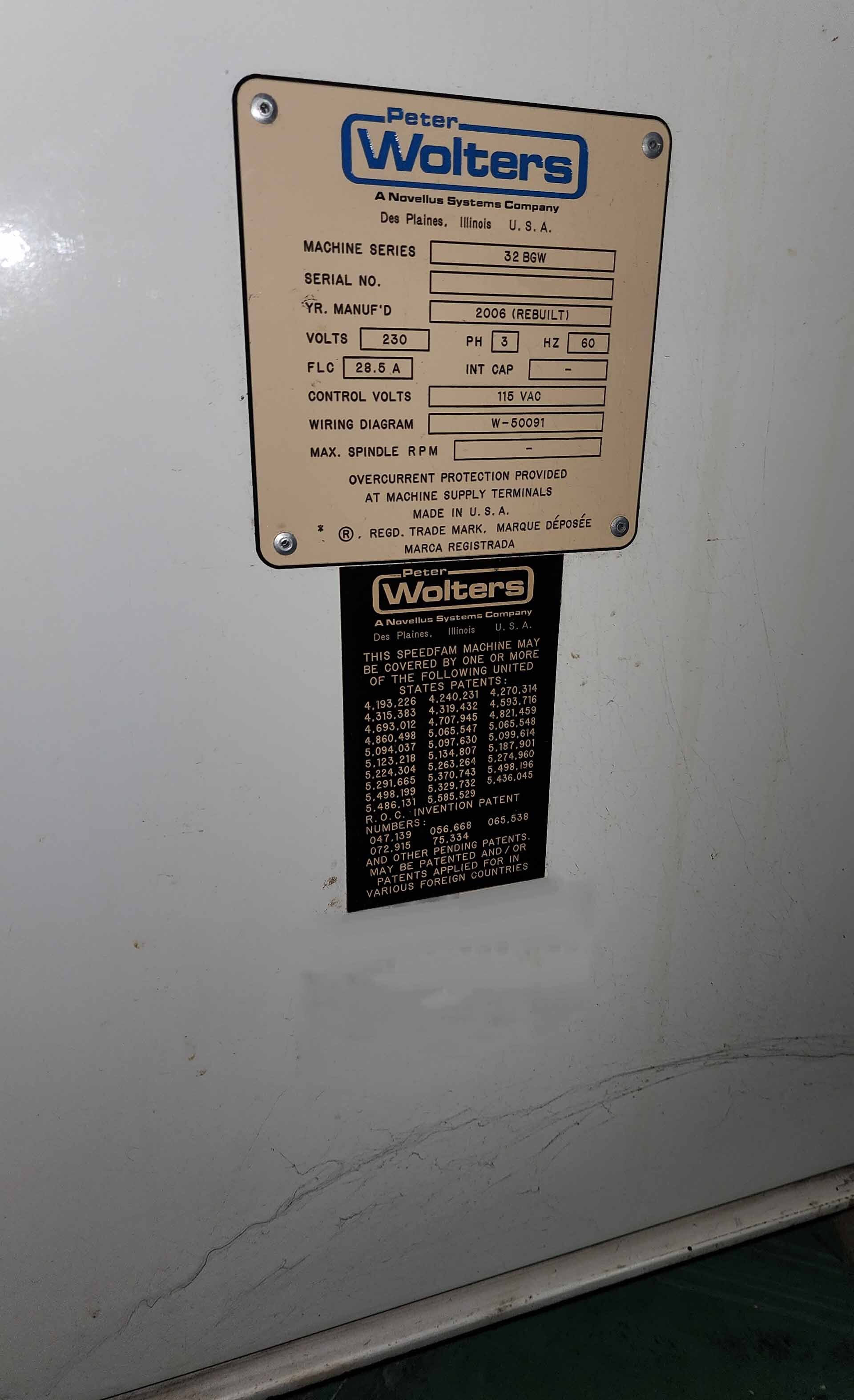

Used SPEEDFAM / PETER WOLTERS 32 BGW #9194310 for sale

URL successfully copied!

Tap to zoom

ID: 9194310

Vintage: 2006

Lappers / Polishers, 32"

Free abrasive machine

Non-functional

2006 vintage.

SPEEDFAM / PETER WOLTERS 32 BGW is a high-precision 'wafer grinding, lapping & polishing' equipment created by two of the world's leading providers of high performance grinding and polishing solutions. It's used for finishing and polishing a wide range of semi-conductors, ICs, and other delicate components with a maximum workpiece size of 500 mm. This is a single-purpose system designed to handle thin wafers with up to five sides simultaneously. It has adjustable swing arm tooling and automated loading/unloading via quick-change wafer holders. The unit is designed with a flexible work envelope, allowing for the rapid reconfiguration of its process chamber and the replacement of manual steps with automated ones. This gives the machine immense flexibility when utilizing different tooling configurations and automates processes such as loading/unloading of components. The tool also comes with a robust safety asset which provides a number of safeguards for the operator's safety when handling fragile wafers. SPEEDFAM 32 BGW features a high-precision S45-16 spindle capable of producing up to 25,000 rpm, with a dynamically balanced rotary table for precise positioning of the wafer. The high-precision tool holders are designed to reduce chatter, eliminate vibration, and keep machining operations safe and consistent. It also utilizes a high-frequency lapping head to achieve the necessary polishing results, and the model also includes both manual and pneumatic holding tools for most wafer sizes. The equipment has an optional computer numerical control (CNC) interface for added control over feedback and calibration steps. PETER WOLTERS 32 BGW system is capable of grinding, lapping, and polishing a variety of parts, including wafers, rectangular pieces, and intricate shapes. It is equipped with an intuitive user interface which provides detailed process control and monitoring of material removal rates. The unit also features an integrated spindle vibration monitoring machine to monitor and isolate vibration sources. This helps to maintain a consistent production rate throughout the entire work envelope. The robust design of 32 BGW allows for precise grinding, lapping, and polishing of a wide range of wafers and components. Its high-precision spindles and tool holders provide consistently precise results, while its advanced safety systems and dynamic operation offer a secure, reliable work environment.

There are no reviews yet