Used STRASBAUGH 37C #77445 for sale

URL successfully copied!

Tap to zoom

ID: 77445

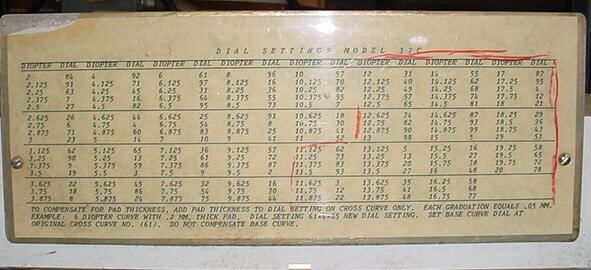

Lap lathe, work oscillates on a 120° arc. Cutter is air / hydraulic fed, 2 di to 20 di, 115 Volts, 2 speed 1 HP motor.

STRASBAUGH 37C wafer grinding, lapping and polishing equipment is a multi-function wafer processing machine utilizing state-of-the-art technology and premium components. 37C has an integrated design for three simultaneous processes: grinding, lapping and polishing, making it a complete and effective solution for the production of high-precision planar microelectronic components. STRASBAUGH 37C uses precision diamond grinding wheels to rough grind the substrate to the desired thickness, shape and profile. The grinding wheel is spun at speeds up to 800 rpm and is automatically loaded and unloaded by a servo-controlled robotic system. The wafers are then transferred to the lapping disc which is driven by a variable frequency drive. This drive allows the operator to adjust the speed and torque of the disc for precision control. The lapping process uses abrasive diamond slurry to polish the surface of the wafer to a desired surface finish. The final process is polishing, where the substrate is buffed using soft, abrasive pads. This polishing process is designed to create an even surface finish with minimal defects. 37C also has a user-friendly interface with a touchscreen display for easy operation. It is equipped with a self-diagnostic function for easy troubleshooting, and a password-protected unit for enhanced access control. Additionally, the machine has built-in data logging and analysis capabilities, allowing the operator to track production results in real-time. STRASBAUGH 37C is an ideal choice for those looking to produce high-quality microelectronic components, offering excellent precision and accuracy. With the advanced features and superior technology incorporated into this machine, it can be relied on to manufacture superior parts quickly, efficiently and cost-effectively.

There are no reviews yet