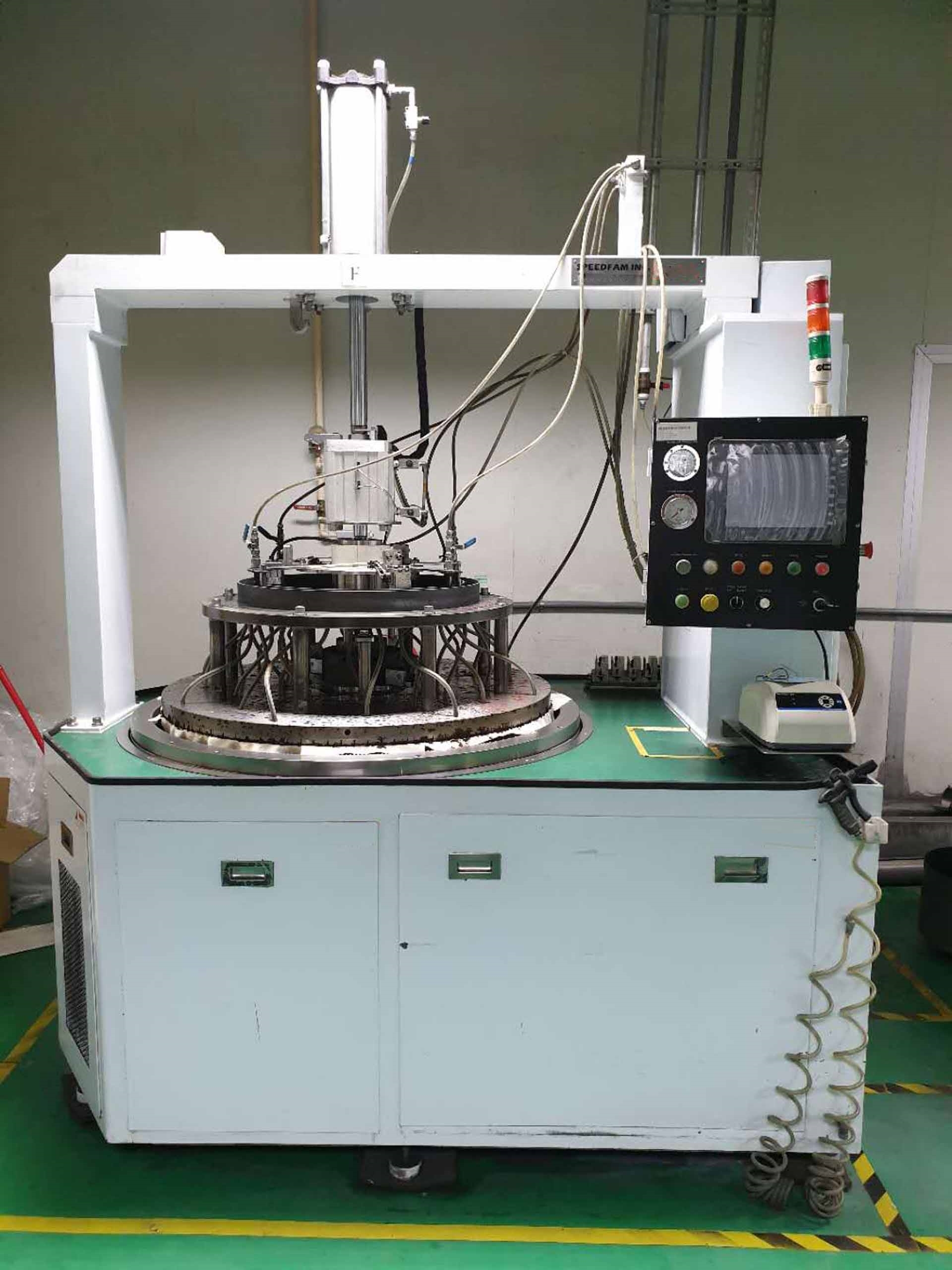

Used SPEEDFAM DSM 16B-5L #9235706 for sale

URL successfully copied!

Tap to zoom

ID: 9235706

Lappers / Polishers

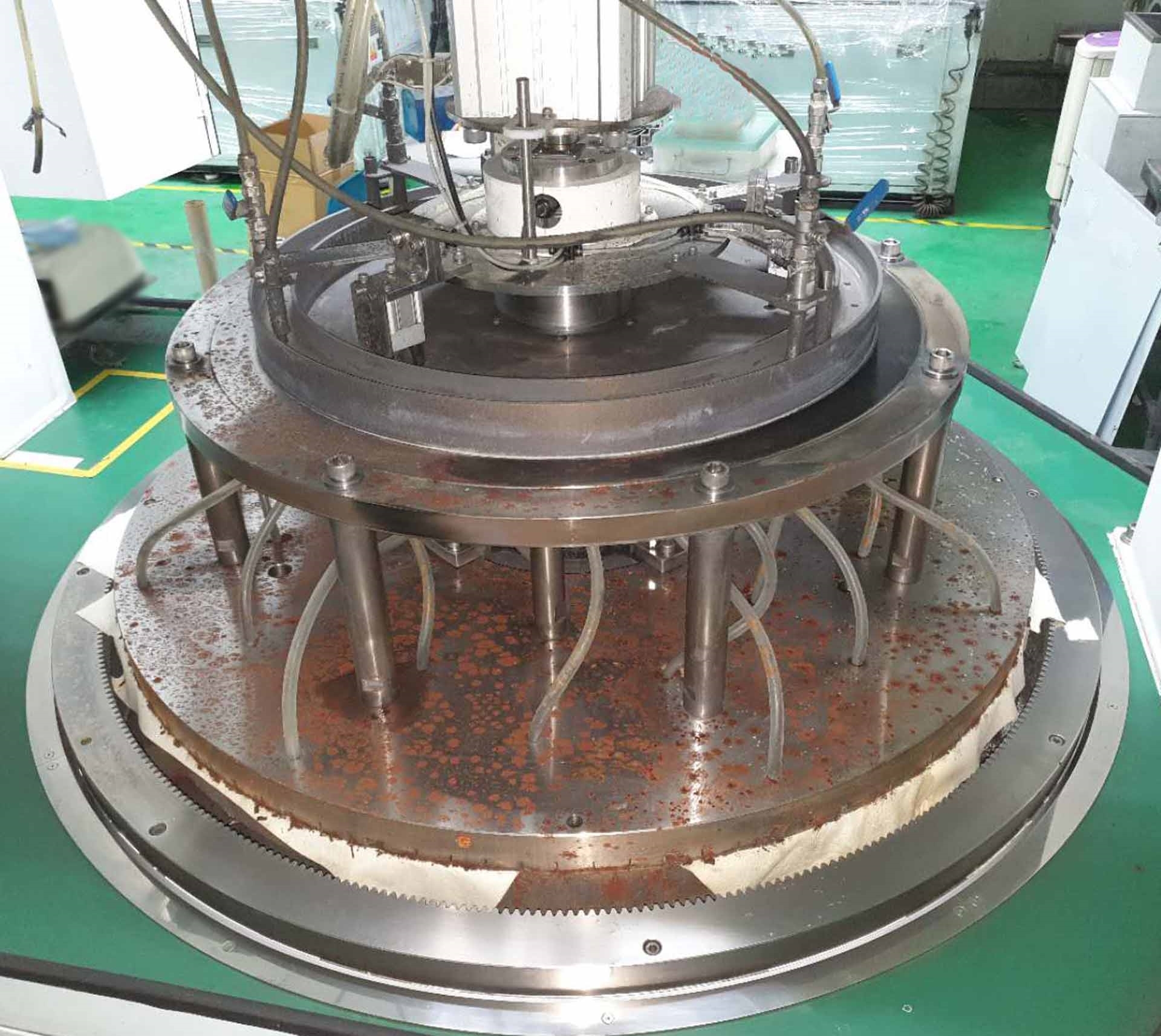

ATC

Load cell

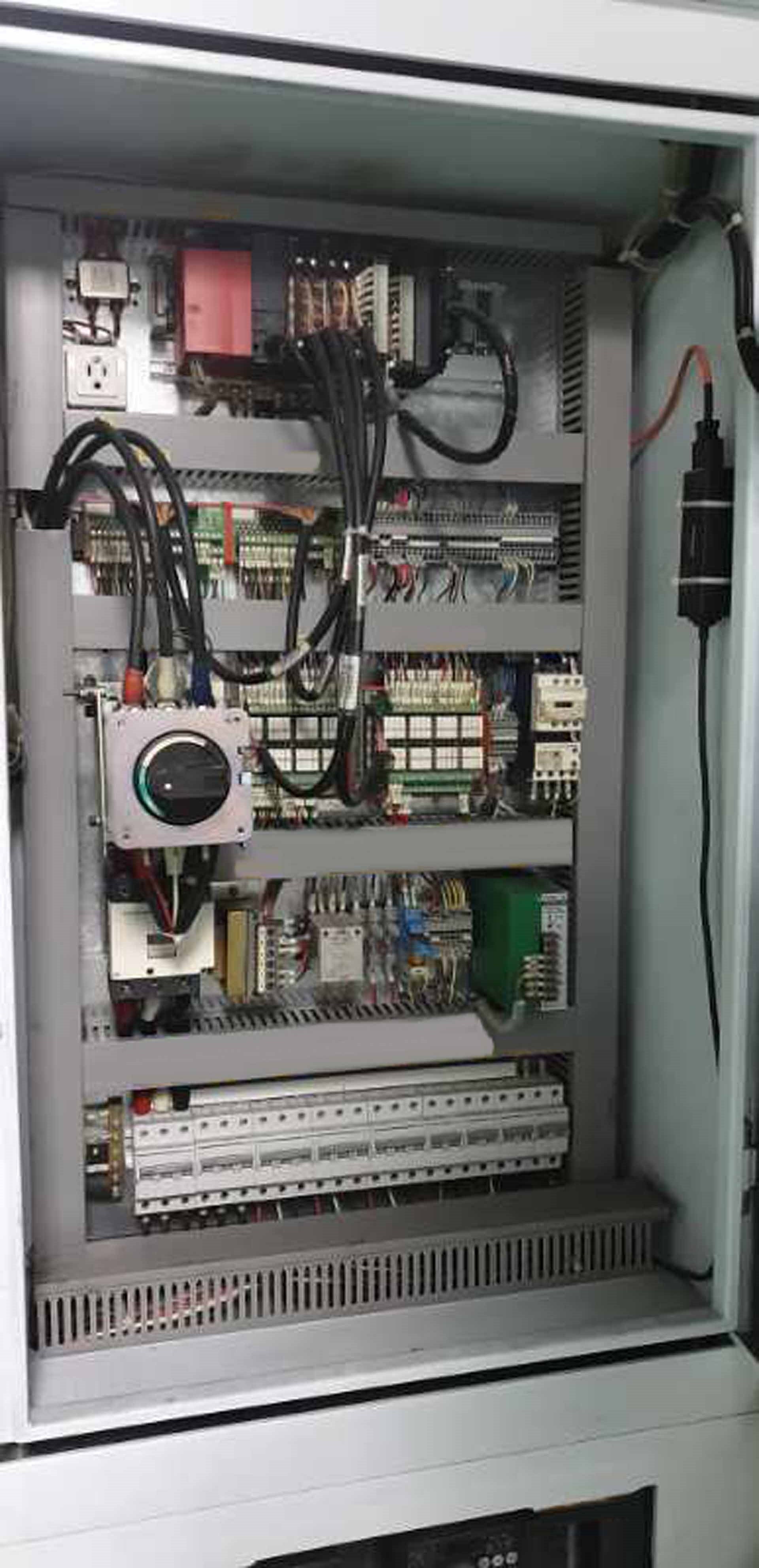

PLC Control

Touch screen

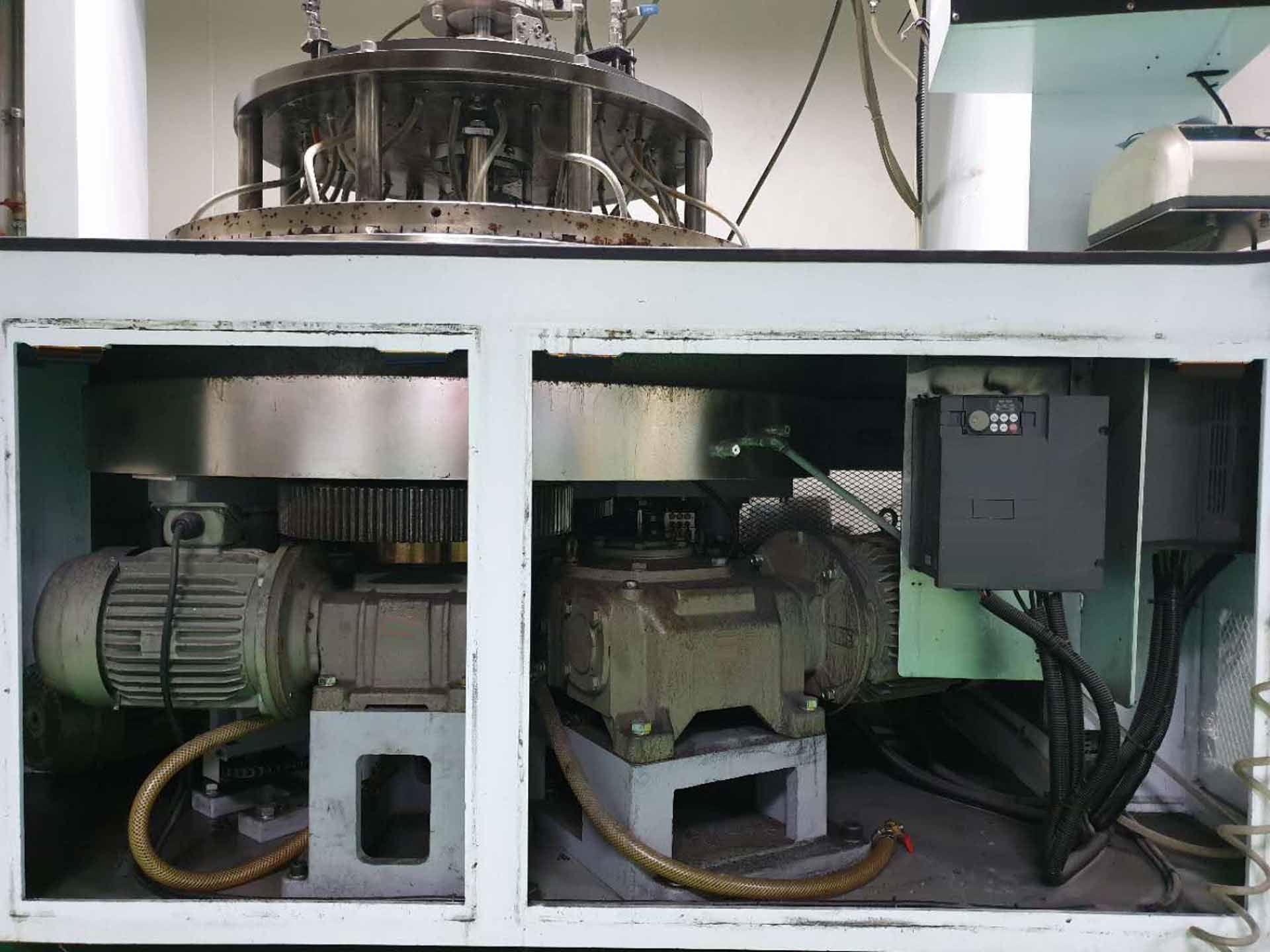

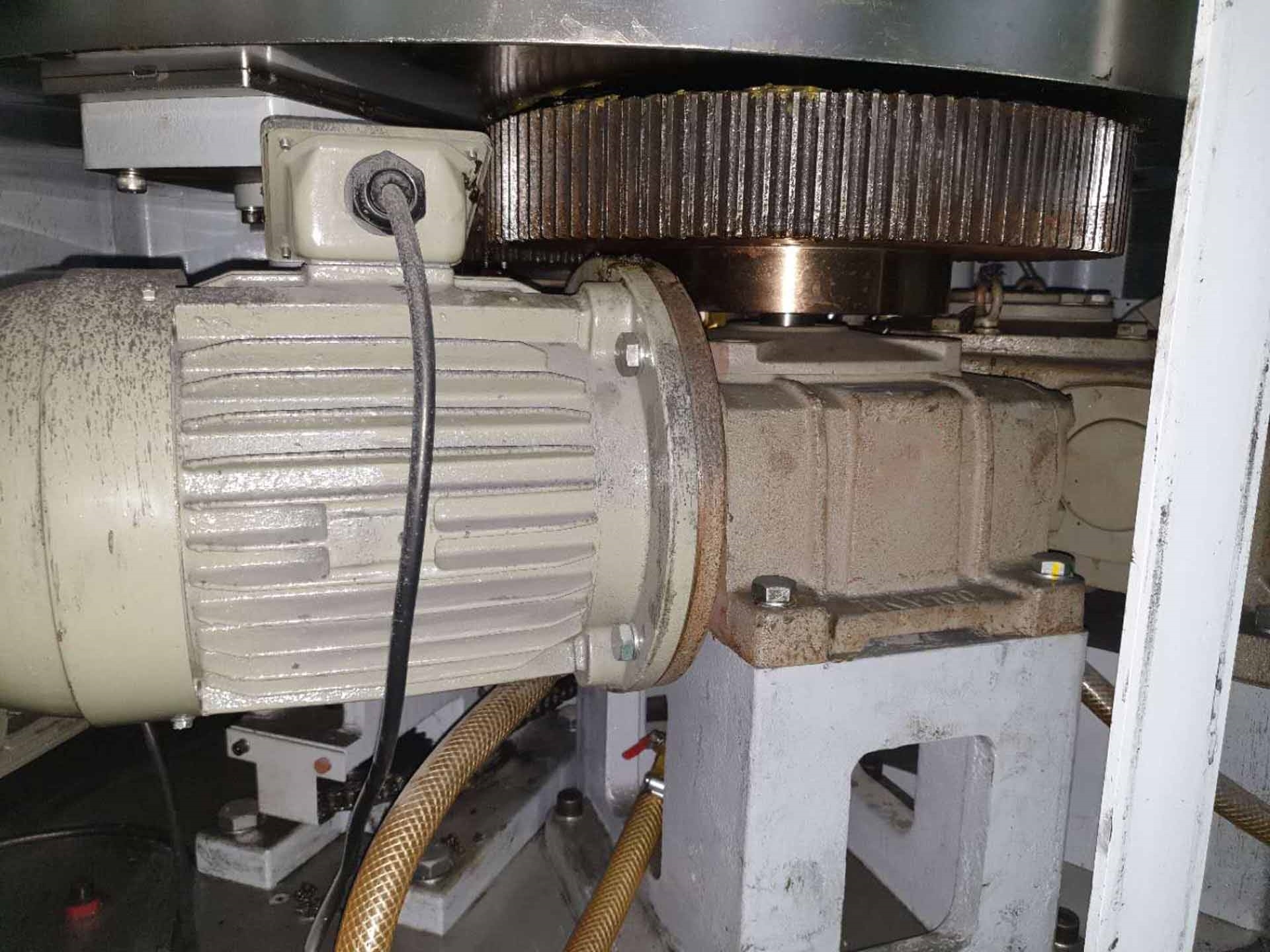

Lower plate drive: 7.5 kW

Upper plate driver: 7.5 kW

Ring gear driver: 2.2 kW

Sun gear driver: 1.5 kW

Power supply: 220 V, 50/60 Hz, 3 Phase

2010-2011 vintage.

SPEEDFAM DSM 16B-5L is an innovative wafer grinding, lapping & polishing equipment designed to meet the exacting requirements of the high-yield semiconductor fabrication industry. This versatile machine is ideal for grinding, lapping, and polishing a variety of materials including monocrystalline silicon, sapphire, and copper among others. The system is composed of two main components — the grinding head and the lapping/polishing head. The grinding head is composed of two fixed spindles which can be set to operate with different grinding wheel speeds for optimal results. The lapping/polishing head is composed of two motorized stages. The first stage is designed for coarse grinding and lapping to achieve a uniform surface finish, and the second stage is for fine grinding and polishing. DSM 16B-5L features several innovative features designed to make operation intuitive and easy. A programmable control unit allows users to select different grinding or polishing parameters. The machine can be programmed with different wheel speeds, rotation speeds, infeed rates, and pressure settings. In addition, the machine features a spindle ring that automatically compensates for wheel wear and a variety of safety interlocks. SPEEDFAM DSM 16B-5L is also designed to facilitate ease of maintenance with self-diagnostic software and regular maintenance diagnostic reports. In addition, the tool's components are modular, allowing the user to add or remove components as needed. Finally, the asset is compatible with a variety of wafer and substrate sizes. DSM 16B-5L is a reliable and versatile grinding, lapping, and polishing model that offers optimal results and ease of operation. With its innovative features, this machine is ideal for high-yield semiconductor fabrication, allowing users to quickly and accurately produce semiconductor wafers and substrates with uniform surfaces.

There are no reviews yet