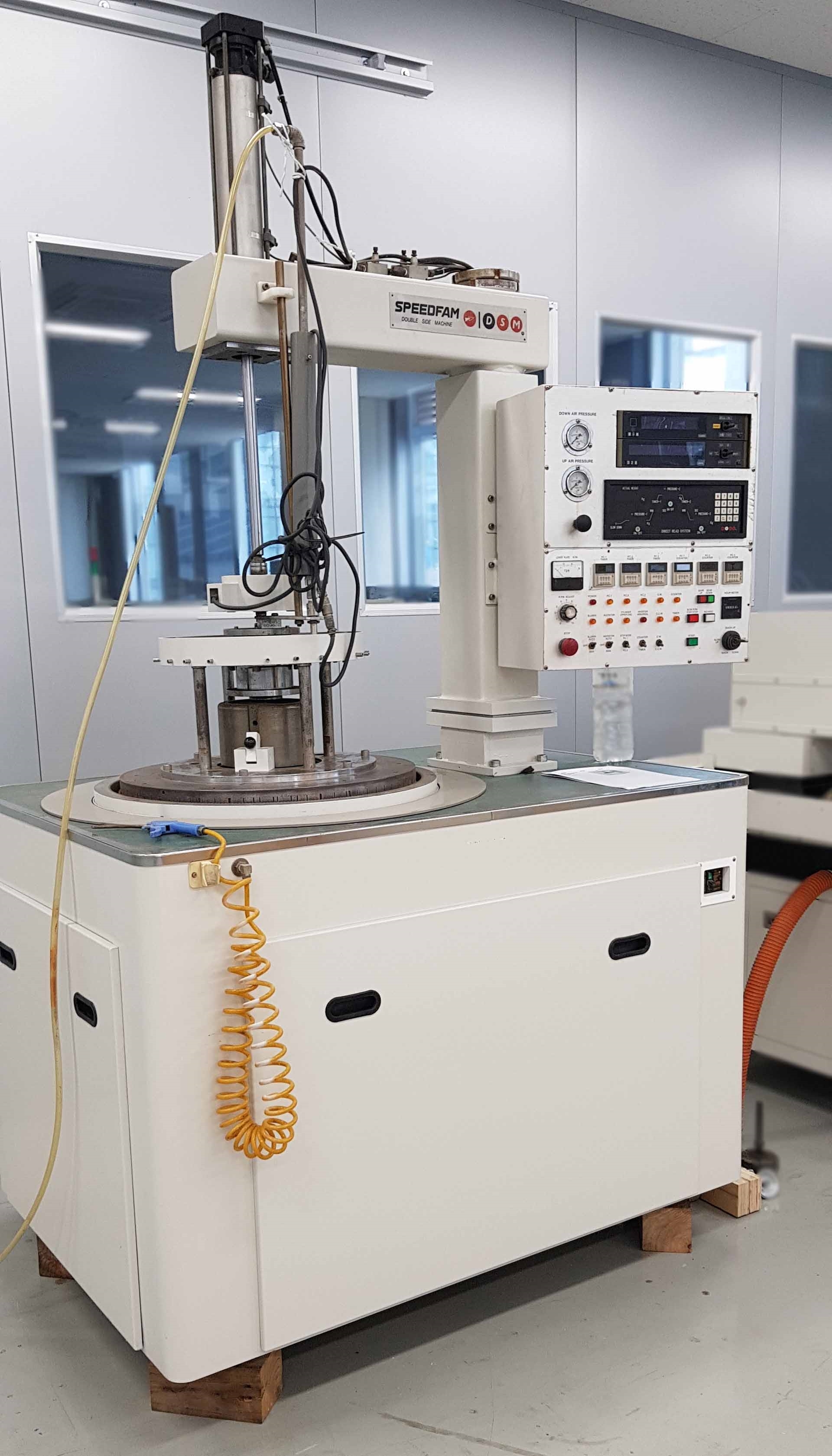

Used SPEEDFAM 9B-5L #9222186 for sale

URL successfully copied!

Tap to zoom

SPEEDFAM 9B-5L is an automated wafer grinding, lapping and polishing equipment designed for use in the production of high precision microelectronic components. This system is a one-step, automated process for grinding, lapping and polishing various materials, such as quartz, silicon, and other semiconductor materials used in microelectronics. The unit is comprised of a base unit and several peripheral components that include an automatic polishing machine, a C-axis eccentric grinding head, a mechanical grinding arm, a lapping machine, and a liquid polishing station. The base unit is constructed of heavy-duty steel with rollers for ease of movement around the production area. It also includes a main control panel and a 10-inch touch screen with programmatically-defined operations and recipes. All accessories are mounted to the stand for complete portability. The automatic polishing machine utilizes diamond-abrasive particles, ceramic laps, and/or resin-bonded abrasive wheels to complete its grinding, lapping and polishing process. The C-axis eccentric grinding head enables complete accessibility to the wafers and components being processed, providing a smoother finish and higher precision control. The mechanical grinding arm features an adjustable speed mechanism and adjustable positions, enabling it to penetrate deeper into the material and to shape it more accurately. The lapping machine works by abrading the surface of materials with an abrasive surface. This is achieved using variable pressure and speed and a vacuum-conducted liquid slurry that assists in producing a uniform finish. The liquid polishing station provides final polishing of quartz by dispersing non-reactive liquid particles that are programmatically-programmed to polish the quartz material. This ensures a standardized, high-precision finish. SPEEDFAM 9B5L is a powerful, automated machine that enables rapid, high-precision finishing of microelectronic components. It is an ideal choice for production processes that require the highest quality, repeatable products. Its advanced programming capabilities, efficient abrasive processing, and adjustable speeds, positions, and pressures provide reliable and consistent results with every use.

There are no reviews yet