Used SPEEDFAM 9B-5L-IV #9181284 for sale

URL successfully copied!

Tap to zoom

ID: 9181284

Vintage: 2006

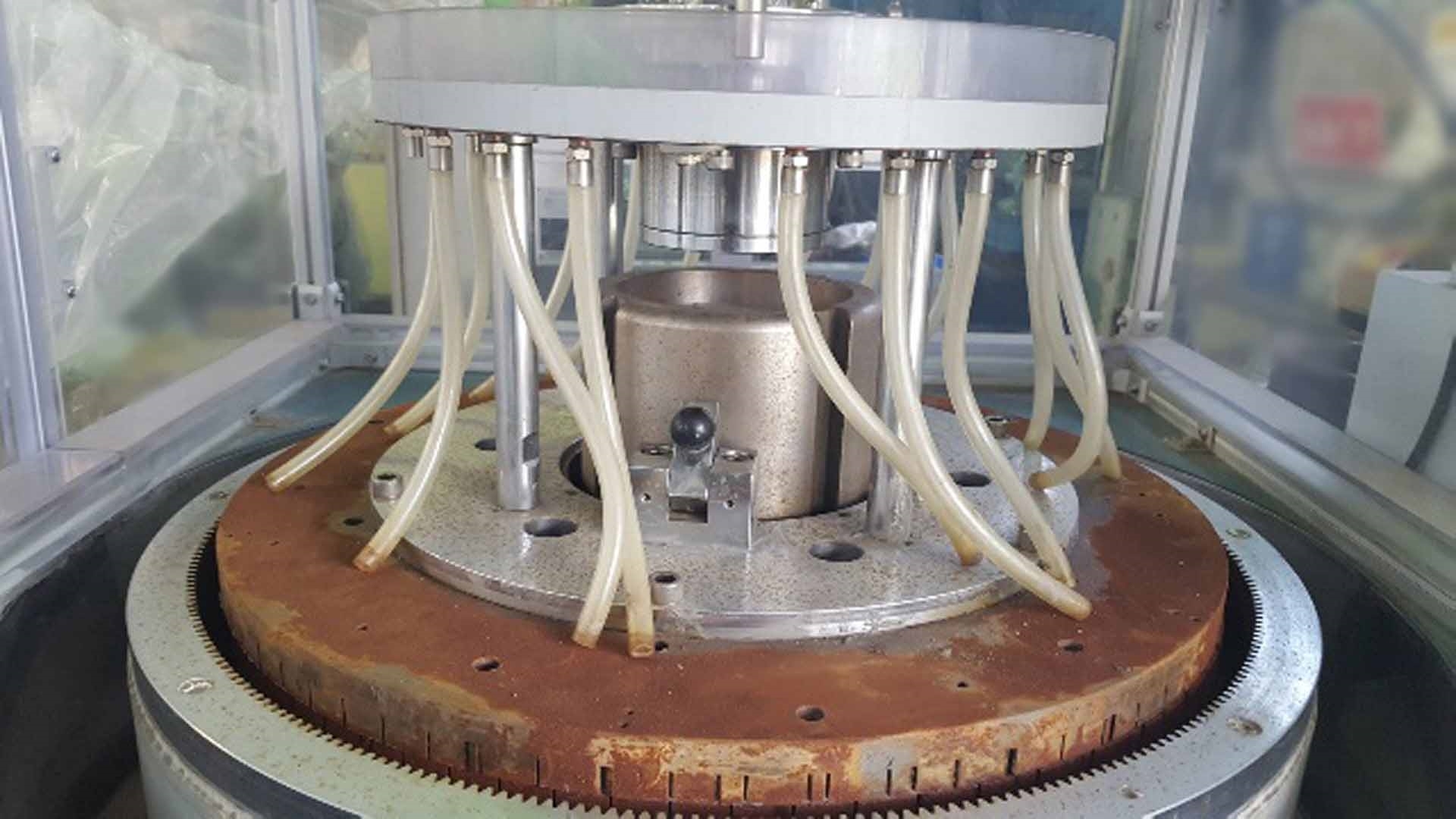

Double sided lapping machine

(2) Motors

Direct read system

Lapping plate

No ATC

No tank

No manual

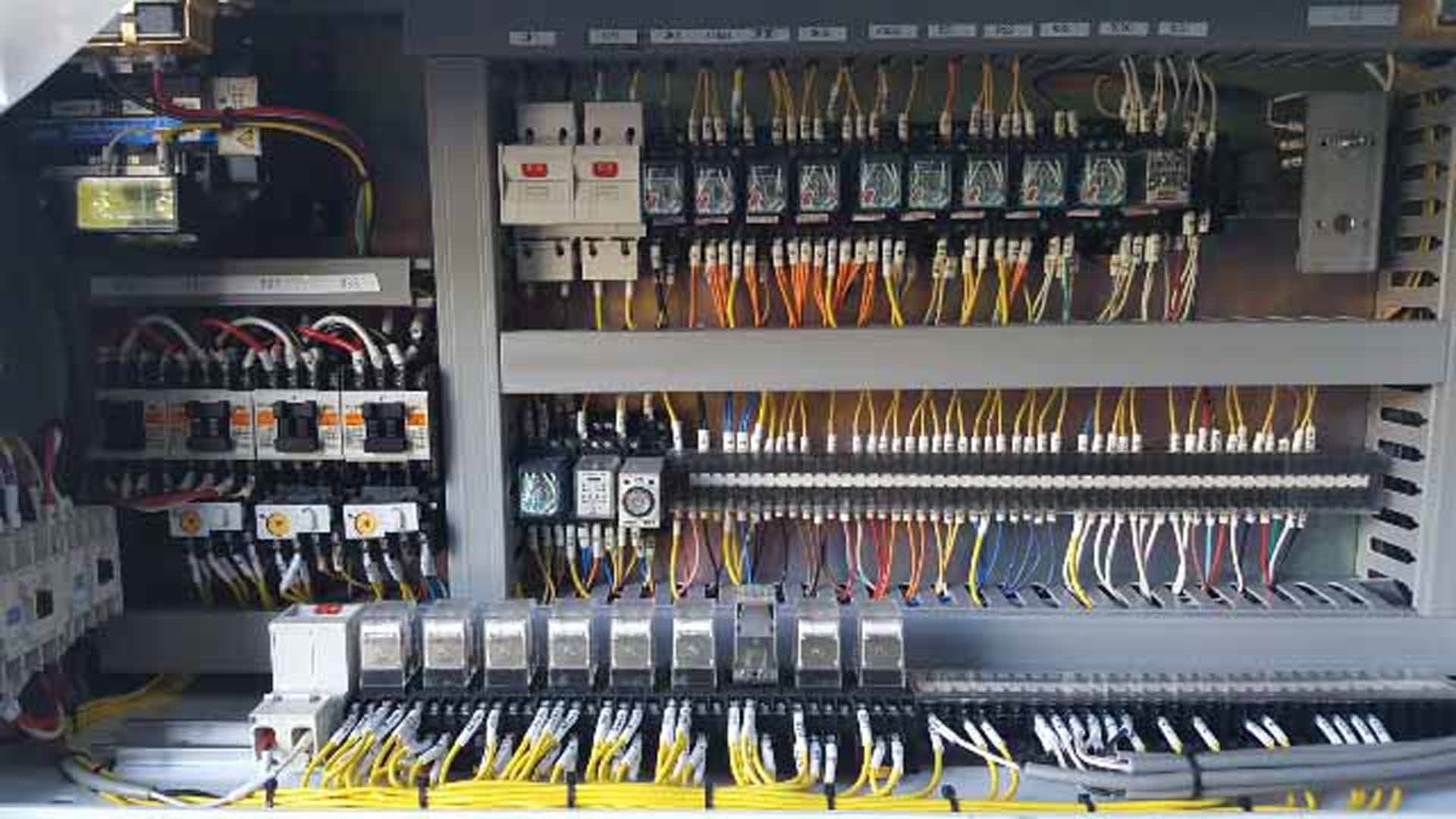

Operation panel

Safety cover

Cast iron plate included

2006 vintage.

SPEEDFAM 9B-5L-IV wafer grinding, lapping and polishing equipment is a fully automated and programmable machining process for precision grinding and polishing of semiconductor wafers. This system combines the free abrasive grinding, lapping and diamond polishing capabilities of several different pieces of equipment into one machine to provide a single-step process. The main component of the unit is the abrasive grinding head, which features a 5" diameter platen that can hold up to 9 wafers. It also contains two sets of grinding wheel holders, which can accommodate up to 36 grinding wheels ranging from 500 - 2000 grit for polishing and surfacing applications. The grinding heads are equipped with variable speed motors and adjustable depth of cut settings, allowing the process conditions to be adjusted for fine tuning. The next component is the lapping head, which uses a precision floating, knife-edge platen to ensure that the lapping operation is consistent across the wafers. This head features a two-axis motion for precise control over the cutting depth and speed. The lapping head is also equipped with an adjustable diamond nozzle that can be used to disperse the abrasive compound, allowing the operator to carefully control the lapping parameters. The final component is the diamond polishing head, which uses an ingenious 3-axis turn table that can move the wafers in a 'figure 8' motion to ensure a uniform surface finish. This feature enables the machine to achieve flat and scratch-free finishes without the need for manual intervention. The polishing head also comes with a fixed-position diamond nozzle for efficient dispersal of polishing compound. The ability to integrate grinding, lapping and polishing operations into a single workcell makes 9B-5L-IV wafer grinding, lapping and polishing machine ideal for high-precision semiconductor applications. The adjustable parameters of the grinding, lapping and polishing heads allow the operator to easily fine-tune the machine for various process requirements and produce repeatable, defect-free results. Combined with its high maneuverability, this tool is suitable for any production environment.

There are no reviews yet