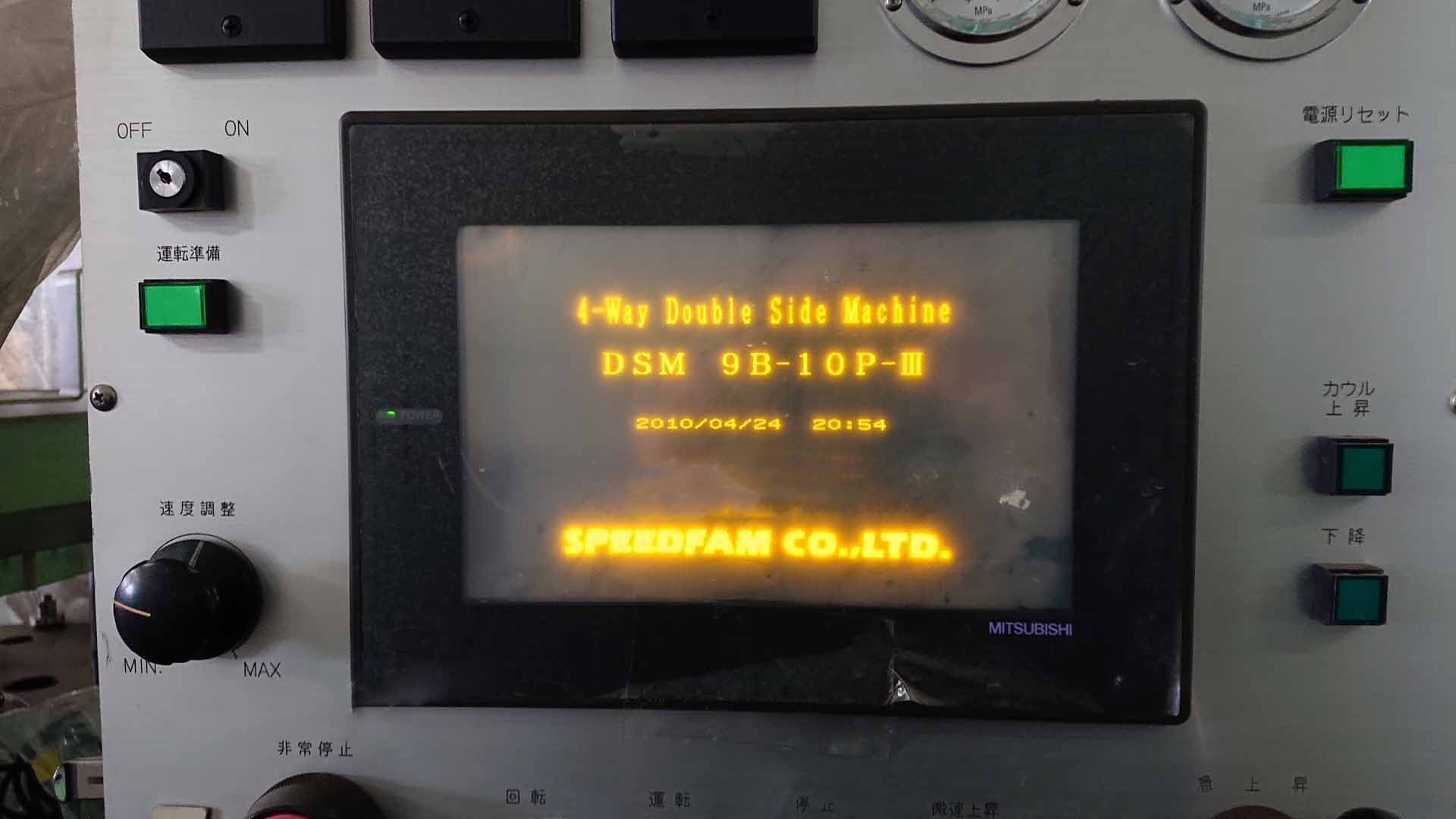

Used SPEEDFAM DSM 9B-10P-lll #9224691 for sale

URL successfully copied!

Tap to zoom

ID: 9224691

Vintage: 2003

Double side polisher

Polisher: SUS (Stainless)

(3) Motors

Touch screen

Internal gear: PCD φ1079.5 (DP12 x Gear Z510)

Sun gear: PSD φ613.8 (DP12 x Gear 290)

(10) Carriers: DP12 x Z108

Machine surface: (Upper & lower platen)

φ1056.8 x φ636.6

Platen thickness:

Upper: 65 mm

Lower: 50 mm

Revolution: Lower platen 10~60m i n -1

Internal gear: 5~30m i n -1

Power: 200 V, 3 Phase, 50/60 Hz

2003 vintage.

SPEEDFAM DSM 9B-10P-lll is a wafer grinding, lapping & polishing equipment designed for advanced precision surface finishing and characterization of wafers across a wide range of materials. This system provides a superior level of surface roughness and accuracy, delivering a high level of surface uniformity, surface finish and microstructure. The unit integrates numerous technologies to enable superior grinding, lapping and polishing capabilities up to 300mm silicon and compound semiconductor wafers or larger. The machine itself consists of a grinding, lapping, and polishing spindle, a two-tiered, single arm loader, a three-axis galvanometer optical scanning tool, an advanced high frequency inverter controller, and an array of software. The spindle consists of two grinding wheels and a polishing wheel with an adjustable speed range from 500-3000 RPM, which allows for the grinding and lapping of many types of wafer, as well as achieving a precise surface finish. The loader can hold two wafers; as one is processed, the other is prepped for loading. The optical scanning asset tracks and compensates for wafer shape or surface defects to ensure consistent, high-precision grinding, lapping, and polishing. The advanced high frequency inverter controls the power of the spindle to ensure surface finish quality and uniformity, minimizing stress and vibration. The software components of DSM 9B-10P-lll model provide an intuitive user interface to simplify the day-to-day operation of the equipment. It features real-time inspection and analysis functions, automatic in-process and post-process measurements, advanced process control algorithms, 3D mapping functions, and fault diagnosis systems. Additionally, the system can be integrated with automated load and unload modules, process automation systems, and customized software applications. Overall, SPEEDFAM DSM 9B-10P-lll is set to be a powerful tool to take wafer surface finishing technology to the next level. Its advanced features, versatile capabilities, and intuitive user interface make it exceptionally well-suited to the needs of both research and industrial operations.

There are no reviews yet