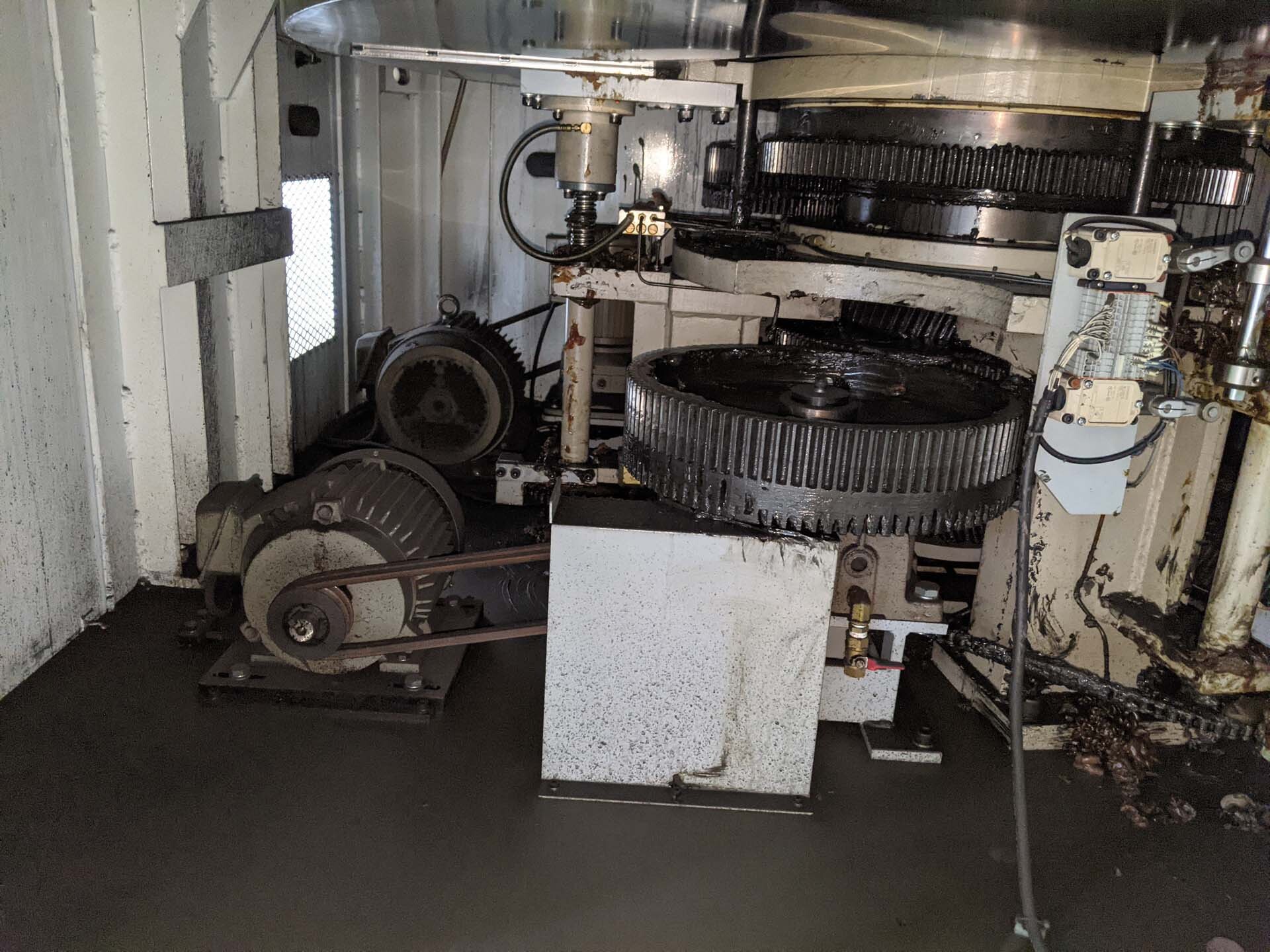

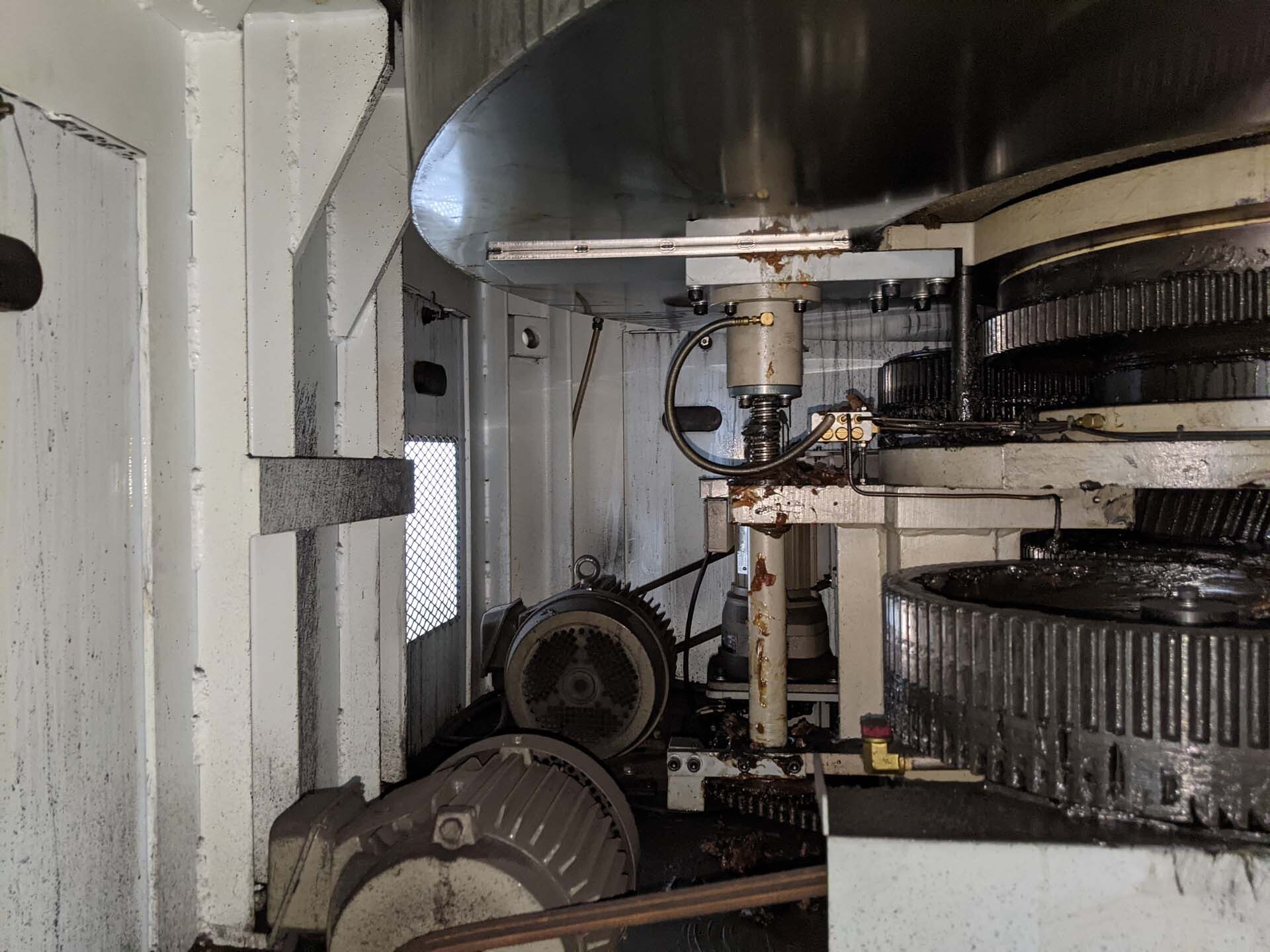

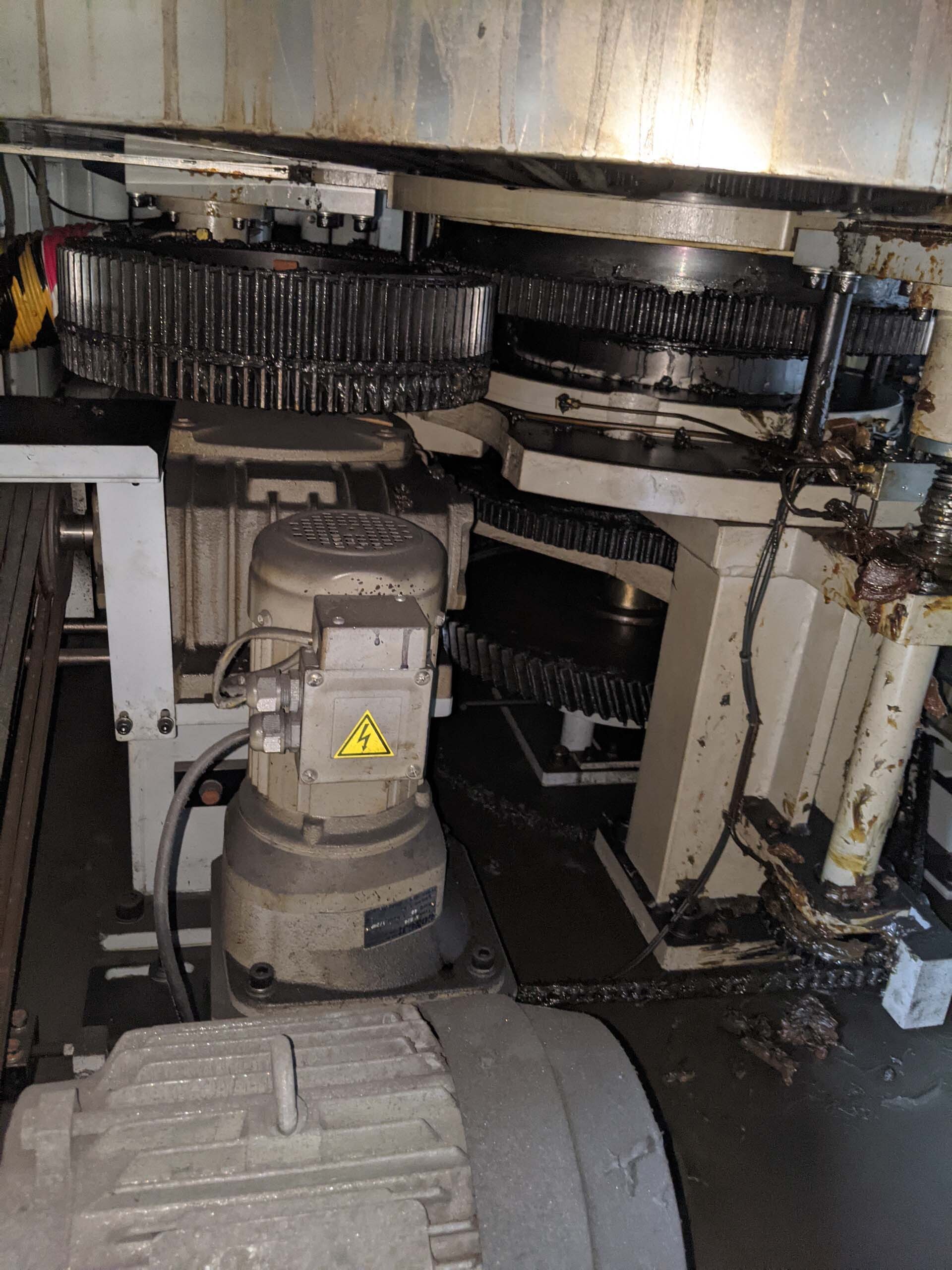

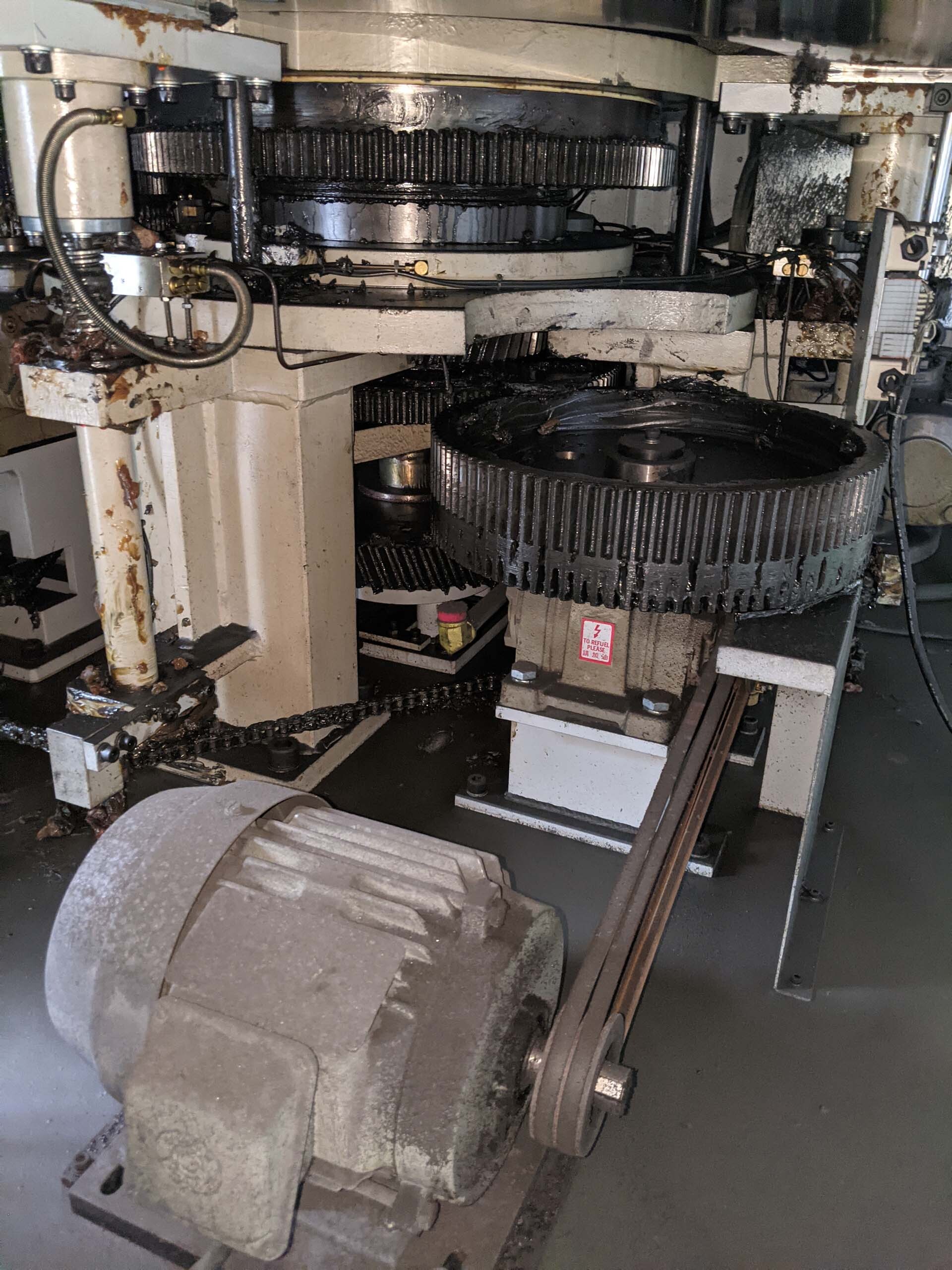

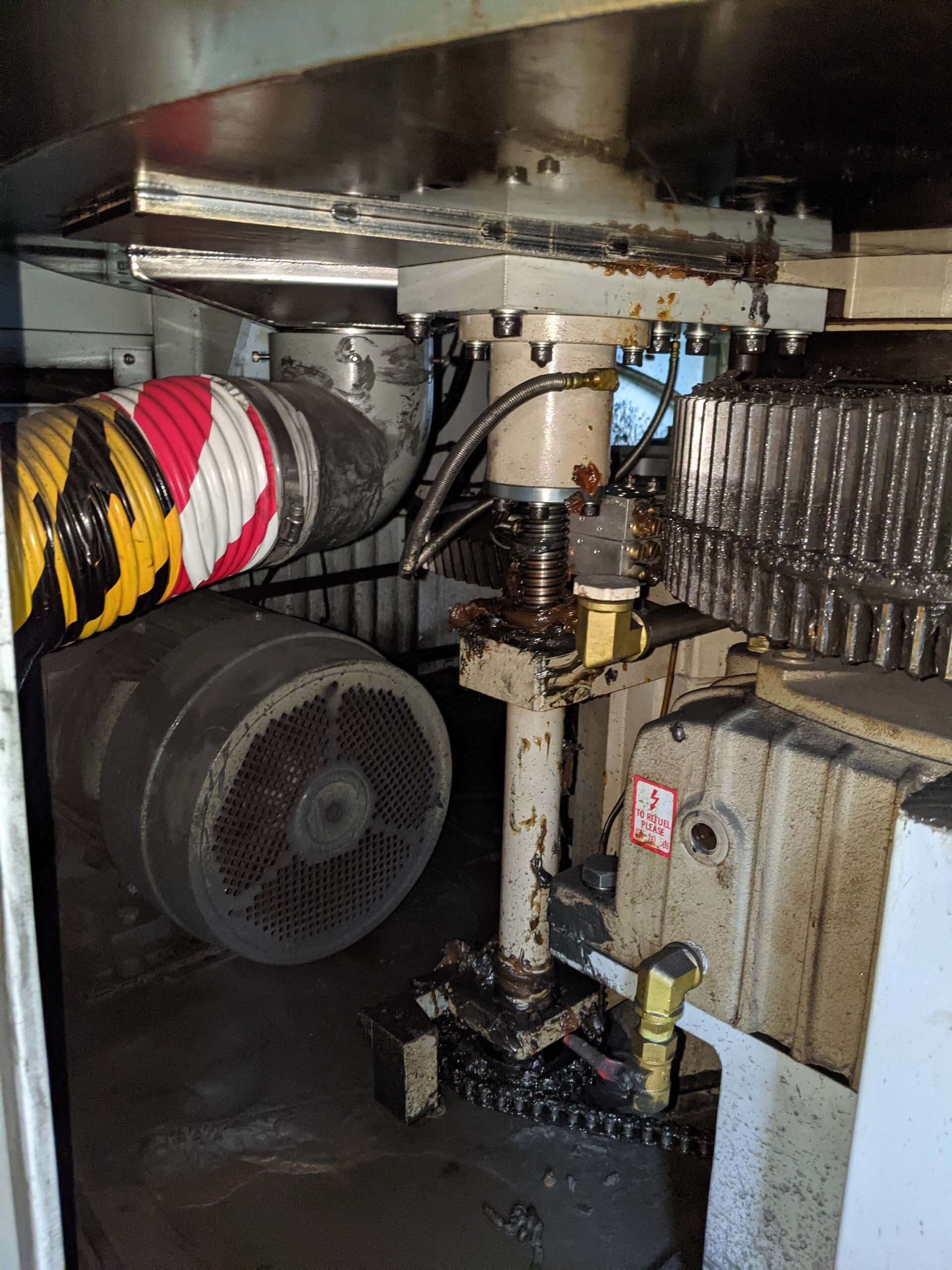

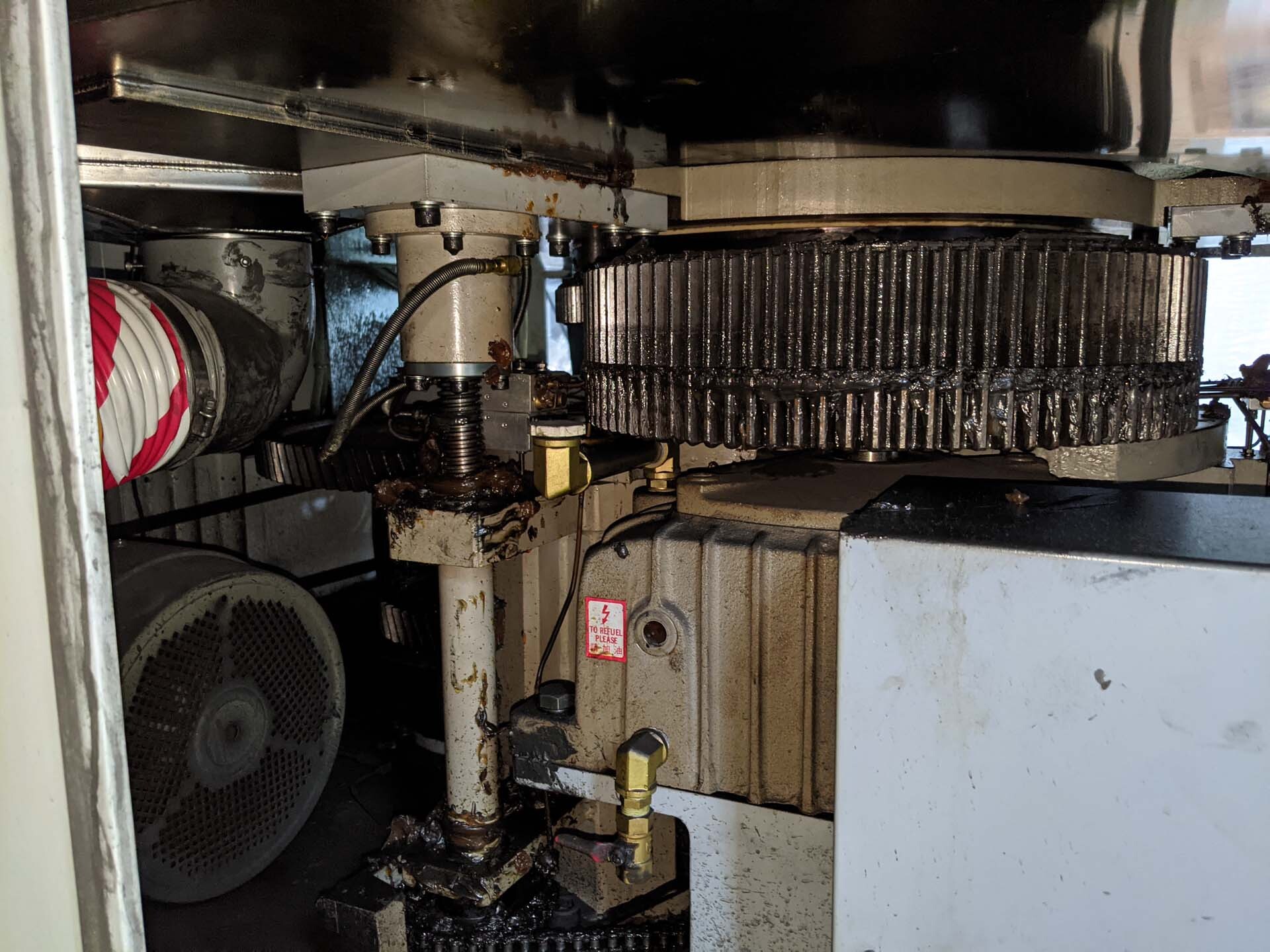

Used SPEEDFAM 20B-5L #9363669 for sale

URL successfully copied!

Tap to zoom

ID: 9363669

Vintage: 2013

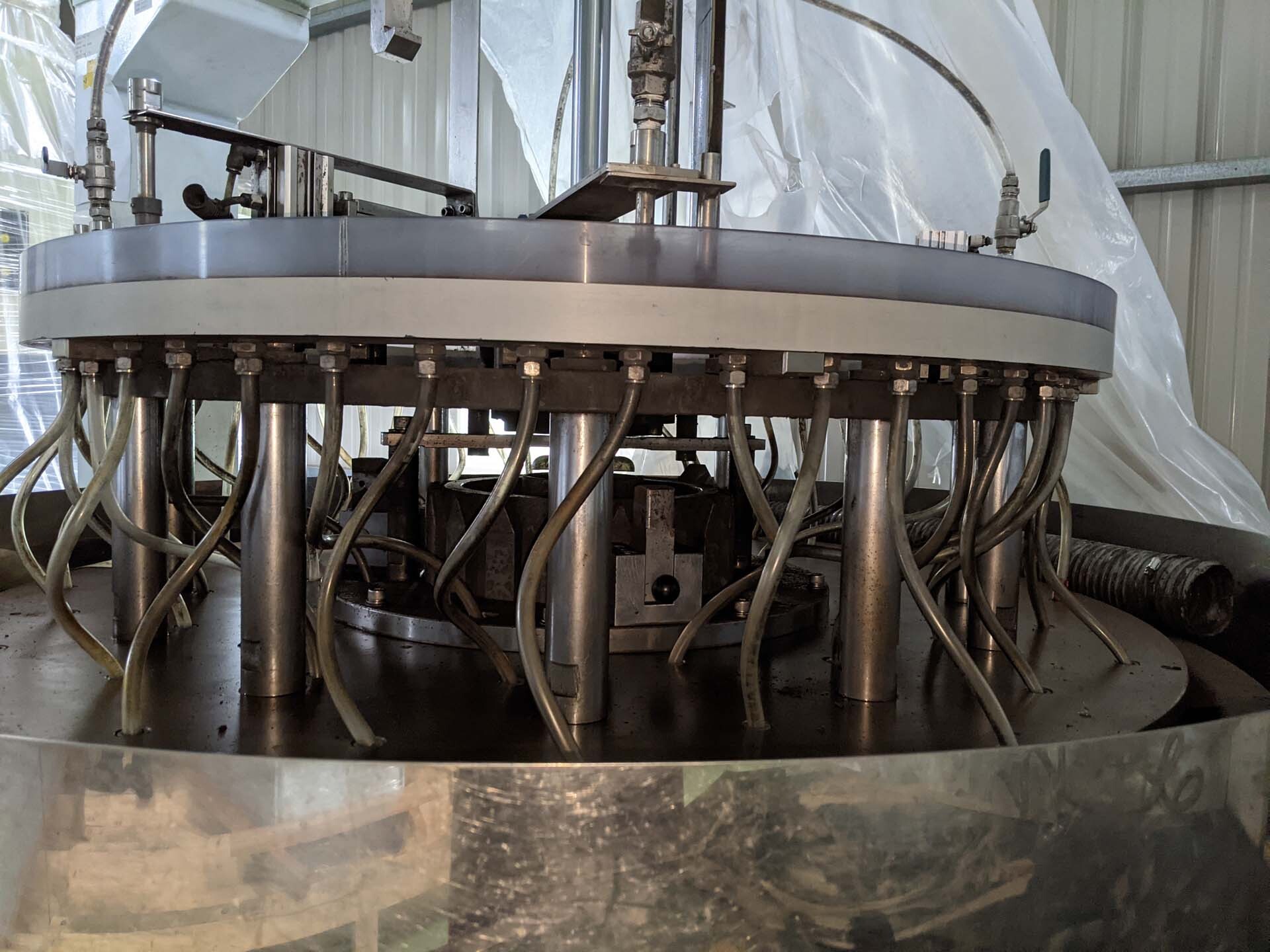

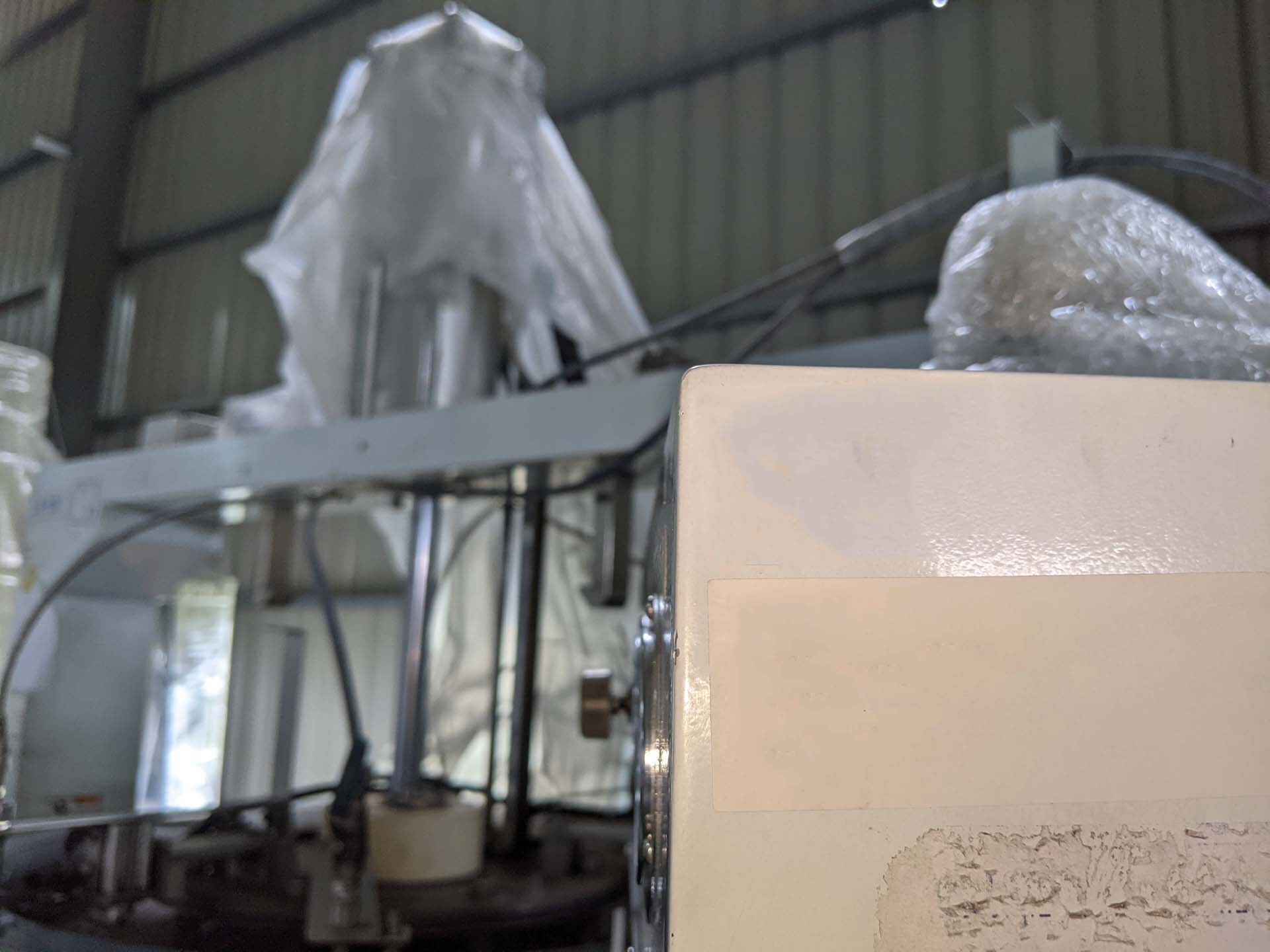

Double sided lapping machine

Workpiece dimensions:

Maximum diameter: 410 mm

Minimum thickness: 0.5 mm

Maximum thickness: 30 mm

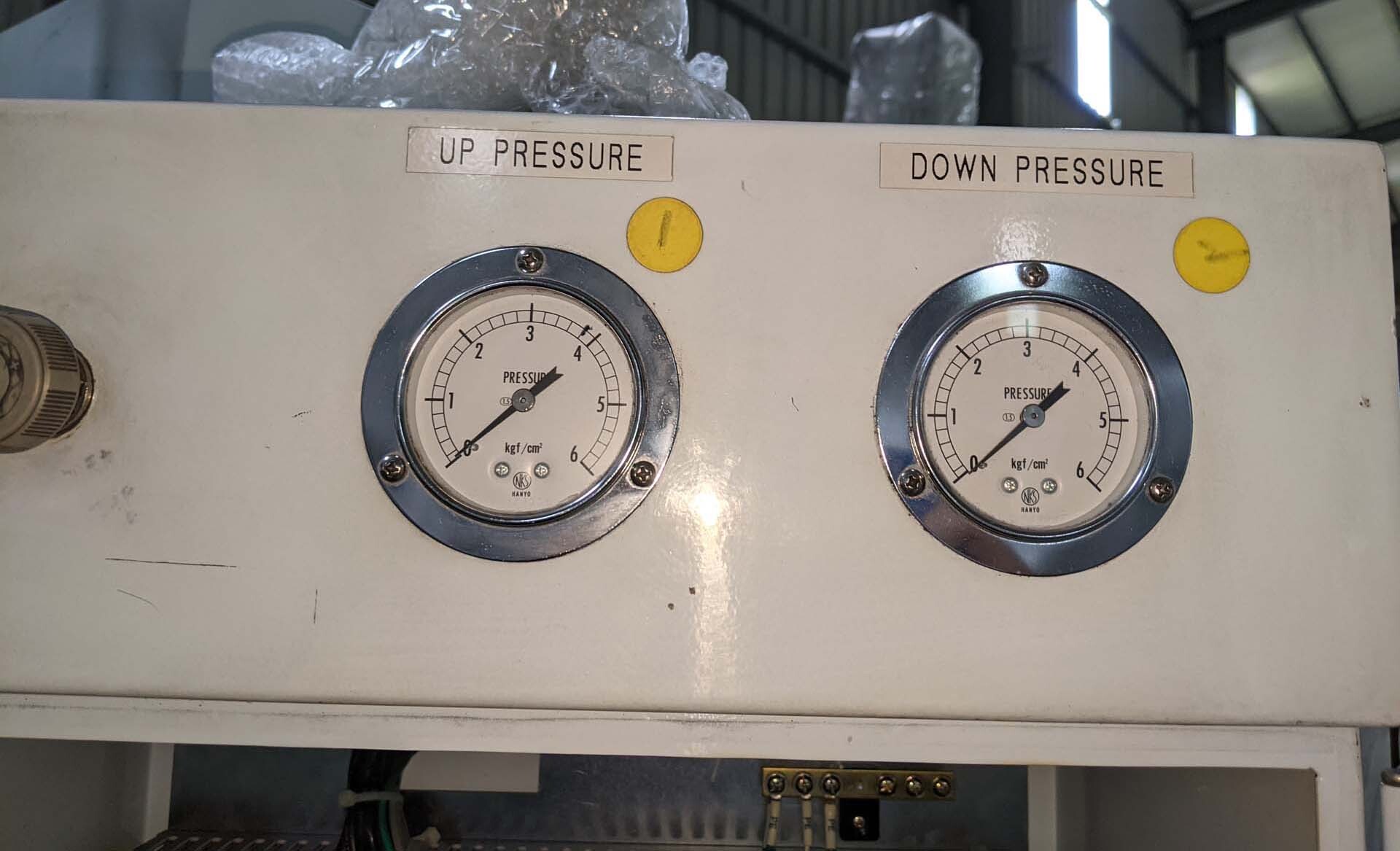

Maximum down force: 684 kg

Down force range: 0 to 684 kg

Plate dimensions: φ 1355 x φ 458 x 50 t

Upper plate: 434 kg

Upper ring assembly: 460 kg

Lower plate: 18-60 RPM

Frequency: 50/60 Hz

(5) Carriers: 20B

Main cylinder: 180 φ x 500 st

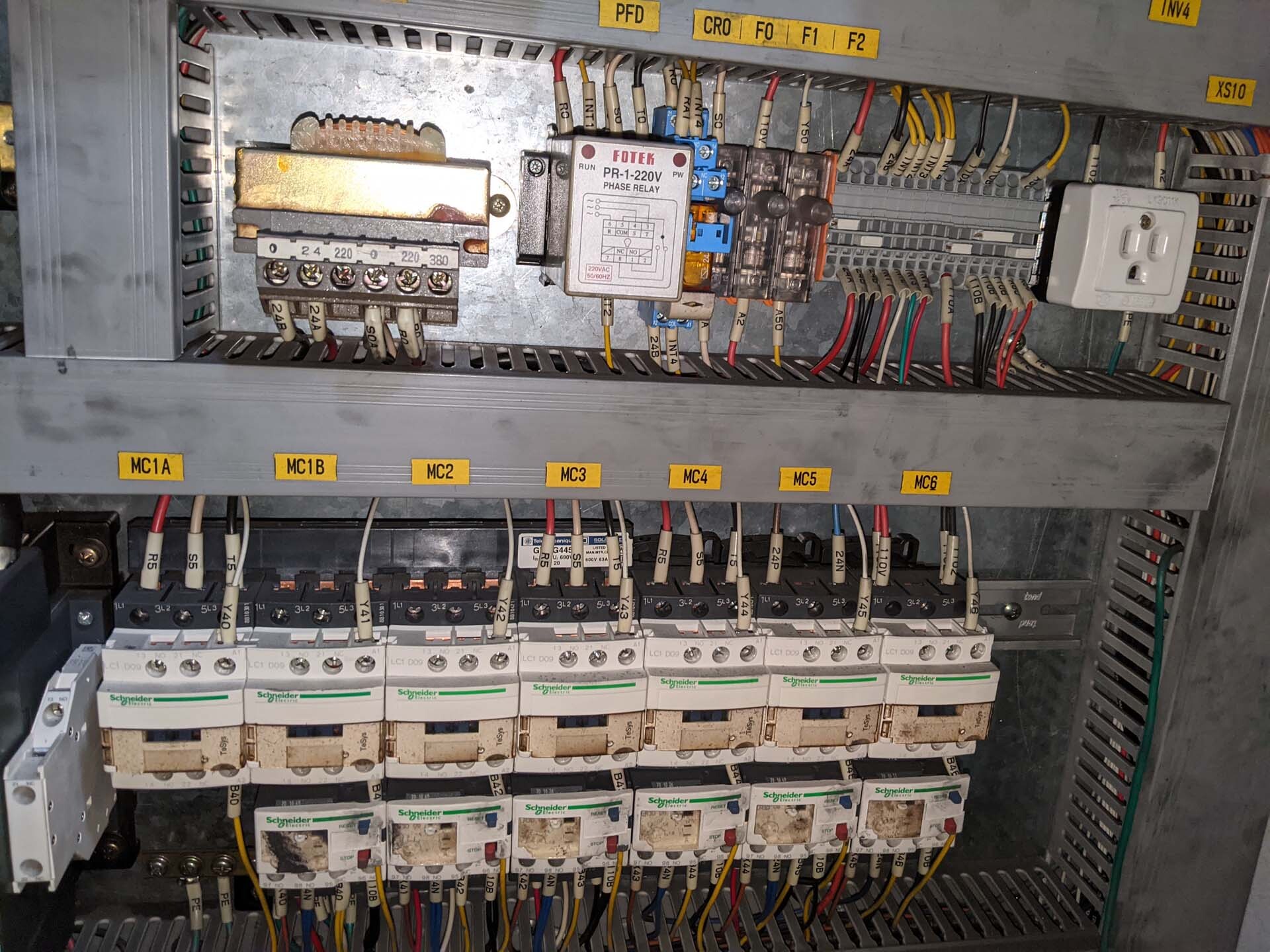

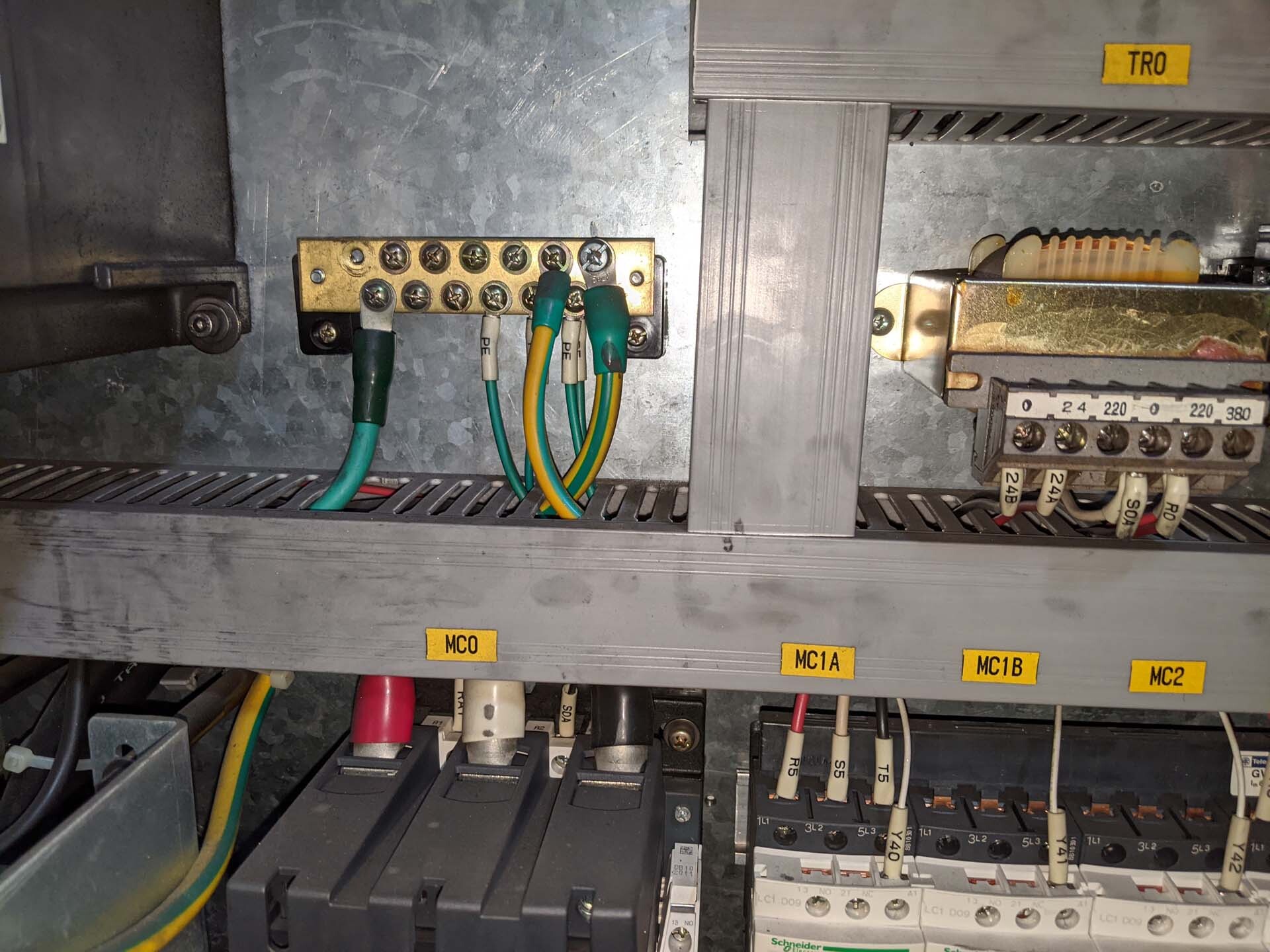

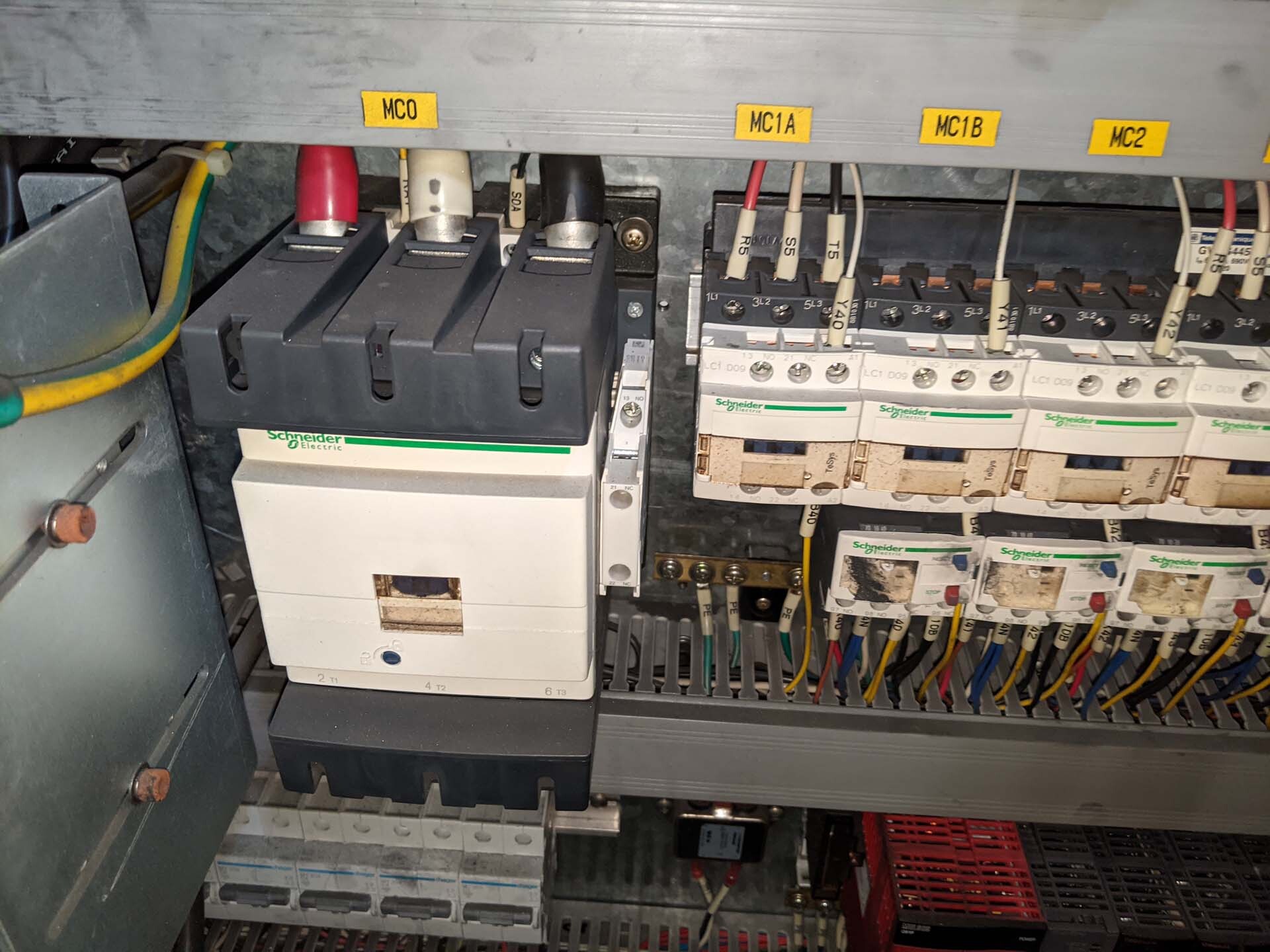

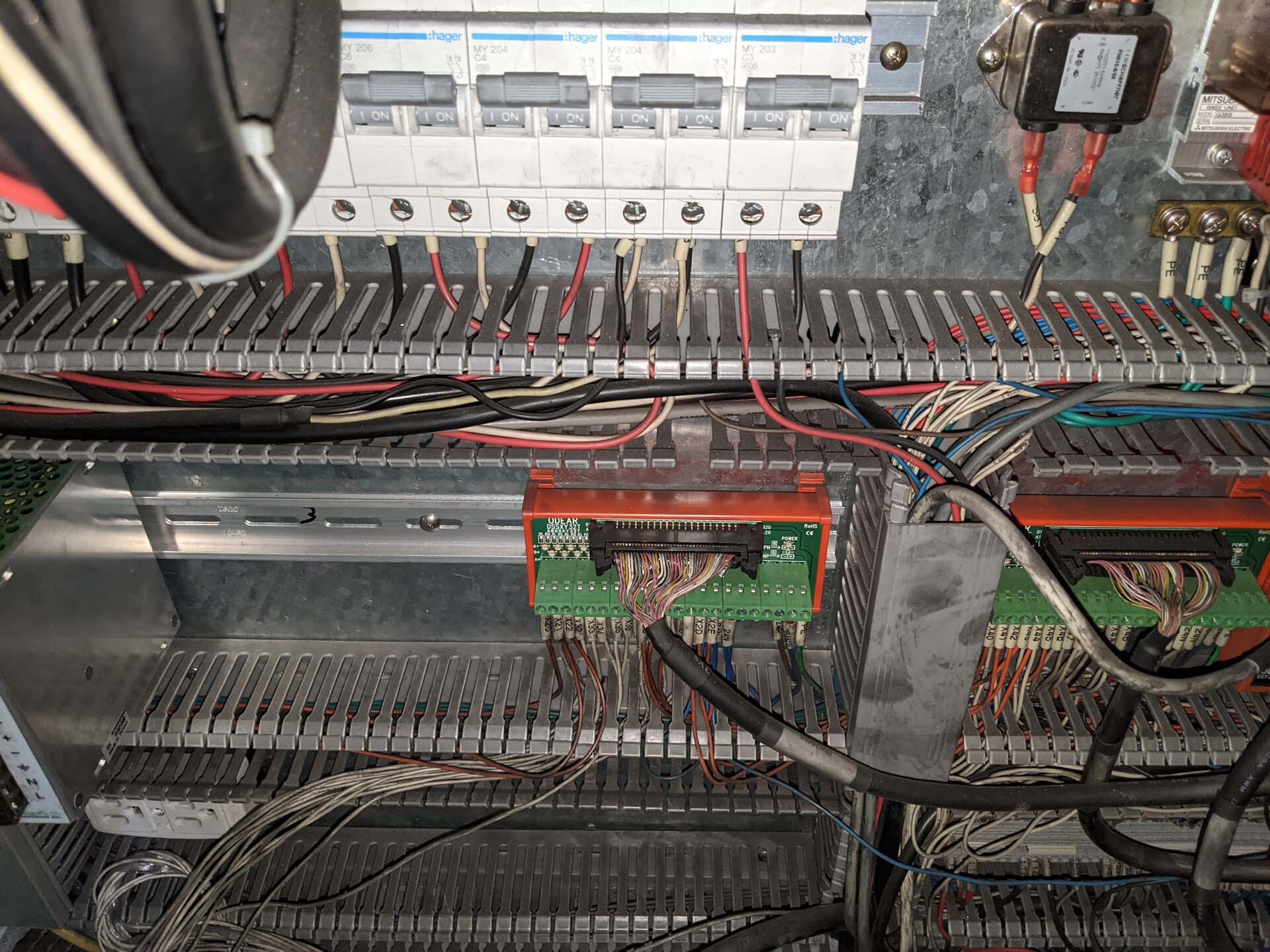

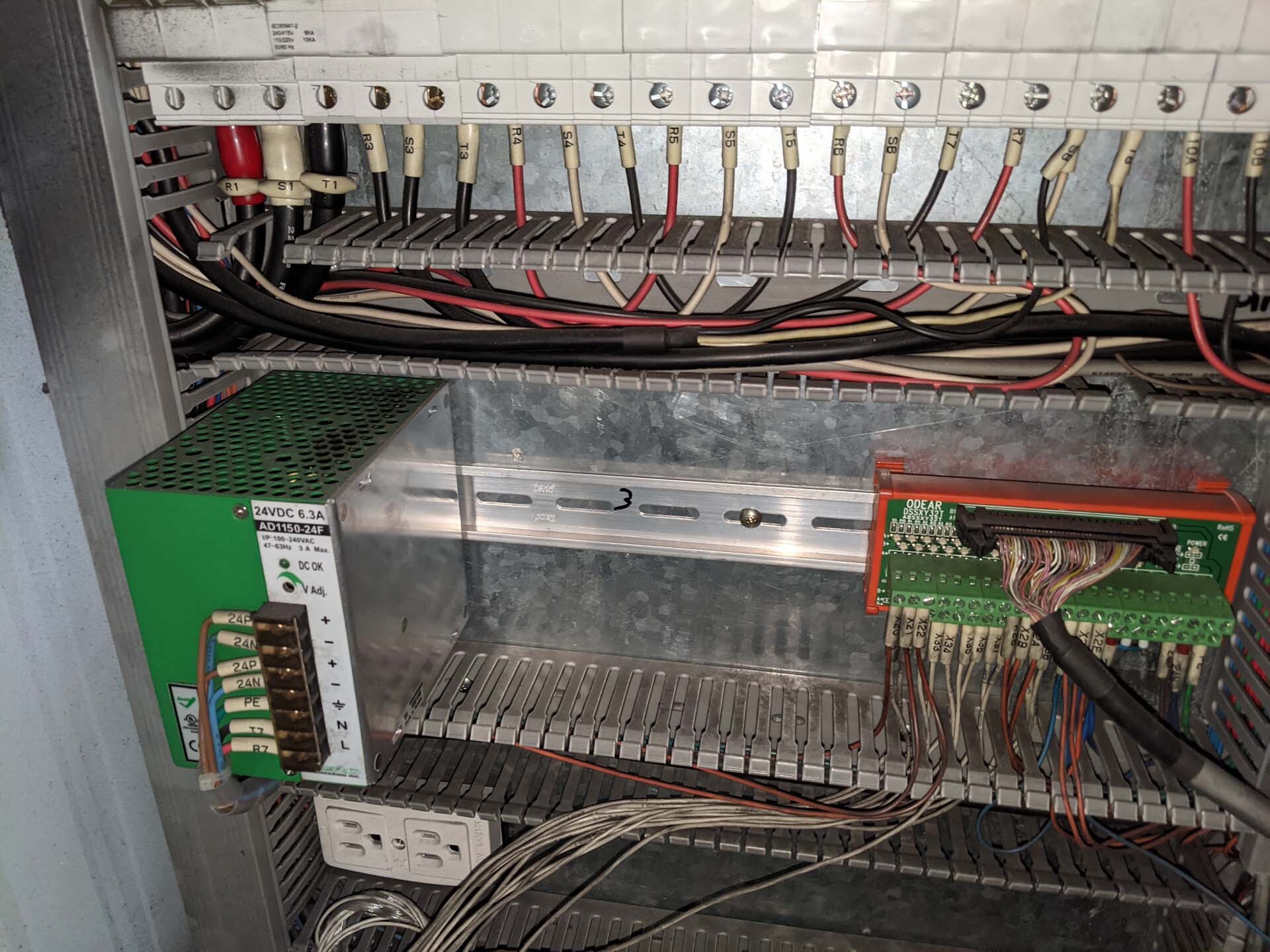

Breaker capacity: 125/75 Amps

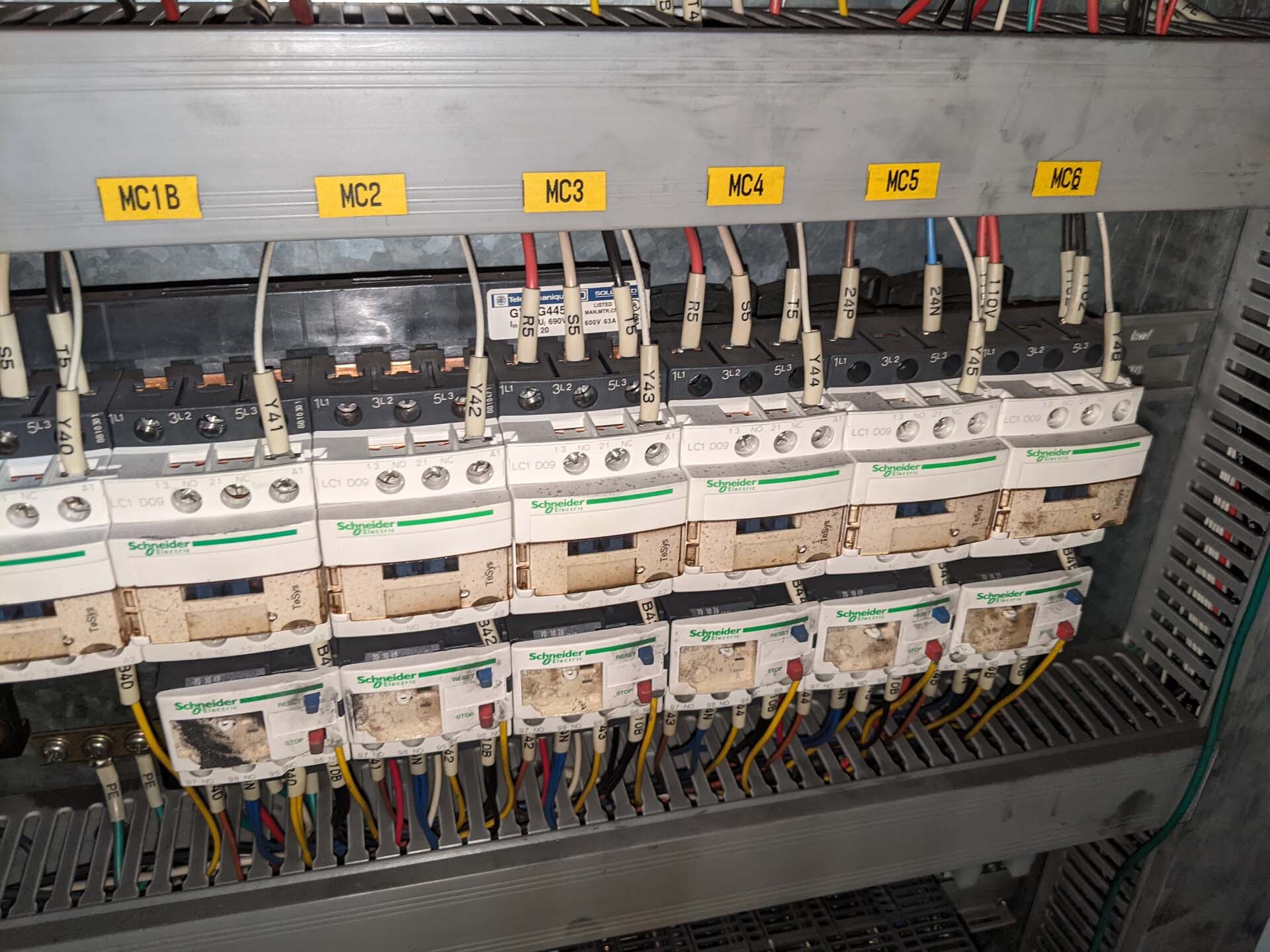

Main motor: 15 kW

Ring gear motor: 3.7 kW

Sun gear motor: 1.5 kW

Ring gear / Sun gear motor (Up / Down): 0.4 kW

Slurry pump: 0.4 kW

Agitation motor: 0.1 kW

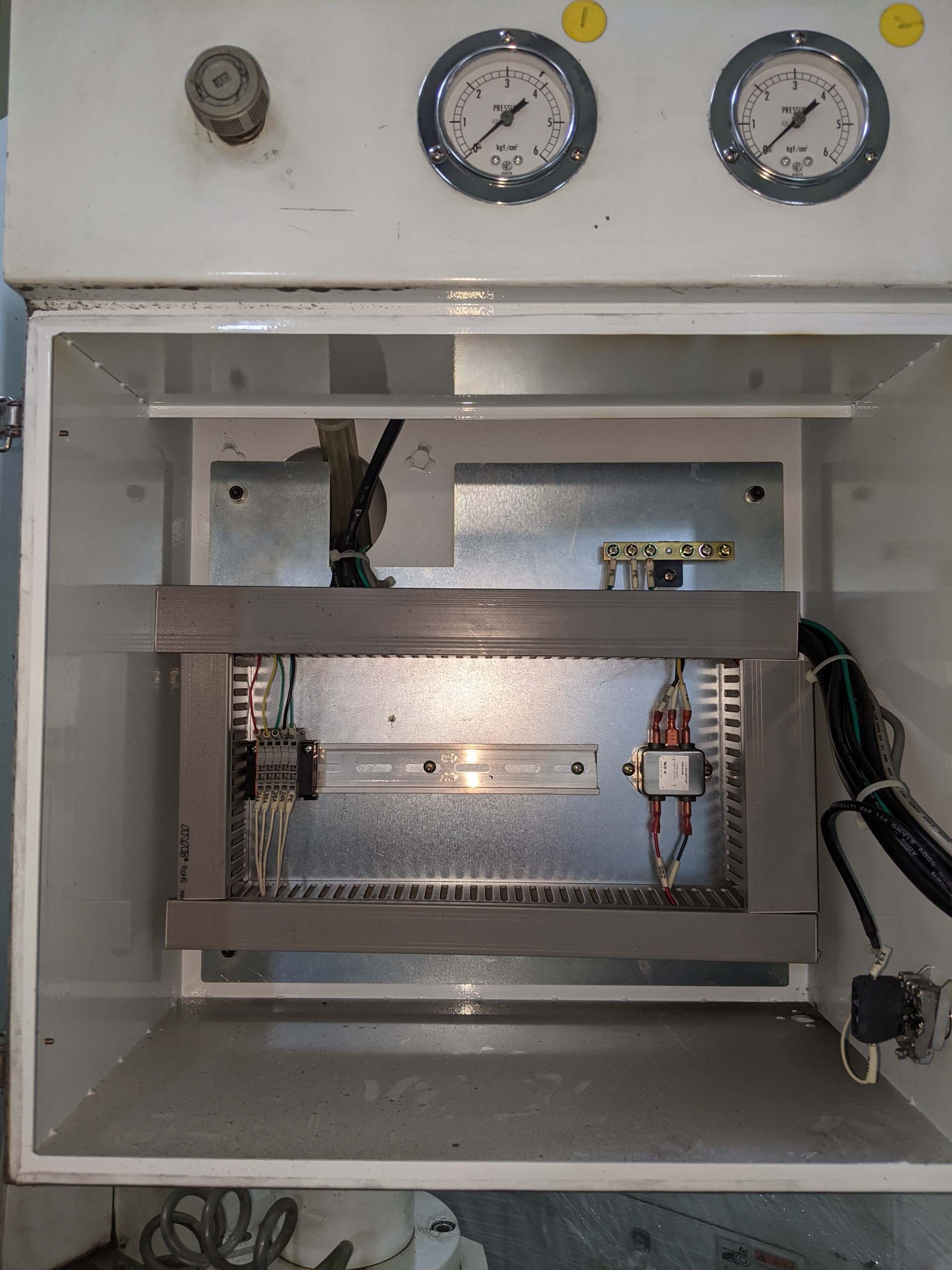

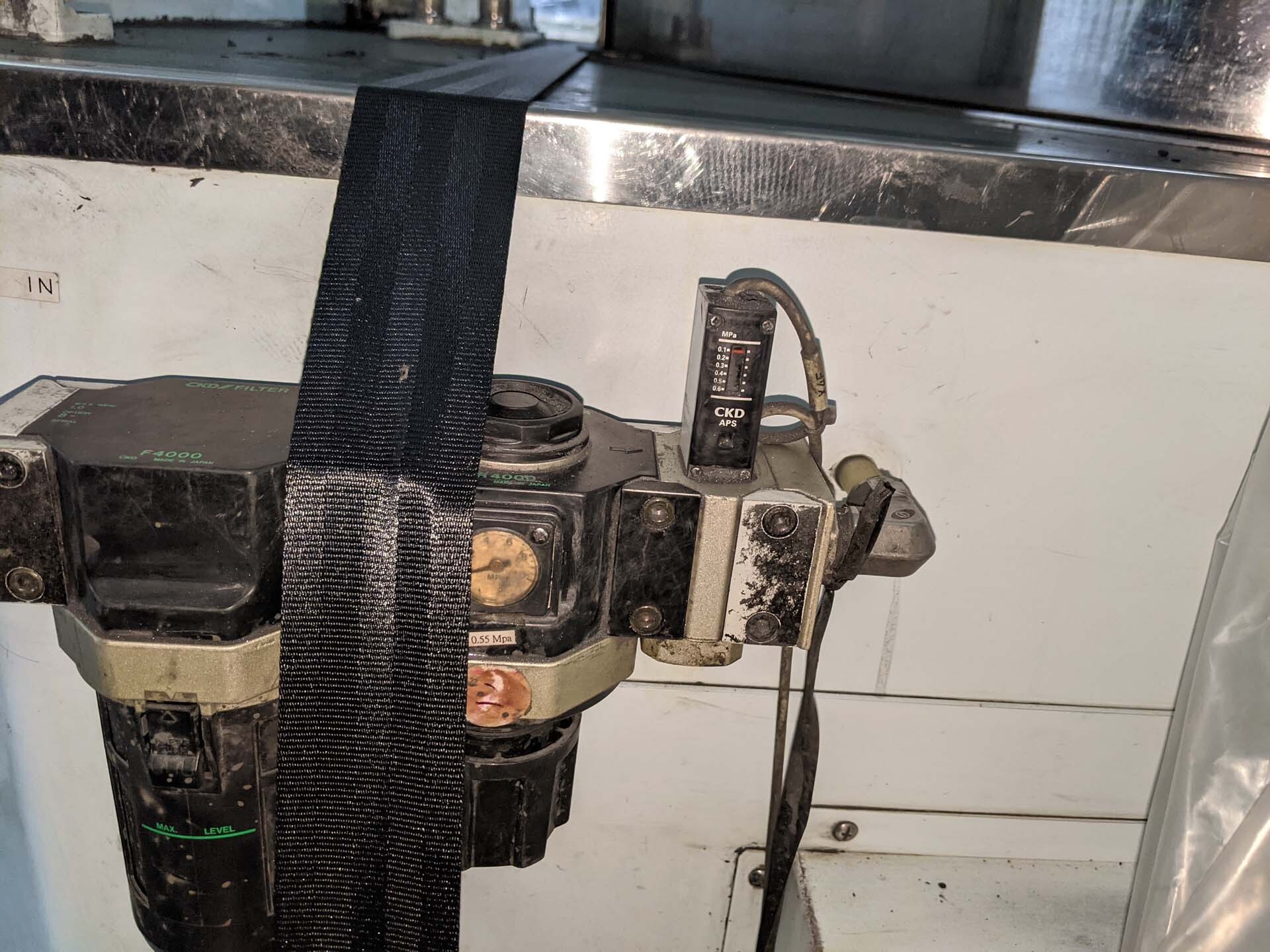

Air pressure: 5-6 kgf/cm², 127 N1/min (5.5 kgf/cm²)

Carrier / Ring gear / Sun gear

M: 3 / 3 / 3

Z: 170 / 472 / 132

PCD: 510 / 1416 / 396

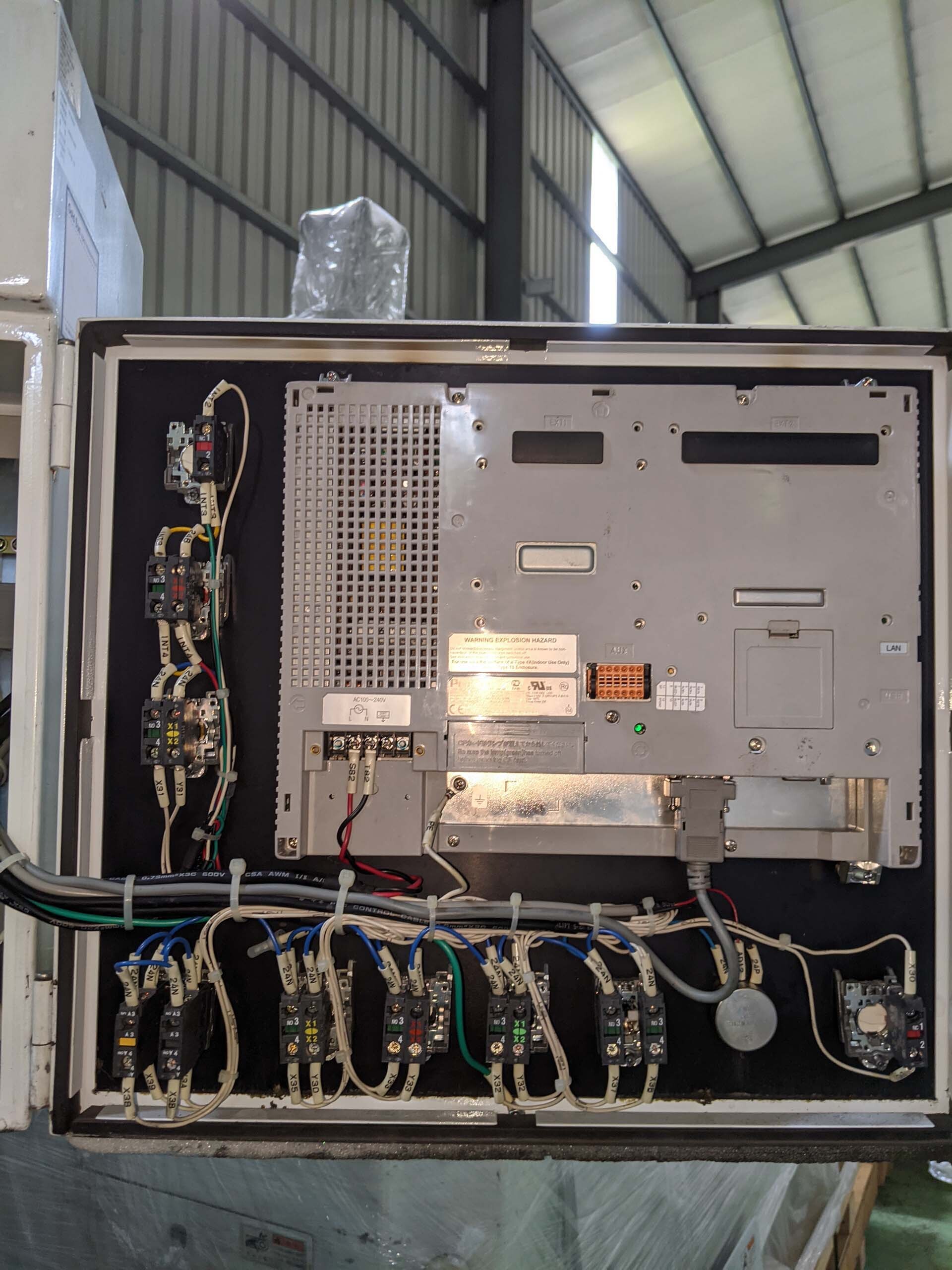

Power supply: 200/380 V, 50/60 Hz, 21.1 kW, 3 Phase

2013 vintage.

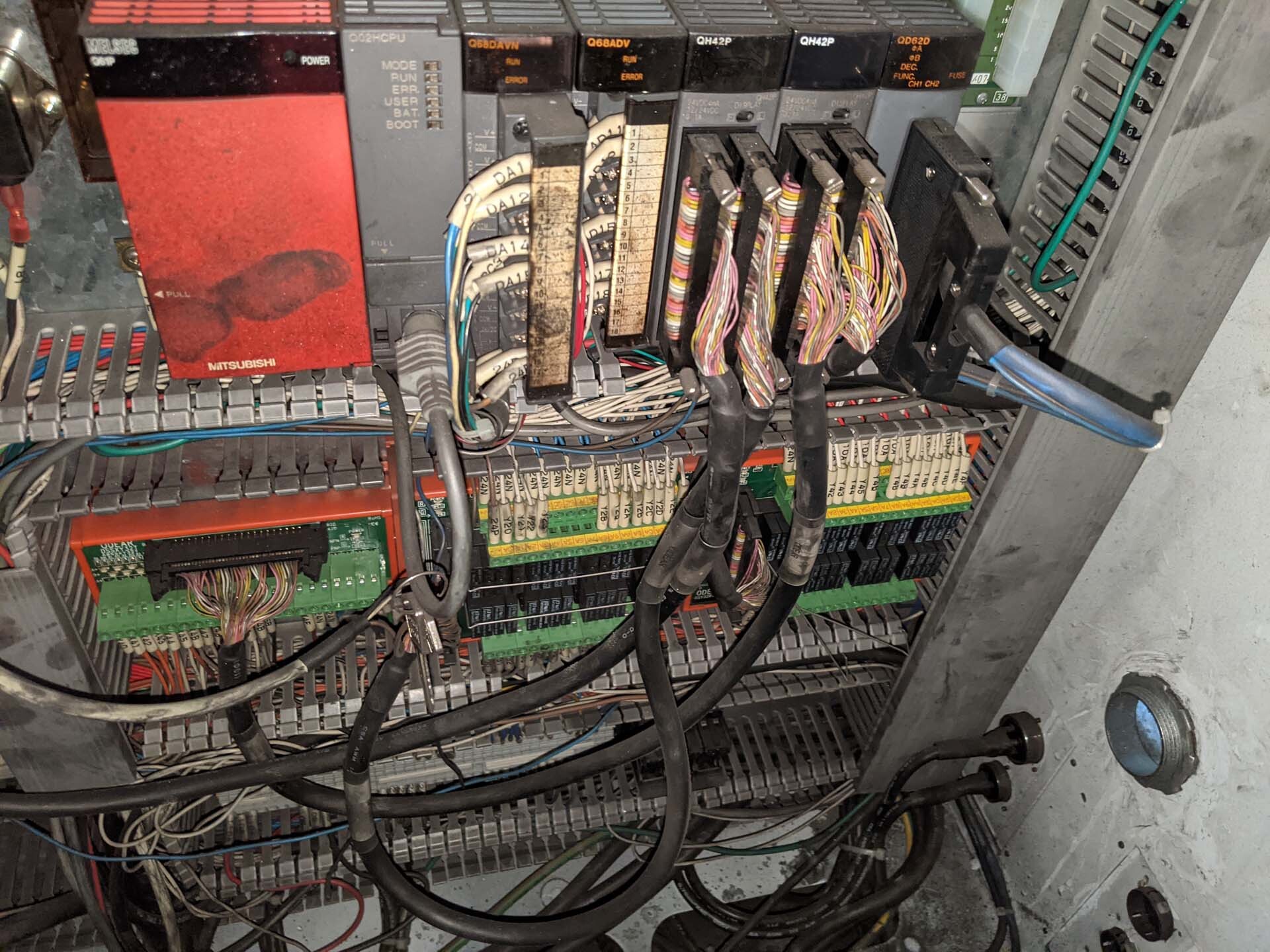

SPEEDFAM 20B-5L is a versatile precision wafer grinding, lapping, and polishing equipment. It is designed to produce a high quality, ultra-flat, and precisely textured surface on a variety of materials and substrates. The system utilizes a unique, dynamic, self-loading/unloading unit integrated with a 20-inch wafer grinding and polishing machine to quickly and accurately process substrates. It incorporates a special artificial diamond grinding and lapping surface for the most precise flat grinding and polishing results. The machine is equipped with advanced automatic water jet cooling systems to maintain the necessary working temperature. 20B-5L is designed to be used in a range of research, supply and manufacturing operations requiring precision wafer grinding, lapping, and polishing. Its modular, multi-functional design provides maximum flexibility to produce a range of substrates including silicon, polysilicon, silicon dioxide, gallium arsenide, aluminum oxide, and quartz glass. It is also suitable for high precision production of micro-electronics or MEMS. The tool is equipped with a high quality 2 axis digital readout, PLC controlled servo-motor drive, and an integrated data collection asset, allowing for precise control and monitoring of each cycle's operation. In addition, it offers a range of advanced safety features for user safety, such as an emergency stop button, lapping hood safety features and failure-resistant guarding doors. SPEEDFAM 20B-5L is equipped with a variety of productivity resources including a full suite of process optimization functions, allowing for the most accurate results. It features a multi-stage operation control to ensure uniform results, optimal grinding, lapping, and polishing. It also supports a full range of settings for process parameters, such as lube pressure, grinding and polishing speed, material removal rate, edge break, etc., to provide precise results with every cycle. Finally, 20B-5L offers an ergonomic design, allowing for easy operation and setup. It is also compact and cost-effective, making it perfect for tight production spaces with limited budgets. With all these features, SPEEDFAM 20B-5L is the ideal choice for research and production operations requiring precision grinding, lapping, and polishing.

There are no reviews yet