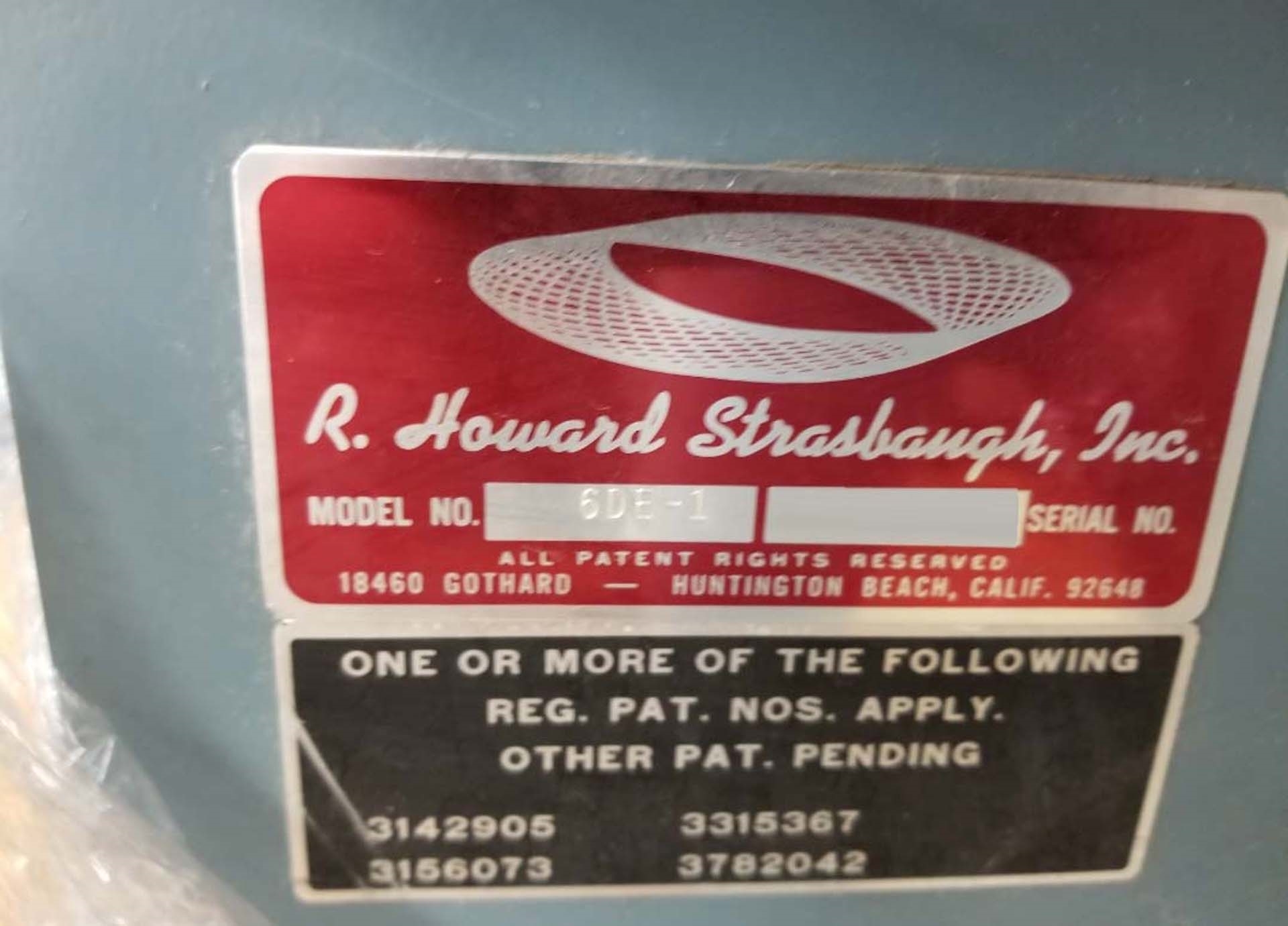

Used STRASBAUGH 6DE-1 #9256748 for sale

URL successfully copied!

Tap to zoom

STRASBAUGH 6DE-1 is a wafer grinding, lapping and polishing equipment designed for precision material removal and improved surface smoothness of semiconductor wafers and other related substrates. This system utilizes a high-precision, programmable 6-axis motion control unit to provide a superior level of control for the grinding, lapping, and polishing process over traditional mechanical grinding machines. The heart of 6DE-1 is at its six CNC servo-controlled axes that provide a smooth, repeatable, and angled grinding/lapping/polishing process. The main component of the grinding/lapping stage is the programmable high-precision CNC servo-controlled robot arm which accurately controls the motions of the polishing process in order to achieve the desired results. The robot arm is mounted on a support arm to provide horizontal and vertical adjustment capability, while the polishing head is mounted on an acrylic stand-off, allowing for a more accurate position during polishing operations. The machine also utilizes a diamond-impregnated platen to provide superior polishing results. This platen is driven by four AC induction motors which are specifically designed for the type of abrasive material used. The platen is fixed on a track tool which allows for the platen to move in variable speeds from slow and highly-controlled movements to high-speed surface polishing. To ensure the desired surface finish is achieved, it is also possible to vary the platen speed and polishing pressure. STRASBAUGH 6DE-1 is designed for automated, cleanroom operation, which helps to minimize the exposure of the substrates to contamination. The asset is outfitted with numerous features to protect against contamination, such as the closed-loop filtration model, the ability to control and monitor the process temperature, and the automatic detection and shutdown of process anomalies. 6DE-1 is a precise, reliable, and repeatable equipment for wafer grinding, lapping, and polishing. It has been designed to offer a cost-effective solution to high-precision material removal and improved surface smoothness of semiconductor wafers and other related substrates. With its programmable 6-axis motion control system, diamond-impregnated platen, and numerous safety and contamination features, STRASBAUGH 6DE-1 is a unit specifically designed for precision wafer machining.

There are no reviews yet