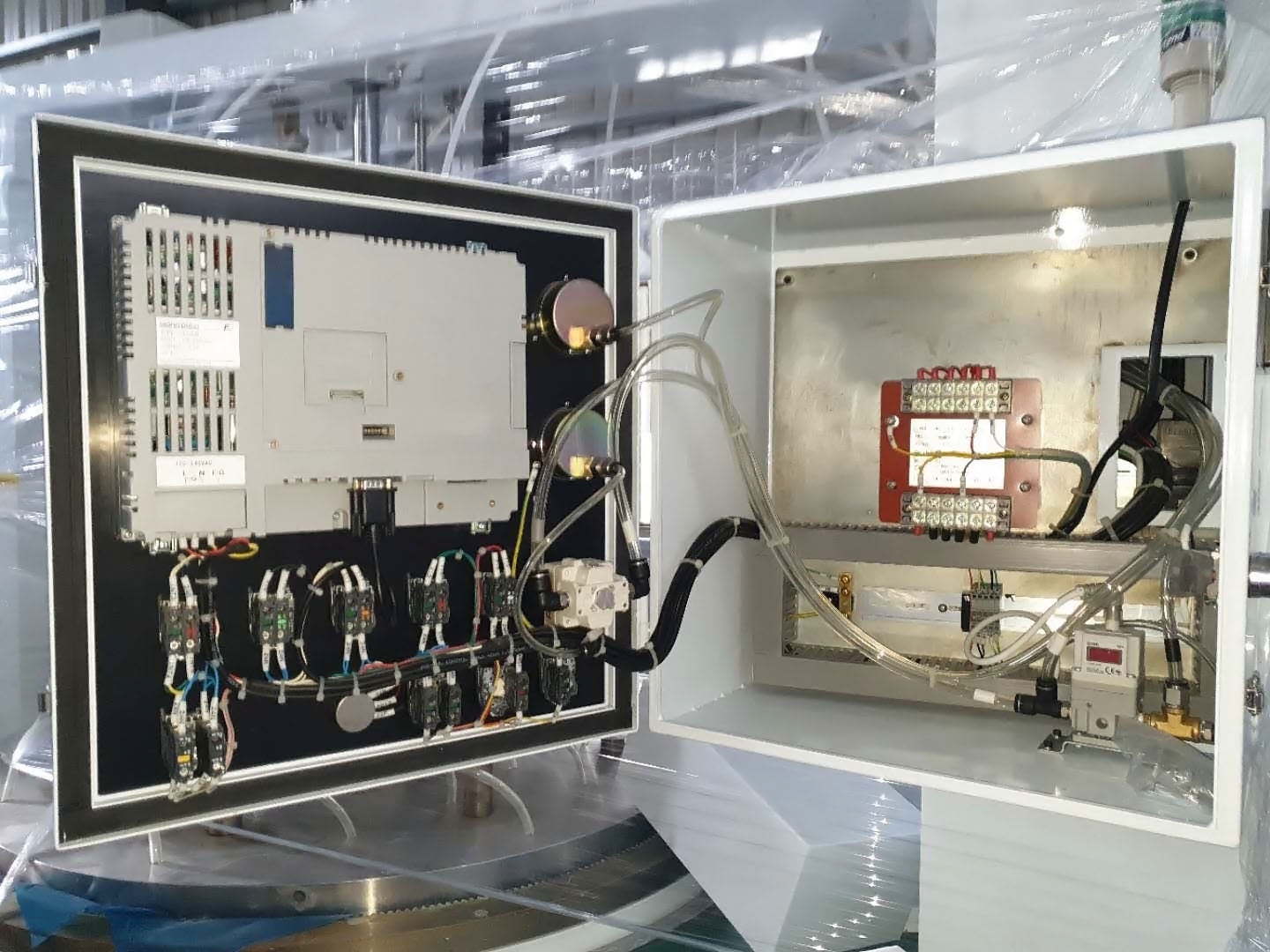

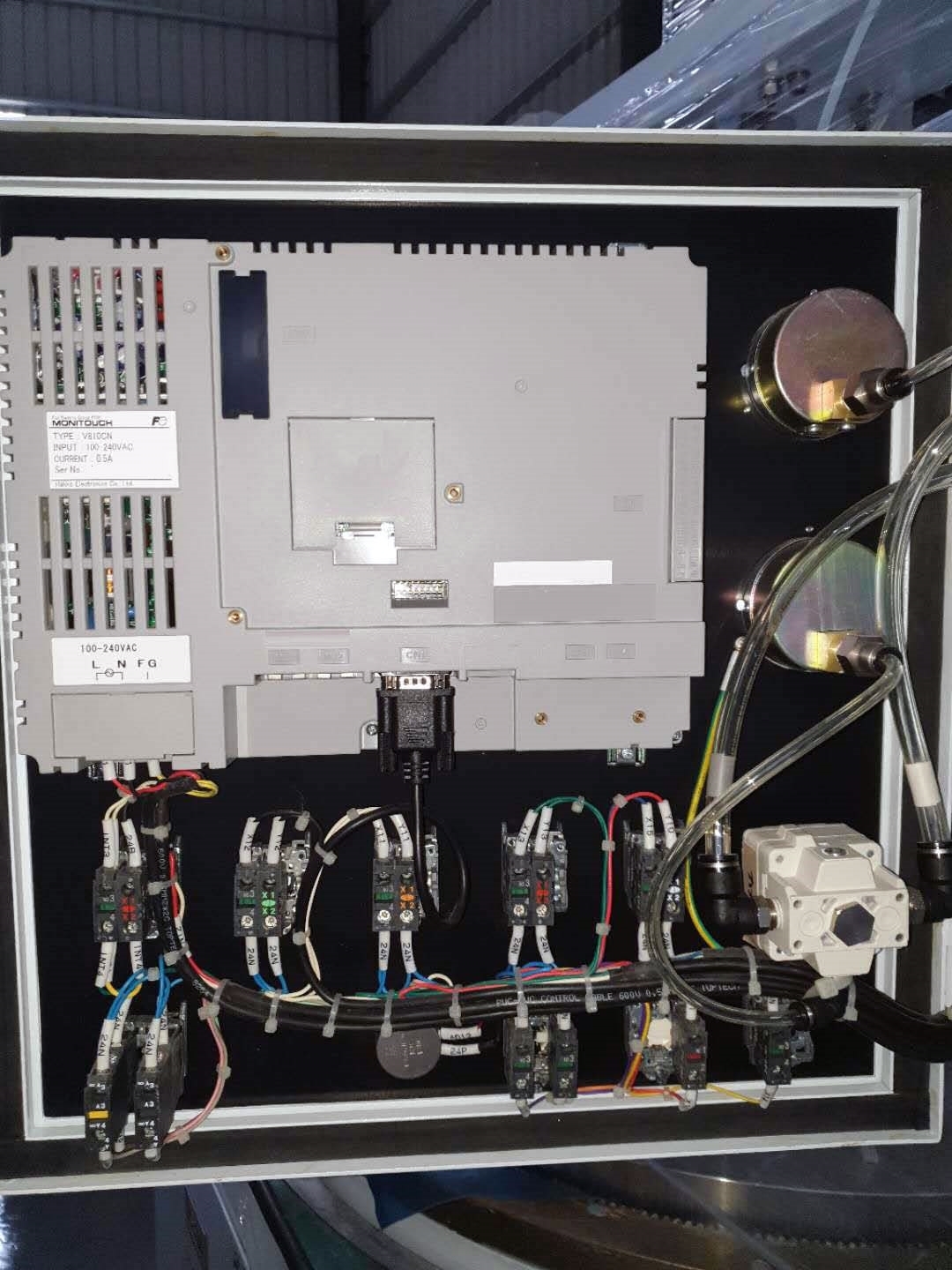

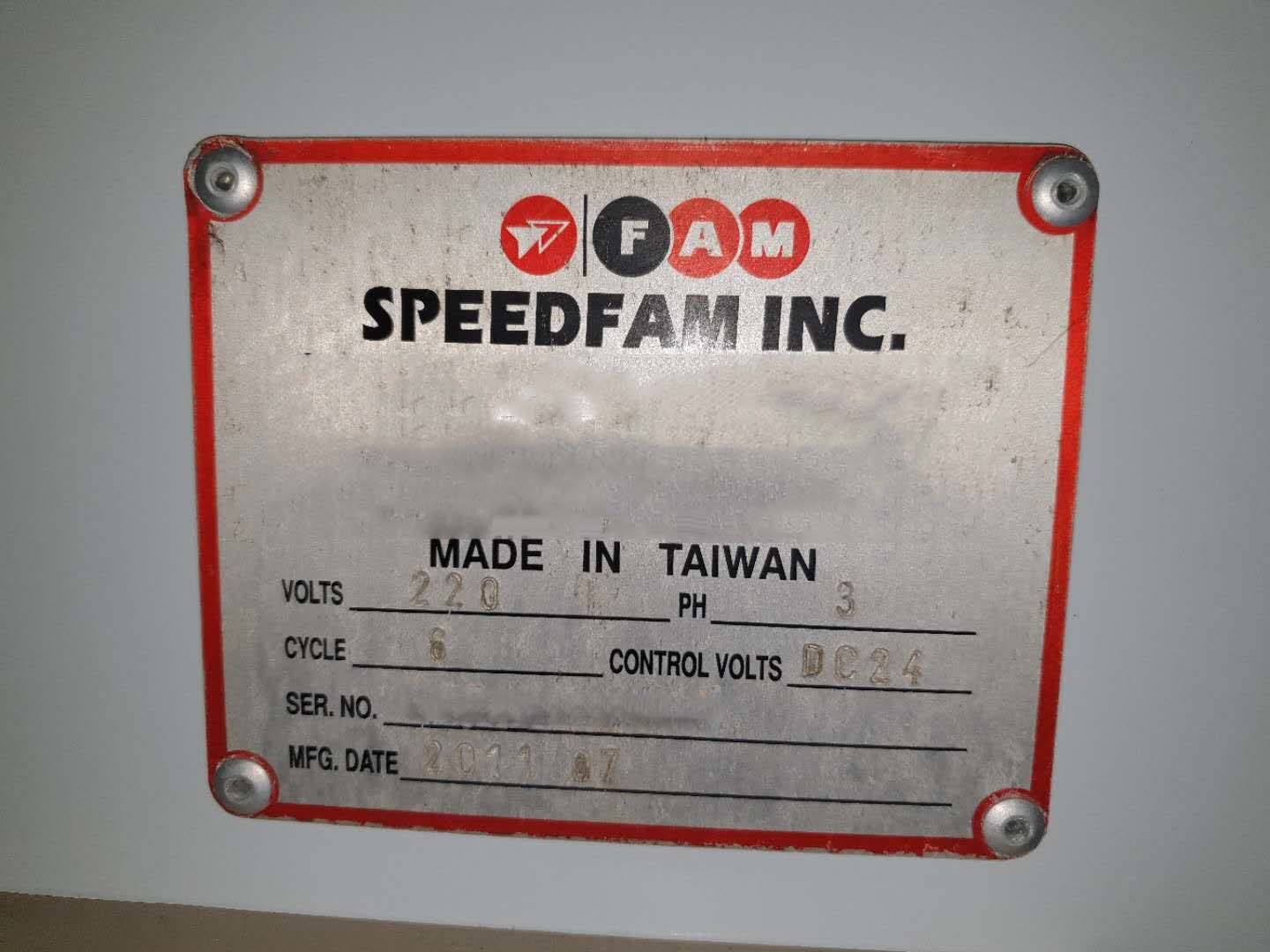

Used SPEEDFAM DSM 16B-5L #9276479 for sale

URL successfully copied!

Tap to zoom

ID: 9276479

Wafer Size: 4"-6"

Vintage: 2011

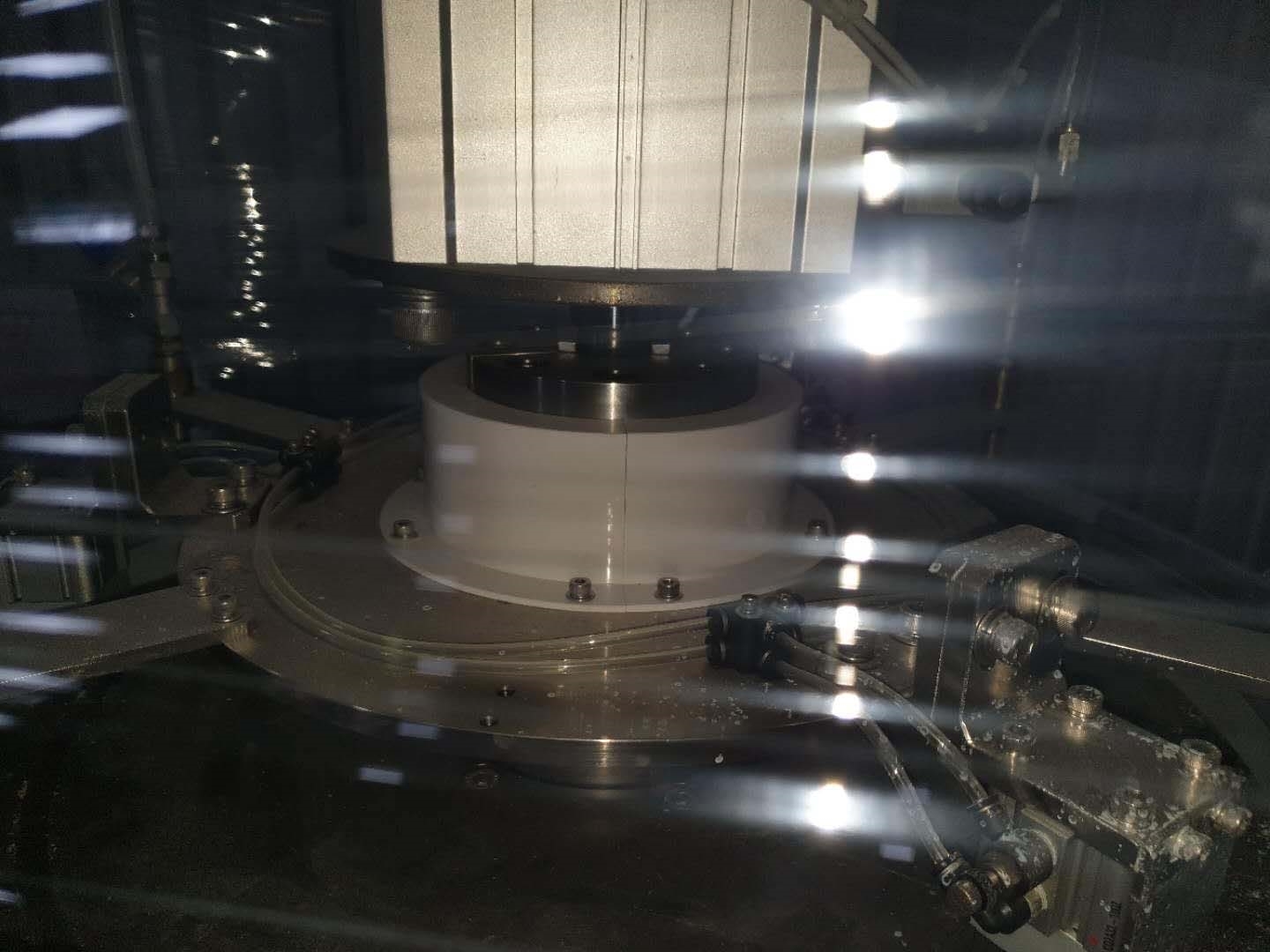

Double side polisher, 4"-6"

Maximum down force: 500 Kg

Down force range: 0-500 Kg

Upper ring assembly weight: 530 Kg

Plate dimension:

Lapping: φ1125 x φ393 x 50 t

Polishing: φ1154 x φ364 x 50 t

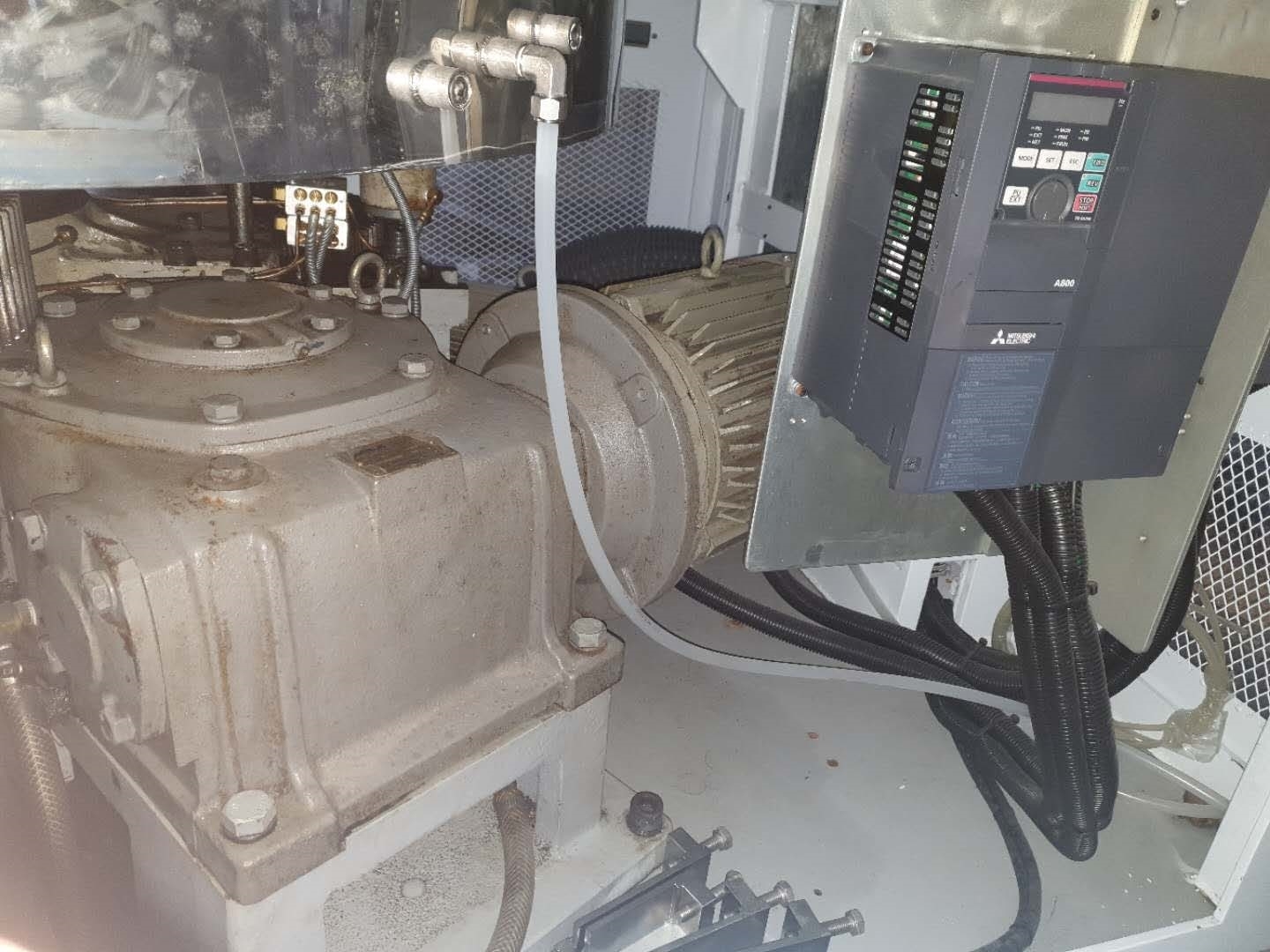

Lower plate RPM: 15 to 60 RPM, 50/60 Hz

Main cylinder: φ160

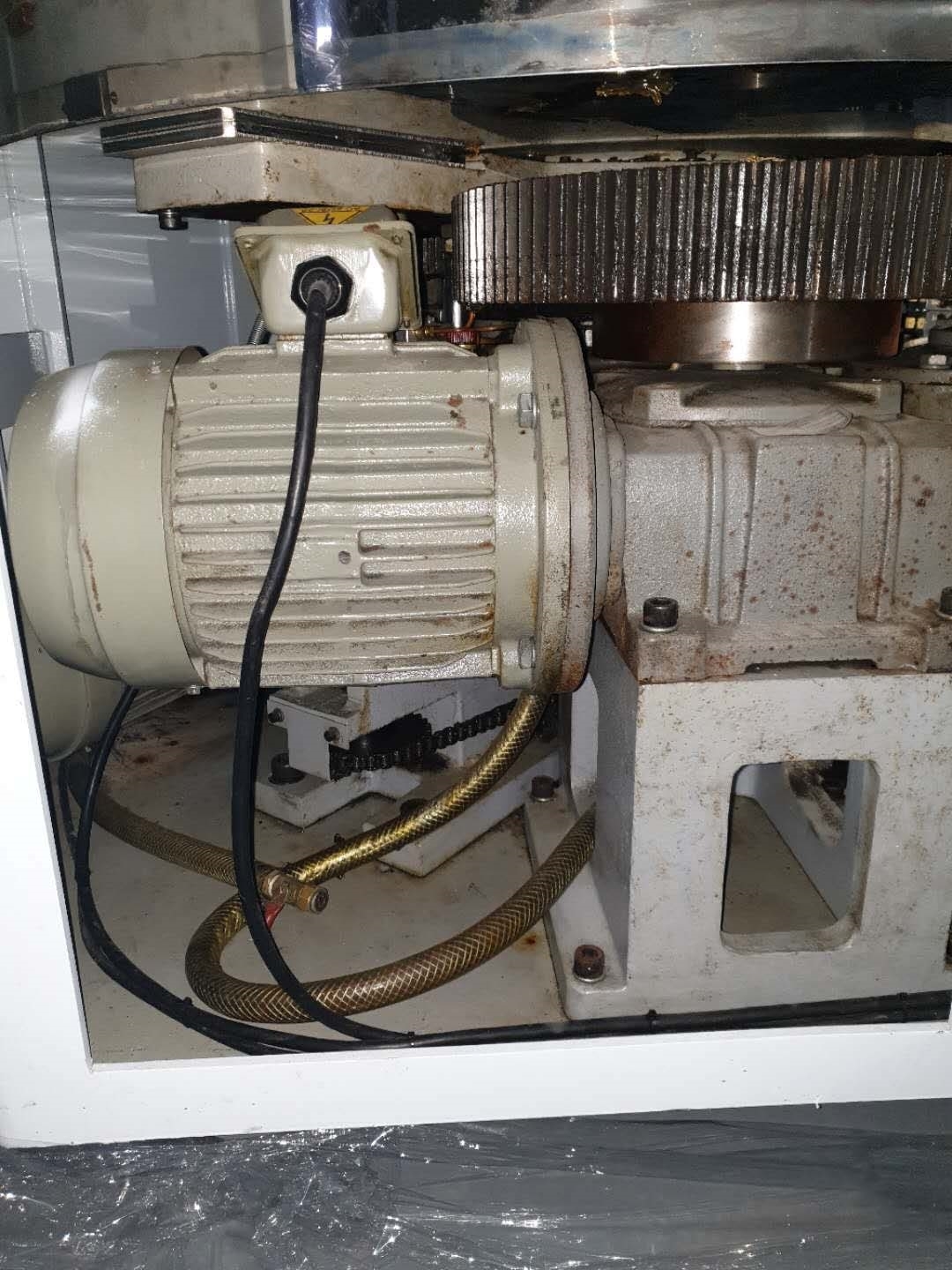

Upper and lower plate driver motor: 7.5 kW

Ring gear drive motor: 2.2 kW

Sun gear drive motor: 1.5 kW

Ring gear / Sun gear Up / Down motor: 0.4 kW

Options:

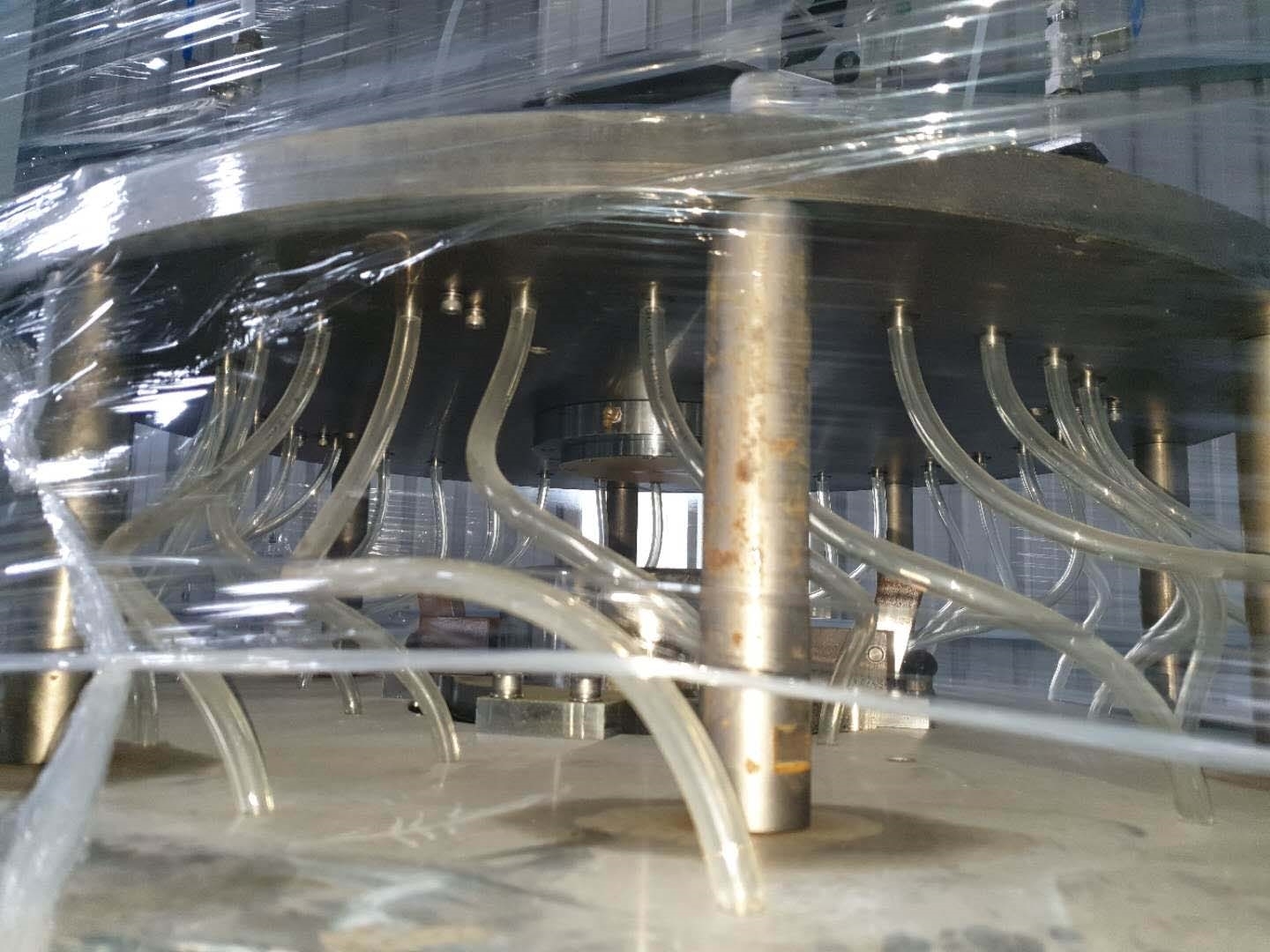

Slurry pump: 0.4 kW

Agitation motor: 0.18 kW

Breaker capacity: 75 Amps

Air supply: 6 Kg/cm²

(5) Carriers

Carrier:

M: 3

Z: 142

Ring gear:

M: 3

Z: 395

Sun gear:

M: 3

Z: 110

Power supply: 220 V, 3 Phase, 50/60 Hz, 19.68 kW

Power supply: 220 V, 3 Phase, 60 Cycles

2011 vintage.

SPEEDFAM DSM 16B-5L is a modern wafer grinding, lapping, and polishing equipment that utilizes proven and reliable abrasive technology to achieve superior surface finishes in the shortest possible time. This multifunctional unit consists of a single motor-driven grinding wheel and five separate lapping and polishing modules. The first module is a lapping system with an integrated set of grinding media that can be used with either loose or slurry abrasives, while the second module is a separate lapping wheel for finishing operations on both soft and hard materials. The third and fourth modules are both perform polishing processes including glass and diamond-polishing operations. Additionally, the fifth module is dedicated for use with a special pressure source to achieve specific surface finishes. DSM 16B-5L also includes an automatic loading and unloading unit that allows the user to minimize setup time and maximize efficiency of operations. Furthermore, this machine is equipped with an advanced computerized numerical control (CNC) tool that provides extremely precise production capabilities for any number of components. The operator can program various parameters for each component to be processed and the asset will automatically register the desired process parameters. The unit also offers complete functionality for grinding media and abrasives. It includes a closed-loop cooling model, adjustable water spray nozzles, and a dust disposal equipment which help to minimize the buildup of debris on the grinding media and ensure optimal efficiency of grinding operations. SPEEDFAM DSM 16B-5L is easy to maintain and requires very little operator oversight due to its automated operation. It has a smaller foot-print than competing models and is very cost effective. Additionally, the precision motors provide very low vibrational and noise levels. Overall, DSM 16B-5L is an excellent choice for any manufacturing environment. With its automated operation and precise results, it can be relied upon to provide surface finishes with superior accuracy and repeatability.

There are no reviews yet