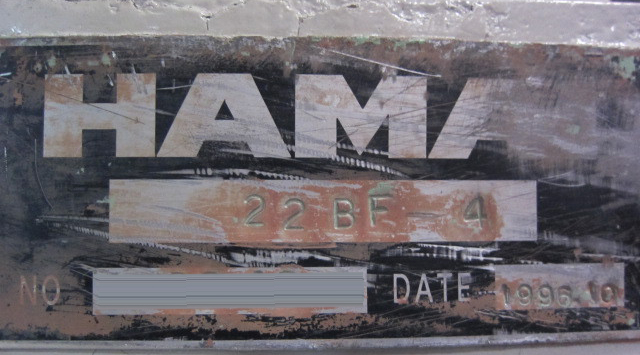

Used SPEEDFAM 22BF-4 #9057336 for sale

URL successfully copied!

Tap to zoom

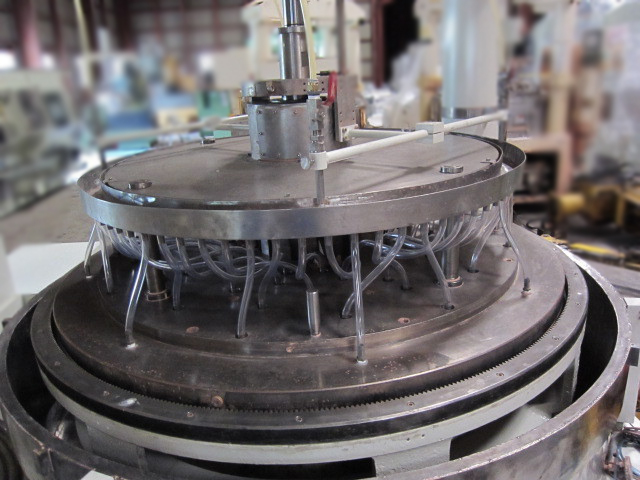

SPEEDFAM 22BF-4 is a wafer grinding, lapping, and polishing equipment designed specifically for silicon and compound semiconductor wafer production. This system offers speed, accuracy, and repeatability to reduce valuable time and steps during the lithography process. The grinding process employs a three-axis motion control unit to control the positioning and movement of the rotating abrasive tool holders across the wafer surface. This motion control machine provides positional resolution of 0.001 mm (10 microns) ensuring highly accurate and repeatable results. The tool also has a spindle speed controlled from 200 to 10,000 rpm, with an adjustable in-feed rate of 0.1 to 20mm/sec., allowing for fine-tuning of the grinding process. The lapping process consists of two cross-linked machines, which are used for planar grinding and polishing of the wafer. With the use of a slurry pump, the abrasive material is pumped onto the wafer surface and simultaneously controlled into pressure and flow for the desired result. The machines use diamond abrasives to ensure a level grinding and polishing without gouging or damaging the wafer. Both the lapping machines have adjustable speeds from 150 to 7,500 rpm allowing for process optimization. The polishing process is used to smooth down rough edges and remove small pits and scratches from the wafer surface. The polishing stage utilizes a either a chemical mechanical polishing (CMP) machine or a lapping station, depending on the yield requirements of the product. The CMP machine offers modified polishing, lapping and profiling of wafers with respect to size. With a computer-controlled polishing head pressure, platen speed and the polishing time, the CMP machine provides high yield production with consistent control of the polishing process. 22BF-4 has an advanced asset design that combines grinding, lapping, and polishing processes into one platform for increased efficiency. This model eliminates the need for manual operation and technique pressure application during the process. The overall design reduces repetition while providing precision results. Additionally, the equipment is also equipped with safety features to ensure operator safety during operation. SPEEDFAM 22BF-4 is a powerful and reliable production machine developed specifically for wafer grinding, lapping and polishing. With its advanced functions and system design, the unit can be used to produce high-quality, repeatable wafers. It is an essential tool for increasing production efficiency and safety in semiconductor wafer production.

There are no reviews yet