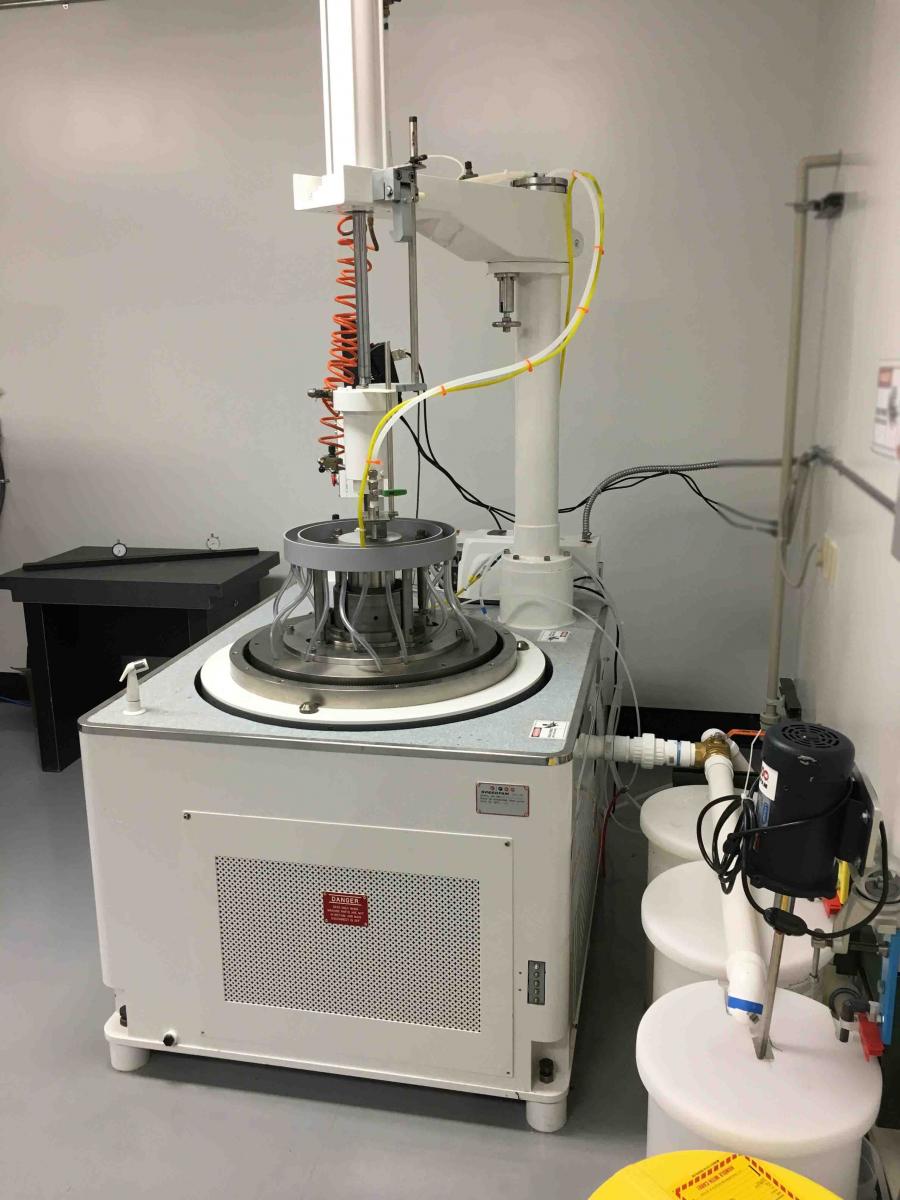

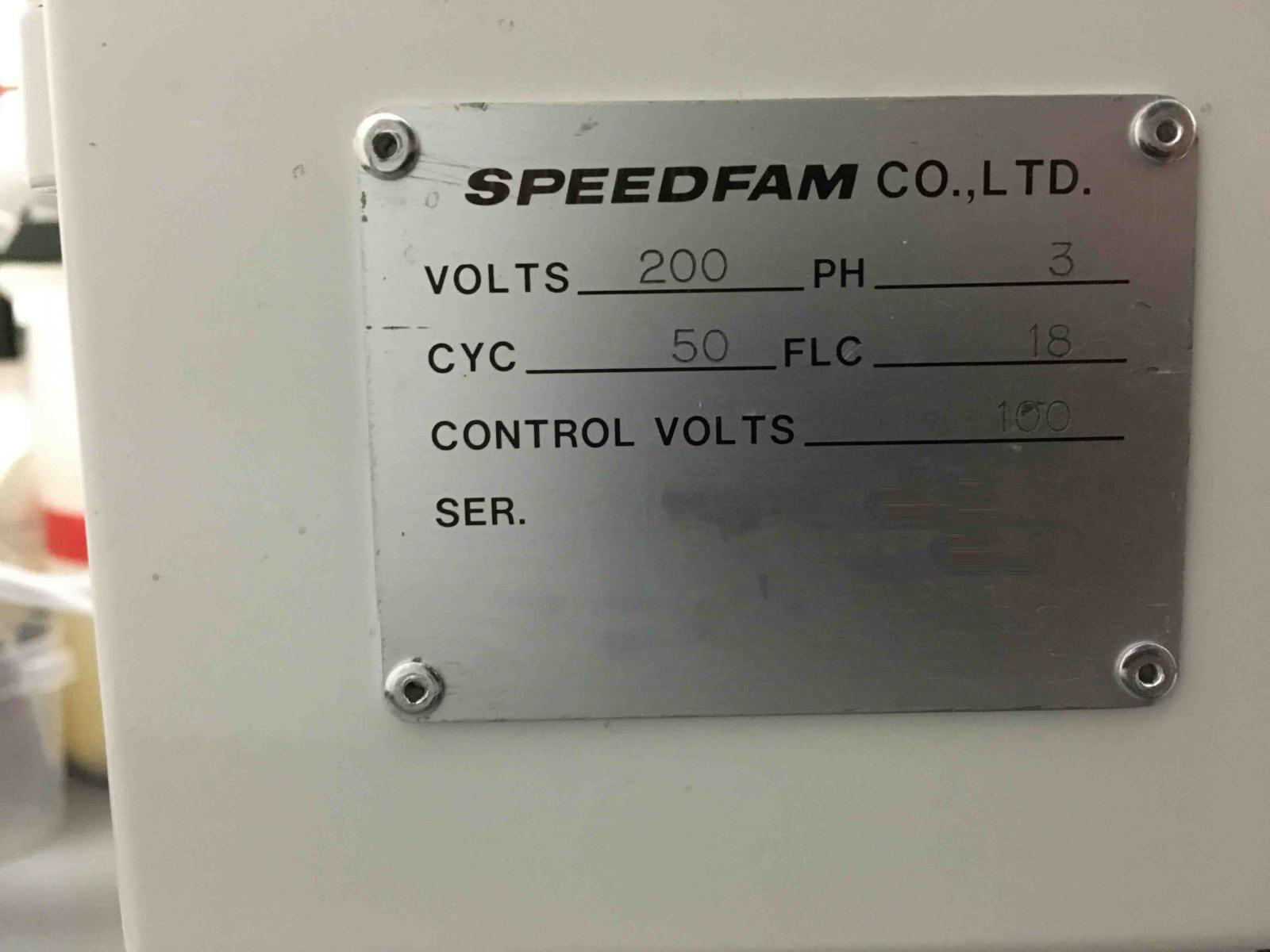

Used SPEEDFAM 9B #9131295 for sale

URL successfully copied!

Tap to zoom

ID: 9131295

Vintage: 1987

Lapper

Specifications:

Material: Glass / Alumina oxide

Carrier diameter: 9”

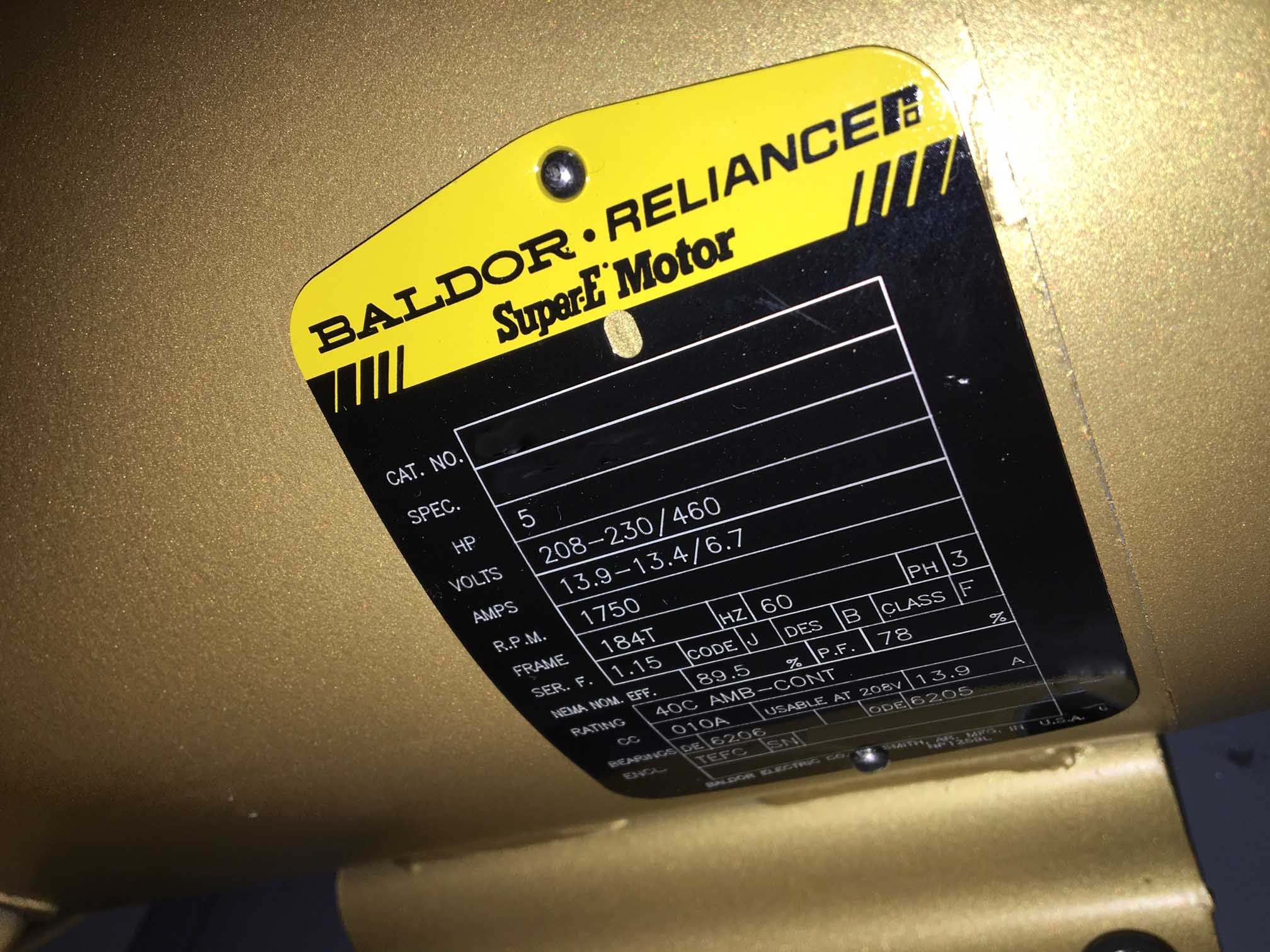

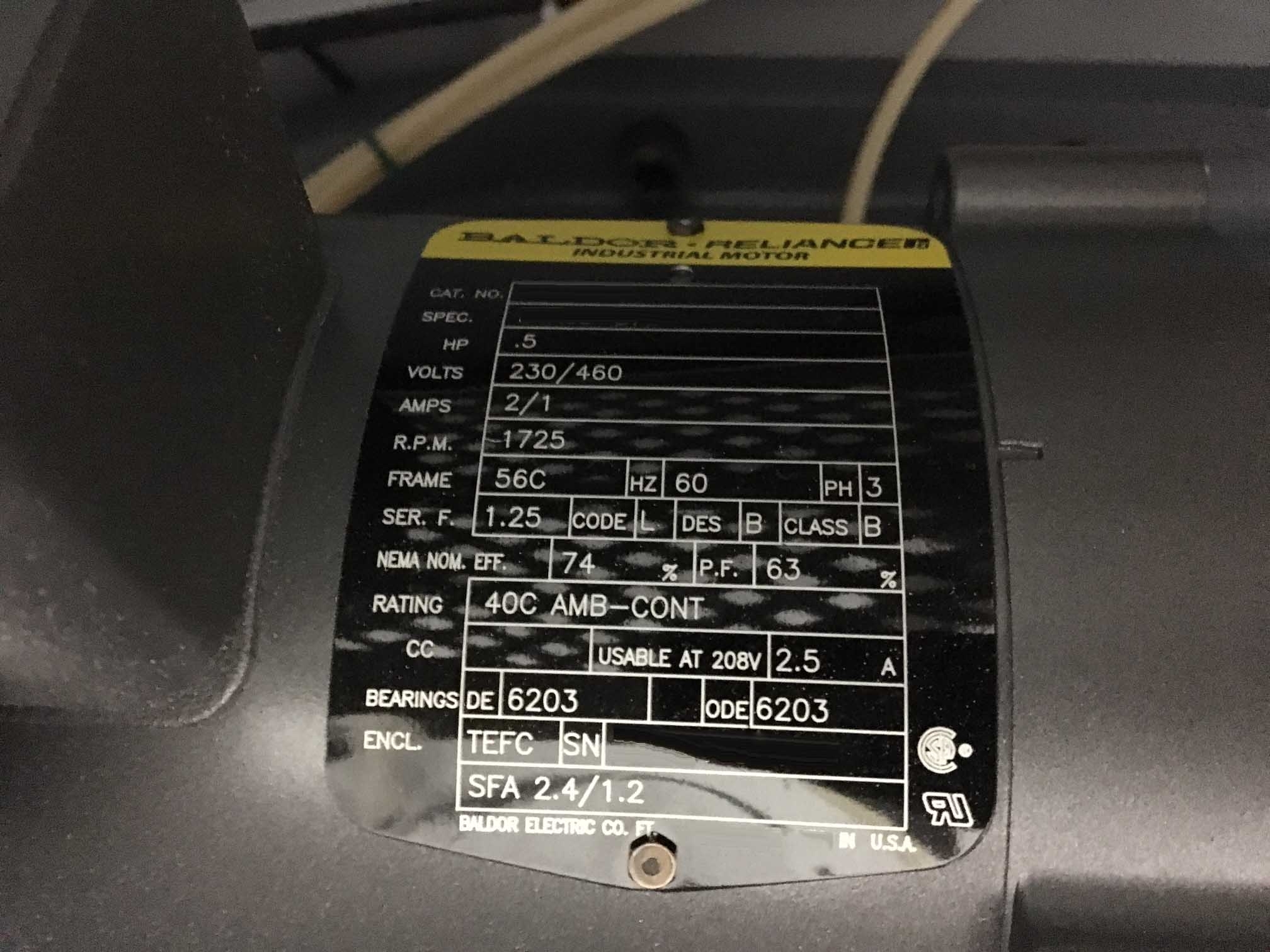

(2) Motors

(2) Inverter drives

Controller

Main cylinder and sub cylinder included

Lap plates

Plate diameter: 24.5”

Cast iron lap plates

Minimum thickness: .15 mm

Maximum thickness: 25 mm

Maximum part size: 150 mm

(5) Carriers

Maximum down force: 105 kg

Down force range: 0-105 kg

Lower plate: 8-60 RPM

Sun gear: 8-21 RPM

Pressure system: Manual settings

Main motor: 5 HP, 220/440 V

Sun gear motor: 5 HP, 220 V

Air supply: 5-6 kg/cm, 3-Phase

(3) Timers

Ring gear

Sun gear

Bearings

Gear box drive

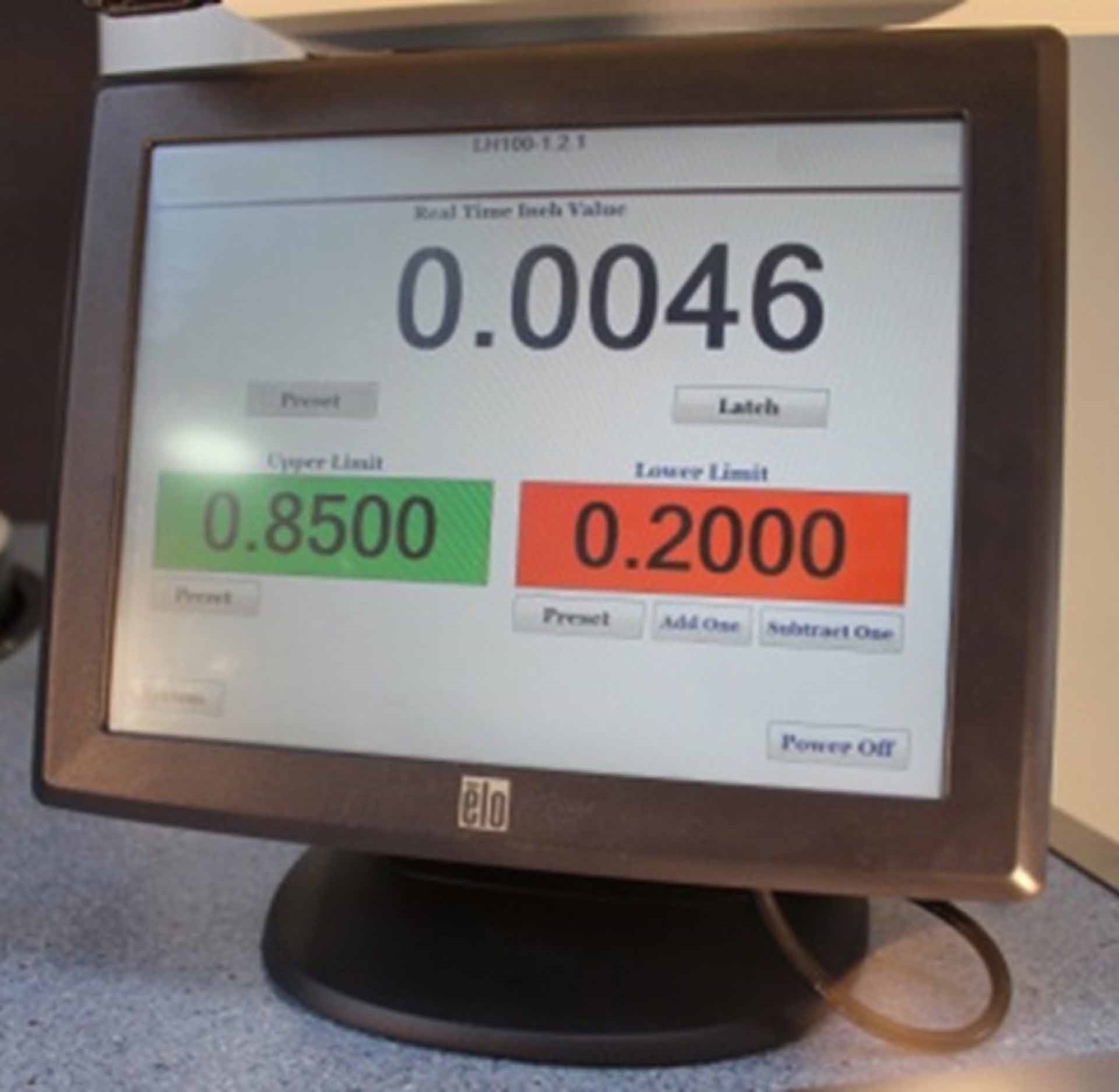

Auto thickness controller

Operations: Silica carbide / DI Water

Automatic Thickness Control (ATC)

1987 vintage.

SPEEDFAM 9B is a precision wafer grinding, lapping, and polishing equipment. It is designed for use in high-end semiconductor processing applications where exacting tolerances and superior surface finish are required. The system is comprised of a grinding stage, a polishing stage, and lapping stage, and an inspection stage. The grinding stage uses grinding wheels made from abrasive material to shape the surface of the wafer. The polishing stage utilizes a polishing pad and chemicals to smooth the surface of the wafer. The lapping stage is used to further smooth and refine the surface of the wafer by removing any remaining material from the polishing stage. Finally, the inspection stage allows for the wafer to be inspected for any defects or irregularities. SPEEDFAM 9 B has an easy to use control unit that allows users to program the grinding, polishing, and lapping stages to specifications. This gives the user the ability to customize the process to meet their exact requirements. The machine is equipped with safety features such as an emergency stop and an anti-vibration tool to reduce the risk of operator injury. The asset is also designed for compatibility with other equipment, such as grinding media and polishing consumables. 9B is a robust solution for high-precision grinding, lapping, and polishing. Its robust construction ensures reliable operation and long service life. The model is also highly efficient, allowing for higher throughput and reducing processing time. The equipment has the capability to handle wafers up to 8 inches in diameter. Additionally, 9 B has an easy to use interface and is compatible with many different software and control systems. This allows users to take advantage of the latest advancements in automation and process control. Overall, SPEEDFAM 9B is a reliable, efficient, and easy to use system for achieving high-precision grinding, lapping, and polishing results. In combination with other process automation and control technologies, SPEEDFAM 9 B is an ideal choice for wafer processing applications.

There are no reviews yet