Used SPEEDFAM 20B-5L #9372666 for sale

URL successfully copied!

Tap to zoom

ID: 9372666

Vintage: 2013

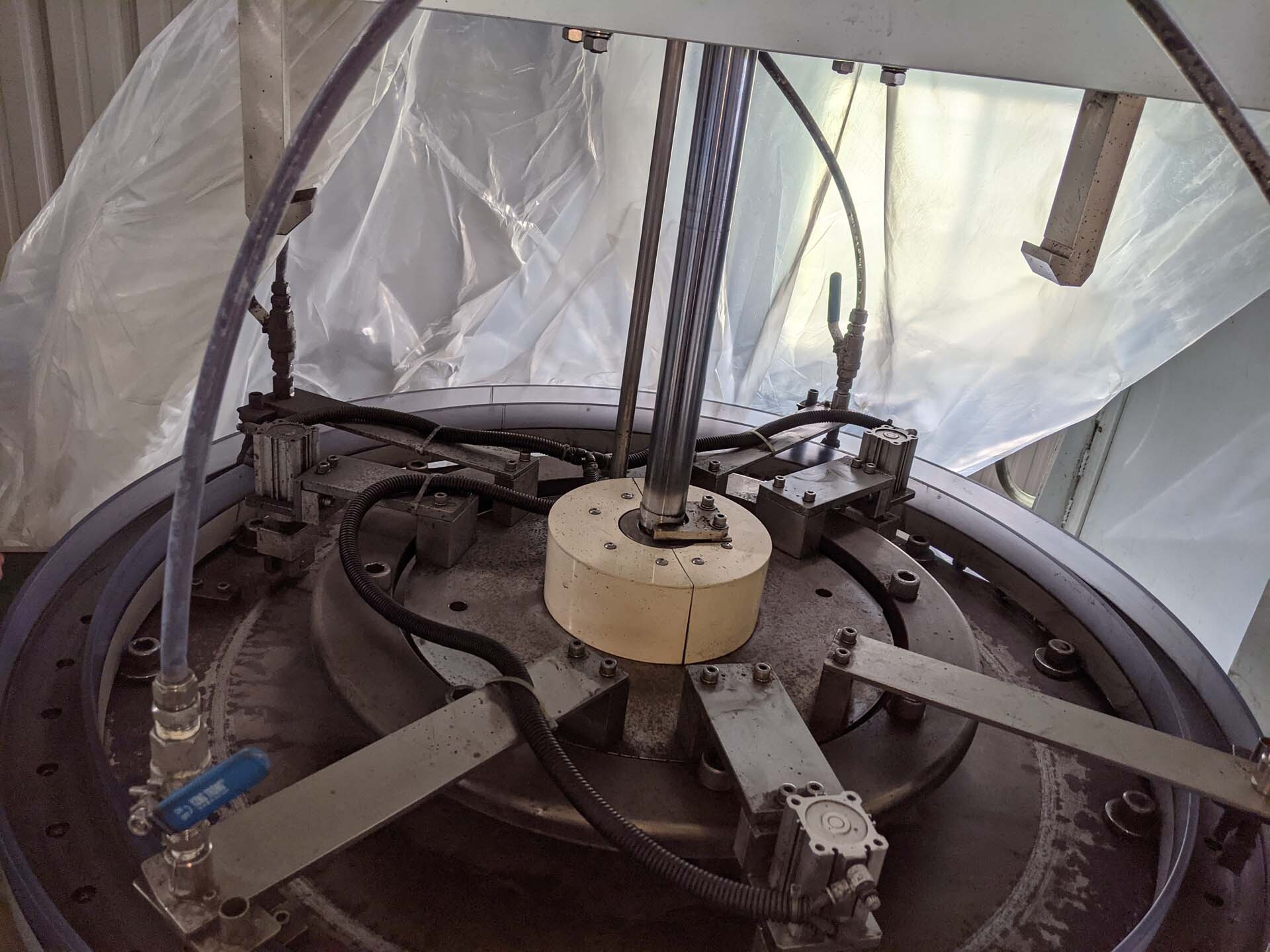

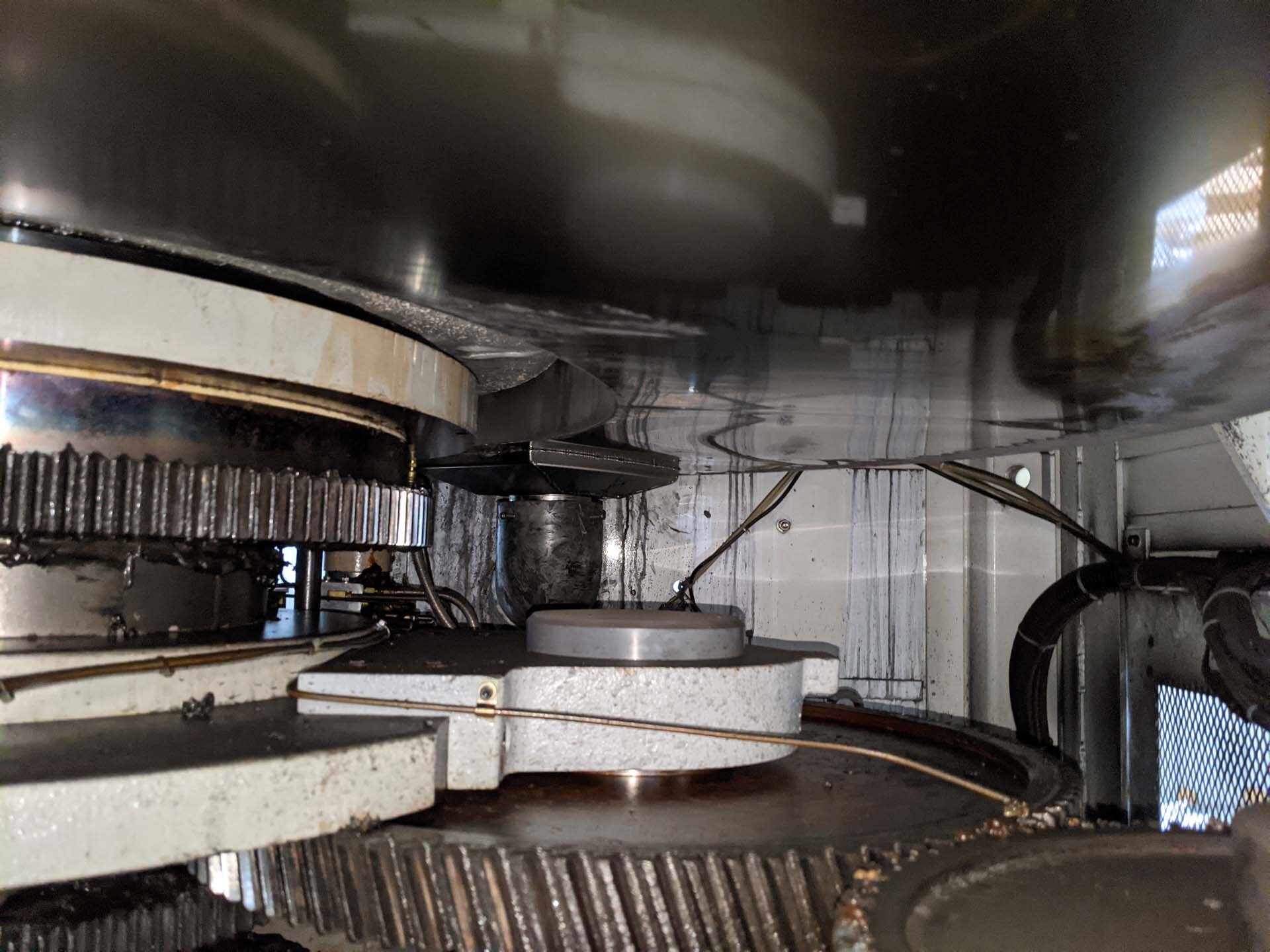

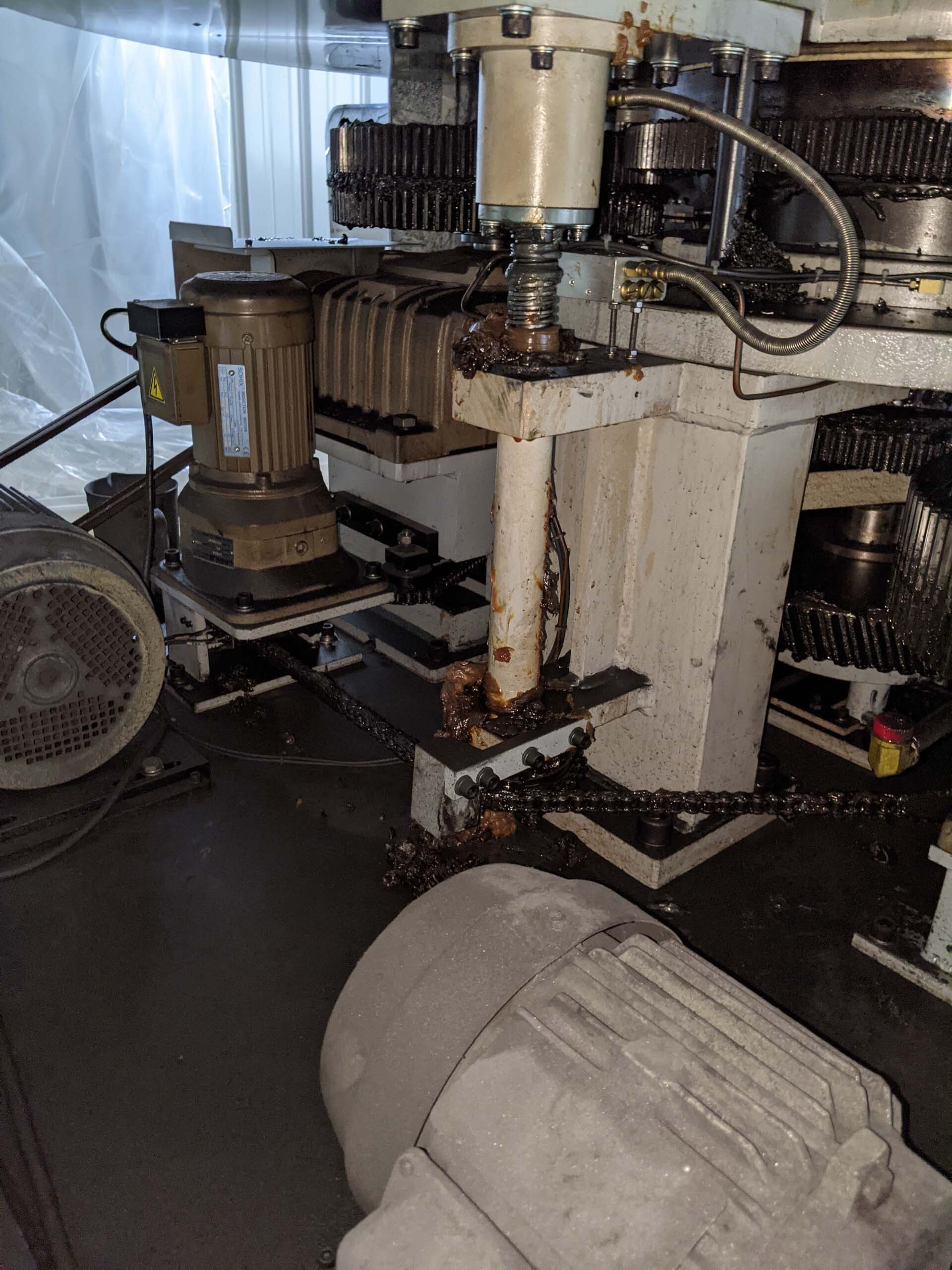

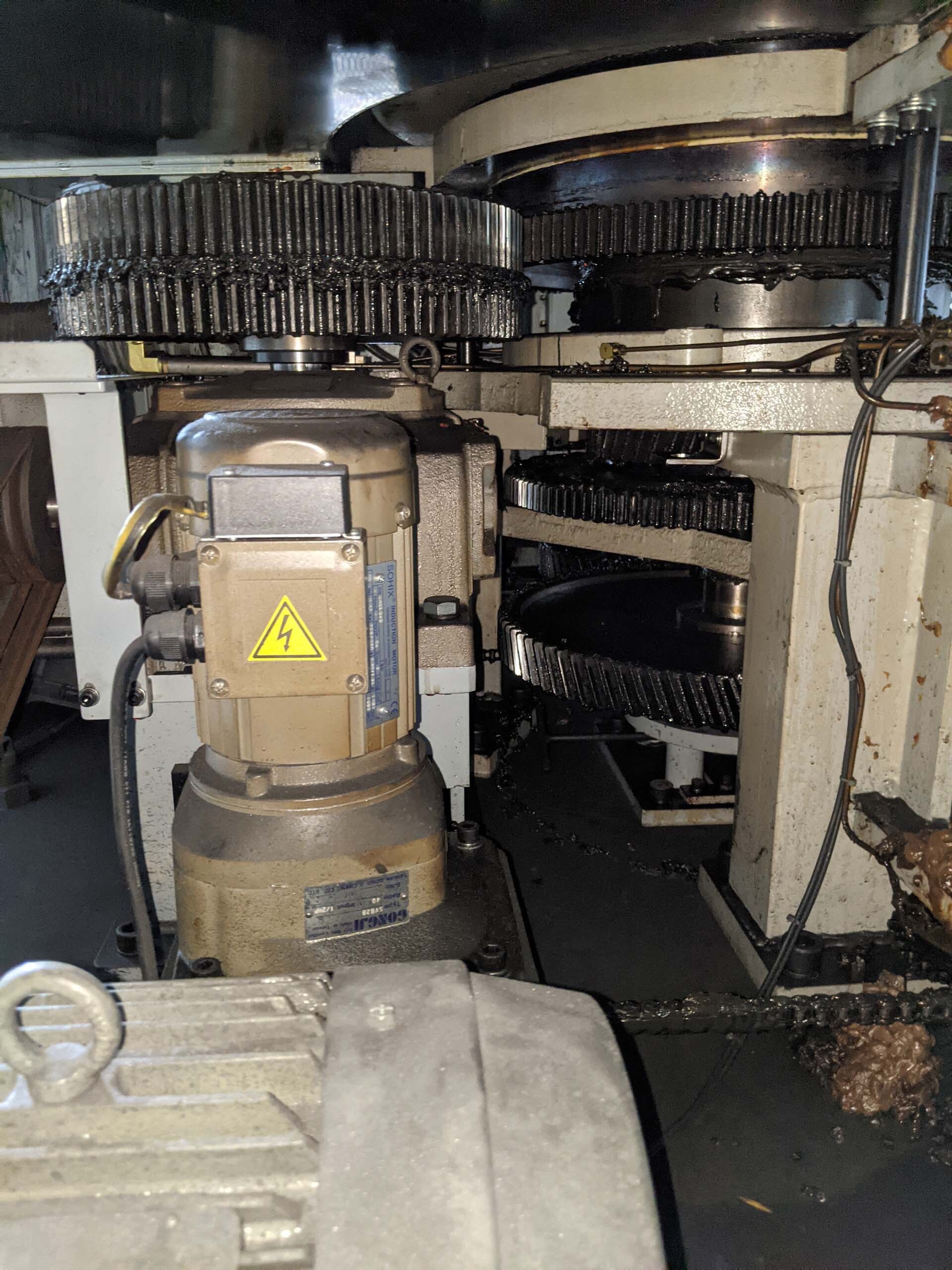

Double sided lapping machine

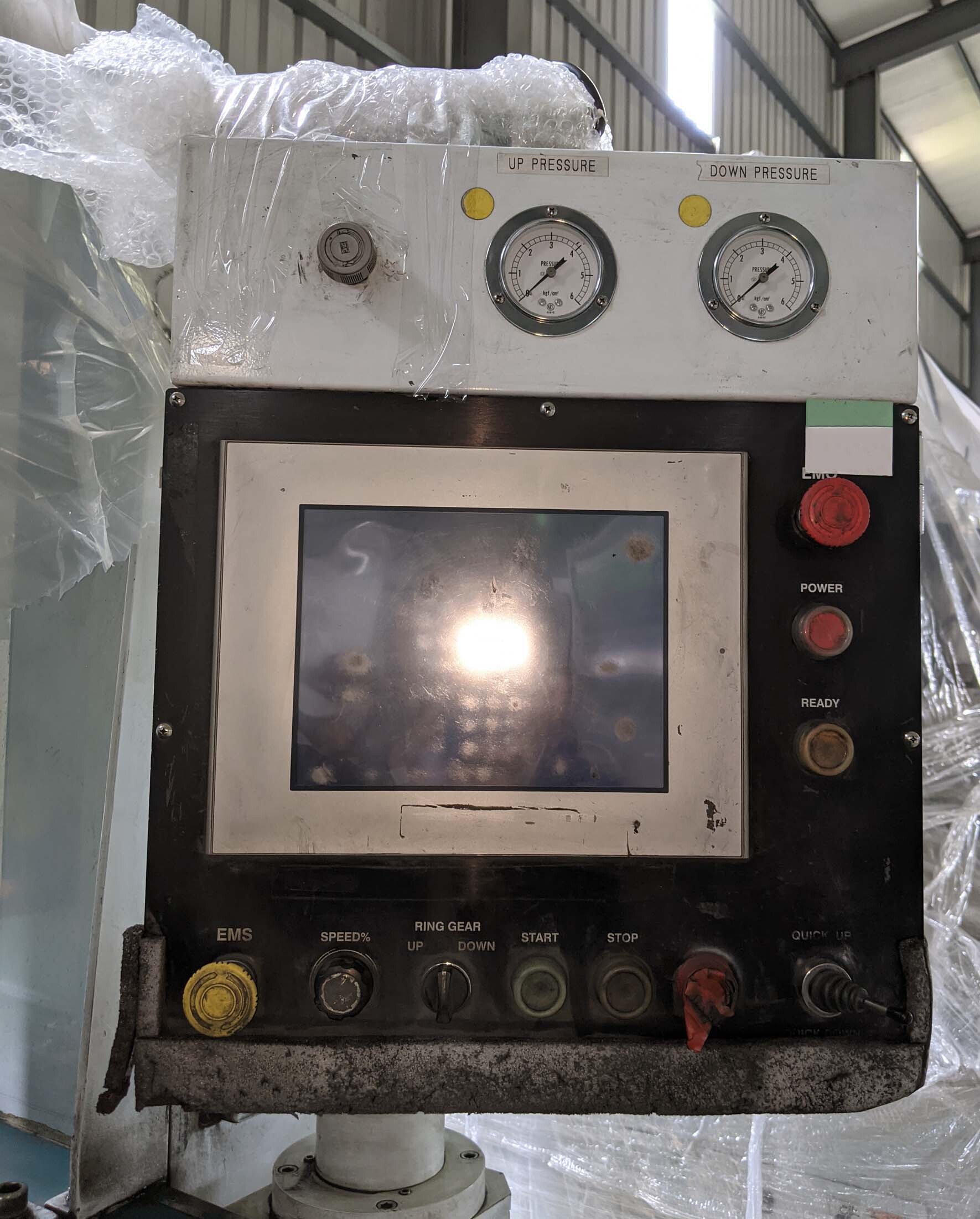

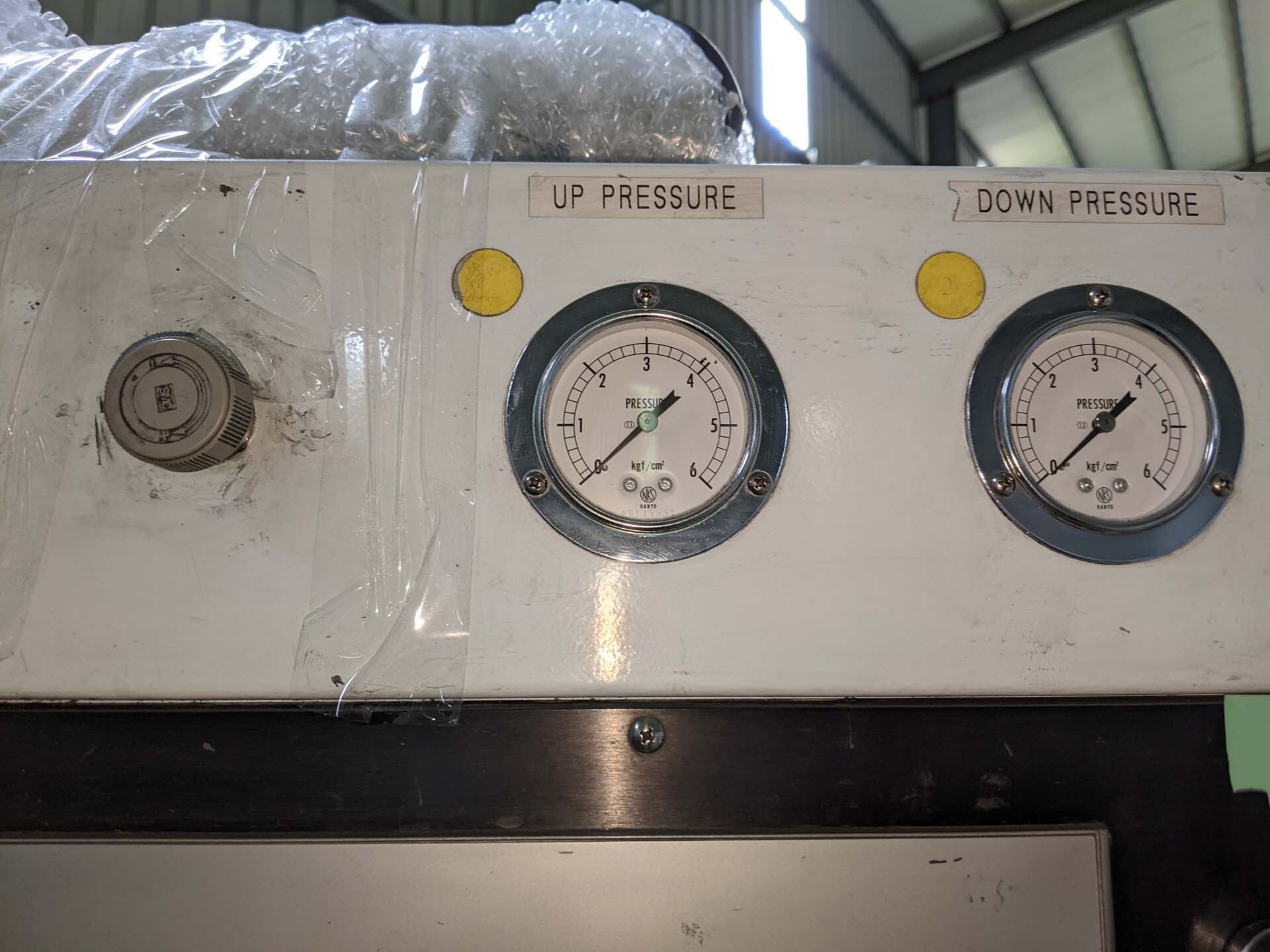

Maximum down force: 648 kg

Down force range: 0-684 kg

Plate dimension: φ 1355 mm x φ 458 mm x 50 t

Upper plate: 434 kg

Lower plate assembly: 460 kg

Lower plate RPM: 18-60 RPM, 50/60 Hz

(5) Carriers: 20B

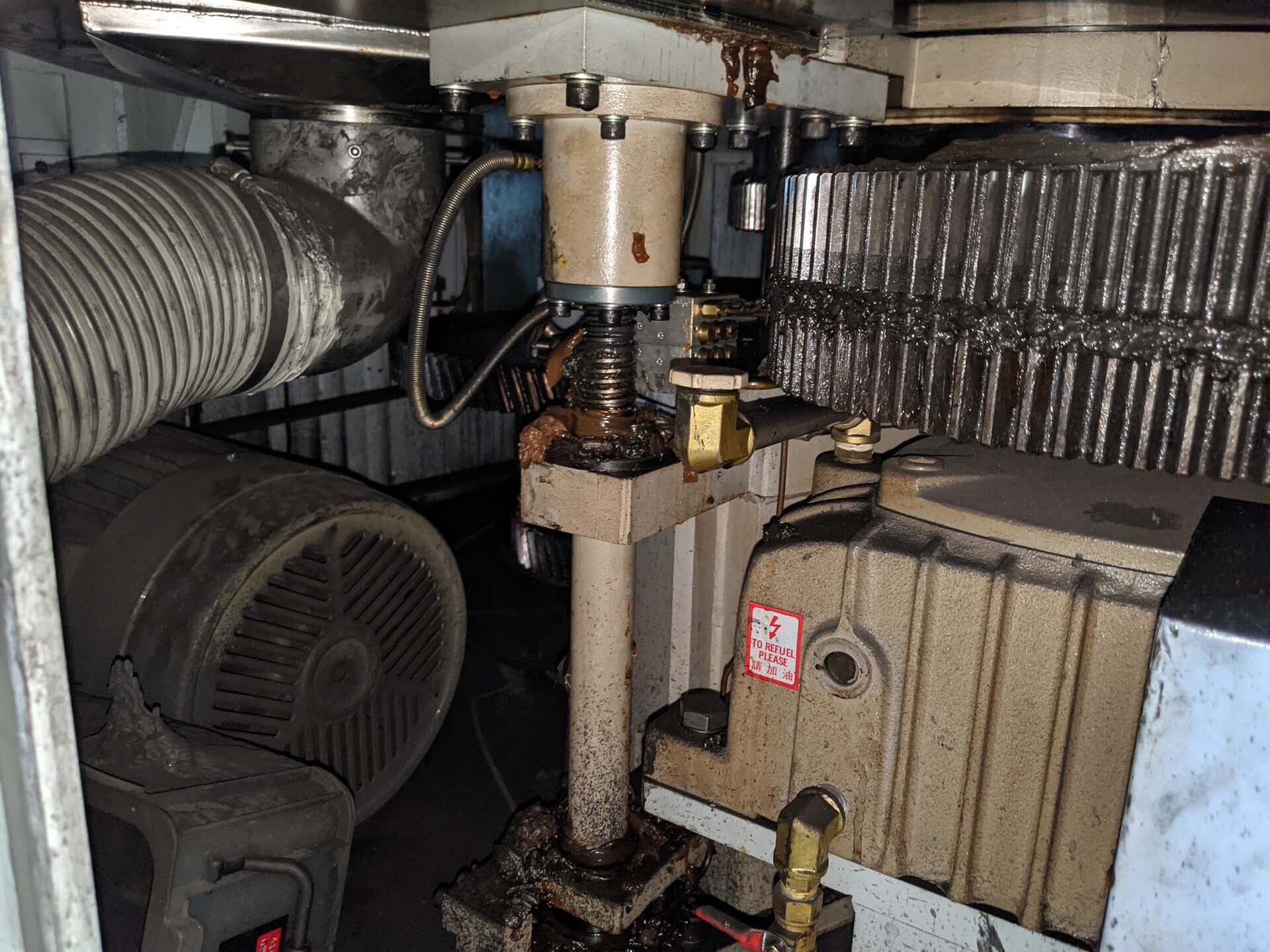

Main cylinder: φ 180 mm x 500 St

Air supply: 6 kg/cm², 127 Nl/min (5.5 kg/cm²)

Work piece dimension:

Maximum diameter: φ 410 mm

Minimum thickness: 0.5 mm

Maximum thickness: 30 mm

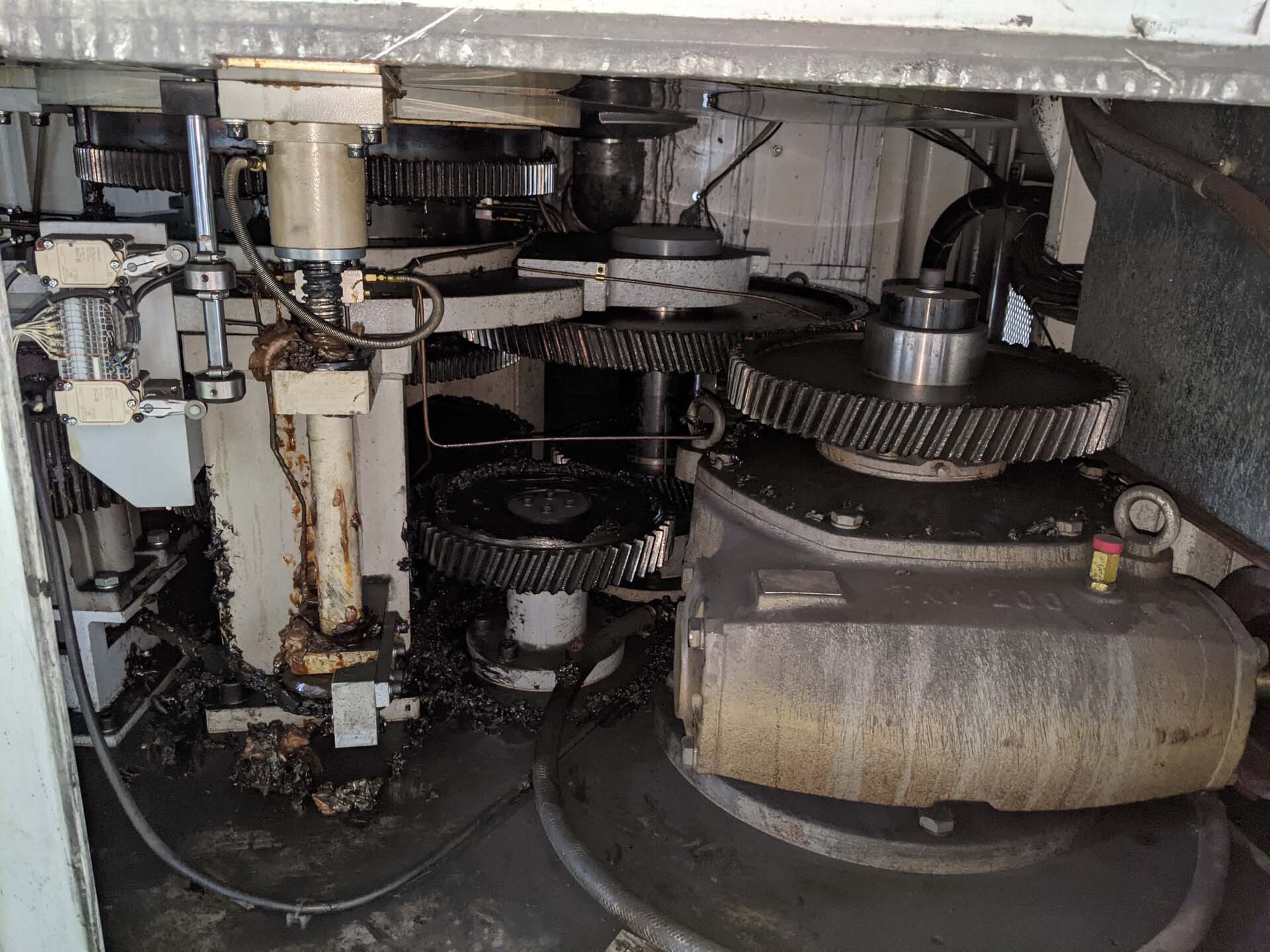

Carrier / Ring gear / Sun gear:

M: 3 / 3 / 3

Z: 170 / 472 / 132

PCD: 510 / 1416 / 396

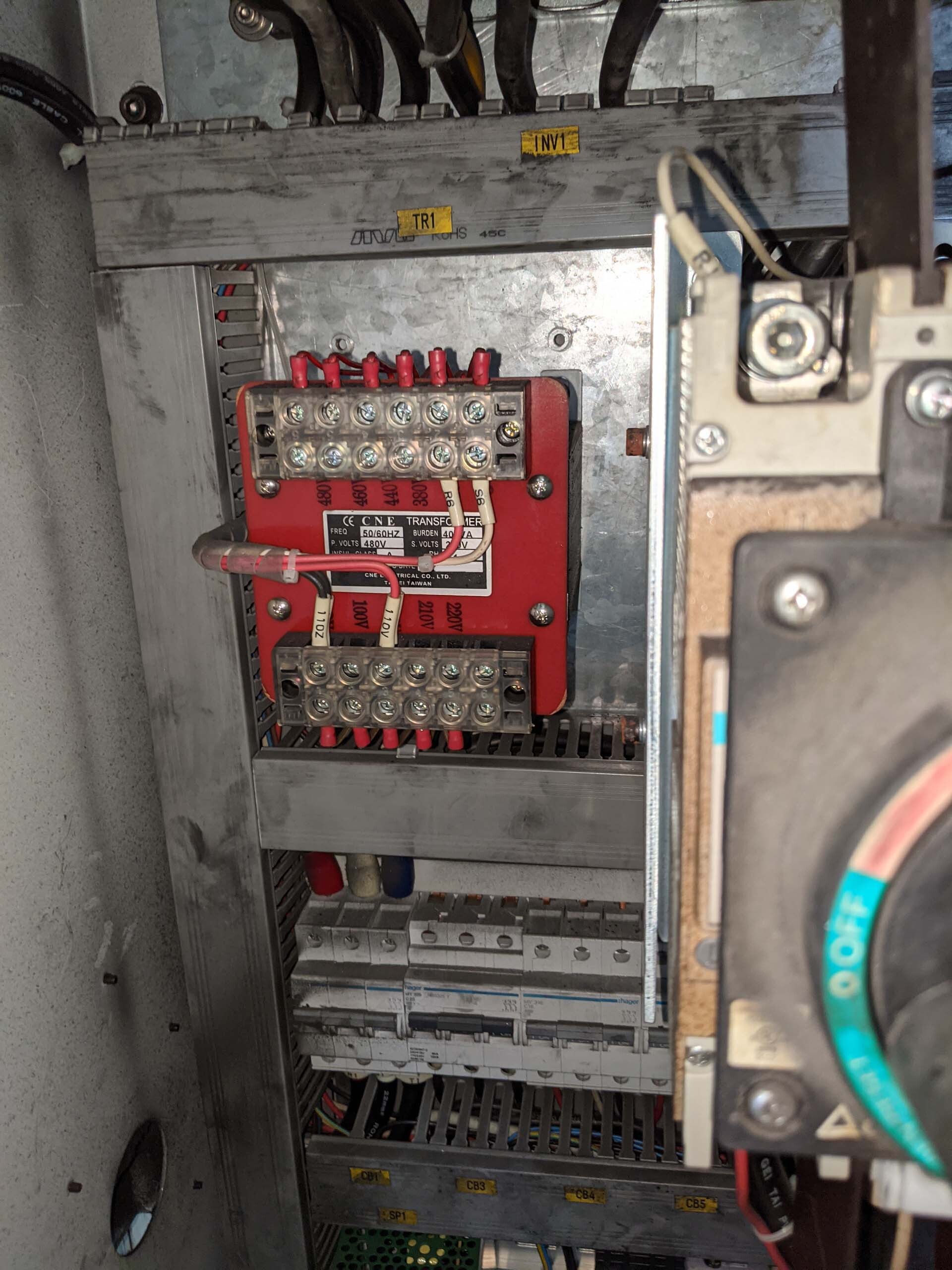

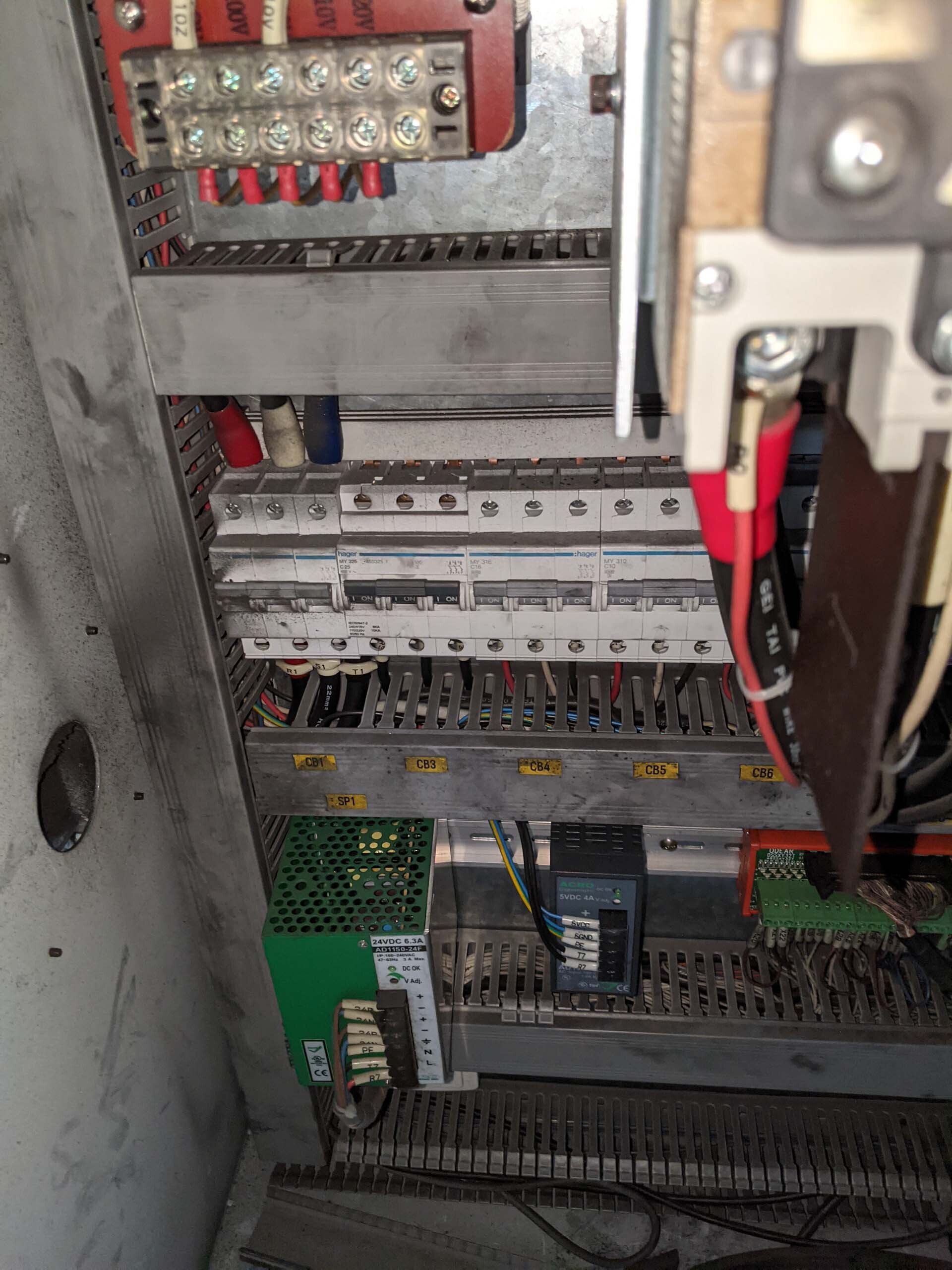

Breaker capacity: 125/75 A

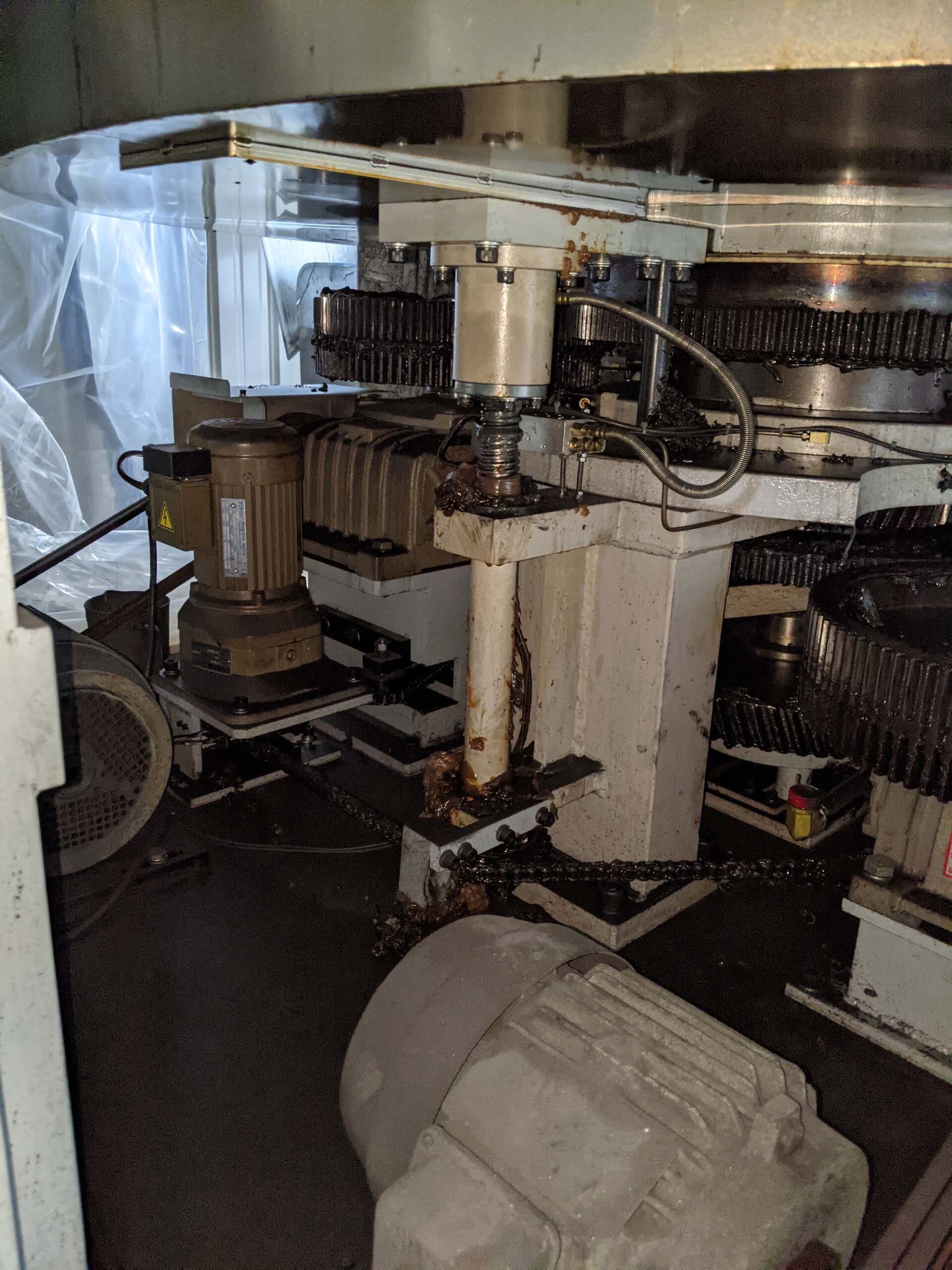

Main drive motor: 15 kW

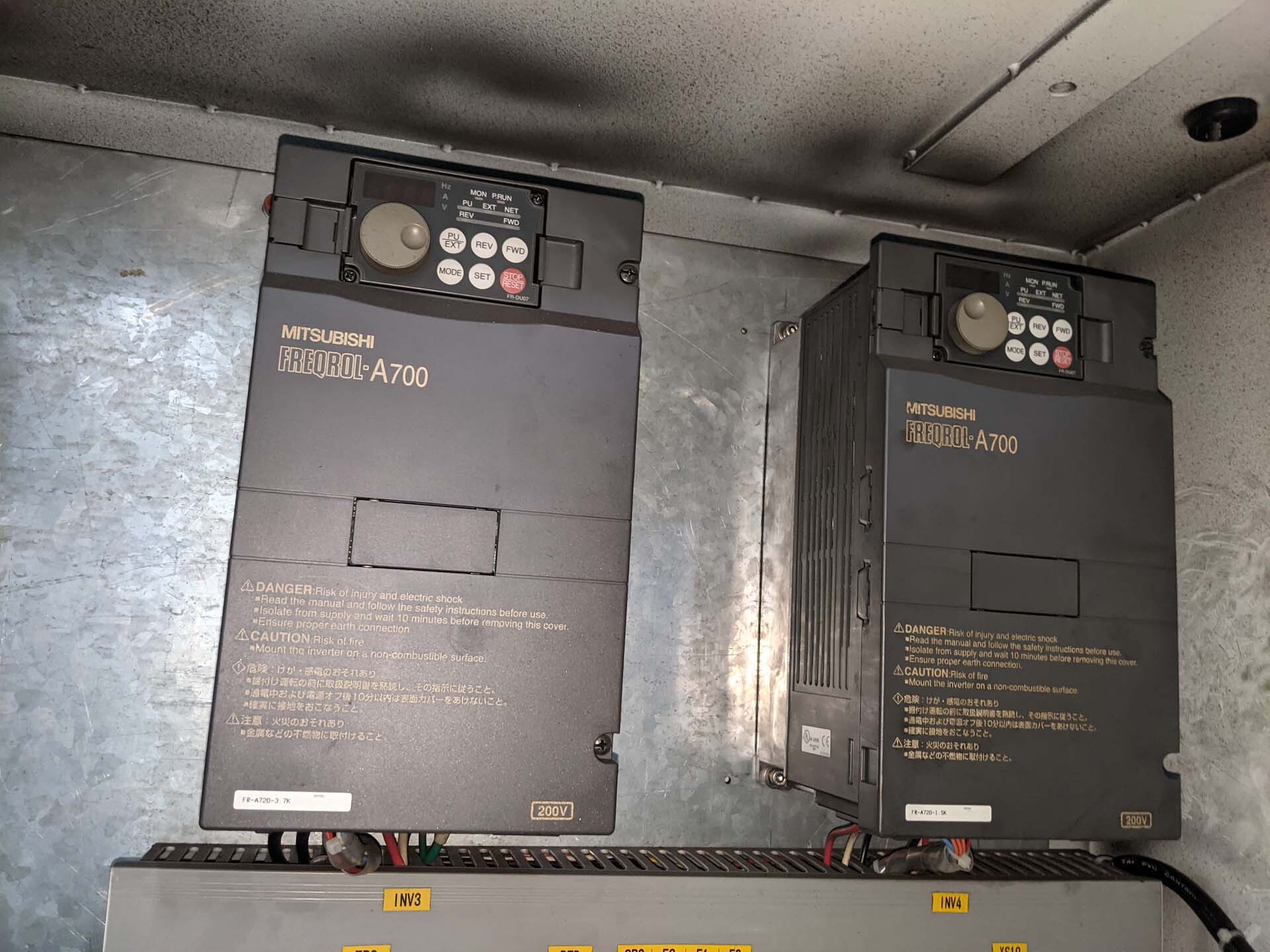

Ring gear drive motor: 3.7 kW

Sun gear drive motor: 1.5 kW

Ring gear / Sun gear motor (Up / Down): 0.4 kW

Slurry pump, agitation motor: 0.4 kW, 0.1 kW

Power requirement: 220/380 V, 3-Phase, 21.1 kW

2013 vintage.

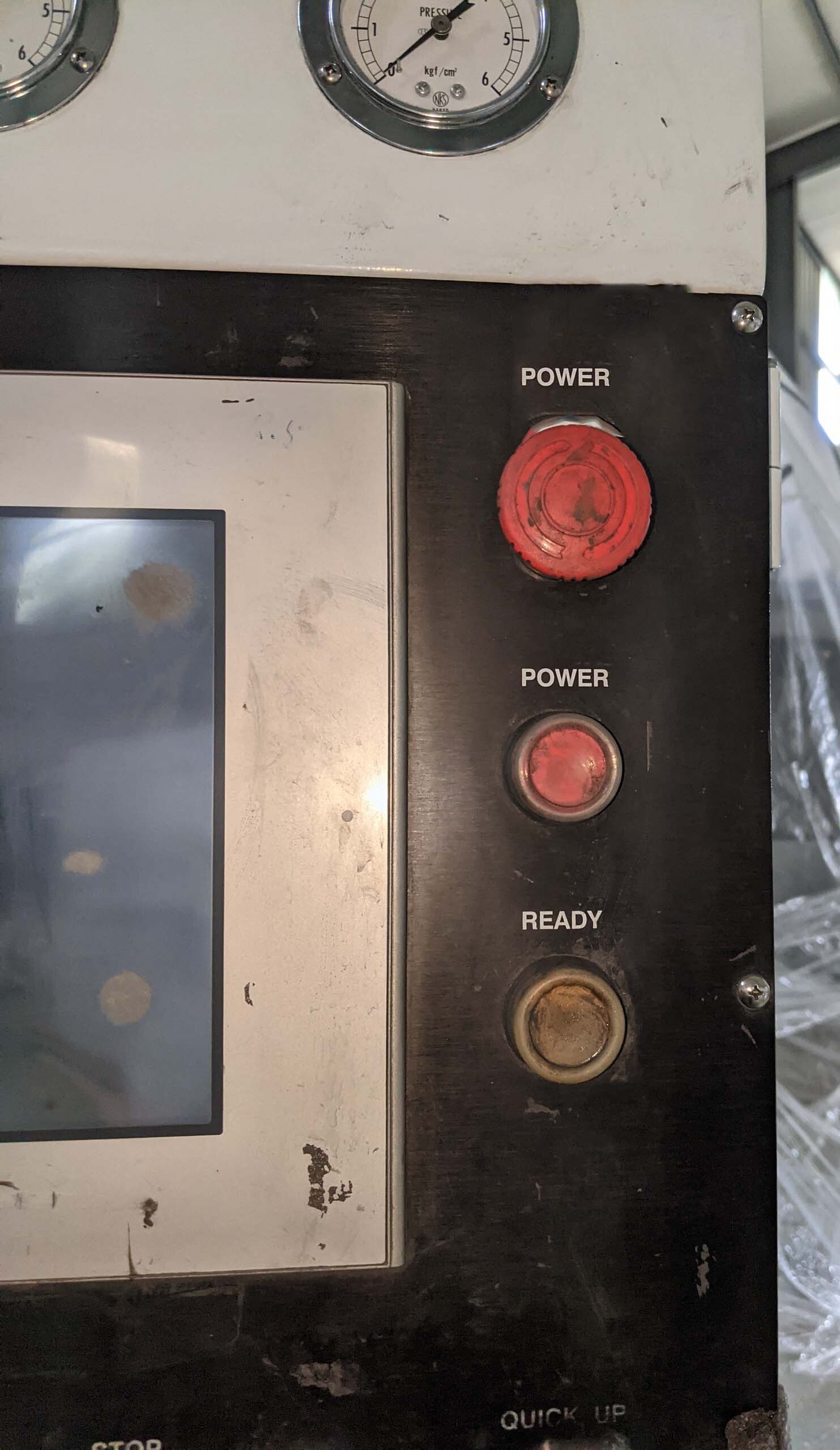

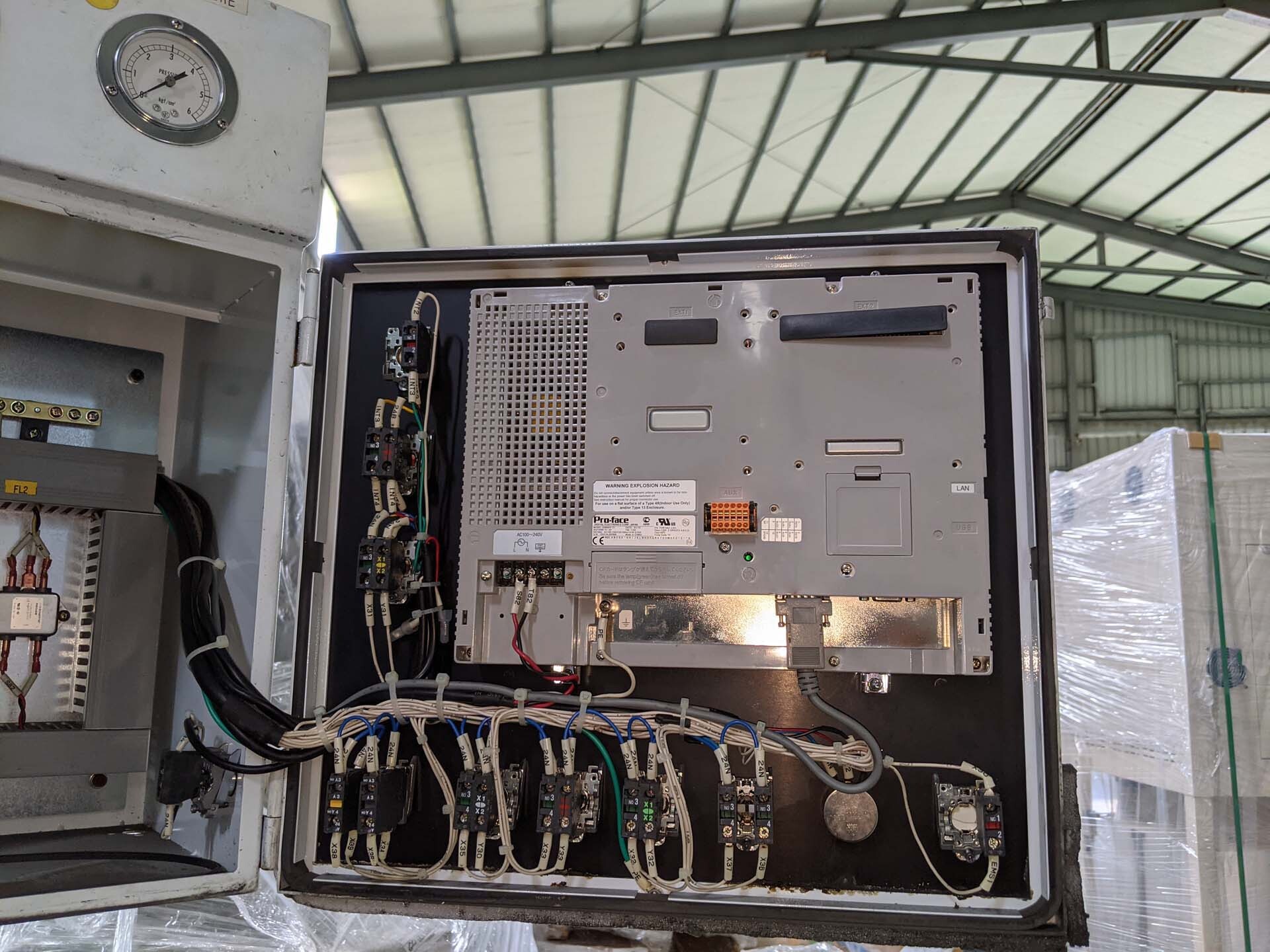

SPEEDFAM 20B-5L is a precision wafering, lapping, and polishing equipment designed for the semiconductor industry. The system consists of a 5-axis robot head, a robotic stage for handling wafers up to 20-inch diameter, a high-temperature grinding table, and a lapping plate. The robot arm has a maximum speed of 140 cm/sec and can handle all kinds of grinding operations from coarse to fine. The robotic stage is equipped with a high precision linear motor to deliver precise movement and accurate results. Thanks to an automated vision unit and advanced software, 20B-5L is capable of fast and reliable surface grinding and lapping operations. The grinding table is capable of delivering a range of grinding forces, from gentle to aggressive. A programmable feature, the table can be set to deliver specific force levels according to the application. The table is also equipped with a high temperature air blower to improve the grinding speed and optimize the cutting performance. The lapping plate features a high-torque motor to drive the lapping process, and the support table includes a drive mechanism to allow for precise wafer rotation. SPEEDFAM 20B-5L is designed for use in harsh production environments, and a rugged construction ensures reliable operation even in extreme working conditions. The machine features an advanced touch-screen interface to provide users with easy access to all tool operations. Additionally, a powerful computer control asset allows for programmable speeds and tooling changes, providing users with the ability to customize the machine's performance to their exact needs. 20B-5L is ideal for high-precision wafer grinding, lapping, and polishing operations. The model's advanced technology and rugged construction facilitates a variety of grinding and polishing operations with tight tolerances and excellent surface finish. The advanced vision equipment and touch screen interface also make it easy to configure, operate, and monitor the system, helping to make the process more reliable and efficient.

There are no reviews yet