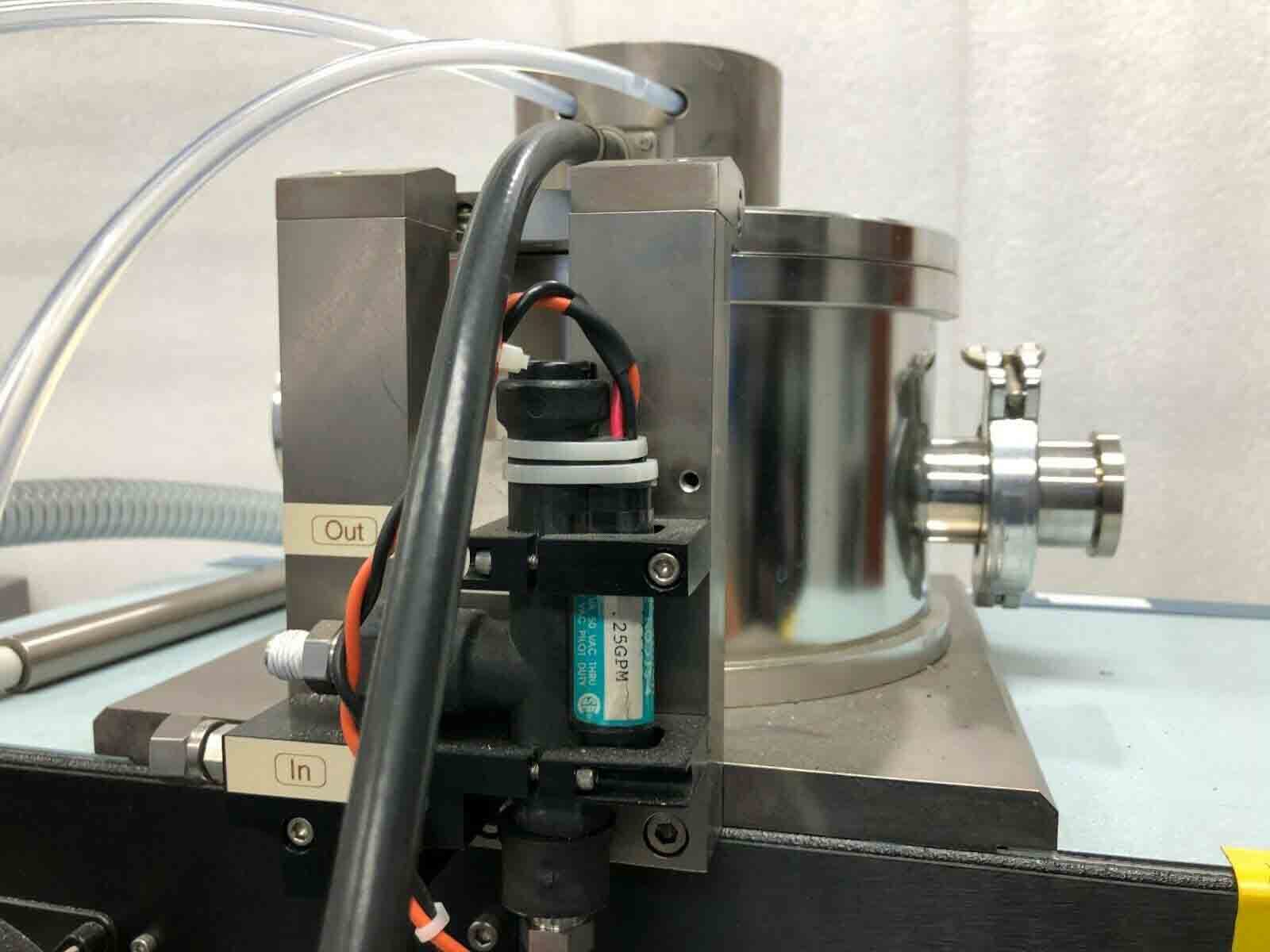

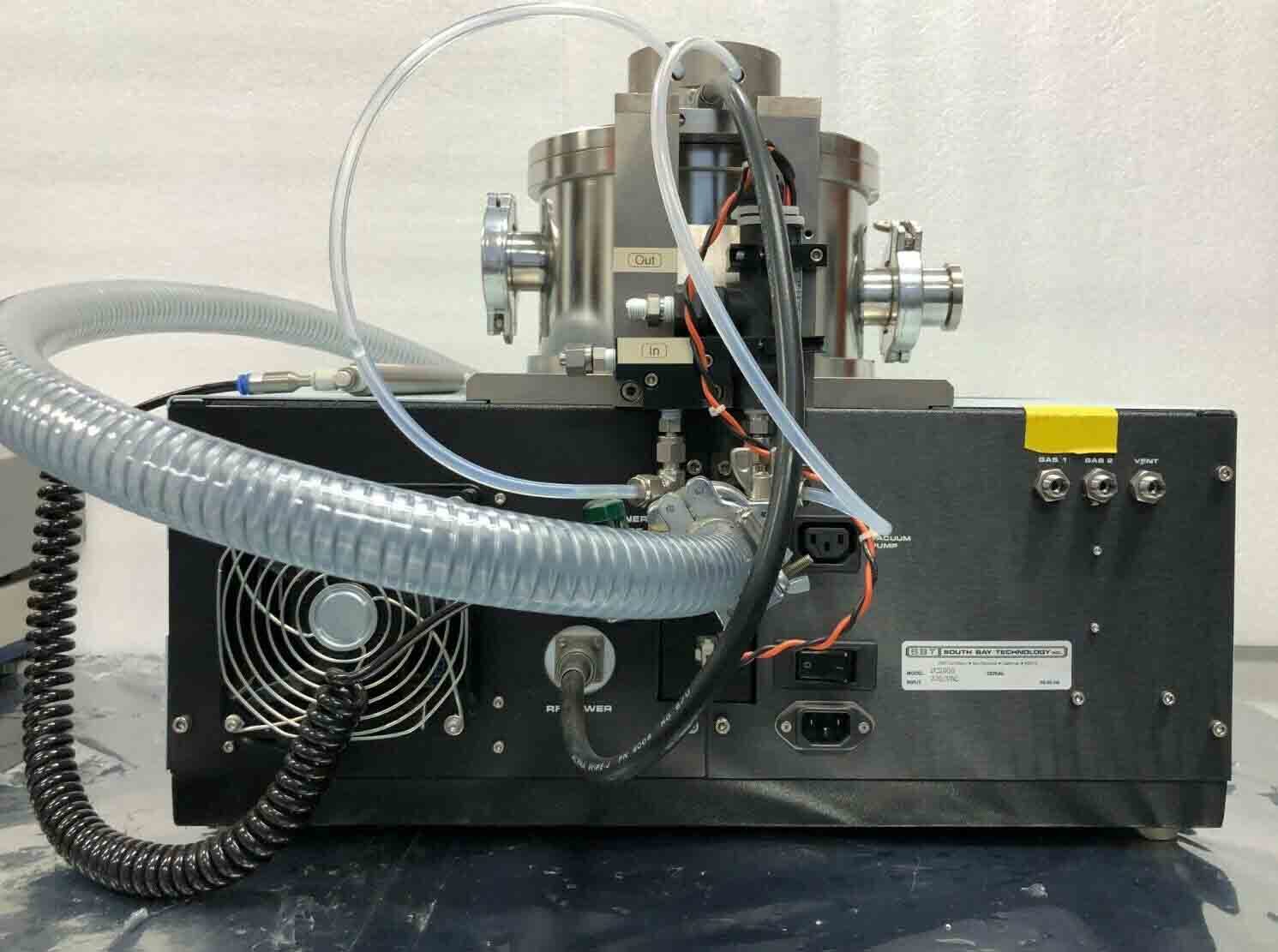

Used SOUTH BAY TECHNOLOGY PC-2000 #9409814 for sale

URL successfully copied!

Tap to zoom

SOUTH BAY TECHNOLOGY PC-2000 is a versatile wafer grinding, lapping, and polishing system designed for use in the semiconductor industry. It features a large working area, measuring 26" x 32", with a 2.2kW, 3 phase motor and a precision spindle drive. PC-2000 allows for a variety of grinding, lapping, and polishing operations, making it ideal for a range of different tasks. The spindle drive can be adjusted to provide a controlled speed of up to 2800 rpm, enabling a wide range of grinding, lapping, and polishing operations. This spindle speed vary is ideal for both coarse and fine abrasive particle processes. SOUTH BAY TECHNOLOGY PC-2000 also features an adjustable depth of cut which allows for uniform grinding and lapping in order to achieve consistent results. In addition to its main lapping and polishing capabilities, PC-2000 can also be used for wafer propagation and surface finishing operations. This includes wafer back-grinding, wafer slicing, wafer dicing, and wafer finishing operations. All these operations are completed using a variety of diamond grinding and polishing tools that have been specially designed for SOUTH BAY TECHNOLOGY PC-2000 system. PC-2000 is designed for automated operation. It has an integrated programmable controller that can be programmed with a range of specific operations from surface preparation to the final polishing stages. This allows for automated and repeatable processes that can be used to achieve consistent results. SOUTH BAY TECHNOLOGY PC-2000 is a reliable and cost-effective wafer grinding, lapping, and polishing system. Its robust design, adjustable spindle and depth of cut, and integrated programmable controller make it ideal for a variety of grinding, lapping, and polishing operations, making it a great choice for any semiconductor facility.

There are no reviews yet