Used SPEEDFAM 32 BTAW #9366028 for sale

URL successfully copied!

Tap to zoom

ID: 9366028

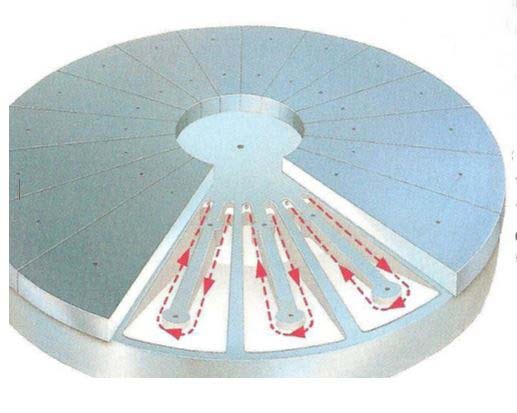

Lapping machine, 32"

Water cooled spiral grooved lapping plate, 27"

Lapping plate rotation speed: 30 - 87 RPM

(4) Conditioning rings

Conditioning ring inside diameter: 11 7/8"

(4) Pneumatic pressure plates

Center reversing gear

Dispensing system

Electrical component

Cylinder

Control valve

Power supply: 220 VAC, 3 Phase.

SPEEDFAM 32 BTAW is a state-of-the-art wafer grinding, lapping and polishing equipment, designed to provide high levels of accuracy and repeatability. The system provides an effective solution for low- to high-volume process steps in the fabrication of semiconductor-related processes such as photolithography and metrology. SPEEDFAM 32BTAW unit is composed of two main components: a wafer carrier and a grinding/polishing head. The wafer carrier is designed with a low center of gravity for a high degree of stability, allowing for an accurate application of the material to the surface of the wafer. The carrier is also implemented with an electro-magnetic clamps which provides an additional measure of security against slipping or moving parts. The grinding/polishing head is an automated machine that facilitates parallel grinding/polishing operations up to a 3.2mm wafer diameter. This tool provides higher accuracy due to enhanced applications of the grinding and polishing material. The head is integrated with a high speed spindle rotation for dynamic grinding processes, allowing for increased depths of material removal. The head is also integrated with an accurate optical 3-D scanner for precise measurement of the material removal. The unit has a front loaded design which offers easy access and on-the-fly adjustments for both the grinding and polishing phases. It includes an automated polishing process control asset to provide precise control of parameters such as load, speed, and timing. It also includes an intelligent control model for monitoring, diagnosing, and regulating the grinding and polishing process in order to continuously adjust and fine-tune the process for optimum results. 32 BTAW is configured for operation in either manual or automated sequence. The unit is also fitted with a fully automated robot arm which adds versatility and flexibility to the process operation. This allows for the adjustment of the robot arm, automatically loading and unloading cassettes of wafers with minimal manual intervention. The additional advantage of the robot arm is that it enables the simultaneous processing of a varying number of wafers to meet the most demanding production schedule. 32BTAW provides a reliable and efficient solution for a wide range of grinding and polishing applications. The combination of easy-access operational design, robust construction, and automated equipment control enables a low risk of operator errors and a high degree of process accuracy. The system is ideal for industries producing products such as semiconductors, compact discs, and data storage disks, as well as any other application that requires a high degree of process precision.

There are no reviews yet