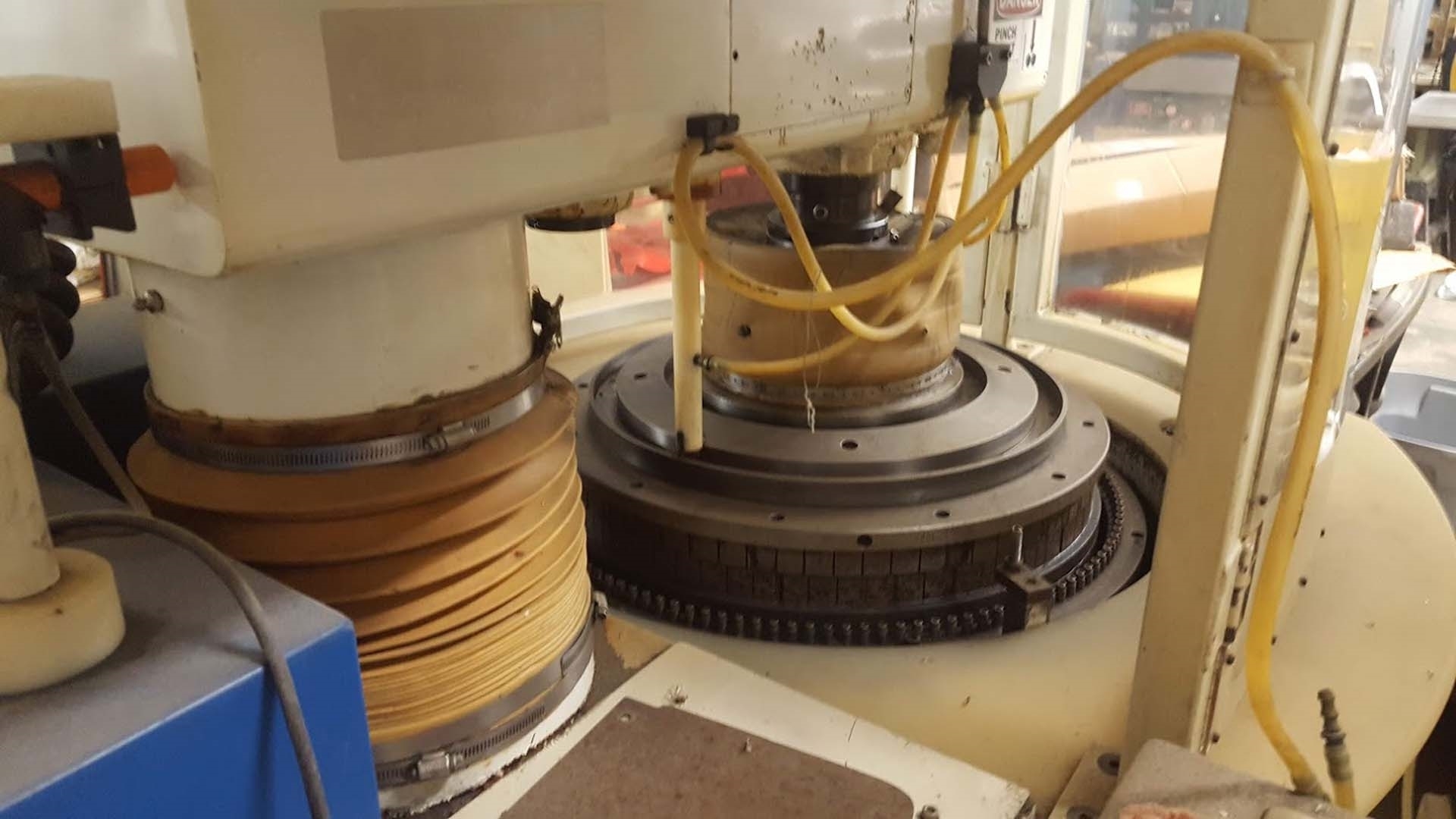

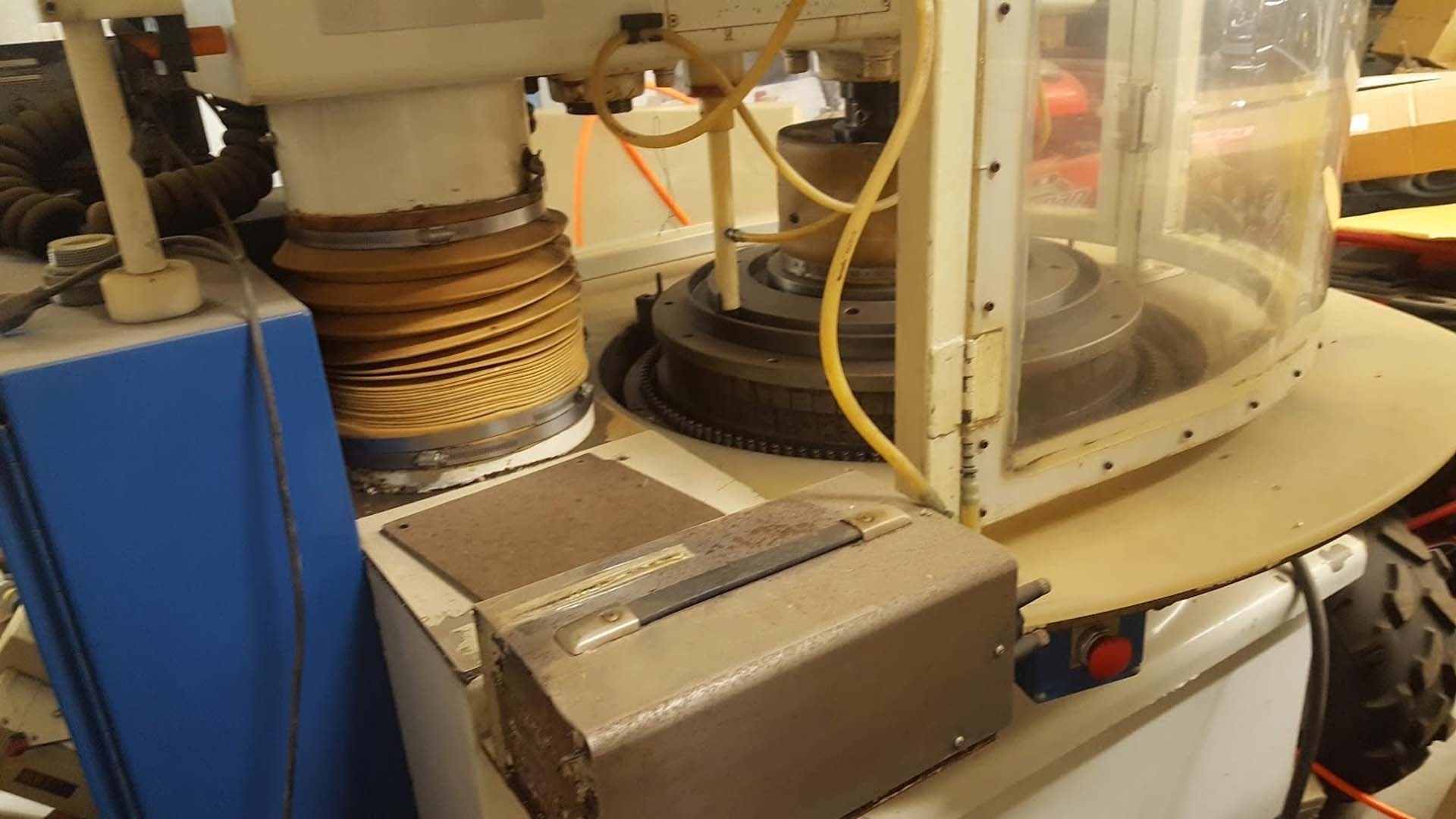

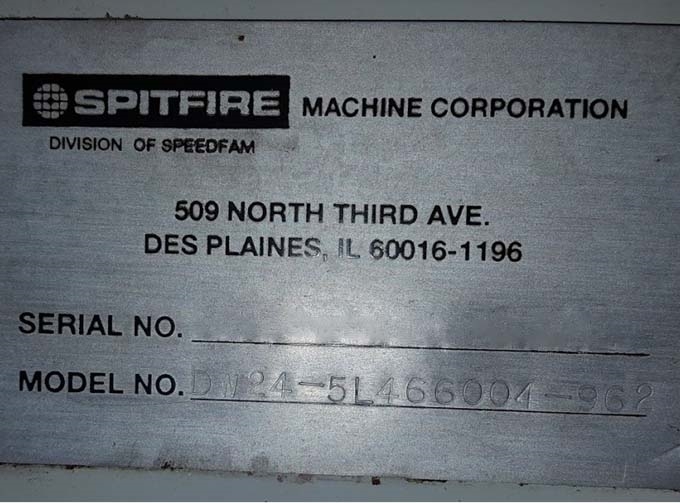

Used SPITFIRE 360 #9232359 for sale

URL successfully copied!

Tap to zoom

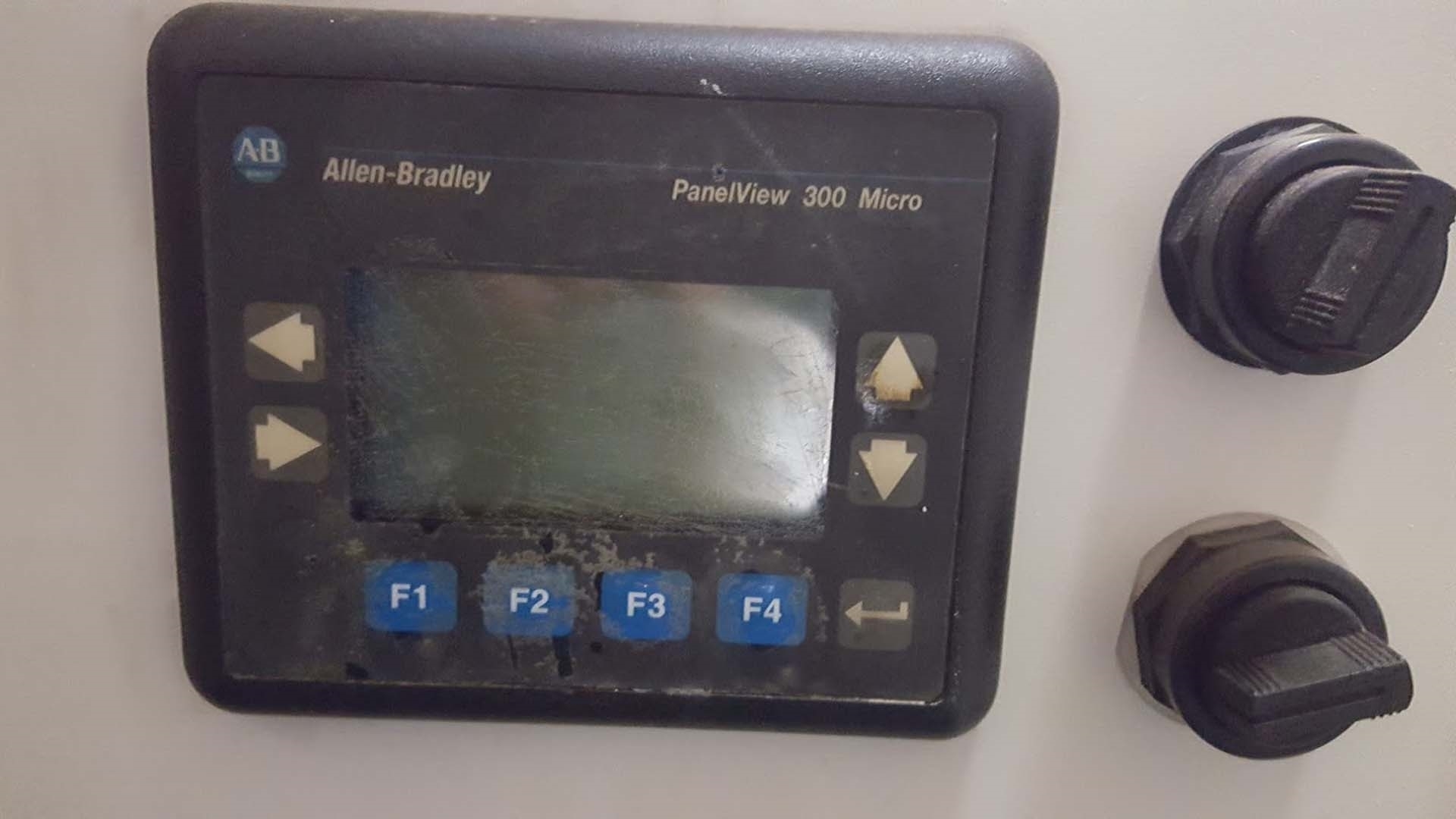

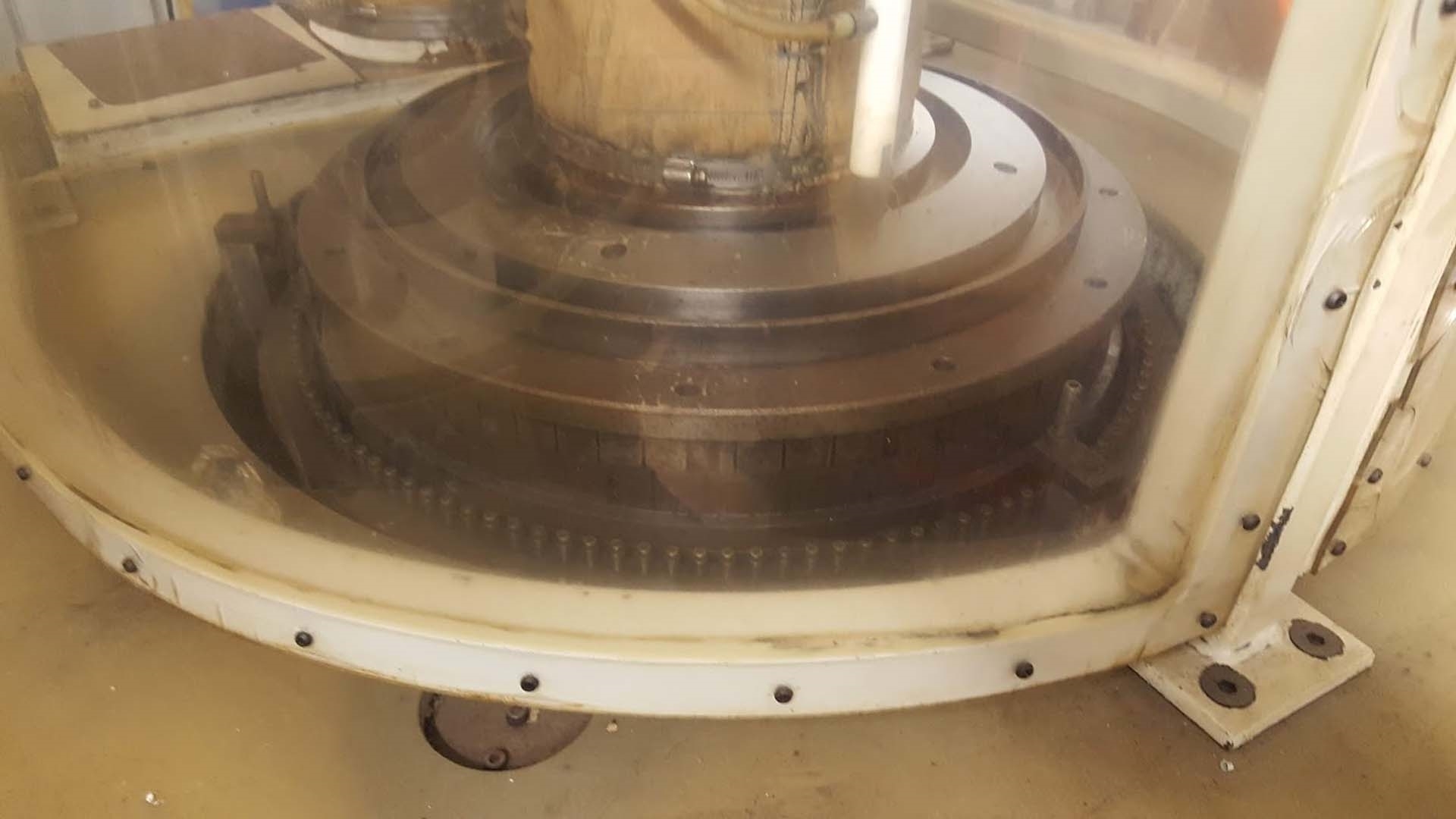

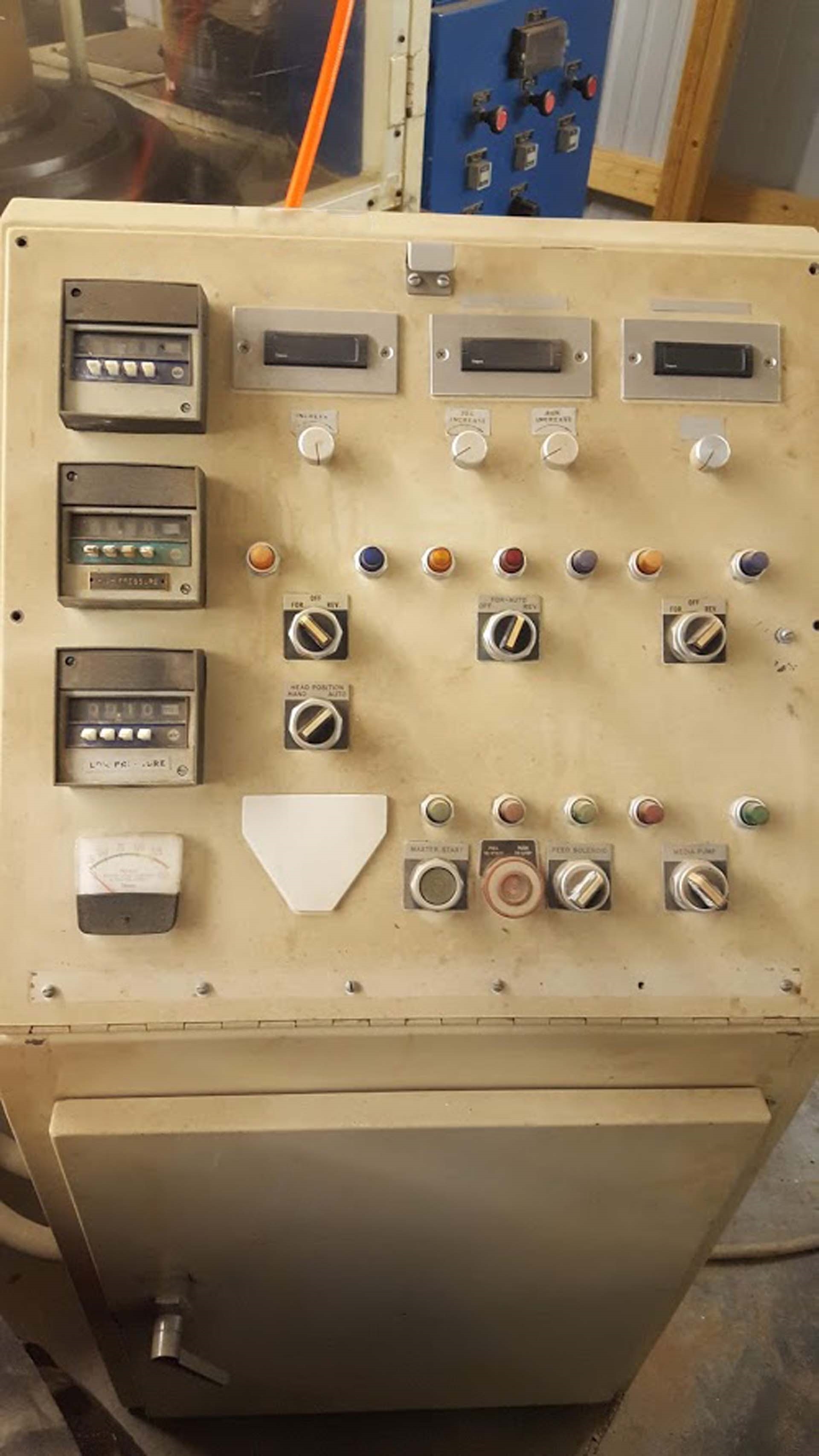

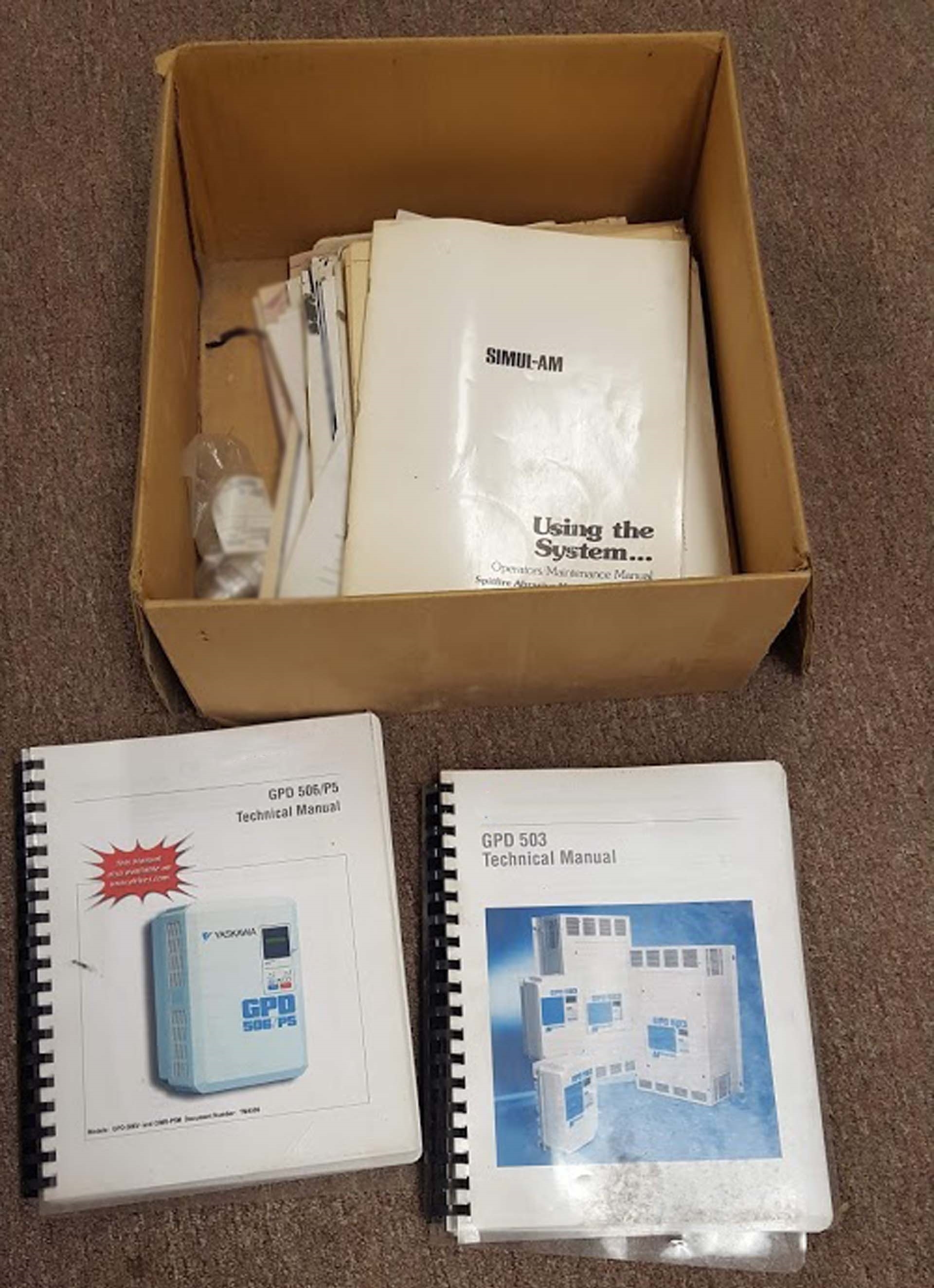

SPITFIRE 360 Wafer Grinding, Lapping & Polishing Equipment is a comprehensive solution for the ultimate in grind and lap machine performance. The system is designed to provide a consistent grinding and lapping quality, as well as precision results. It utilizes advanced technologies like our proprietary laser interferometry and non-contact air bearing alignment systems to insure accuracy and repeatability. The high performance driven motors are designed for high speed operation, allowing for higher throughput and reduced cycle time. The all-in-one design has integrated hardware and software controls for easy operation and user-friendly interface. The unit consists of the grinding and lap stages, and each stage is designed to obtain the best results. The grinding stage uses diamond wheels to obtain a surface finish and dimensions conforming with the required standard. The lapping stage utilizes diamond discs and sponges to get a smooth, pairable surface finish while maintaining the desired size tolerances. The polishing stage follows, in order to achieve mirror-like finishes. 360 Machine offers a number of features that make it perfect for precision applications. It employs a variable-position bridge over the grinding wheels, which allows for the necessary flexibility to get consistent results. The tool also utilizes a custom-made robotic arm, which moves the lapping and polishing carriers around during each stage, eliminating the need for manual intervention while optimizing throughput. The entire asset is enclosed in a secure air chamber to keep the dust out and to maintain temperature stability. SPITFIRE 360 Model is also highly automated, with a variety of features designed to keep the user focused on the process at hand. It has a real-time display that allows for data acquisition and analysis, as well as modification of parameters. This provides excellent feedback for process optimization and product quality control. The equipment also features automated grinding, lapping and polishing cycles, which reduce user setup time and manual handling. Additionally, the machine has an integrated air operator console, providing an intuitive, graphical user interface for easy, even if unfamiliar, operation. In conclusion, 360 Wafer Grinding, Lapping & Polishing System is a comprehensive solution for wafer processing with high performance and precision levels. This unit offers a wide range of advantages, such as its robust design, advanced technologies, precision results, integrated hardware and software controls, high speed operation, automated cycles, and intuitive user interface. Furthermore, SPITFIRE 360 is one of the best solutions available to obtain results of the highest quality with repeatability, in a cost-effective manner.

There are no reviews yet