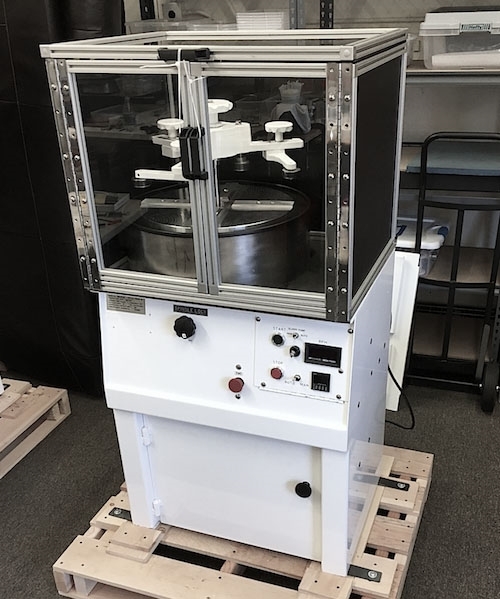

Used STRASBAUGH 6BK #9211851 for sale

URL successfully copied!

Tap to zoom

ID: 9211851

Polisher

Recirculating slurry system

With under cabinet 5-10 gallon reservoir and pump

Process table speed control: 0-150 rpm

DC Variable speed

3/4 HP

Retainer: Ring / Spider

Table:

Outer diameter: 16.0”

Inner diameter: 5.0”

Annular width: 5.5”

Motor: 3 / 4 HP

Torque: 600 lbs @ 10 rpm

Load rating 1000 lbs

Rings:

Inner diameter: 5.00”

Outer diameter: 6.62”

Offset range: 0.50”

Table speed range: 0-100 rpm

(3) Driven wheels

(3) Carriers to co-rotate synchronization with the table

OMRON Digital timer

Spindle lock

Heavy cast-iron table

Diameter cast-iron table: 16"

(3) ID Work rings, 5"

Power requirements: 110V / 230V, 1 Phase, 50/60 Hz, 10 Amps.

STRASBAUGH 6BK AutopREP wafer grinding, lapping and polishing equipment is a highly sophisticated system that allows manufacturers to quickly and accurately create highly precise prototypes. 6BK is designed for versatile automation that fits any application, requiring multiple operations. It is designed to provide high-precision and ultra-dependable positioning and force control from individual pieces to 70-mm wafers. Additionally, the unit offers precise process control through data input and output for a variety of wafer sizes and shapes. It is capable of multiple grinding/lapping and polishing modes, stroke ranges from 0.1 to 6.5 millimeters, and custom chuck configurations and accessories, such as polishing pads and specialized fixtures. STRASBAUGH 6BK also features a digital drive machine to provide smooth and accurate motion control and three-axis motorized staging. Motion feedback is provided by direct encoder and software-controlled loop control with a total motion resolution of 0.0005 inches. The tool is designed to give users a wide range of flexibility and automated processes. 6BK includes a graphical user interface that allows operators to program and pre-set multiple processes and configurations. It also has a wafer encapsulation asset for through-thickness wafer mapping and process control. With this model, professionals can quickly and accurately measure, analyze, and control the desired manufacturing parameters. For added safety, the equipment features a safety-rated enclosure, interlockable doors, and an emergency-stop button. The flow of coolant and wafer handling is also controlled by pressure sensors and retractors. STRASBAUGH 6BK AutopREP wafer grinding, lapping and polishing system is the perfect solution for rapid prototype creation and high-precision production. This innovative unit provides unparalleled accuracy and process control for a variety of wafer sizes and shapes. And with a digital drive and graphical user interface, operators will find it easy to program and pre-set multiple processes and configurations. With 6BK machine, users can quickly and accurately create high-precision prototypes.

There are no reviews yet