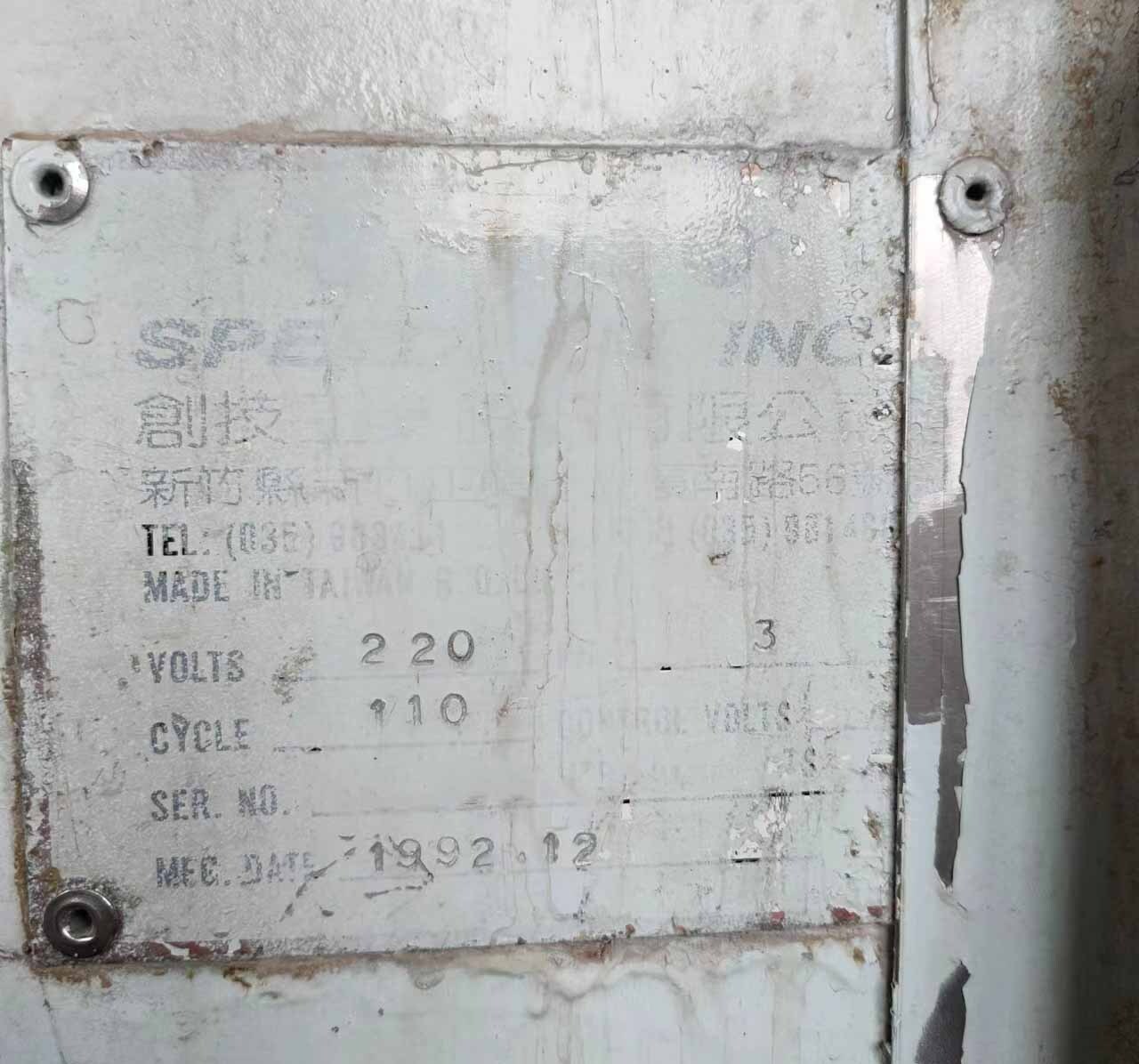

Used SPEEDFAM 9B #293621393 for sale

URL successfully copied!

Tap to zoom

SPEEDFAM 9B is a fully automated CNC-controlled wafer grinding, lapping and polishing equipment designed for low cost and high precision polishing of semiconductor wafers. It has a novel polishing configuration that enables c-direction and w-direction lapping for improved surface roughness control, and a short cycle cycle time for quick process completion. The system consists of a modular high-speed spindle for conducting lapping and polishing on the wafer, and a turntable for automatic repetition of the operation in a given machine cycle. The turntable has a rotational frequency of 1 Hz and is driven by a load trolley. The tool arrangement of the machine is flexible, allowing a custom arrangement of the tools to best suit the process requirements of the wafer during production such as different sizes and thicknesses of wafers. The process of SPEEDFAM 9 B can be controlled through an intuitive, GUI-based software. It contains an auto-recognition algorithm that automatically recognizes the wafer type and adjusts the spindle and lapping plate accordingly. The software also provides full redundancy and monitoring of production processes, which allows streaming of data during operation and provides complete traceability of all processes. The polishing process on this unit is conducted by a high speed spindle, which can obtain a surface quality similar to that of mechanical polishing, but with improved control on the shape and size of the surface. This spindle has a frequency range of 0.1 -8 mm in diameter, at speeds of up to 15,000 rpm and up to 8,000 g-force. For protection of both the wafer and tool, 9B is equipped with safety features that prevent accidents and ensure compliance with personnel safety and process quality standards. This machine is enclosed with transparent covers, so that most operations can be done visually, while providing full protection to the operator. Additionally, the tool is equipped with safety sensors that detect the presence of objects and stop any operations if necessary, providing total safety against dangerous occurrences during production. Overall, 9 B is an advanced and precise wafer grinding, lapping and polishing asset, that provides superior surface quality with faster processes and increased safety. This model is suitable for various production applications in the semiconductor industry, and offers unmatched precision, speed, and versatility.

There are no reviews yet