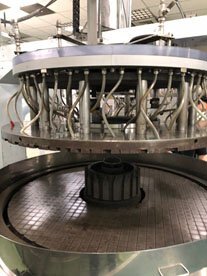

Used SPEEDFAM 20B #9363838 for sale

URL successfully copied!

Tap to zoom

SPEEDFAM 20B is a wafer grinding, lapping, and polishing equipment designed to provide maximum performance and efficient wafer production for processing of substrates. SPEEDFAM 20 B features a 15 in. platen for precision grinding, a 9 in. carrier table for lapping, and a 5 in. carrier table for polishing. The machine is also equipped with a MicroPass variable speed polishing head that can provide a maximum material removal rate of up to 10 μm. For process control, 20B system also comes with a user-friendly graphical interface to manage the polishing, lapping, and grinding program. The polishing area of 20 B unit has a pressure manifold on the front of the table that can be used to vary the pressure for the polishing process. The polishing platen also has two independent polishing heads that utilize variable speed motors, allowing for the fine-tuning of polishing rate. In addition, the machine has an external jig machine that is used to easily adjust the gap between the substrate and the plate. SPEEDFAM 20B also provides an automated dresser tool for both the grinding and lapping activities. This allows the user to dress the grinding and lapping tools automatically and with minimal user intervention. The dresser has a controller that can set the dressing parameters and monitor the dressing activities. The grinding area of SPEEDFAM 20 B asset utilizes a rotary motor to provide high-precision grinding. The motor has a variable speed range of up to 15,000 rev/min with excellent repeatability. The machine also comes equipped with a programmable head for 3-axis (X, Y, Z) coordination of the grinding movement. The platen also has vacuum hold-downs to ensure maximum substrate adherence during the grinding process. The lapping area of 20B model is equipped with a two-stage lapping process. This allows for a pre-lapping process and a precise lapping process to be completed. The lapping process also utilizes an adjustable jig equipment to allow for repeatable lapping parameters. The lapping also has a variable speed motor to allow for optimal material removal rate and a built-in safety system that prevents operator injury. For safety, 20 B also utilizes a light curtain that acts as a safety barrier between the operator and the grinding and polishing area of the machine. The light curtain will disengage anytime an operator enters the area and will reactivate when the operator leaves the area. SPEEDFAM 20B also has a built-in cleanliness unit to ensure that all areas of the machine are kept free from contamination. This machine includes automatic media refill/flush, air filtration, and a static-elimination tool. Overall, SPEEDFAM 20 B is an excellent wafer grinding, lapping, and polishing asset that offers optimal performance and efficient wafer production. With its automated dresser model, variable speed motors, built-in safety systems, and cleanliness systems, 20B provides an all-inclusive solution for precision grinding and polishing of substrates.

There are no reviews yet