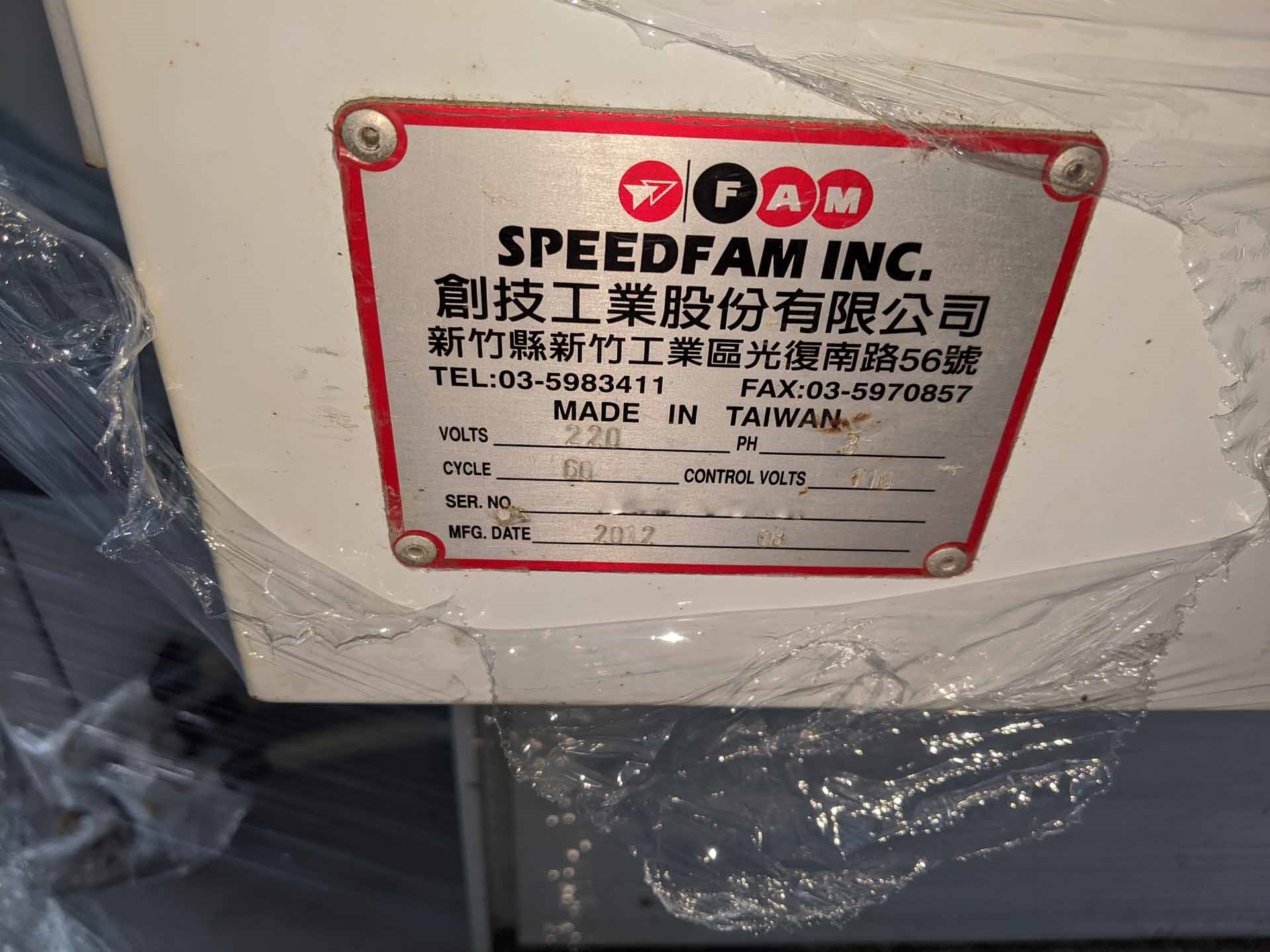

Used SPEEDFAM 36 DPAW #9287360 for sale

URL successfully copied!

Tap to zoom

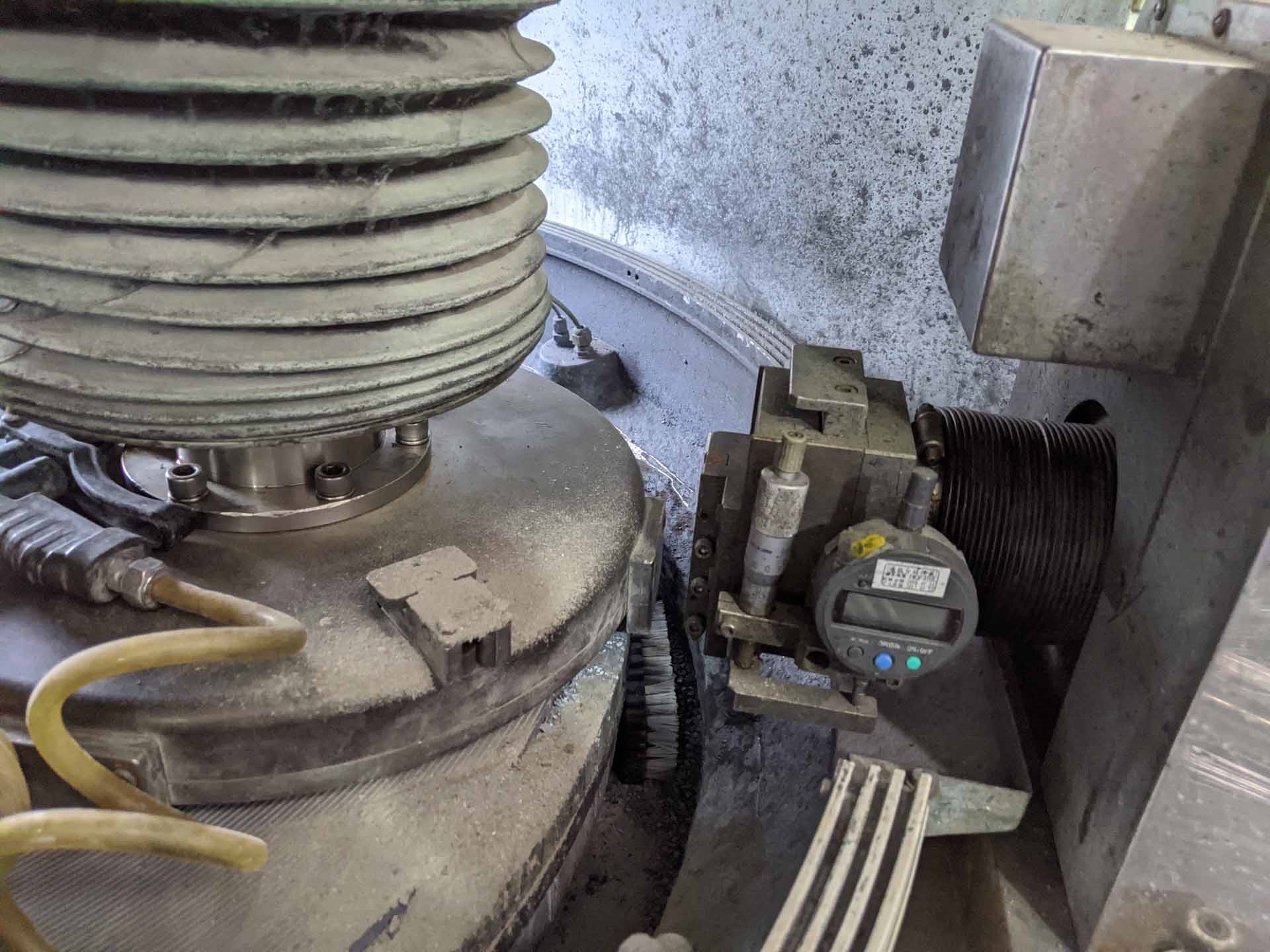

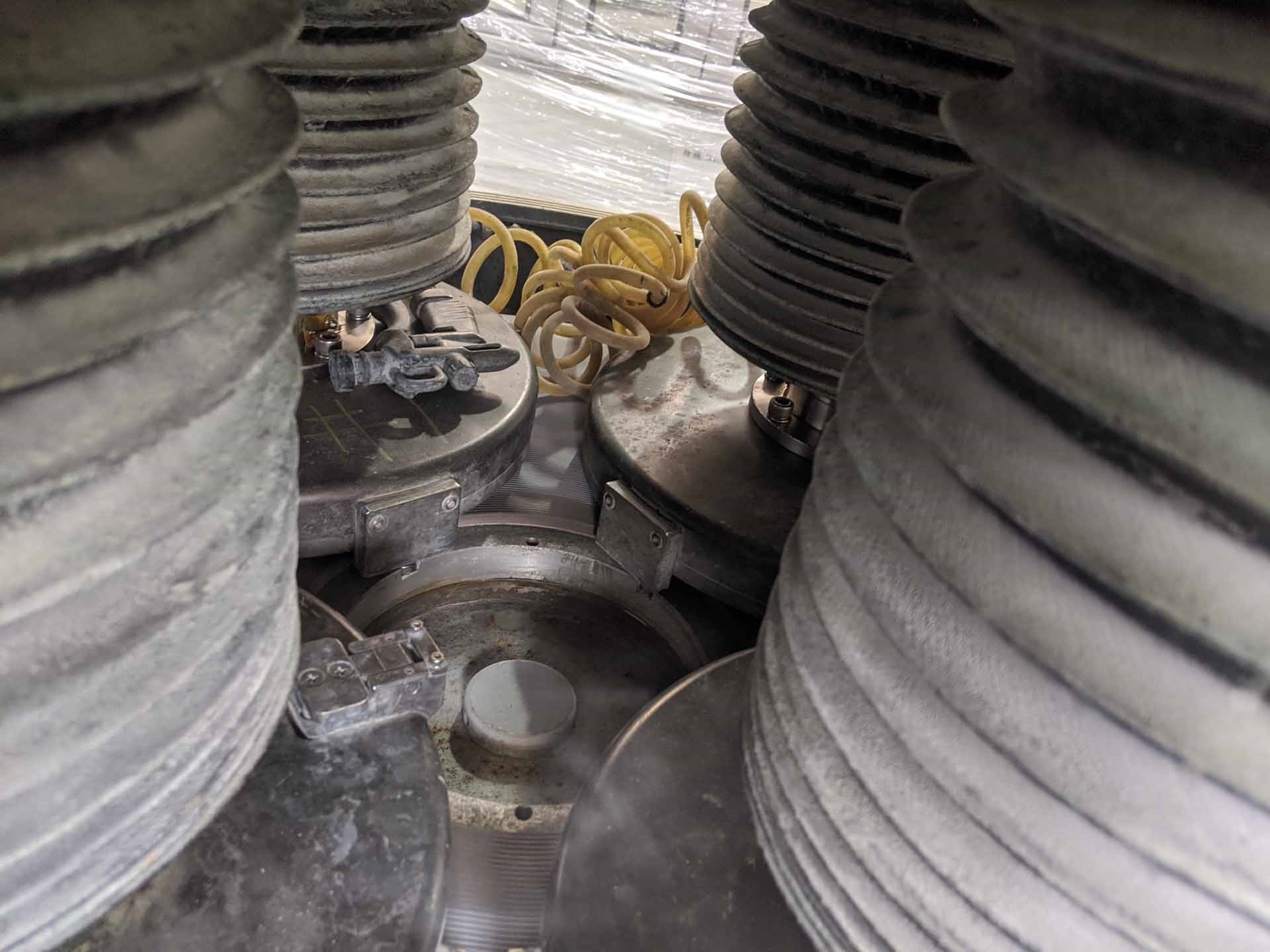

SPEEDFAM 36 DPAW is a fully automated wafer grinding, lapping and polishing equipment designed by SPEEDFAM and manufactured by SPEEDFAM Precision Technologies. It is capable of producing ultra-finish flats and angles on dielectric, magnetic, brittle and ceramic materials. 36 DPAW is an oscillating table system designed for processing wafer-sized pieces. The unit utilizes stroke-based technology allowing for high process accuracy and finish quality. The oscillating table operates on a patented "Z-duty" cycle through two stages of cutting and one polishing step. It provides stable process conditions throughout the polishing process, ensuring uniform process results. SPEEDFAM 36 DPAW's design consists of an indexed holding chuck for precise positioning of the workpiece table, and three separate working stations for grinding, lapping and polishing. The holding chuck is designed to accommodate wafer-sized substrate pieces in both the flat and angled shapes. The grinding station applies a grinding medium such as diamond or Cubic Boron Nitride (CBN) to the substrate surface, in order to cut and remove material from the substrate. The lapping station follows the grinding station and applies a combination of Silicon Carbide (SiC) and diamond abrasives to the substrate in order to further cut and remove material from the substrate. Finally, the polishing station applies a solution — such as alumina — to the substrate to bring it to its desired surface finish. 36 DPAW also features a remote-controlled, operator-friendly GUI, which provides the operator with operation diagnostics and process monitoring. Additionally, the machine comes with a highly accurate temperature control unit, providing temperature-stable grinding, lapping and polishing processes. The temperature control unit is also able to monitor wafer setup and process chamfer conditions. Overall, SPEEDFAM 36 DPAW is an efficient and precise wafer grinding, lapping and polishing tool designed for precise machining and microfabrication of wafer sized pieces. It is a highly automated asset with built-in intelligence for efficient process cycles, as well as temperature control and monitoring capabilities.

There are no reviews yet