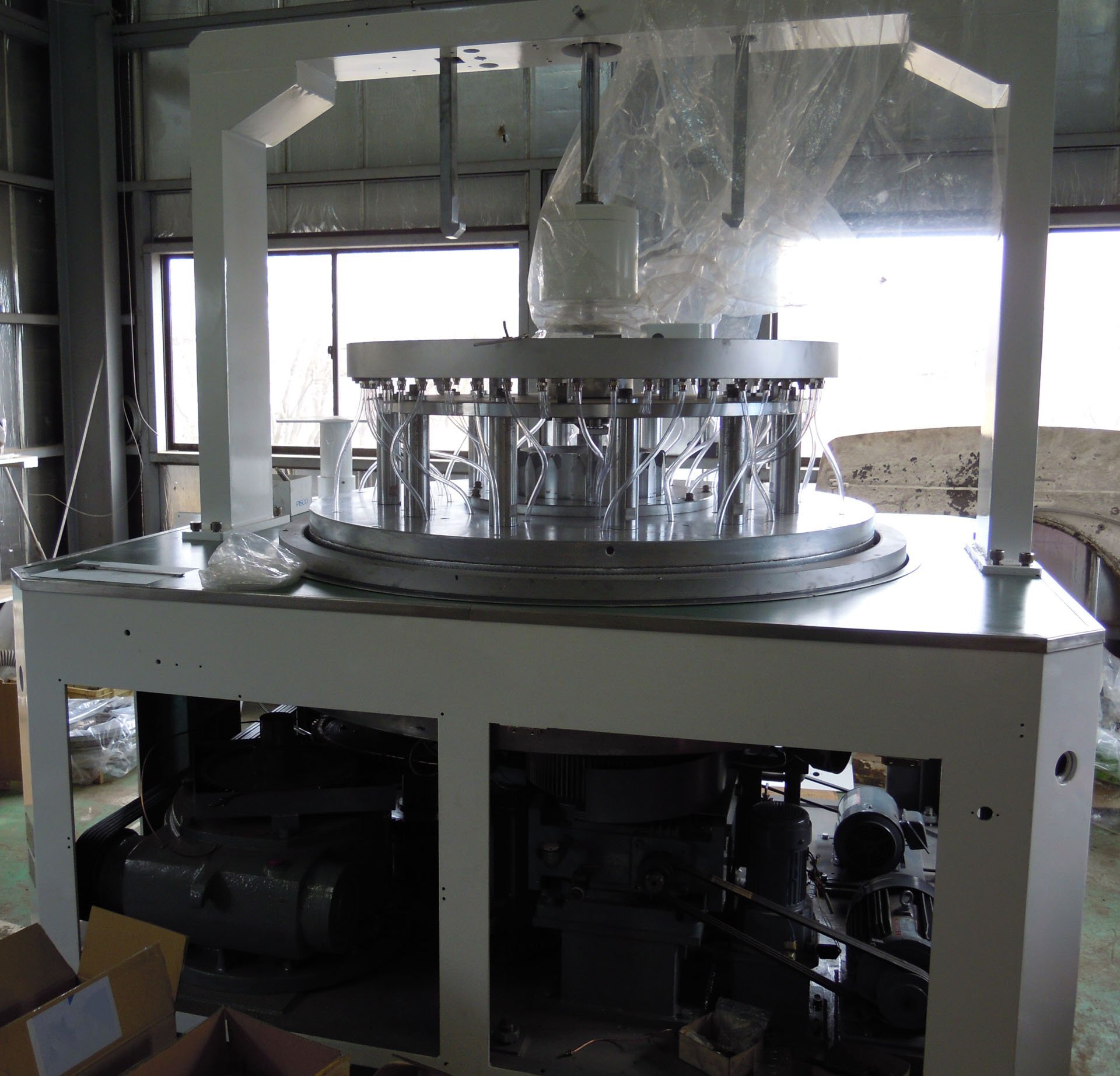

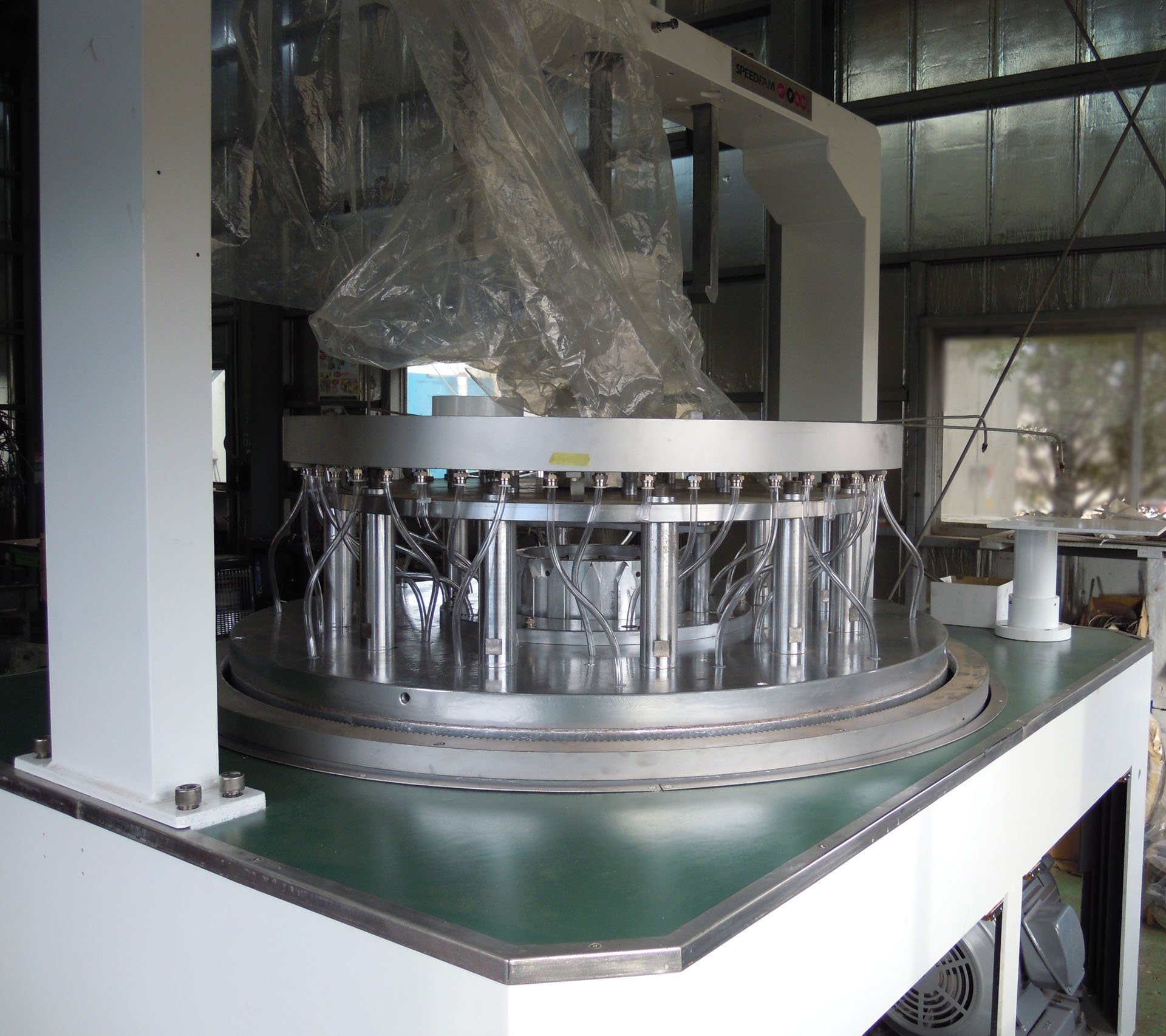

Used SPEEDFAM 20B-5P-II #9359292 for sale

URL successfully copied!

Tap to zoom

ID: 9359292

Vintage: 1996

Polisher

Maximum diameter: 410 φ

Minimum thickness: 0.5 mm

Maximum thickness: 30 mm

Maximum load pressure: 500 kg

Pressure setting range: 0 to 500 kg

Plate size: 1380 φ x 432 mm x 40 t

Lower plate: 6-59 RPM, 50/60 Hz

(5) Carriers: 20B

Main cylinder: 180 φ x 350 st

Sub cylinder: 180 φ x 80 st

Motor: 22 kW

Carrier:

M: 3

Z: 170

PCD: 510

Internal gear:

M: 3

Z: 472

PCD: 1416

Sun gear:

M: 3

Z: 132

PCD: 396

Air pressure:

5 - 6 kgf/cm2

90 N/min

Power supply: 200 V, 400 W + 100 W, 22.9 kW, 3-Phase

1996 vintage.

SPEEDFAM 20B-5P-II is a versatile wafer grinding, lapping, and polishing equipment designed for use in the semiconductor production industry. It is capable of processing a variety of wafer sizes from 50mm up to 200mm. With up to five-axis simultaneous motion, SPEEDFAM 20B-5P II is capable of handling any shape of wafer. The system is highly automated, ensuring precise and consistent grinding and finishing of wafers. 20 B 5 P II employs a wide range of grinding and polishing wheels to offer maximum flexibility and precision during the process. A diamond encrusted grinding wheel is used to shape the wafer's surface to precise specifications. In addition, a combination of diamond, carbide, and ceramic lapping wheels are employed to smooth the wafer's surface. The polishing process is accomplished using a variety of polishing pads and discs. A final polishing step utilizing very fine abrasive is possible if desired. 20B-5P II also utilizes a computerized control unit. This allows the user to precisely adjust the speed, pressure, and timing of the wafer's processing. Additionally, it is able to store the results from each run for review and critical analysis. This gives the user greater control over the process, and allows them to make quick changes as required. SPEEDFAM 20 B 5 P II is also capable of performing multiple wafer runs at any time. This is accomplished with the use of multiple blenders and polishers, which can accommodate several wafer sizes and shapes at the same time. Further, a variety of inspection tools can be employed to ensure quality control. 20B-5P-II is designed for excellent reliability and minimum downtime. The machine utilizes high-grade electrical components, and is designed to exceed industry standards. The tool requires minimal maintenance and can easily be serviced by the user. In conclusion, SPEEDFAM 20B-5P-II is a highly advanced wafer grinding, lapping, and polishing asset offering maximum precision and flexibility. Employing a wide range of grinding and polishing wheels, as well as computerized control, this model can consistently grind, lap, and polish whatever size and shape of wafer. With its reliable construction and easy serviceability, SPEEDFAM 20B-5P II is sure to meet any industrial requirements.

There are no reviews yet