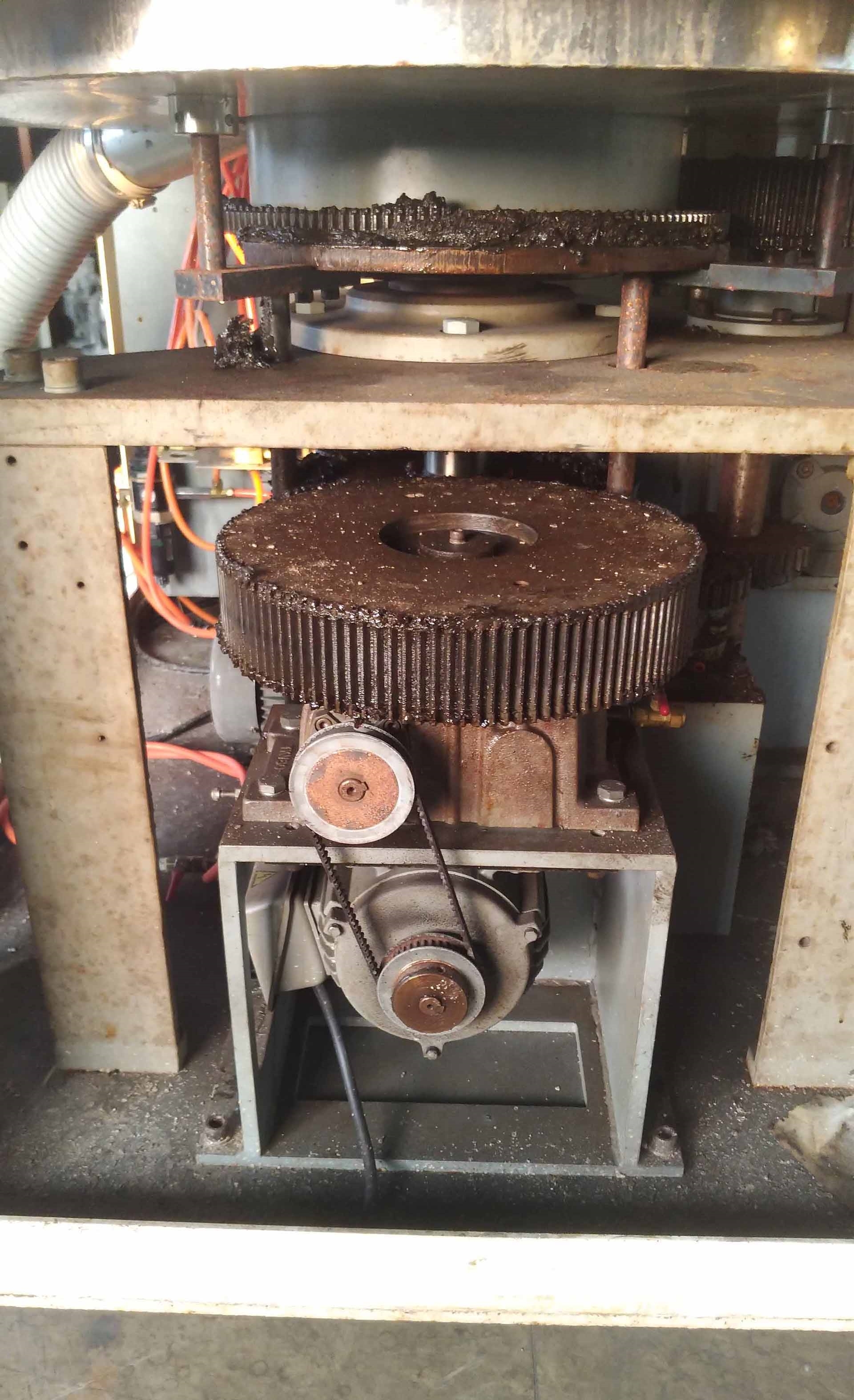

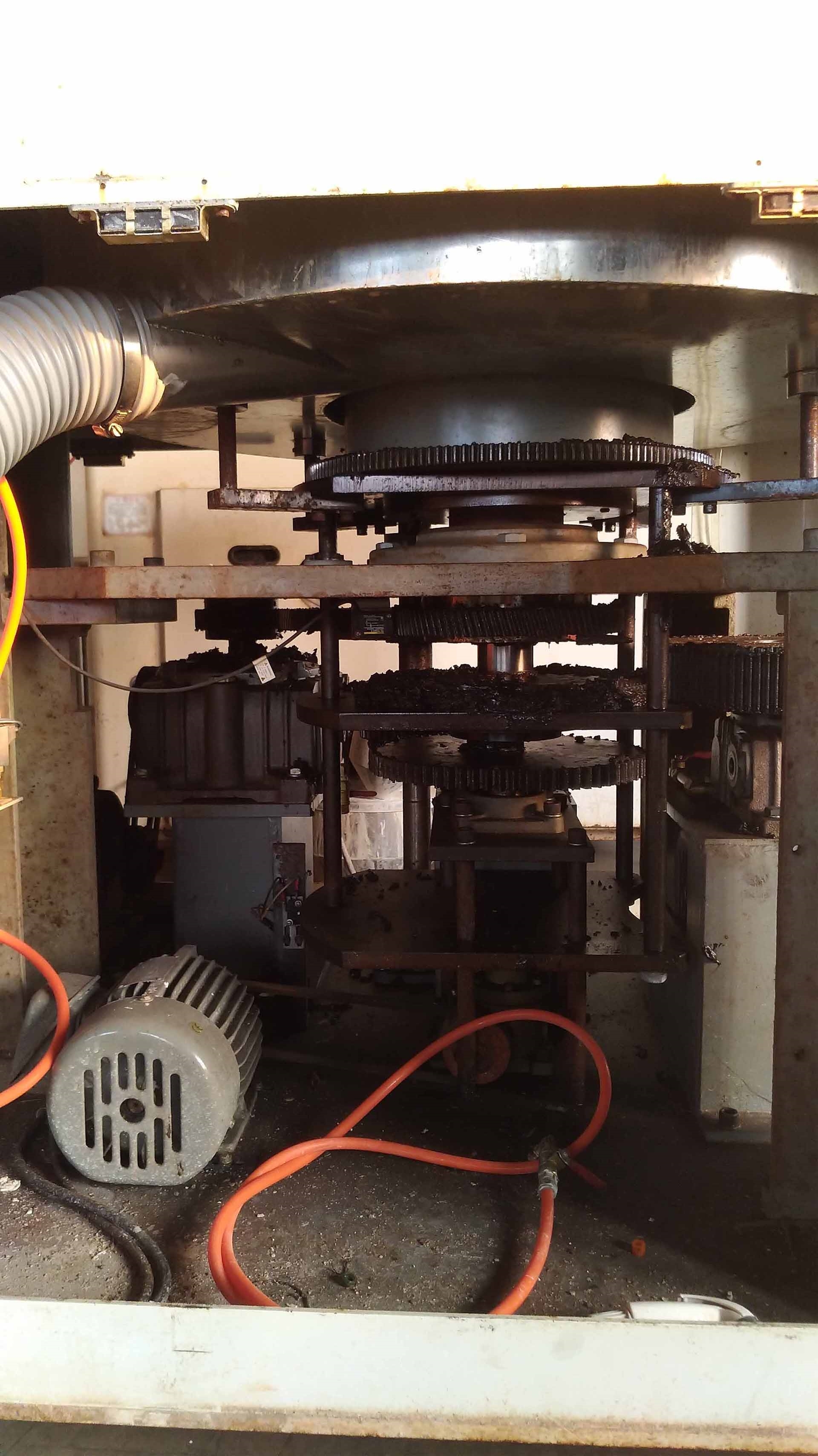

Used SPEEDFAM 9B-5L #9224633 for sale

URL successfully copied!

Tap to zoom

SPEEDFAM 9B-5L Wafer Grinding, Lapping and Polishing Equipment is a fully automated, CNC controlled grinding, lapping and polishing system. It is designed to provide high precision, low contamination surface finishing of semiconductor wafers. The unit can accommodate wafers of various sizes from 2" to 8" in diameter, and features a high speed spindle and a multi-axis servo controls for precise positioning and controlled movements. The machine consists of a base unit to which a spindle is attached. The spindle is adjustable, allowing for expanding and lengthening of the spindle depending on the exact wafer size being processed. The spindle rotates at extremely high speeds, achieving surface finishing of 1μm accuracy in a single pass, and can be adjusted for various wafer thicknesses. The grinding is enabled by a high speed grinding wheel that is positioned at the opposite end of the spindle, allowing the wheel to process the entire surface of the wafer at once. The grinding wheel is adjustable in order to obtain the exact surface roughness required. The lapping and polishing of the wafer surface is accomplished by a floating head, which contains a number of abrasive discs. This ensures that the entire surface of the wafer is simultaneously processed while ensuring that the wafer remains perfectly flat. The abrasive discs can be changed to suit different surface characteristics, such as high gloss, matte, or polished finishes. SPEEDFAM 9B5L is capable of discerning between different types of wafers, allowing it to set up the tool specific to the type of wafer being processed. It also contains a particle detection asset, which helps to detect any small changes in the wafer surface, and can also be used to monitor the model status. The equipment is designed for fast and accurate processing while providing total control to the user. It also provides low contamination processing, removing any airborne particles or debris from the work environment and ensuring that there is no settlement of excess materials on the wafer. This helps reduce wafer rejects and increases yields, ultimately providing a higher return for the user. The user interface of the system is highly user friendly. It provides an intuitive unit display which allows the user quick access to machine settings, material selection, and run time information. The tool can be programmed to run different modes, adding flexibility and reliability to the asset. Overall, 9 B-5 L Wafer Grinding, Lapping and Polishing Model provides a reliable and efficient equipment for the grinding, lapping and polishing of various types of semiconductor wafers. With its high degree of accuracy and precise control over the entire process, it is an ideal choice for those requiring high quality and consistent end results.

There are no reviews yet