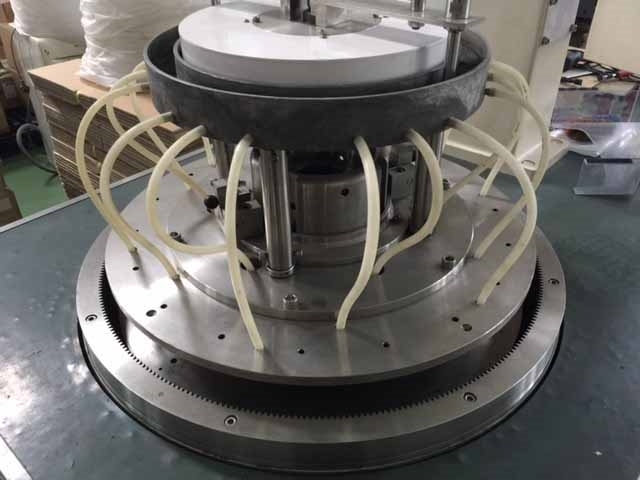

Used SPEEDFAM DSM 9B-5SSG-IV #197149 for sale

URL successfully copied!

Tap to zoom

ID: 197149

Vintage: 1995

Polisher

(2) Motors

Plate size: 635 x 240 x 62 mm

Power: 200 V, 3 Phase

1995 vintage.

SPEEDFAM DSM 9B-5SSG-IV is a wafer grinding, lapping and polishing system capable of producing extremely precise and flat surfaces on wafers used in the production of semiconductor devices. This system is designed to achieve the highest possible level of repeatability in the production of semiconductor devices. DSM 9B-5SSG-IV features several components that enable it to achieve such high levels of repeatability. These components include a diamond plated grinding wheel, a brass-bonded diamond lapping plate, and a polishing wheel. The diamond plated grinding wheel is designed to produce the most accurate surface finish possible on the wafer. It is powered by a 3 HP spindle motor and rotates at up to 15,000 RPM. The brass-bonded diamond lapping plate is used to provide a uniform finish to the wafer. This plate can also be used to adjust the thickness of the wafer. Finally, the polishing wheel is used to give finish the surface of the wafer and further reduce surface roughness. This wheel is powered by a 2 HP, 120 V/60Hz motor. SPEEDFAM DSM 9B-5SSG-IV also features a number of control features that enable it to achieve such high levels of repeatability. These features include a vacuum leveling and holding device, a load per grind pressure control, and a wafer thickness uniformity checker. The vacuum leveling and holding device allows for consistent leveling of the wafer before the grinding process. The load per grind pressure control helps to keep the surface of the wafer uniformly flat by controlling the amount of pressure applied to the wafer while grinding. Finally, the wafer thickness uniformity checker ensures that the wafer has a consistent thickness across its entire length. DSM 9B-5SSG-IV is the perfect solution for any manufacturer that requires high precision, repeatability, and accuracy. The system is capable of providing the highest levels of quality while also reducing costs associated with the production of semiconductor devices. The combination of the diamond plated grinding wheel, the brass-bonded diamond lapping plate, and the polishing wheel ensure that users will get the most accurate and flat surfaces possible from their wafers.

There are no reviews yet