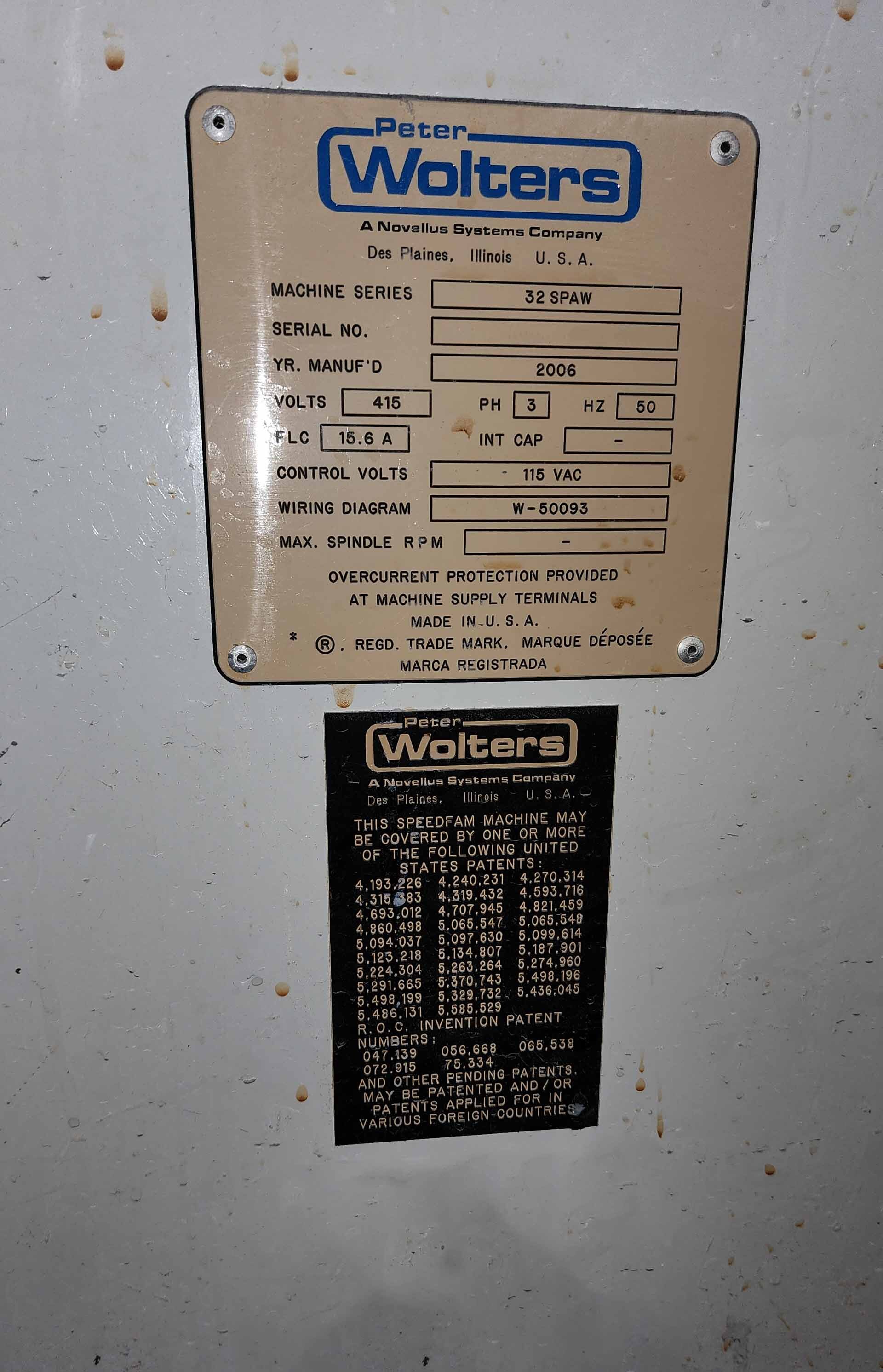

Used SPEEDFAM / PETER WOLTERS 32 SPAW #9074540 for sale

URL successfully copied!

Tap to zoom

ID: 9074540

Vintage: 2006

Lappers / Polisher

Free abrasive machine

Non-functional

2006 vintage.

SPEEDFAM / PETER WOLTERS 32 SPAW is a wafer grinding, lapping and polishing equipment that can be used to achieve ultra-precise machining of semiconductor wafers. This system has been designed specifically to process ultra-thin wafers to a level of quality that classifies them suitable for microelectronic production. This unit has a high degree of automation with features such as vision systems, integrated development software and automated measurement systems. It is capable of achieving up to 6-micron tolerances and very tight flatness specifications. The machine is able to process a range of different materials, from conductive silicon to anodised aluminium. The tool is composed of a process chamber, a polishing table, a spindle, and a control panel. The process chamber is a sealed metal enclosure that houses the polishing table, which consists of a magnesium-alloy plate mounted on bearings and driven by an external motor. This is designed to ensure a smooth and consistent grinding, lapping, and polishing motion. The spindle is a high precision, high-speed spindle that provides the force needed to polish wafers. It is made from hardened steel with a unique double bearing design that offers low vibration operation and very high spindle life. The control panel is where all of the settings for the asset are adjusted, and it allows the operator to control the speed, pressure and time. The control panel also has an integrated development software, which is used to monitor the process, analyse results and optimise the program settings for different wafer types. This model is designed for precision machining of semiconductor wafers and offers unparalleled levels of accuracy and repeatability. It has been designed to meet the strictest requirements of the semiconductor industry and is capable of processing wafers with a tolerance of up to 6 microns and a flatness specification of just 0.5 microns. Its automation and process control features make it the ideal choice for the fabrication of high-end microelectronic devices.

There are no reviews yet