Used SPEEDFAM 18B-4P-1M #9133577 for sale

URL successfully copied!

Tap to zoom

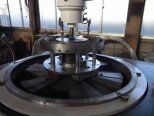

SPEEDFAM 18B-4P-1M equipment is ideal for precision wafer grinding, lapping, and polishing applications. It features a durable, robust design comprised of a steel base and fabricated frame construction capable of accommodating up to four distinct process zones. Mounted to the base are four tilting and scissor lift tables to simultaneously process different angles or work face heights. The working surface of each table is adapted with permanent magnets to securely hold the wafer during either wet or dry grinding, lapping, and polishing applications. High-torque, variable frequency brushless DC motors enable a wide range of speed settings of 0 to 3600 RPM. The system includes dust control and filtration systems to eliminate airborne particulate contamination. The design ensures efficient and operator-friendly operation of the wafer grinding, lapping & polishing process, while reducing the risk of potential environmental hazard exposure. The wet or dry grinding, lapping, and polishing process are carried out using controlled and precisely-timed motion control with three-axis linear and angular motions. This process includes both cutting and removal processes, leading to a pre-processed ready for the optical and/or chemical surface treatments. The unit utilizes sequentially linked operations to enable iterative processing of all wafer sizes. Wafers can be loaded/unloaded manually or through automated wafer handling systems, depending on the application. 18B-4P-1M is designed to accommodate a wide range of process parameters, depending on the application requirements. it can be easily adjusted in order to control the quality of the surface finish and desired ultrastructuring effect. As part of the machine's safety and operating features, all wafer positions are accurately monitored. SPEEDFAM 18B-4P-1M is the ideal tool for wafer grinding, lapping, and polishing. Its integrated design enables tight process control and flexibility to deliver high-quality, precise results while protecting the environment and product from environmental hazards. It provides closed-loop, precision control throughout the entire process, ensuring repeatable accuracy and precision on each wafer run.

There are no reviews yet