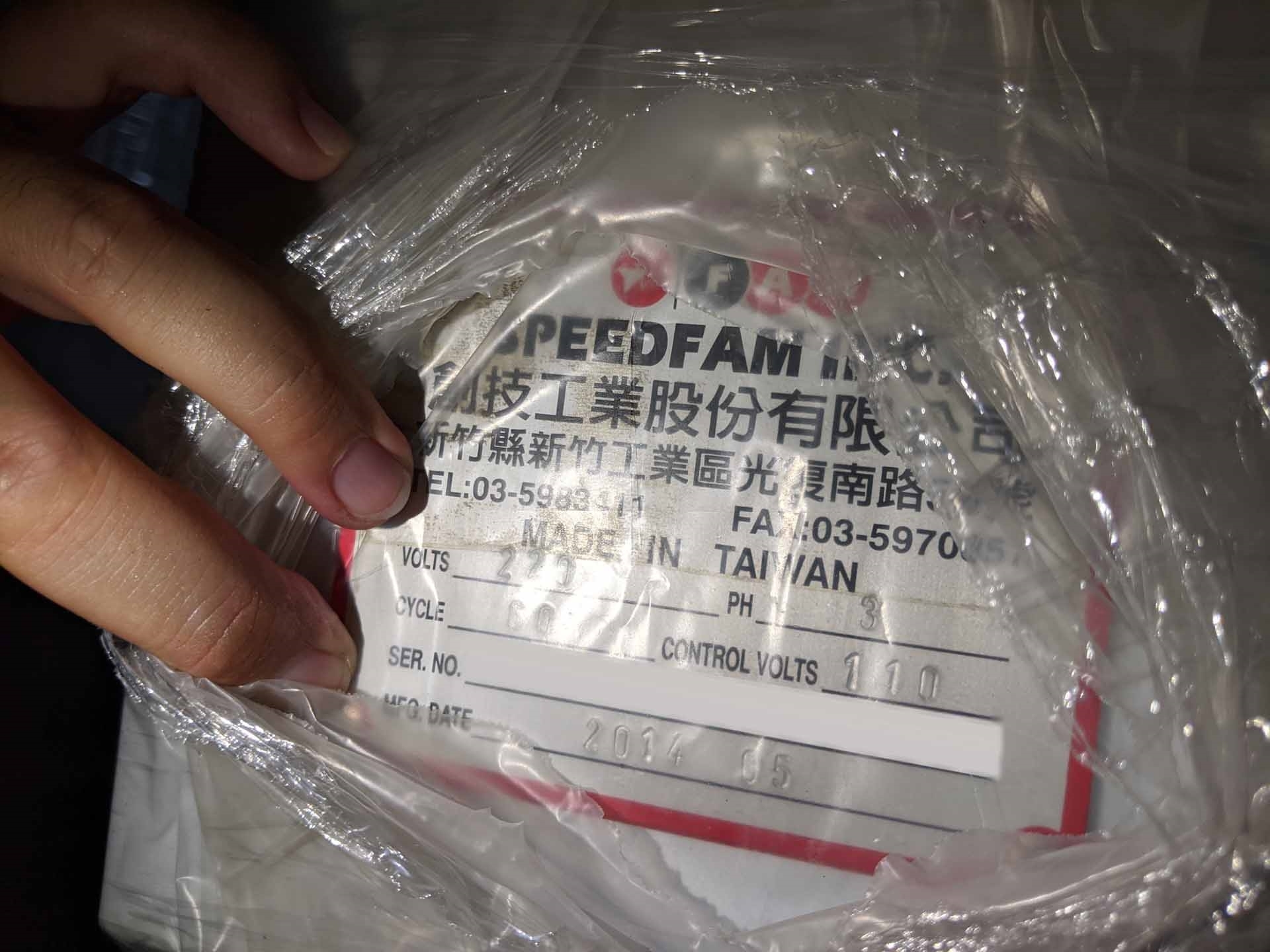

Used SPEEDFAM 50 GPAW #9294585 for sale

URL successfully copied!

Tap to zoom

SPEEDFAM 50 GPAW is a precision wafer grinding, lapping and polishing equipment developed and designed specifically for the semiconductor industry. It is capable of producing flat, smooth and mirror-like polished surfaces with a precision of ±0.5nm. The system is equipped with a high torque, variable speed motor which is capable of delivering up to 50kW power output with a precision of +/- 0.5 microns. 50 GPAW is capable of grinding, lapping and polishing silicon wafers up to 8" in size with a tolerance of up to 1.5 microns. It is equipped with a specialised abrasive papers for use with the unit's grinding and lapping operations. The abrasive papers are available in different grit sizes and different hardness levels. SPEEDFAM 50 GPAW does not require any additional coolant during its operations and is capable of processing surfaces at low temperatures. 50 GPAW is a fully automated machine with its software controlled by a PC based control panel. It is equipped with a vision tool which allows for quick positioning of wafers during the process automation. The asset also houses a robot arm for automated loading and unloading of the wafers. SPEEDFAM 50 GPAW is capable of processing up to 30 wafers per hour and is designed to run in a fully automated, closed environment. The model is also equipped with an automatic cleaning and wafer inspection equipment which helps detect any potential defects in the wafers during the process automation. 50 GPAW features a high-precision measuring system which is used to take measurements of the wafers and display the results on the control panel. This measurement unit is capable of detecting any unevenness in the surface of the wafer. SPEEDFAM 50 GPAW is maintained with regular preventive maintenance service and is inspected regularly to ensure accurate operation. The machine enables users to achieve accuracy and repeatability while producing the finest quality of wafers. With its automated tool, it eliminates the risks of human error and enables users to produce high quality wafers without any inconsistencies or defects.

There are no reviews yet