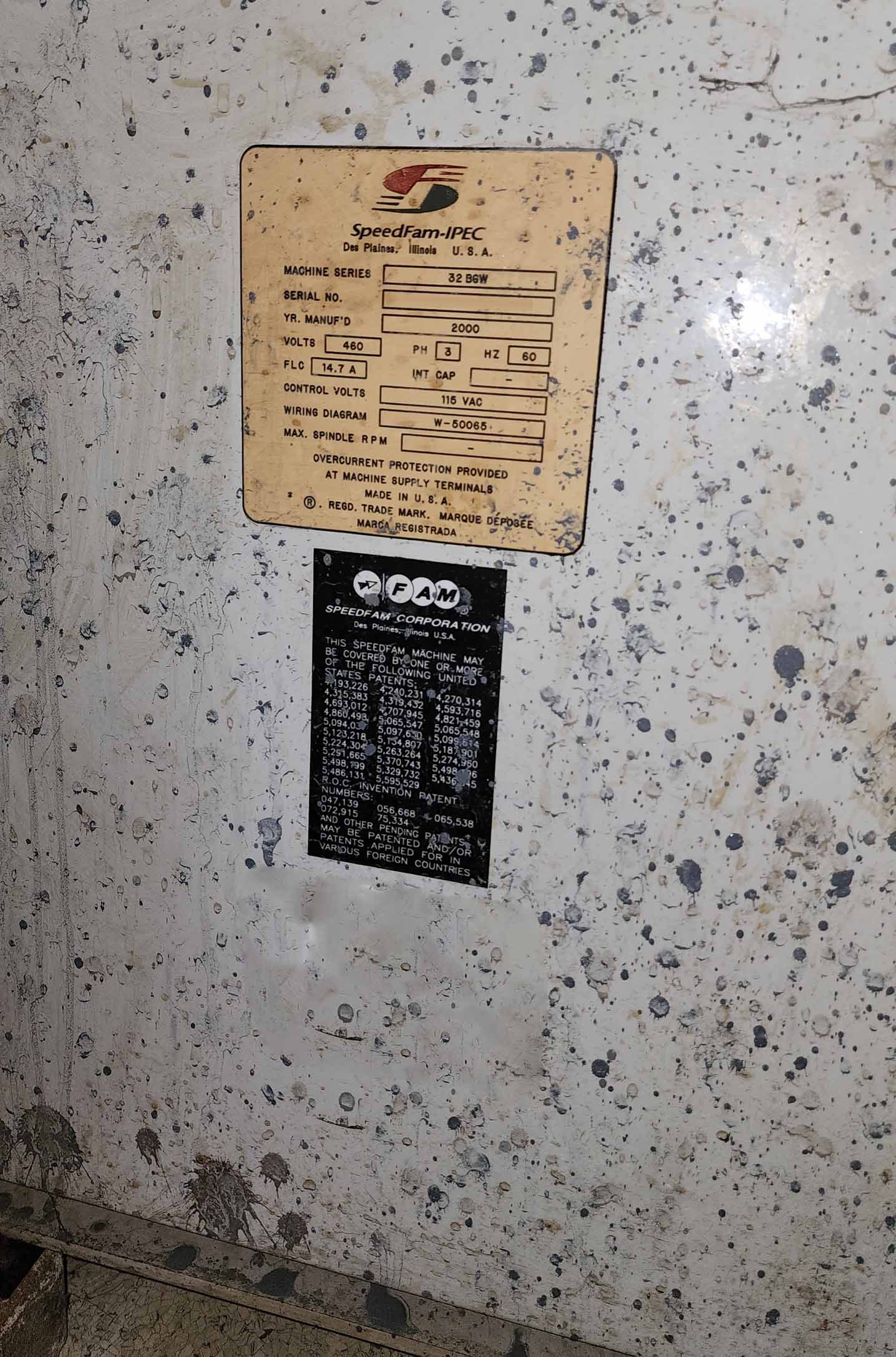

Used SPEEDFAM / PETER WOLTERS 32 BGW #9194316 for sale

URL successfully copied!

Tap to zoom

ID: 9194316

Vintage: 2000

Lapper / Polisher

Type: Single side

Free abrasive machine

Non-functional

2000 vintage.

SPEEDFAM / PETER WOLTERS 32 BGW is a wafer grinding, lapping, and polishing equipment designed to meet the demanding requirements of the semiconductor industry. This machine combines the high throughput capability of a wet grinder with the precision of a lapping machine, in order to produce smooth and uniform surfaces on wafers with a high degree of accuracy and repeatability. The system employs a two-station grinding stage, using diamond grinding wheels with a special diamond and graphite bond for increased cutting efficiency and long tool life. The wheels are spun at high speeds to finely grind the wafer's surface. After the initial grinding step, a second station is used to apply a fine polishing paste and to finish the polishing process. The unit also includes an advanced process monitoring unit, which can provide feedback on the part's speed and the parameters of the polishing process, helping to ensure accuracy and repeatability throughout the machine. Additionally, the tool is capable of controlling each lapping head individually, allowing for precise control over the part's final dimensions and shape. To ensure uniformity of the final surface, SPEEDFAM 32 BGW is also equipped with a wafer cleaning asset. This model is used to remove any contaminants that may have been picked up during the wafer grinding and polishing process. The equipment's integrated automation components, such as part positioning mechanisms and end-effectors, are designed to provide fast and accurate cycle times, while its intuitive controls make it easy for operators to use. PETER WOLTERS 32 BGW is capable of supporting up to four production-level lapping heads, with a maximum grinding and polishing speed of 2000 rpm. Overall, 32 BGW wafer grinding, lapping, and polishing system is a powerful and reliable unit designed to produce smooth, uniform surfaces on wafers with high accuracy and repeatability. Its user-friendly controls, easy-to-use automation solutions, and process monitoring features make it an ideal choice for a wide range of semiconductor manufacturing applications.

There are no reviews yet