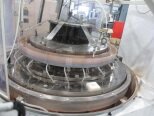

Used SPEEDFAM DSM 22B-6PV-4MH #9293451 for sale

URL successfully copied!

Tap to zoom

SPEEDFAM DSM 22B-6PV-4MH is a high-performance wafer grinding, lapping, and polishing equipment. The system is equipped with a series of high-speed spindles and servo motors designed to offer precise motion control and maximum efficiency in finishing wafers for various industries. The powerful spindle is capable of generating up to 6,000 rpm, and it is capable of delivering high acceleration, torque, and speed in order to grind and finish the hard and delicate wafers. The unit consists of several components, including an electron beam welded central piece, superior air bearing, and two tension arms that provide the frame and hold the spindles. The temperature within the machine is maintained and controlled by advanced temperature controllers, which help to create a more consistent environment for cutting and grinding operations. The tool also includes a conveyor asset that can move the wafers between the grinding, lapping, and polishing processes. DSM 22B-6PV-4MH features diamond grinding wheels and abrasive lapping plates that are engineered to reduce wafer surface defects. It also has a dual-head polisher that helps to ensure consistency across the entire wafer surface. The model also has a conveyor loaded limiter plate that allows for multiple parts to be worked on in sequence. This elimites the need for manual switching. To ensure that the highest quality is achieved for every finished wafer, SPEEDFAM DSM 22B-6PV-4MH is equipped with in-process inspection tools. The equipment has micro-balancing software to ensure the best corrective and preventive maintenance protocols are in place. To further increase the precision of the finishing process, the system features a real-time monitoring unit that displays production information, work value and cycle time data. In summary, DSM 22B-6PV-4MH is a state of the art wafer grinding, lapping, and polishing machine that offers high precision, speed, and efficiency in the production of wafers. Its advanced features and components allow for consistent levels of finish and quality control across multiple parts and processes.

There are no reviews yet