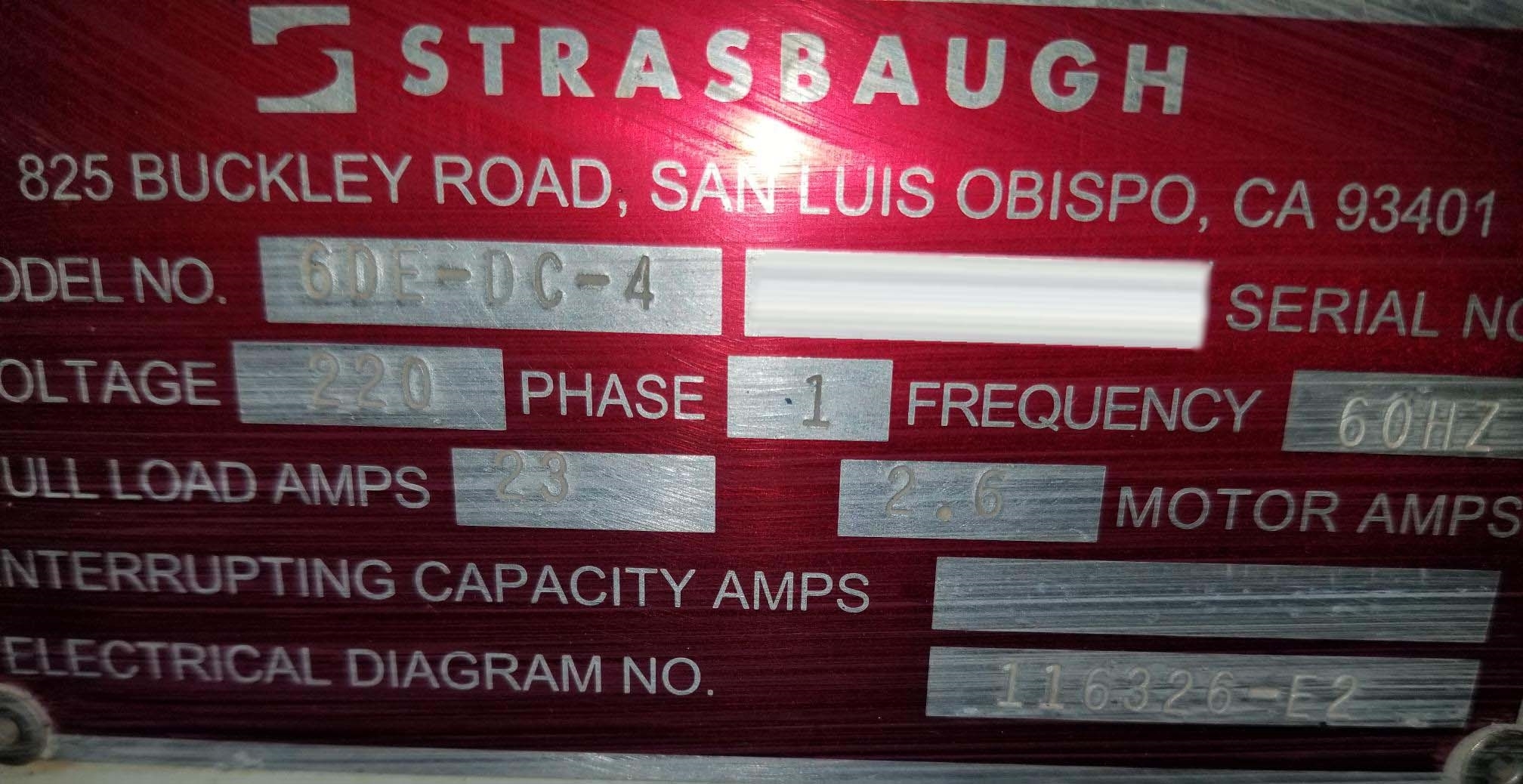

Used STRASBAUGH 6DE-DC-4 #9233423 for sale

URL successfully copied!

Tap to zoom

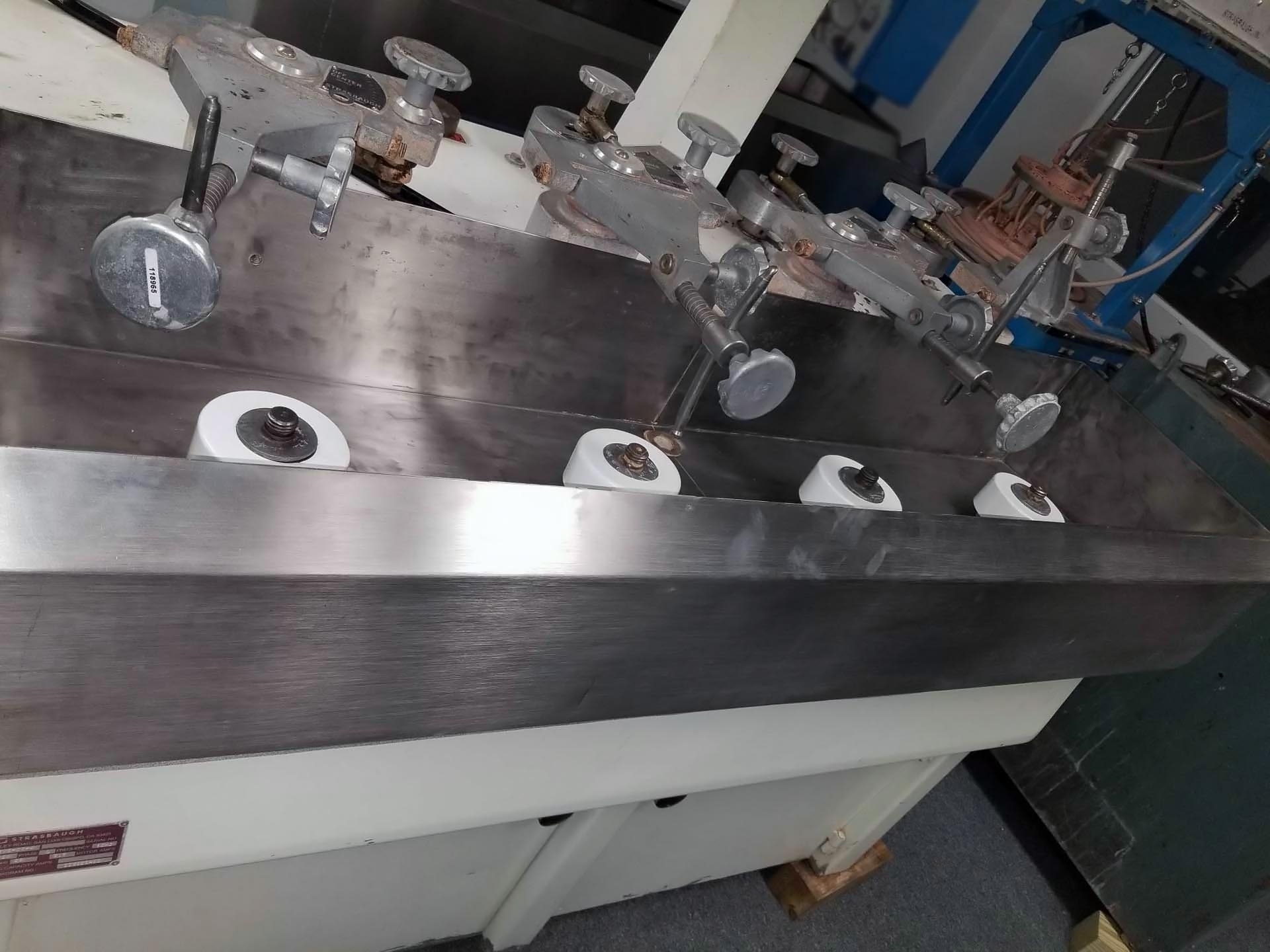

STRASBAUGH 6DE-DC-4 is an advanced wafer grinding, lapping and polishing equipment that is suitable for 10- to 200-mm wafer processing. This system uses the latest abrasive technology, targeting single-point diamond grinding wheels and lapping plates. The unit is built on a 6-degree of freedom (6DOF) platform, providing flexibility in handling any task, from simple grinding to more complex lapping and polishing operations. 6DE-DC-4 uses computer numerical control (CNC) positioning and fine control to provide a high degree of accuracy. The abrasive disk is moved around the wafer using the actuators, where a series of strategically placed nozzles control the pressure and flow of the abrasive fluid. STRASBAUGH 6DE-DC-4 also integrates advanced inspection capabilities. Using line cameras with frame grabber technology, it is able to accurately inspect the wafer surface and determine any processing errors. The process data can then be used to optimize the processing parameters, ensuring consistent and repeatable results. The machine can process both single- and multi-layer wafers, using a unique dual-level approach that allows processing in two stages, with different abrasive fluid intensities. This ensures that each layer is ground and polished to the same level. 6DE-DC-4 is able to achieve extremely high surface finish and flatness, and is also able to process thick wafers. It is used for the production of both silicon and compound semiconductor materials, and is easy to integrate into existing manufacturing lines. STRASBAUGH 6DE-DC-4 is capable of high throughput and provides excellent process flexibility and control. This makes it an ideal choice for any operation that requires high accuracy, high throughput, and efficiency.

There are no reviews yet