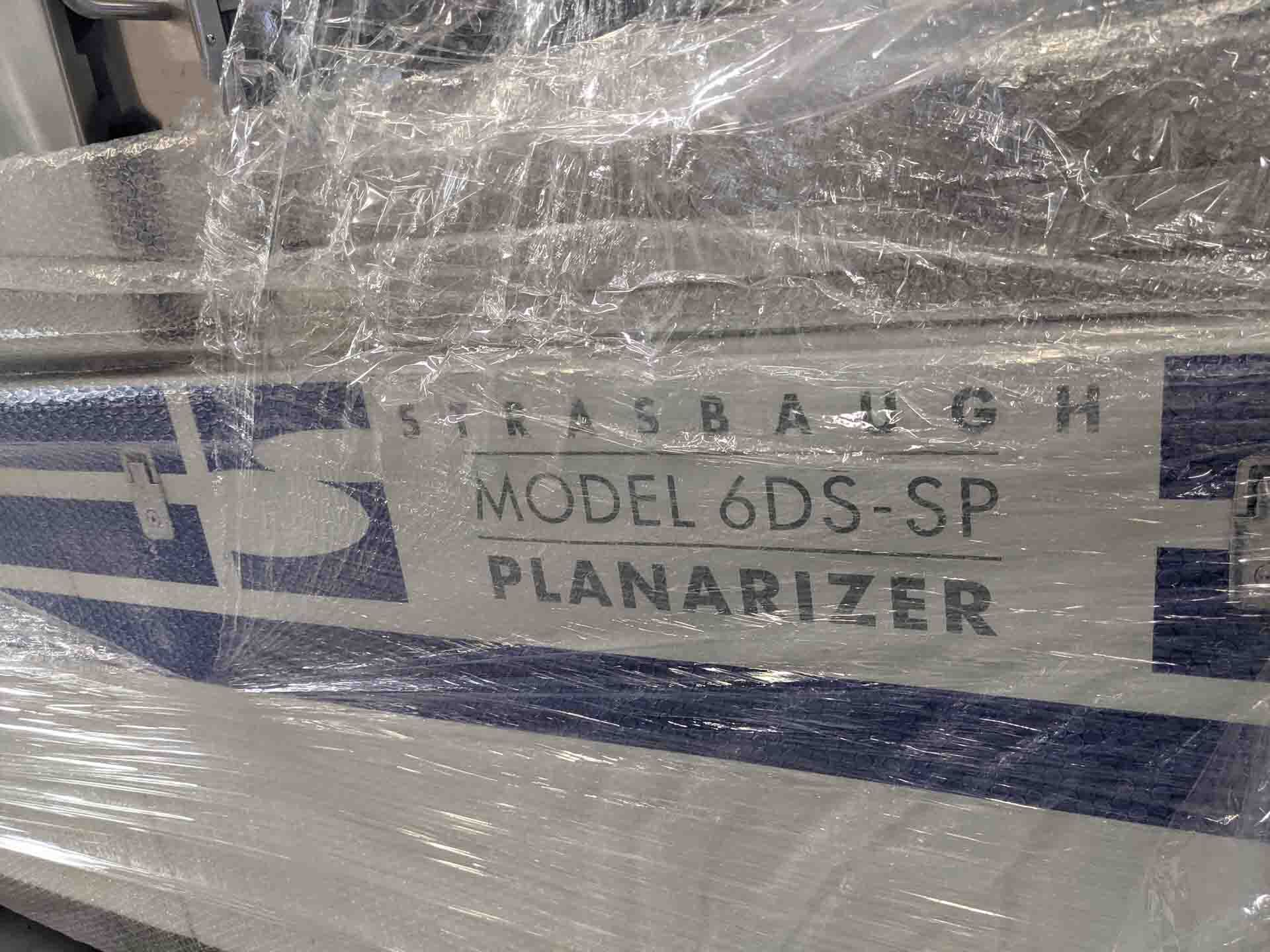

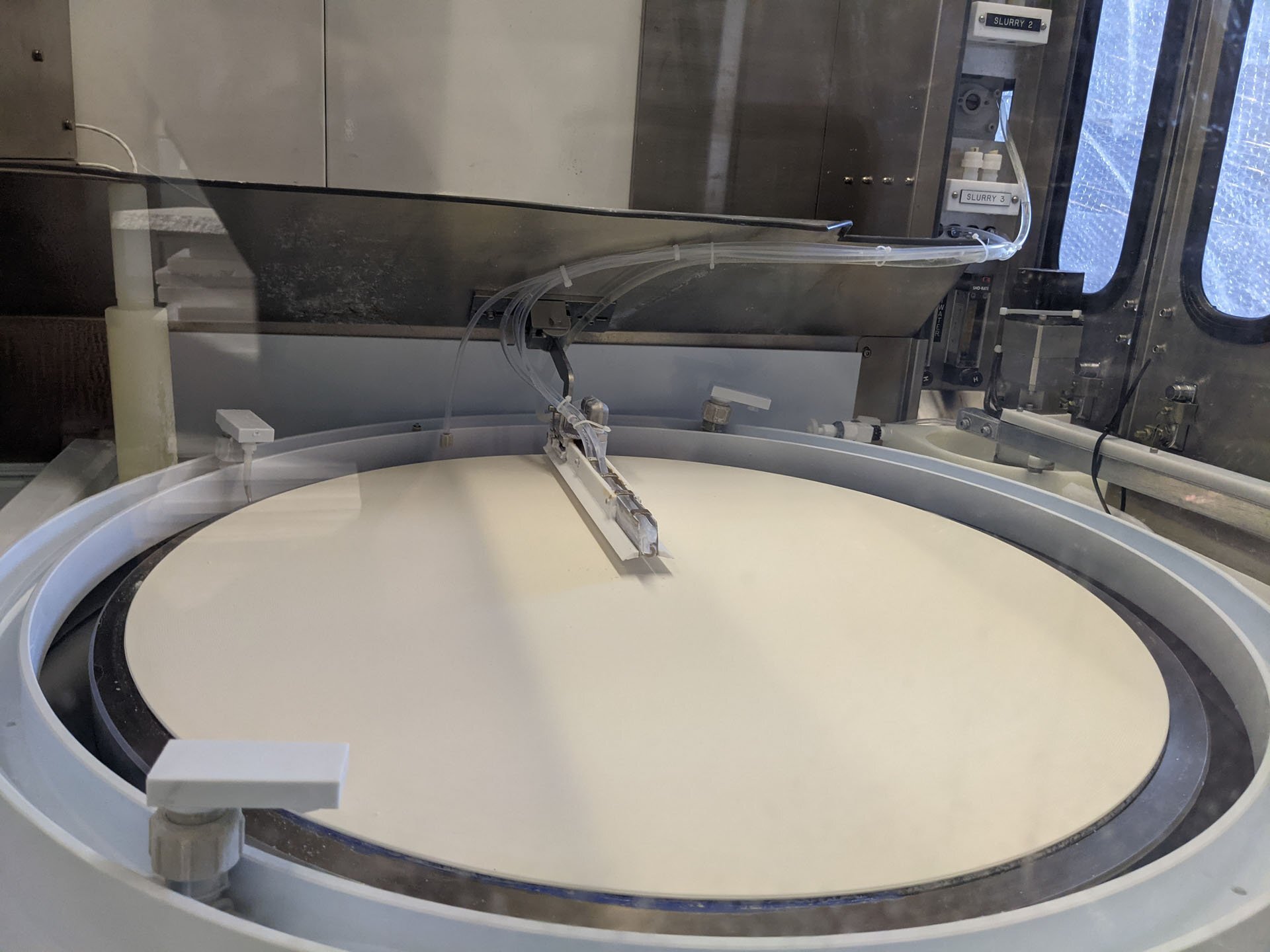

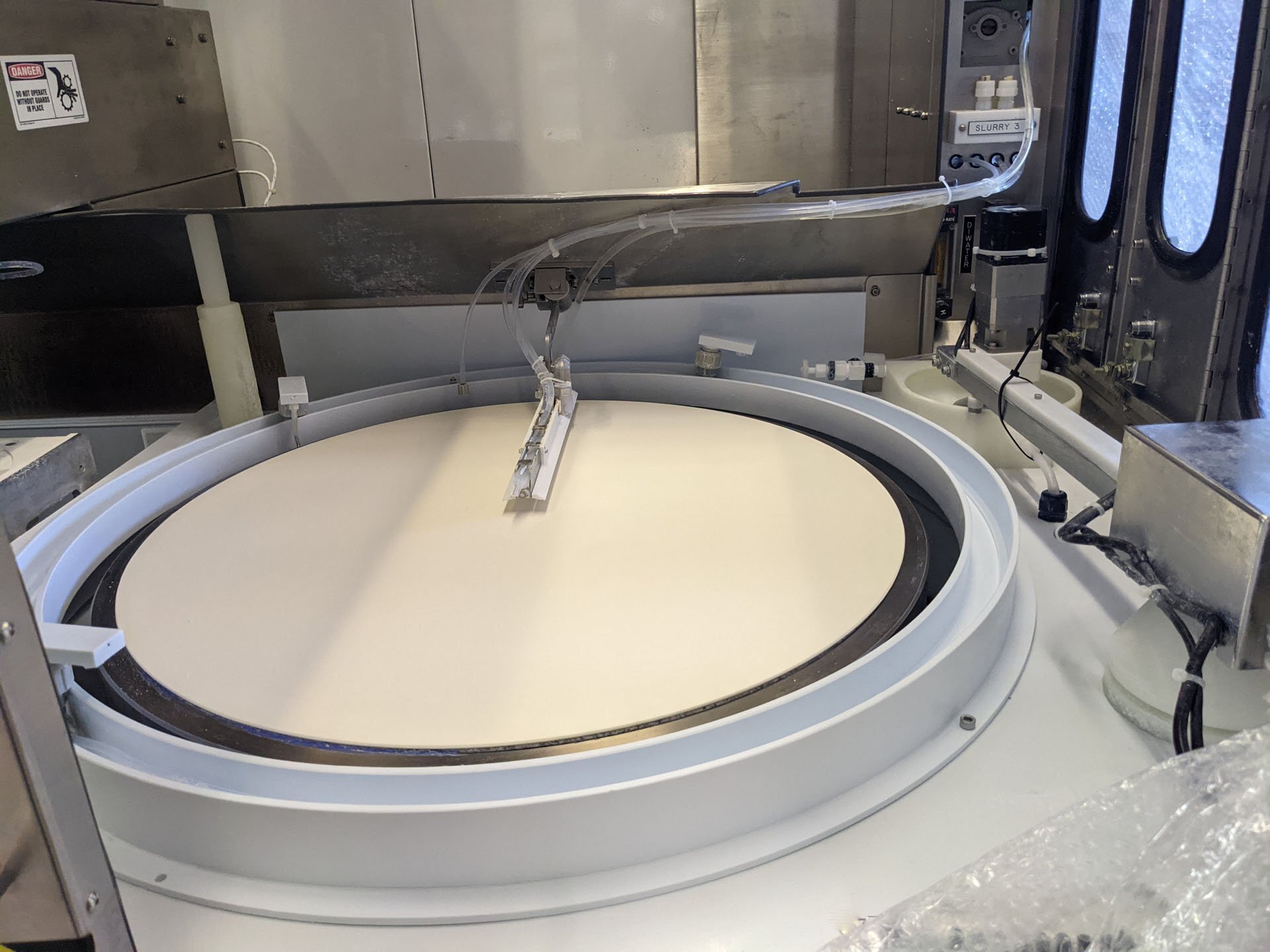

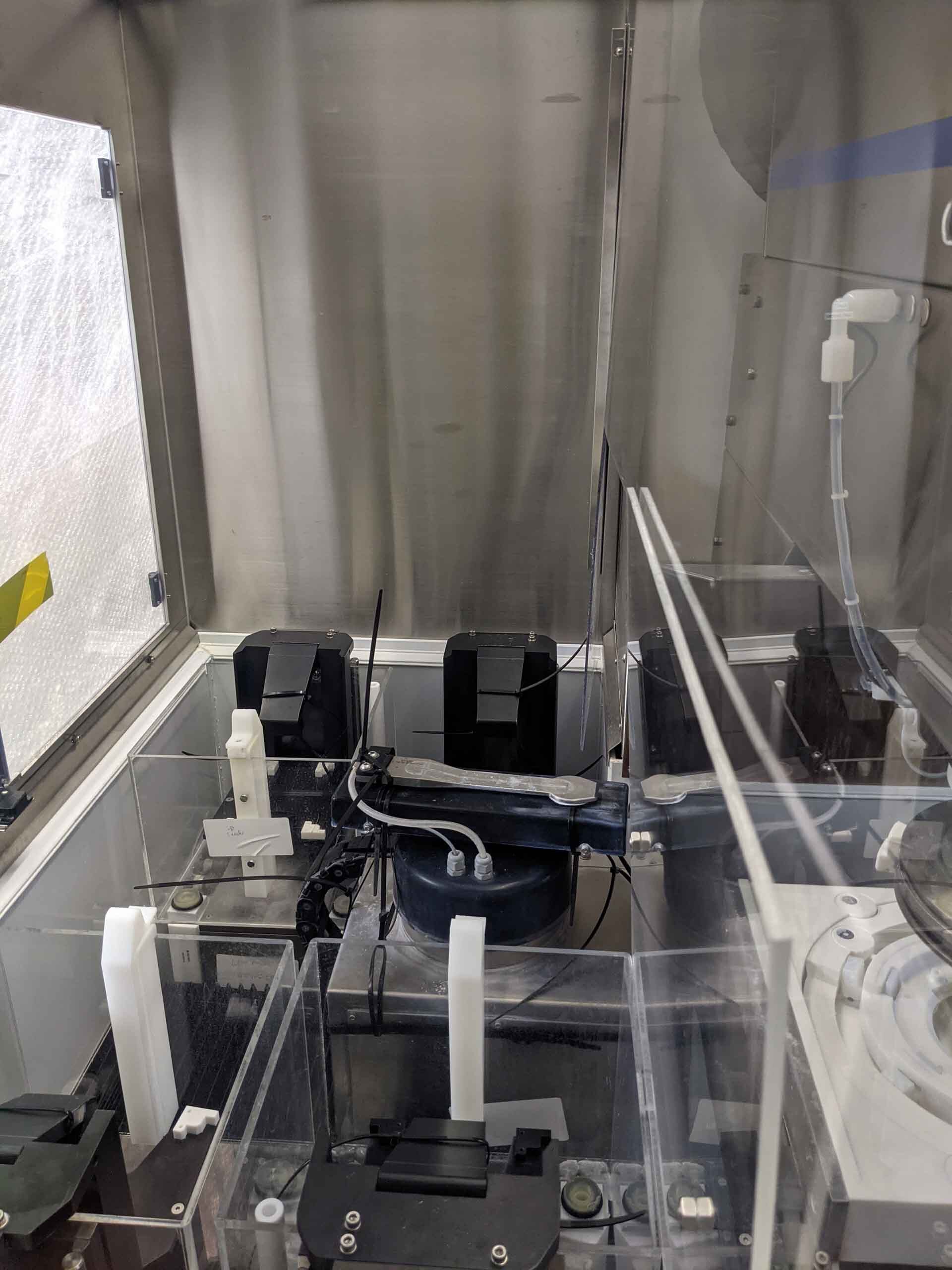

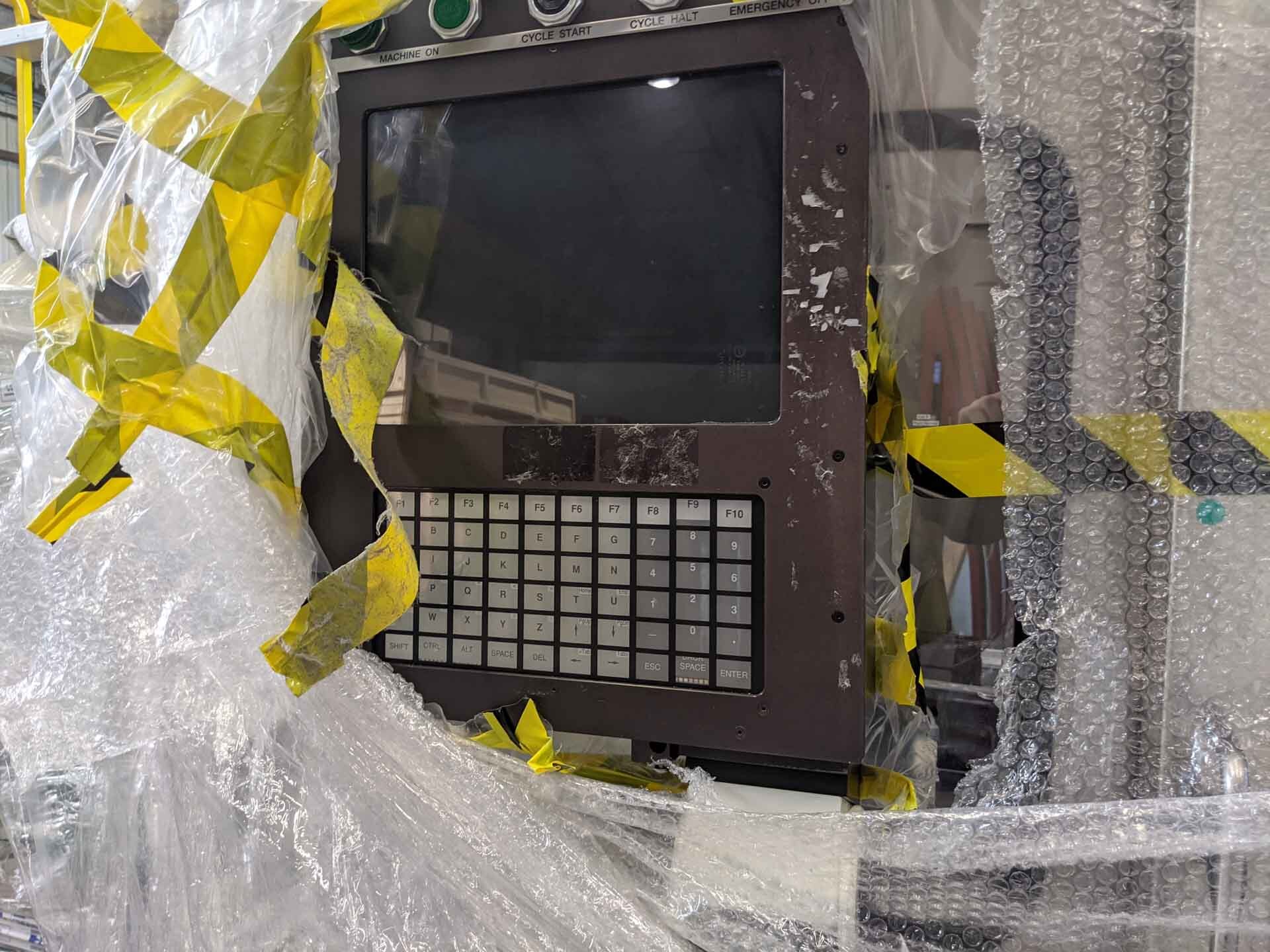

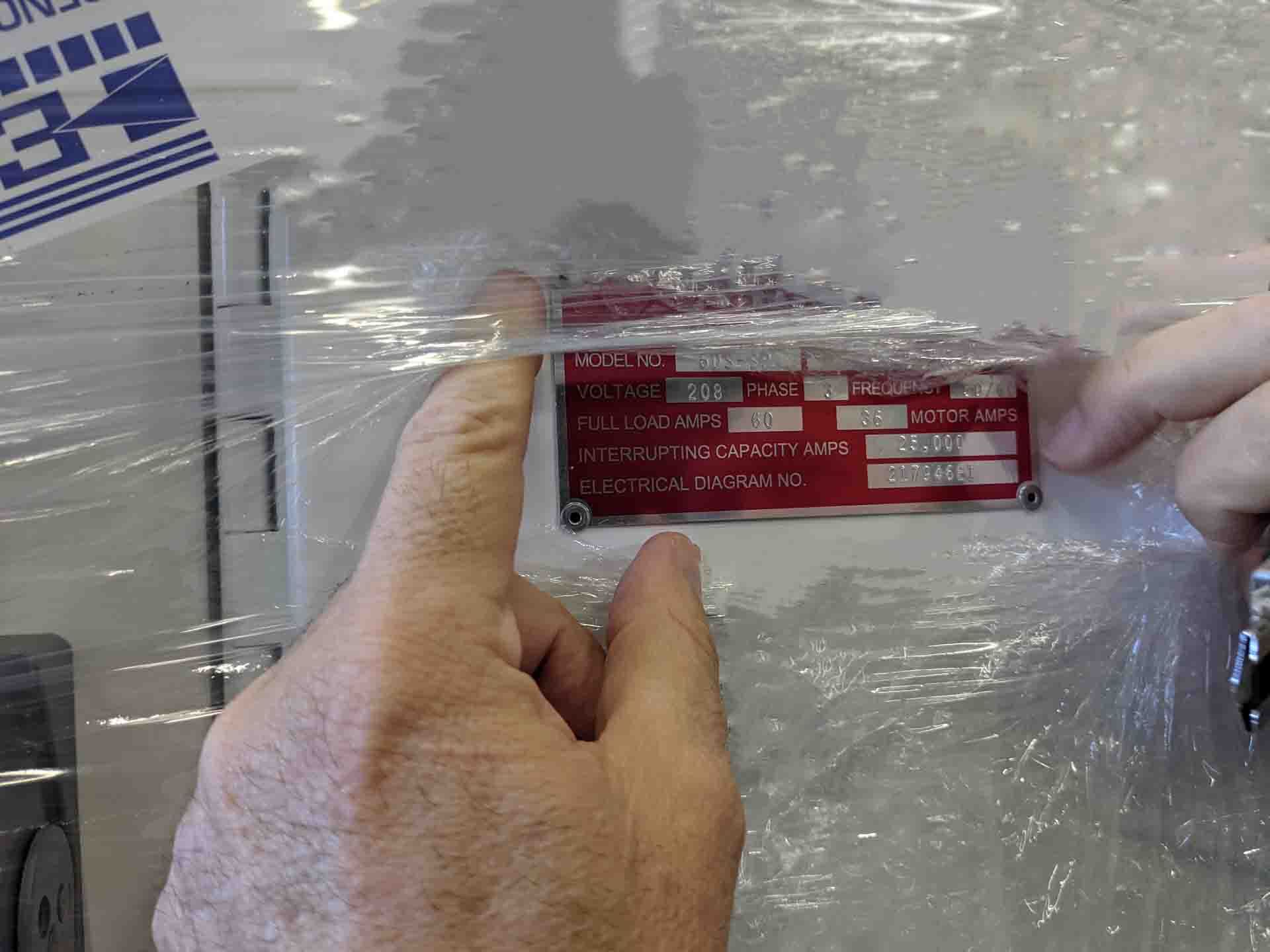

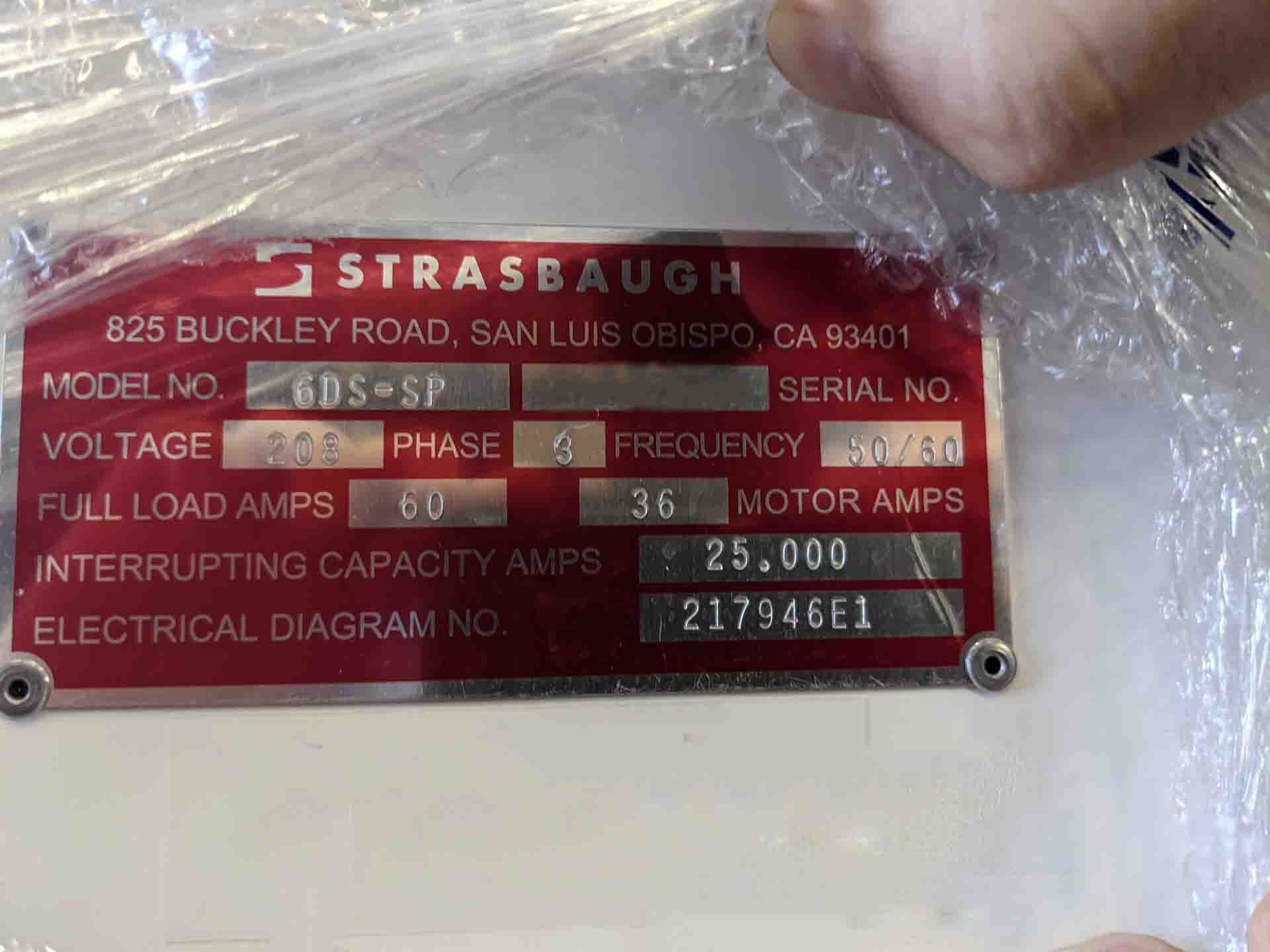

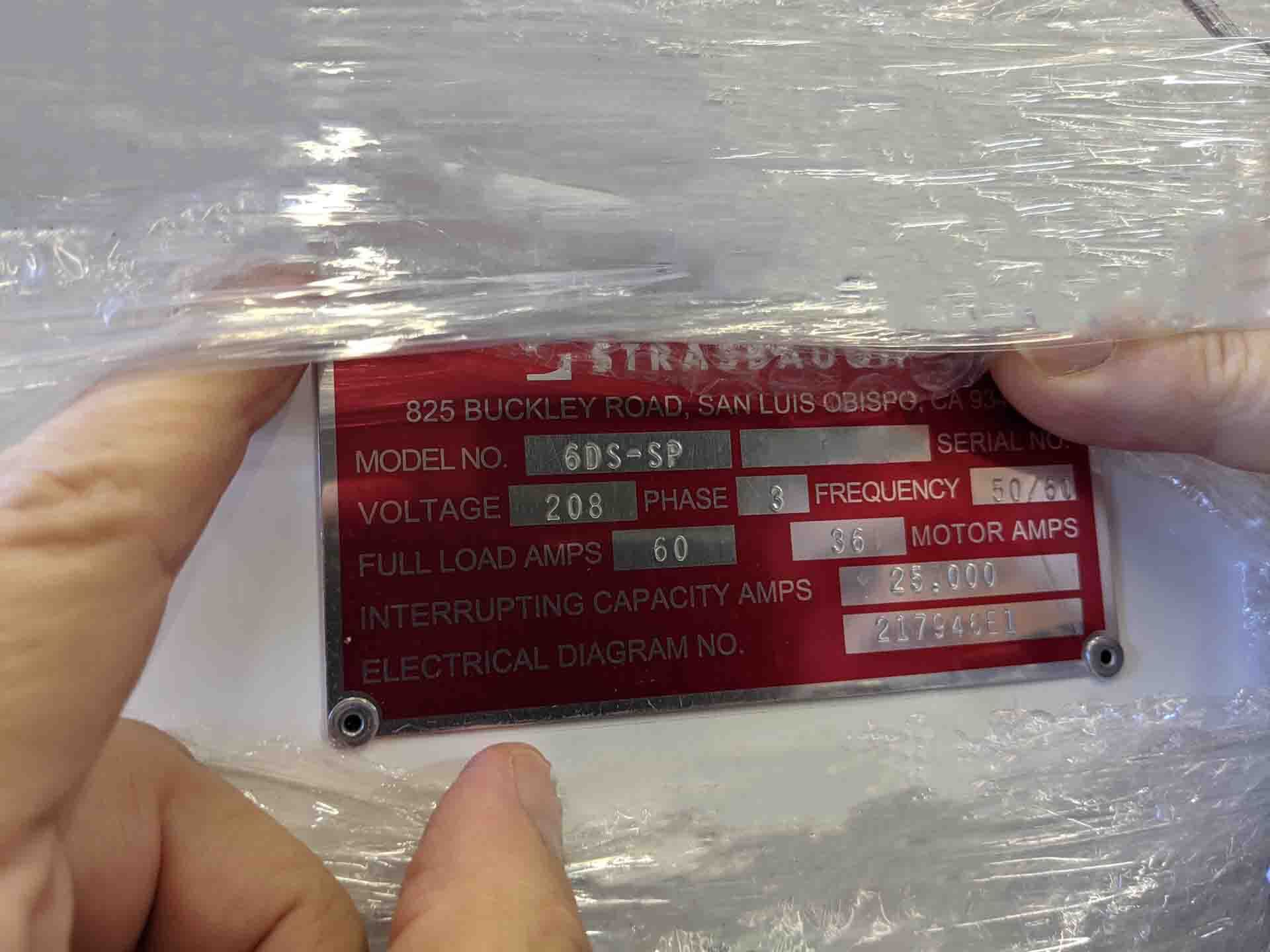

Used STRASBAUGH 6DS-SP #293606075 for sale

URL successfully copied!

Tap to zoom

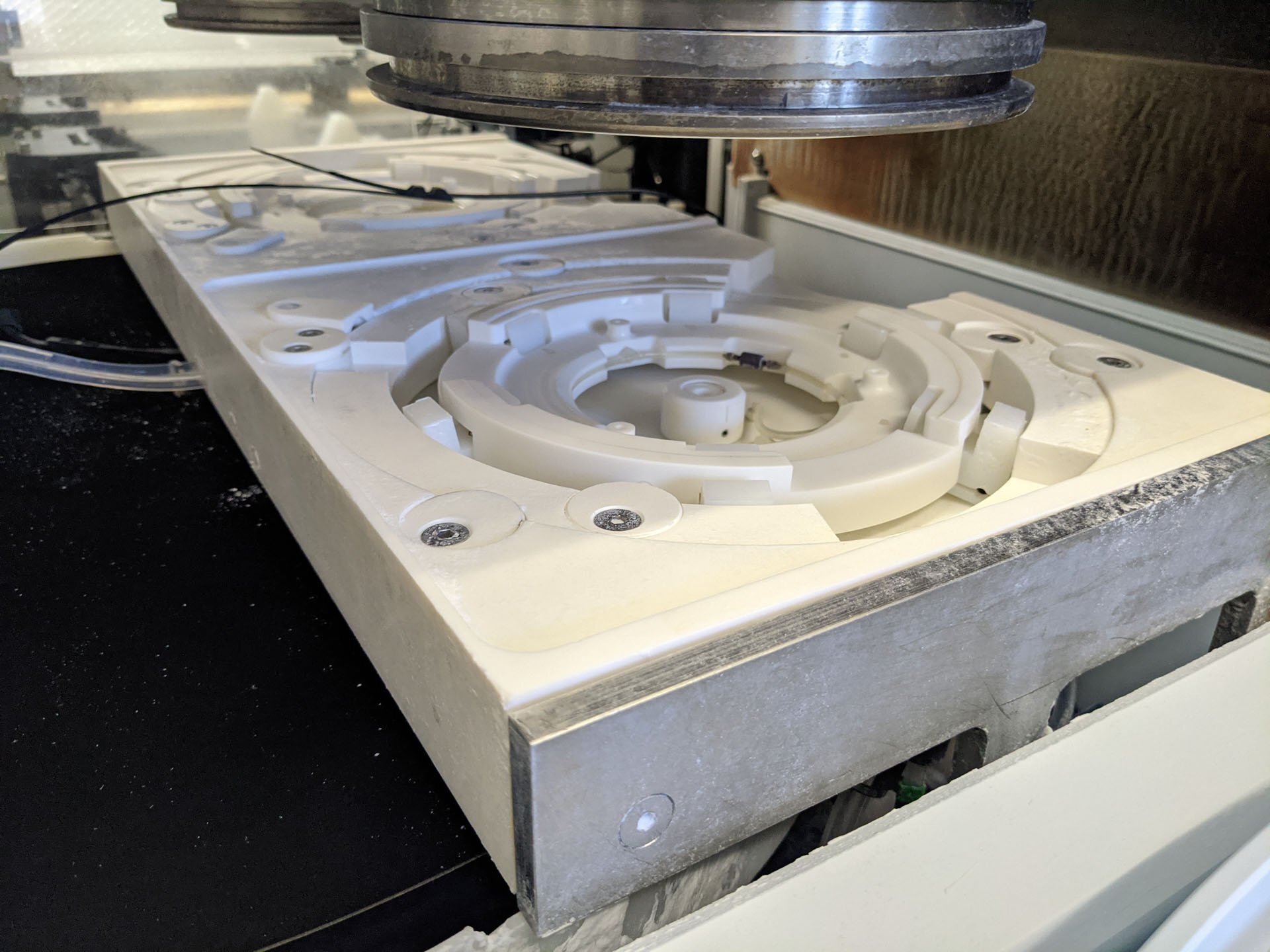

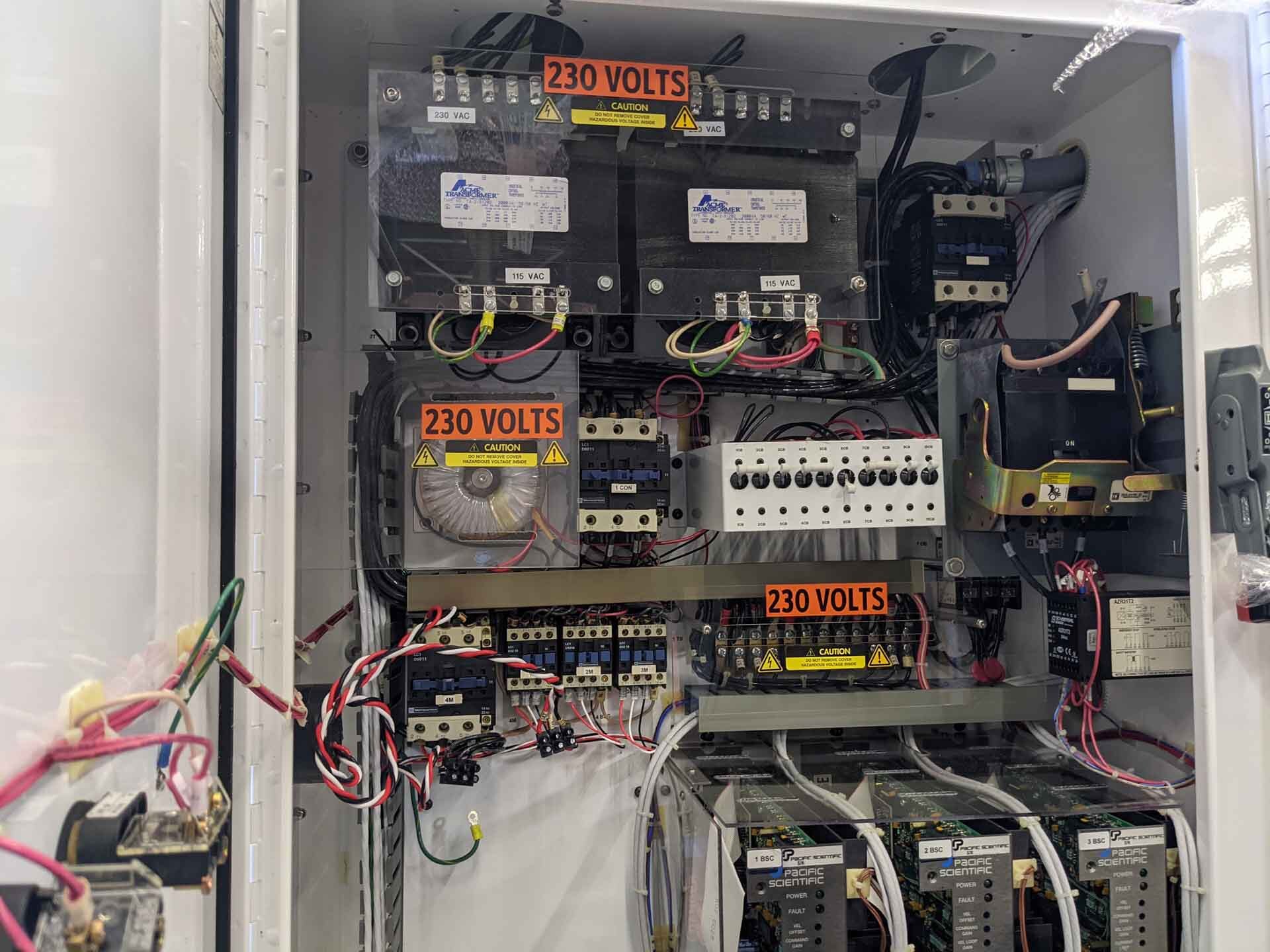

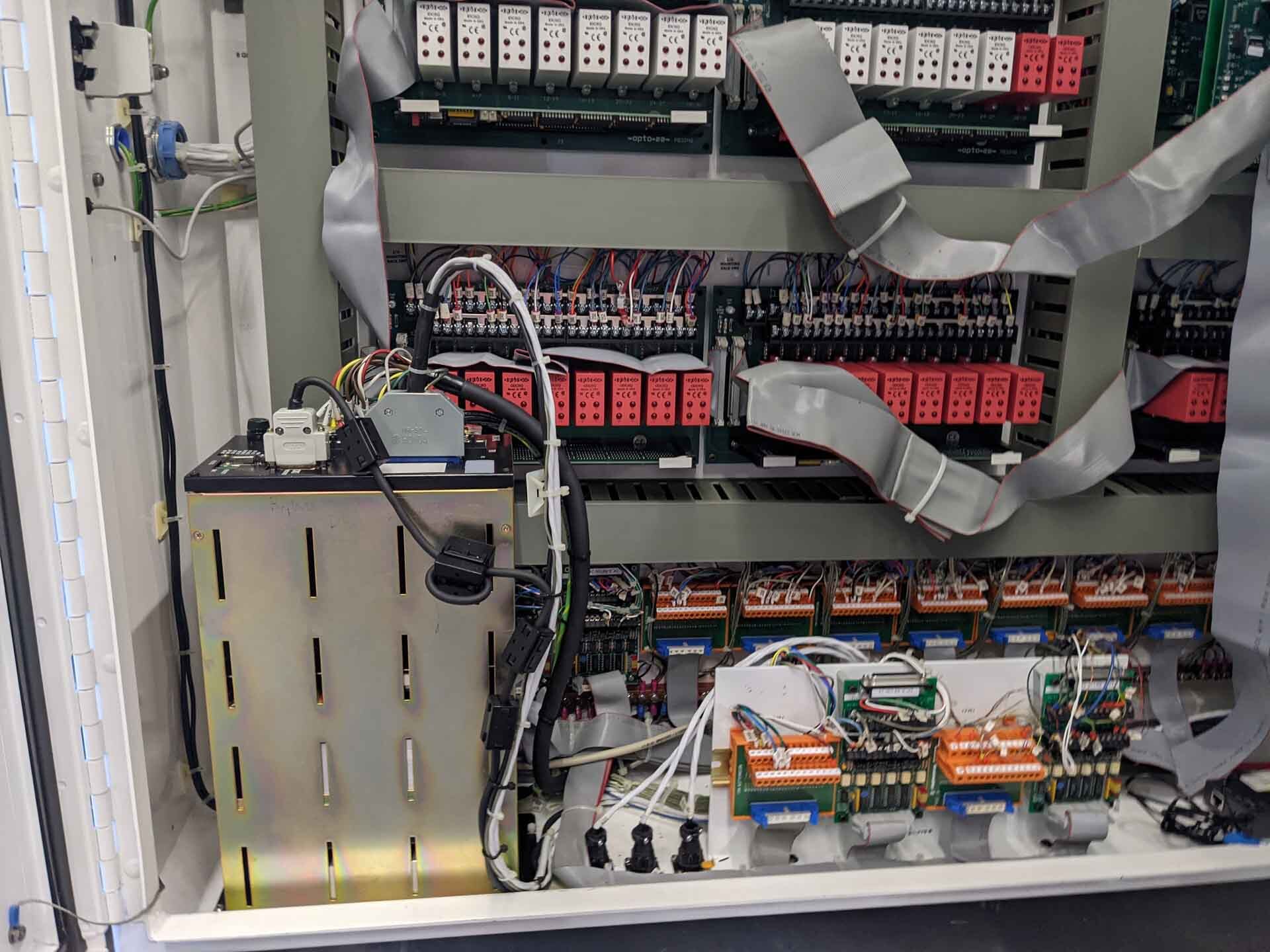

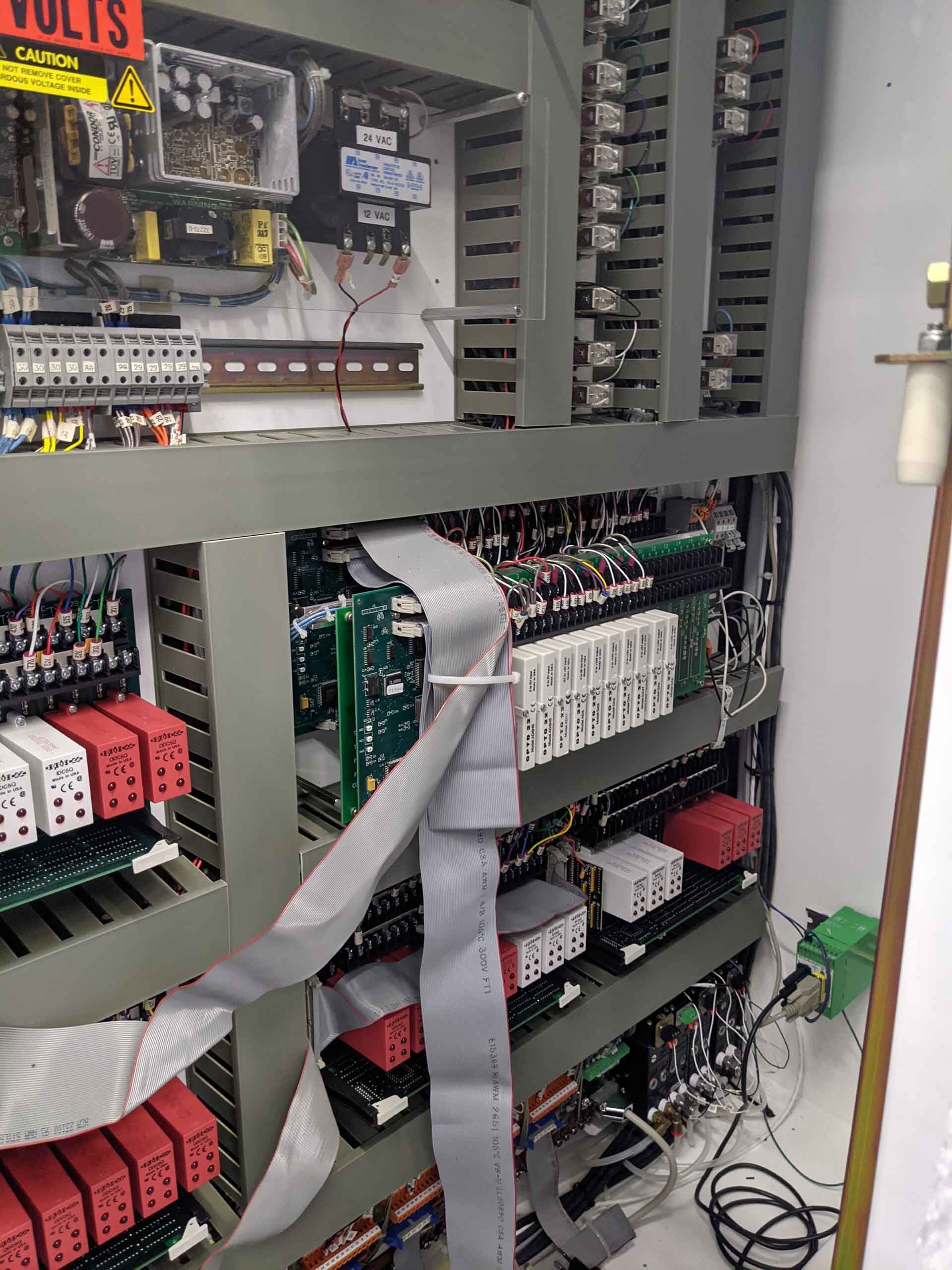

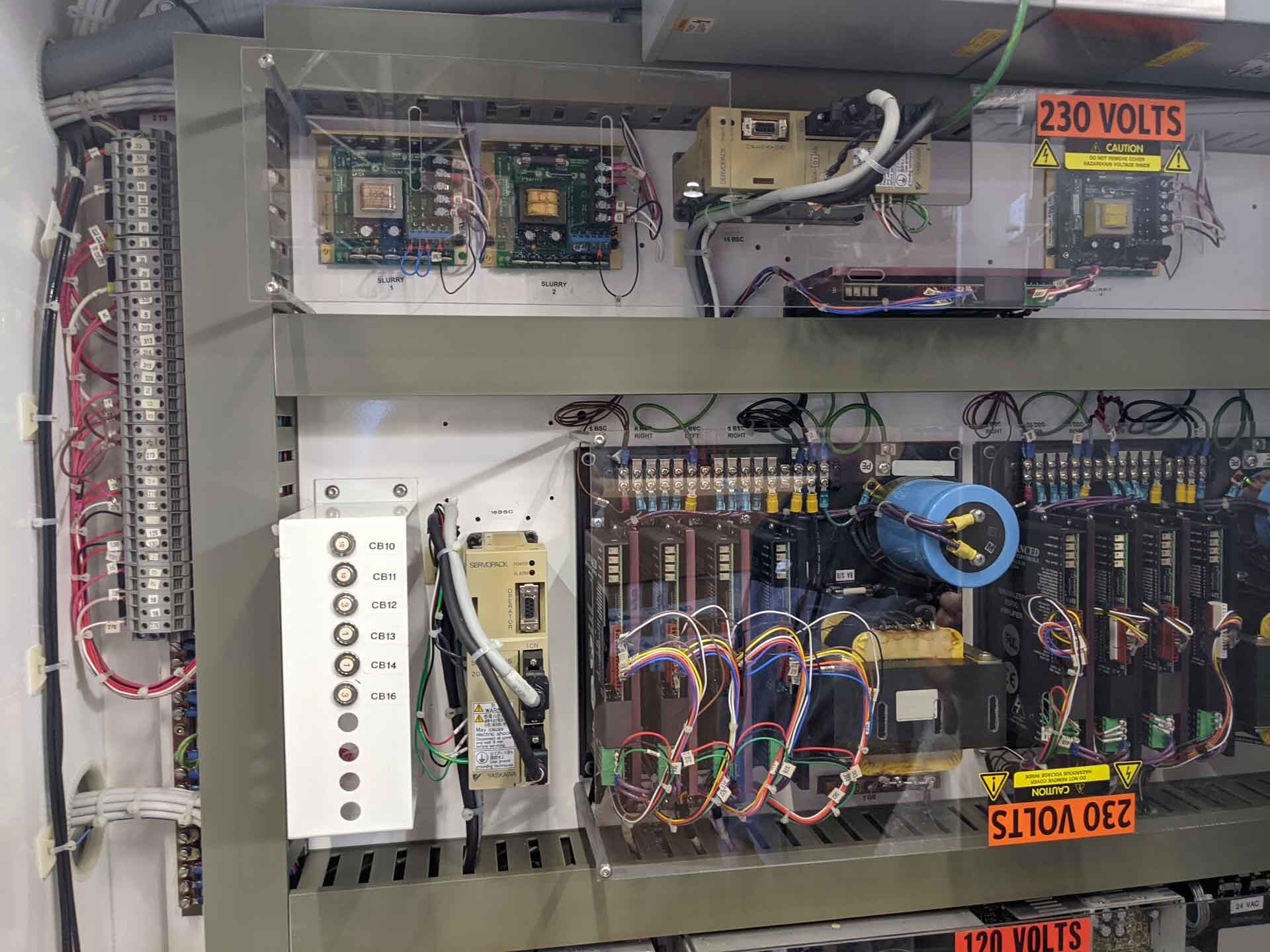

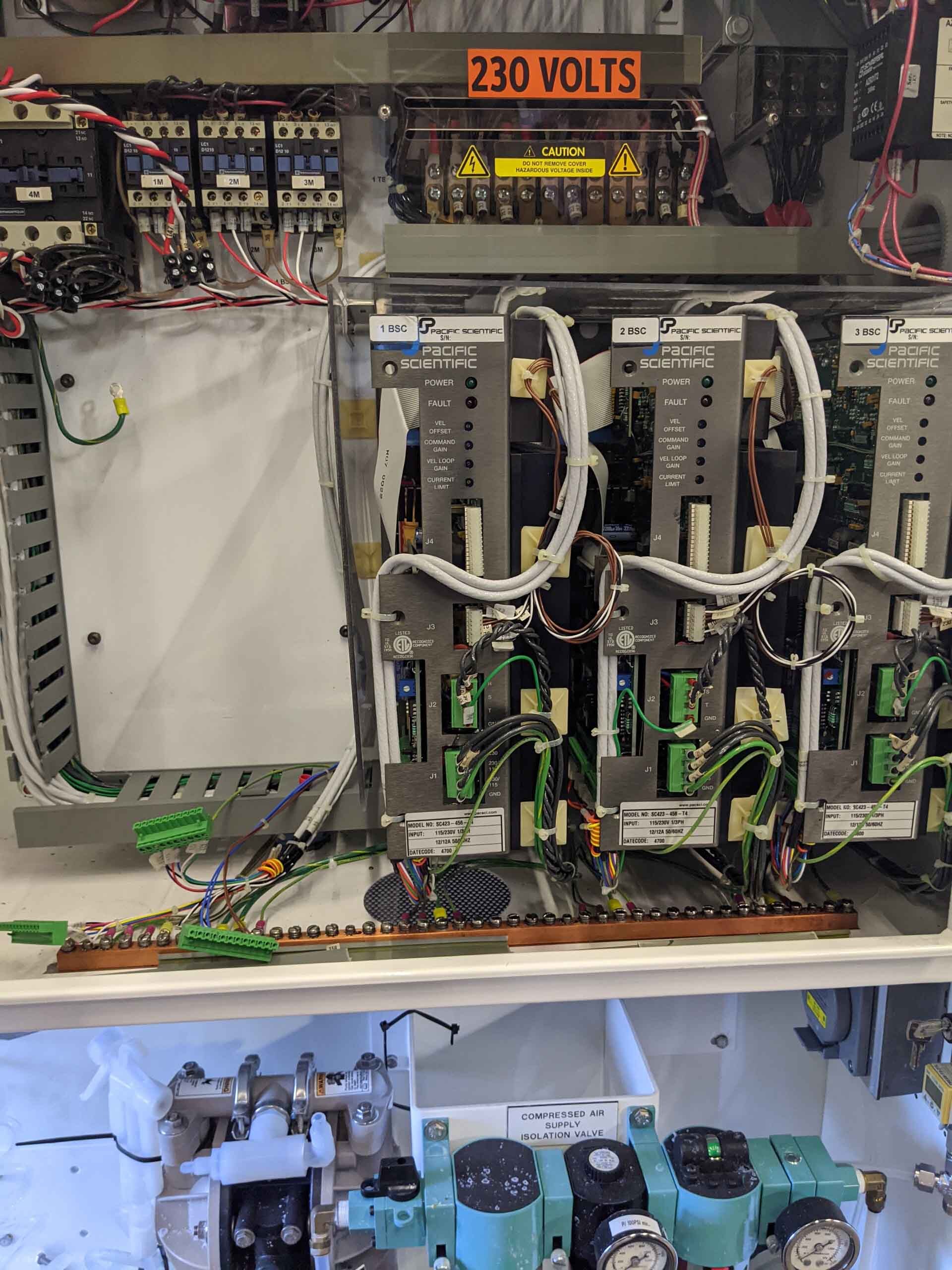

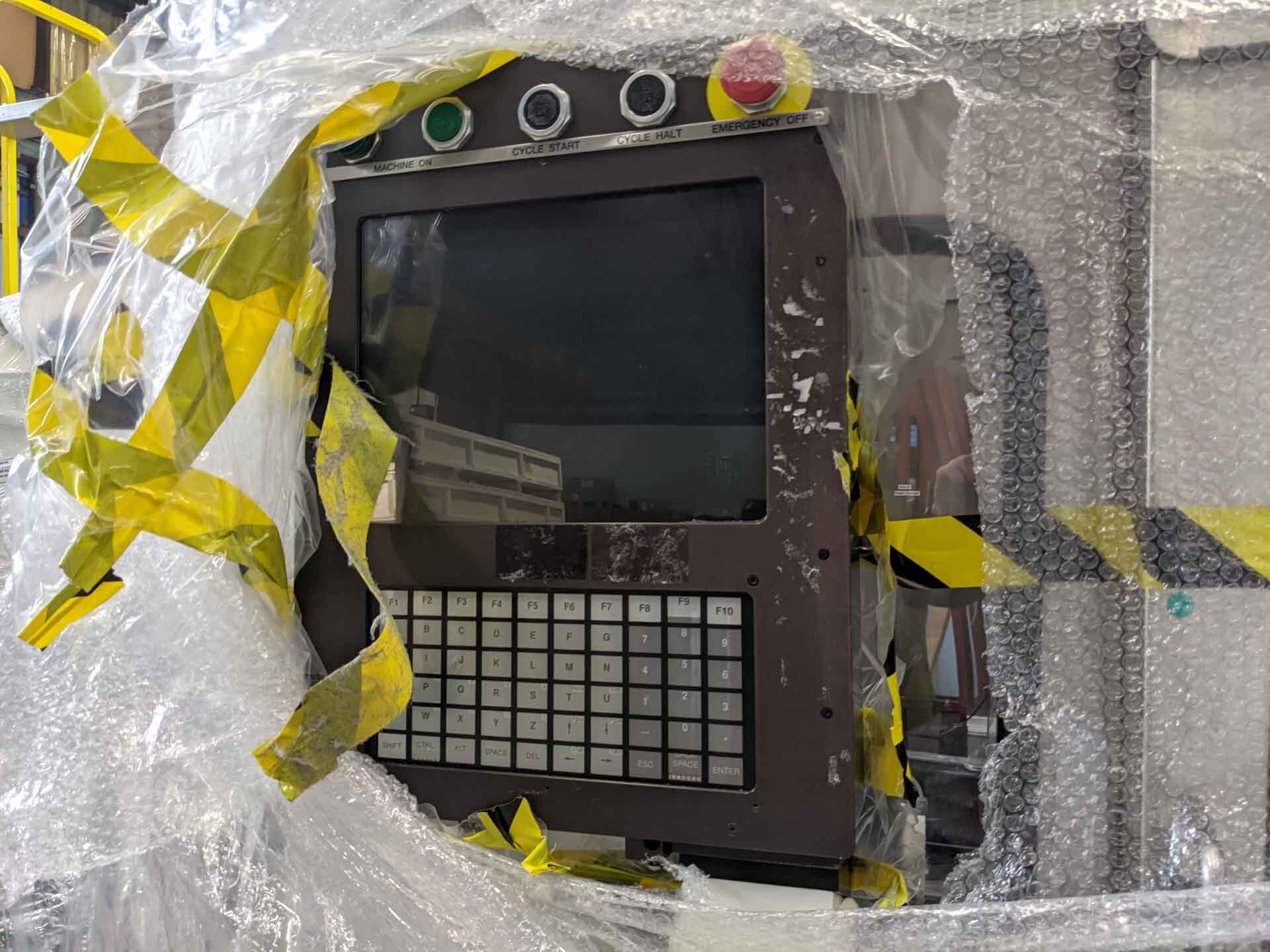

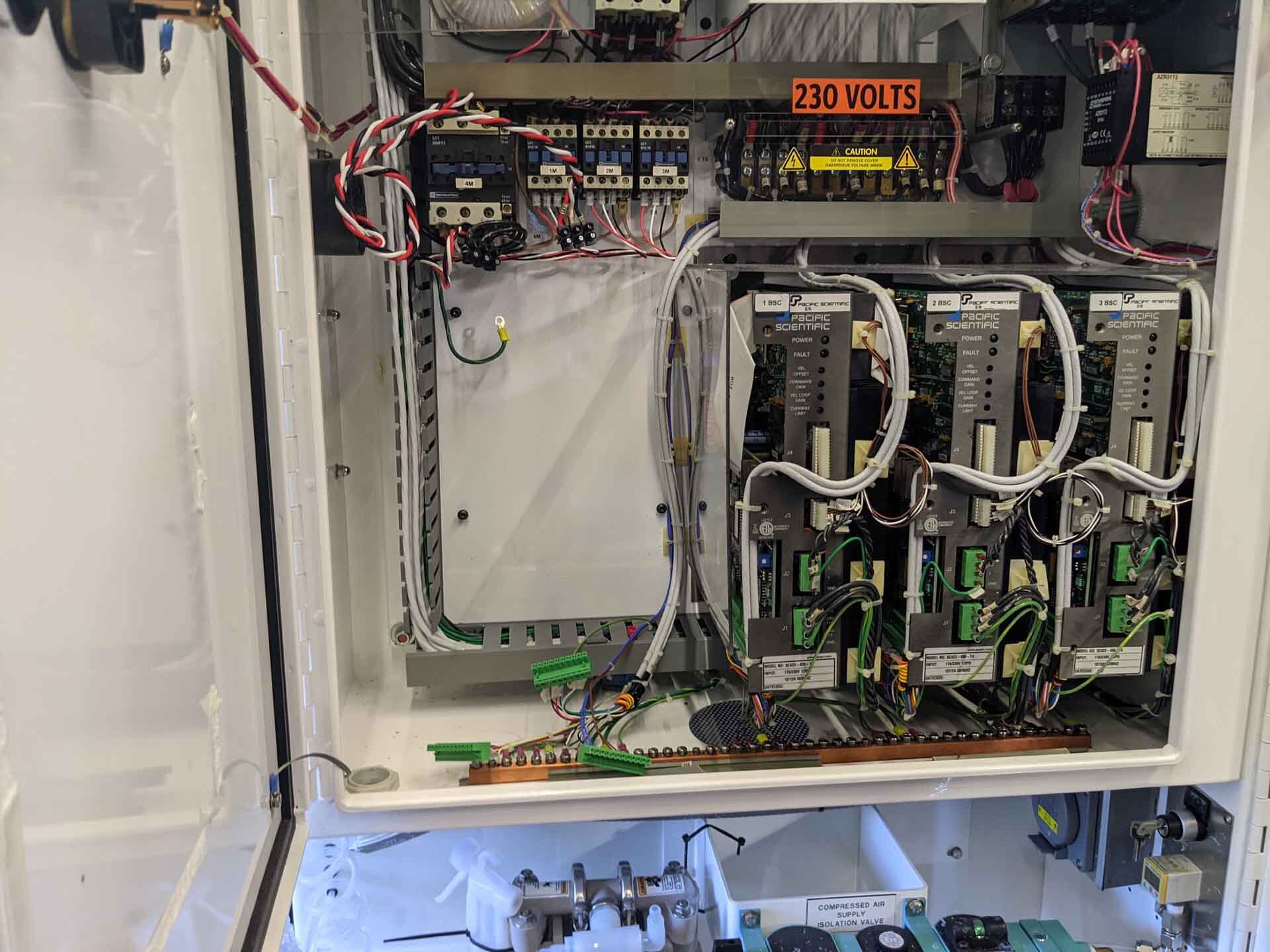

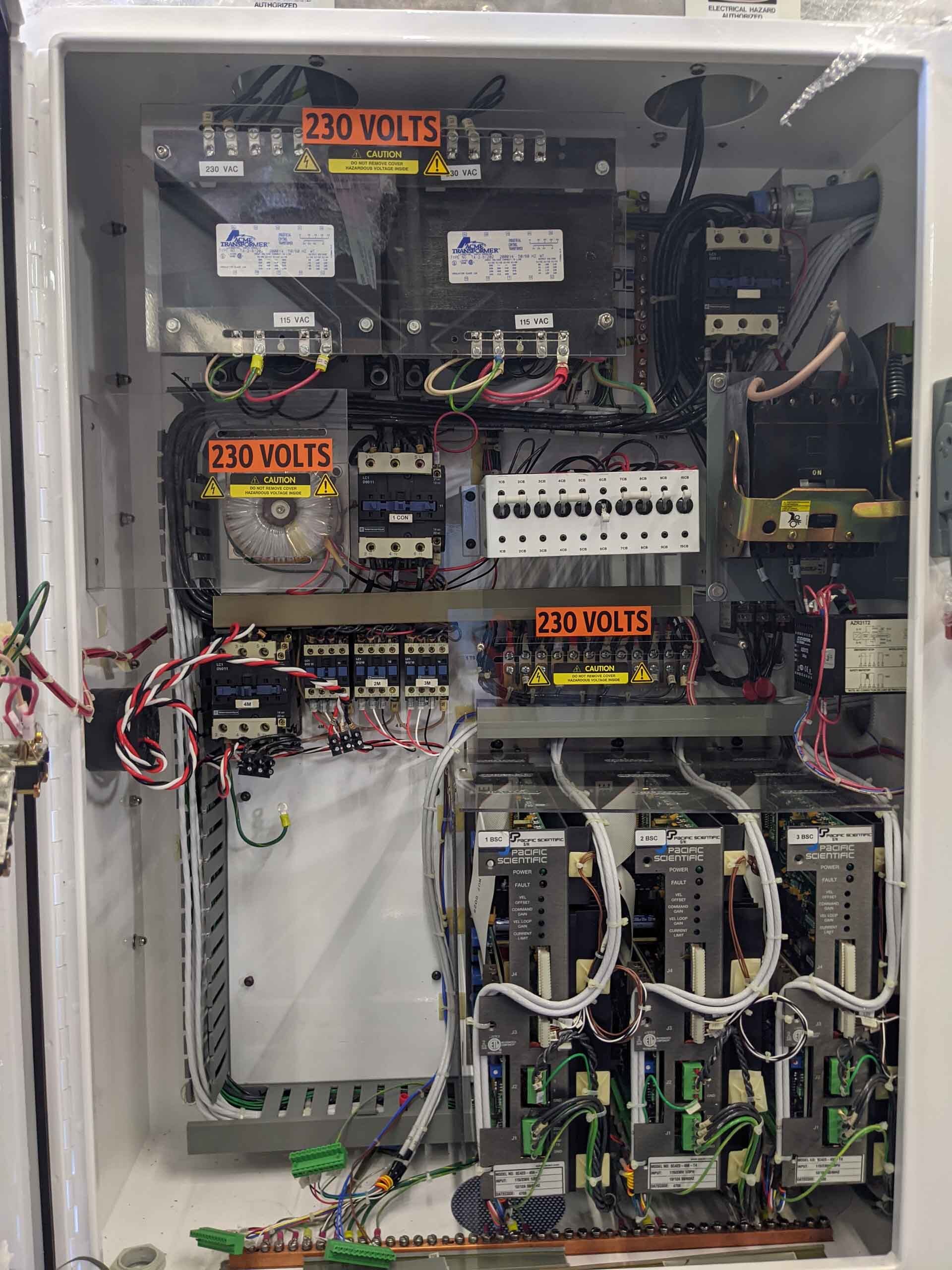

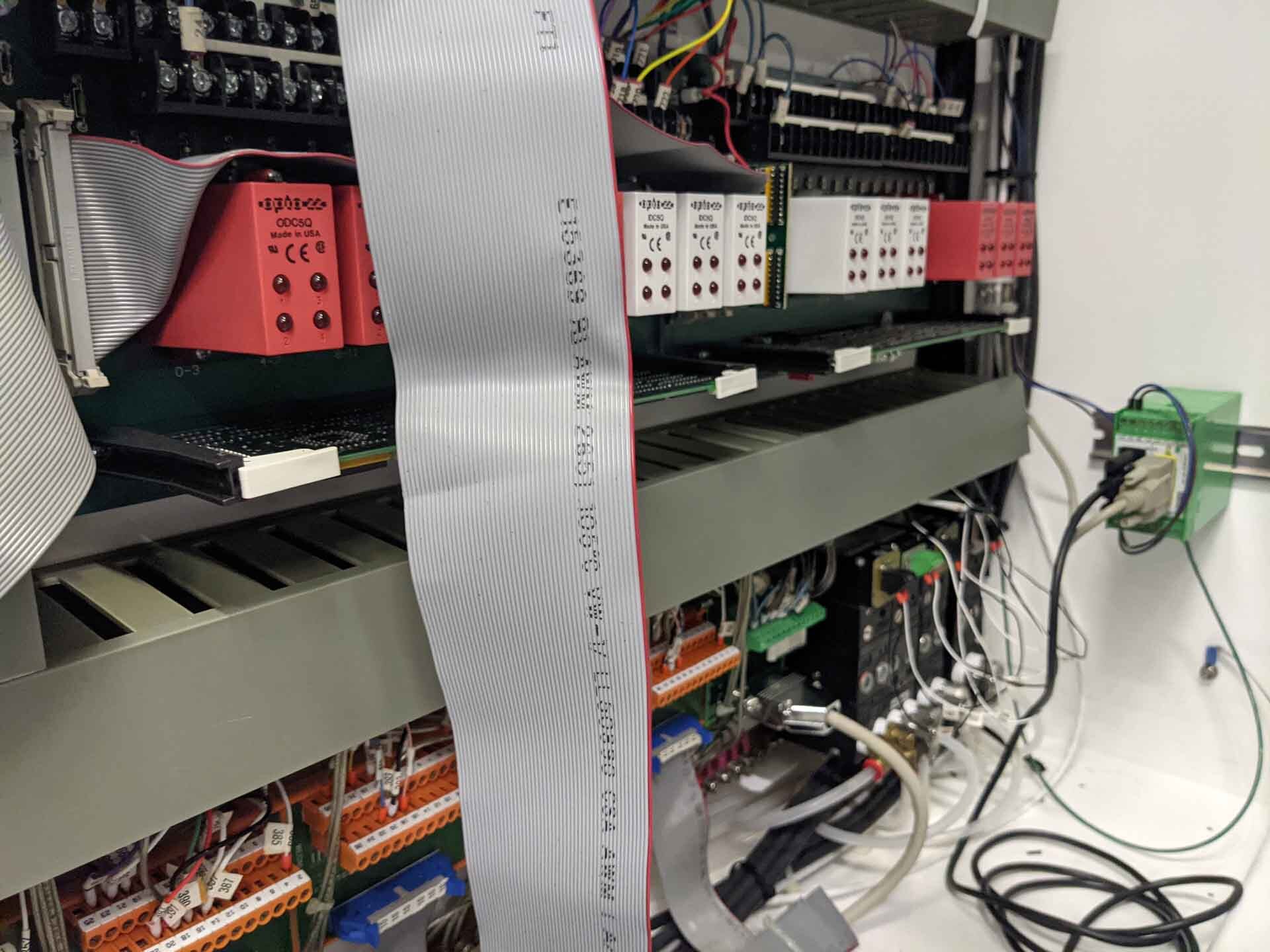

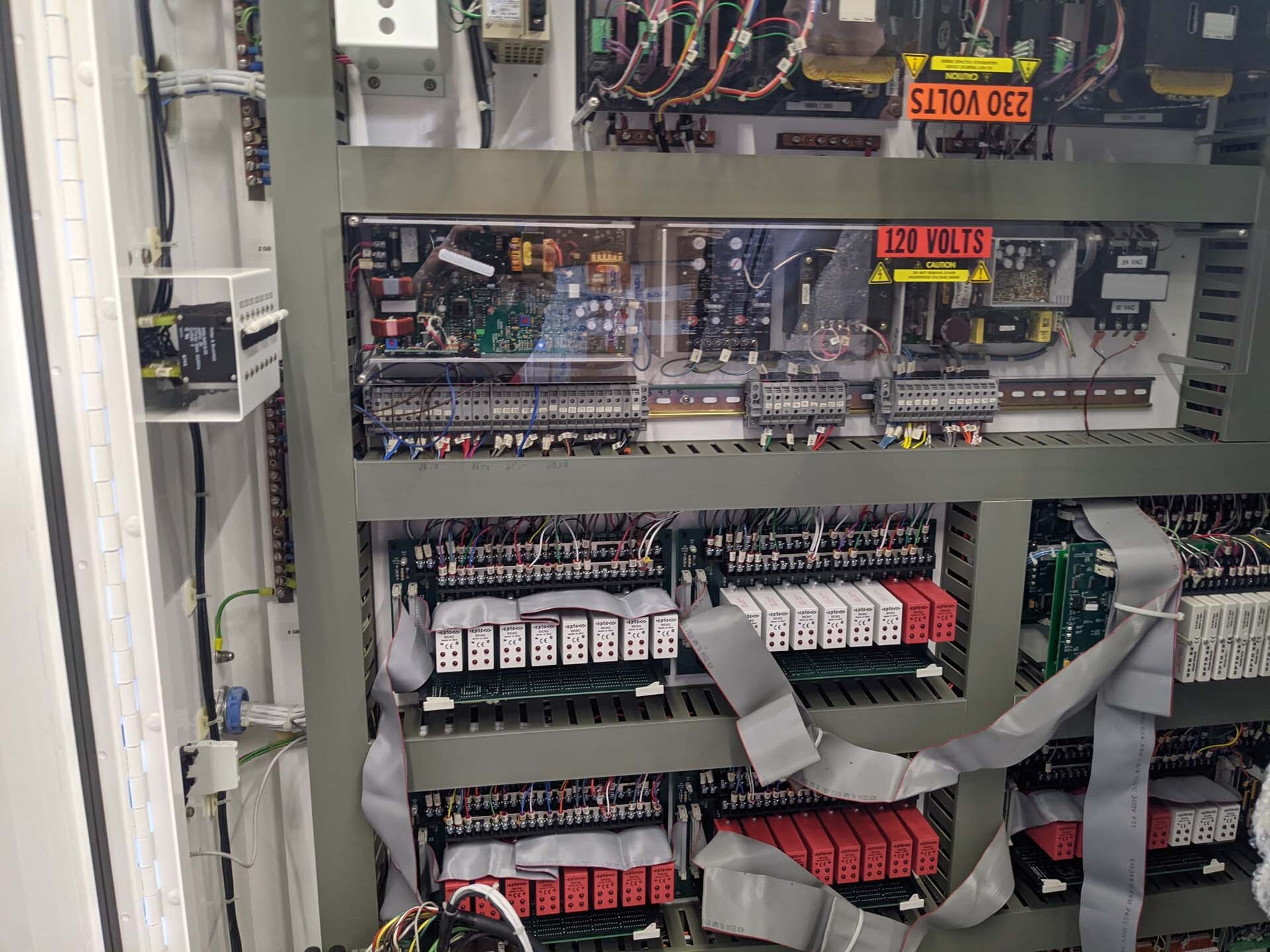

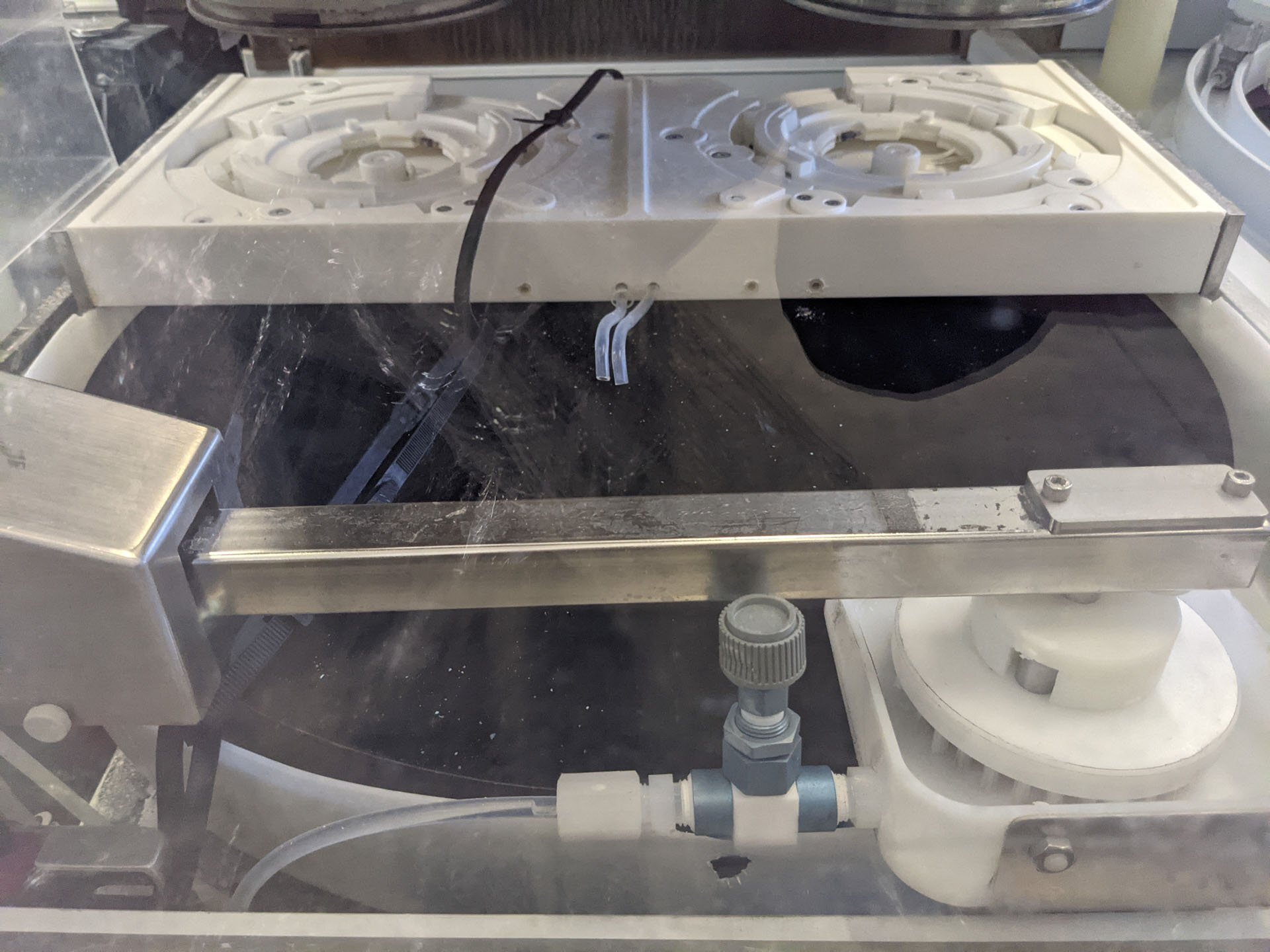

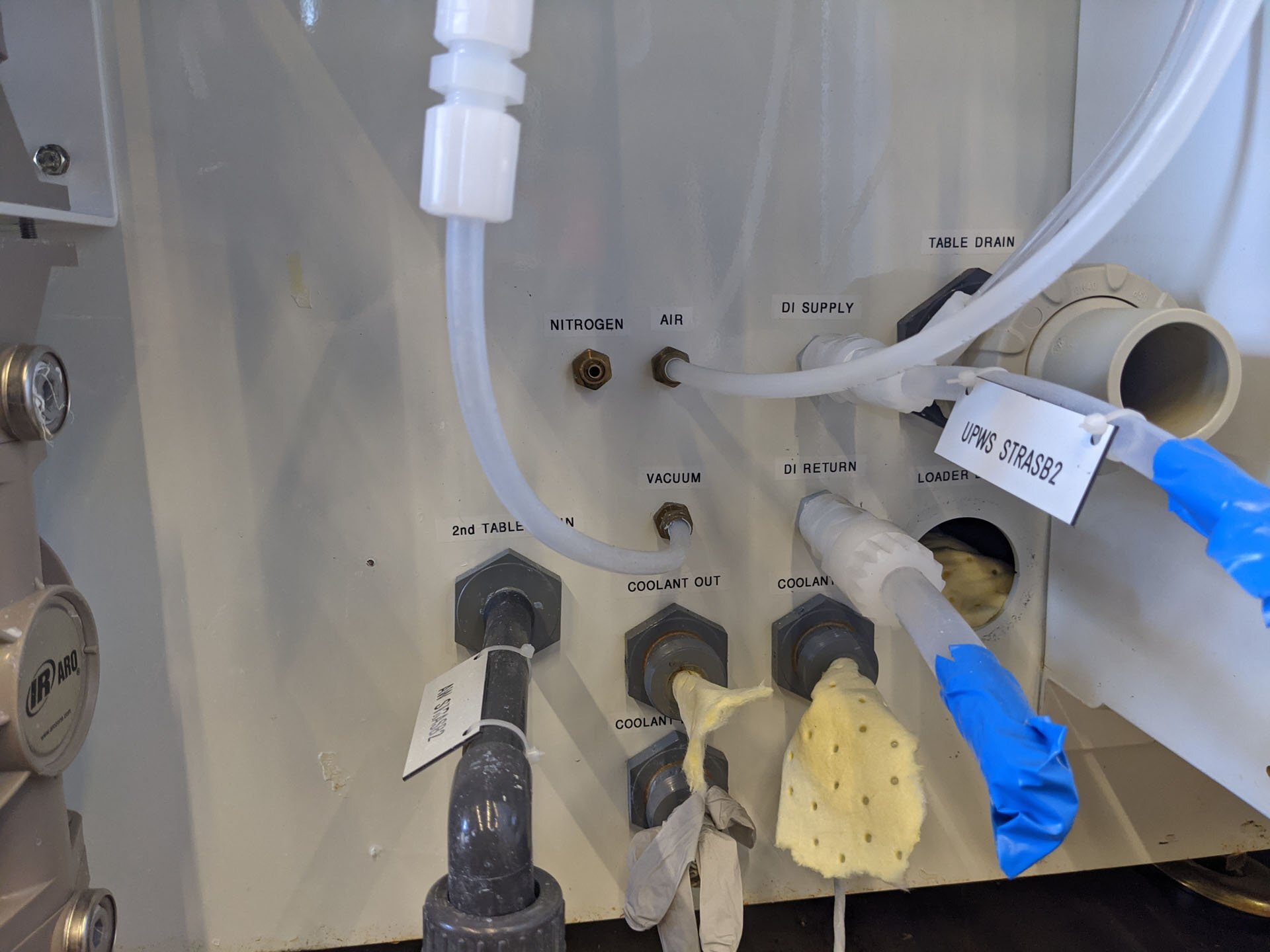

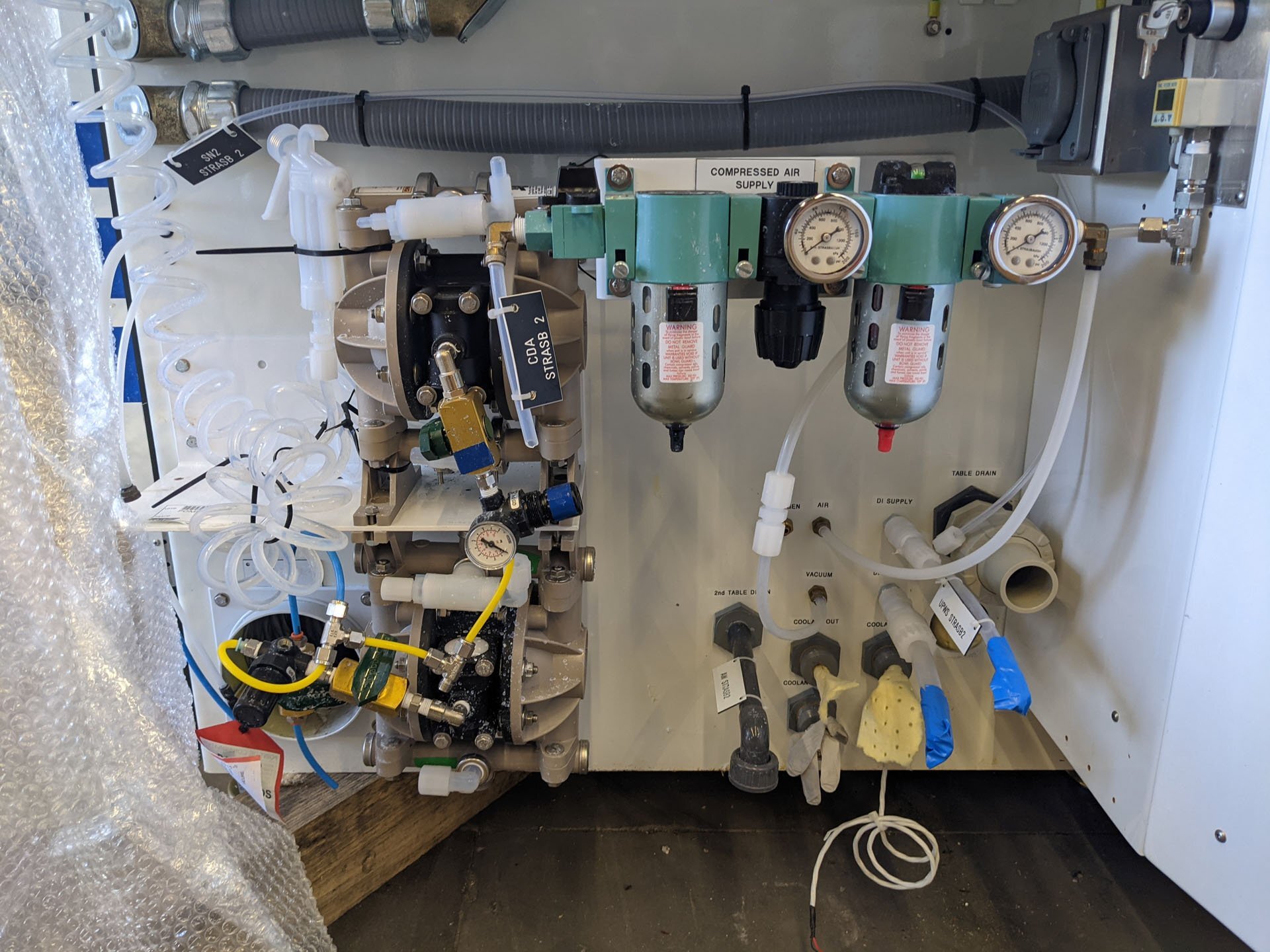

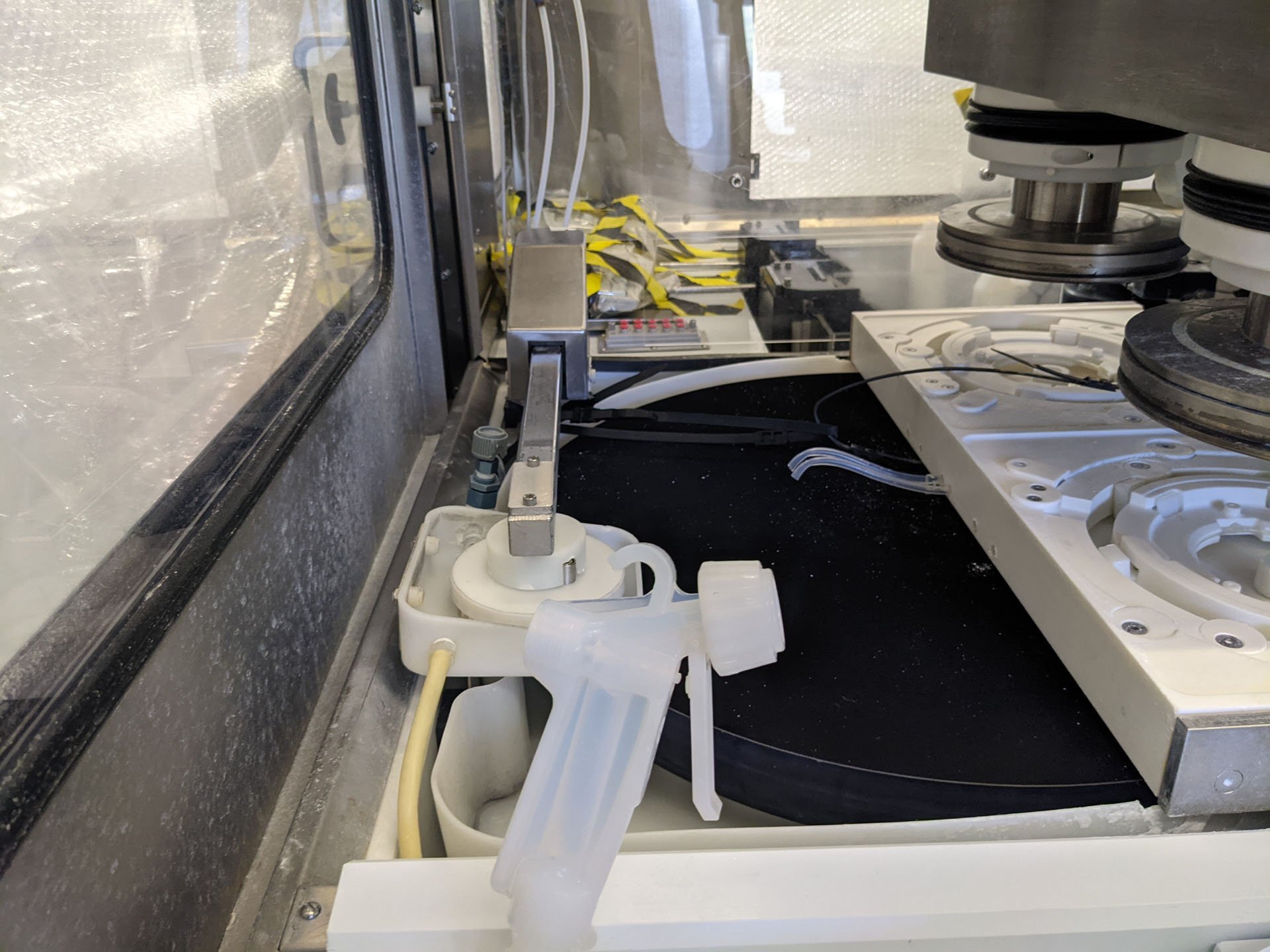

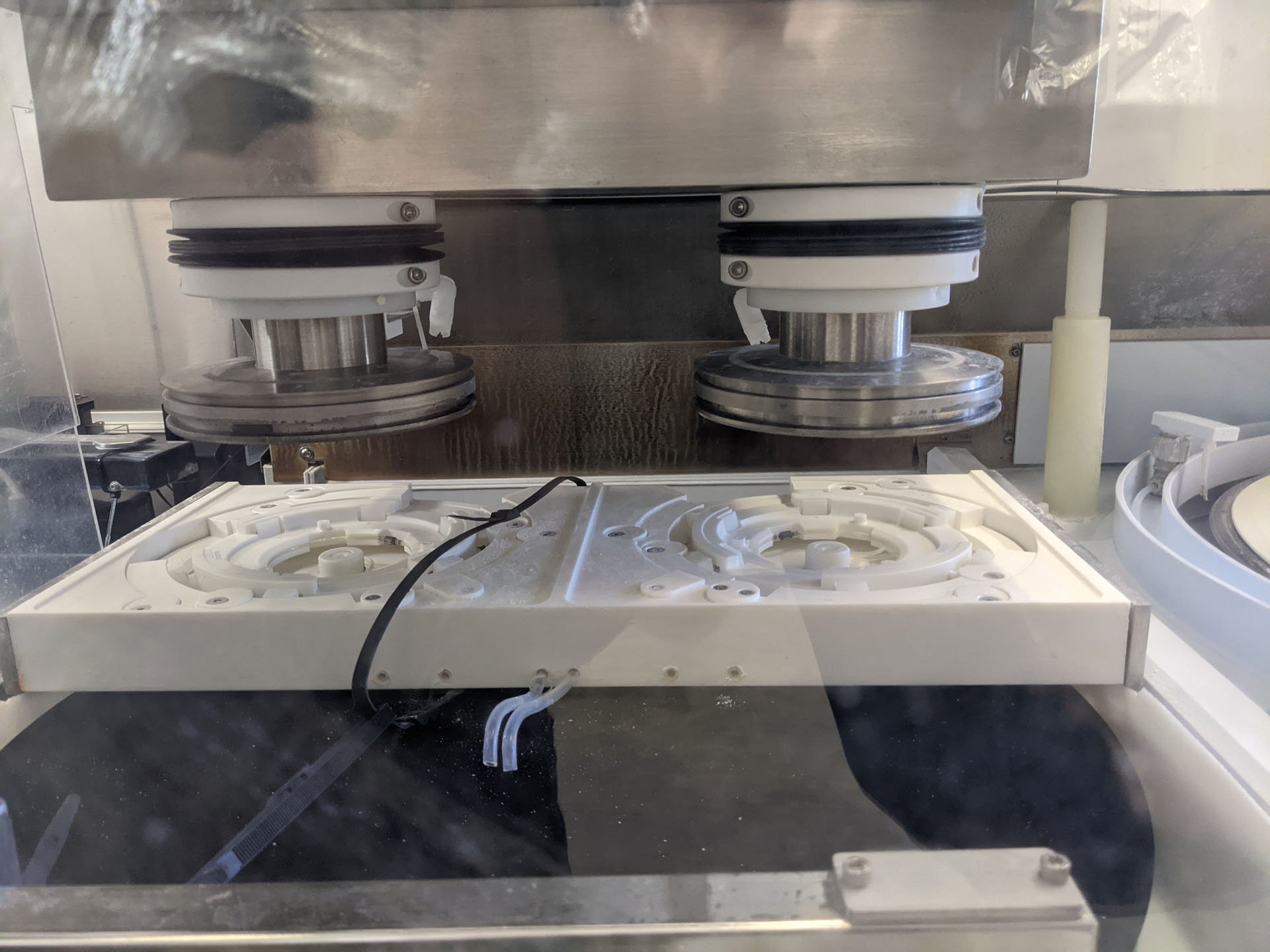

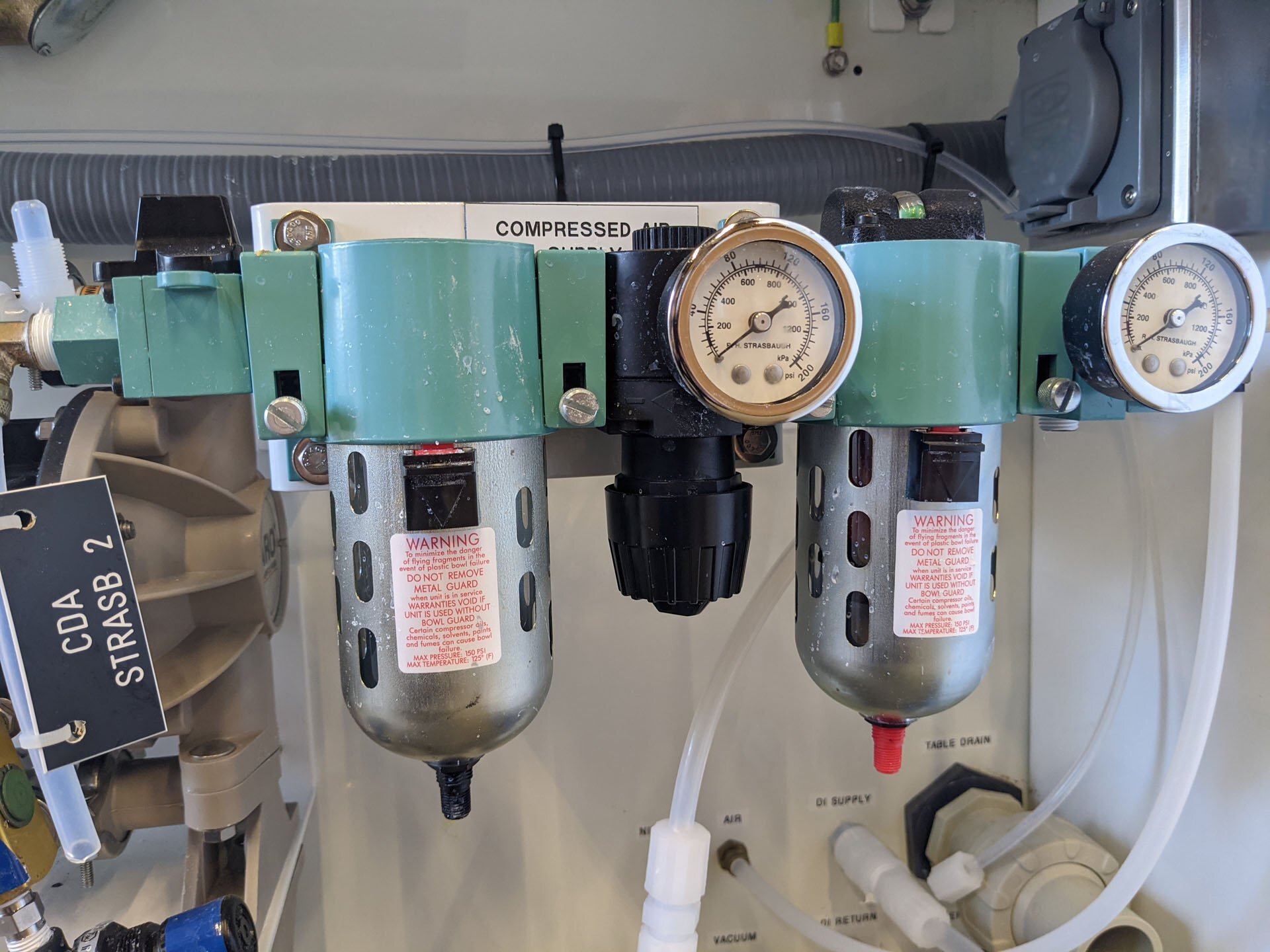

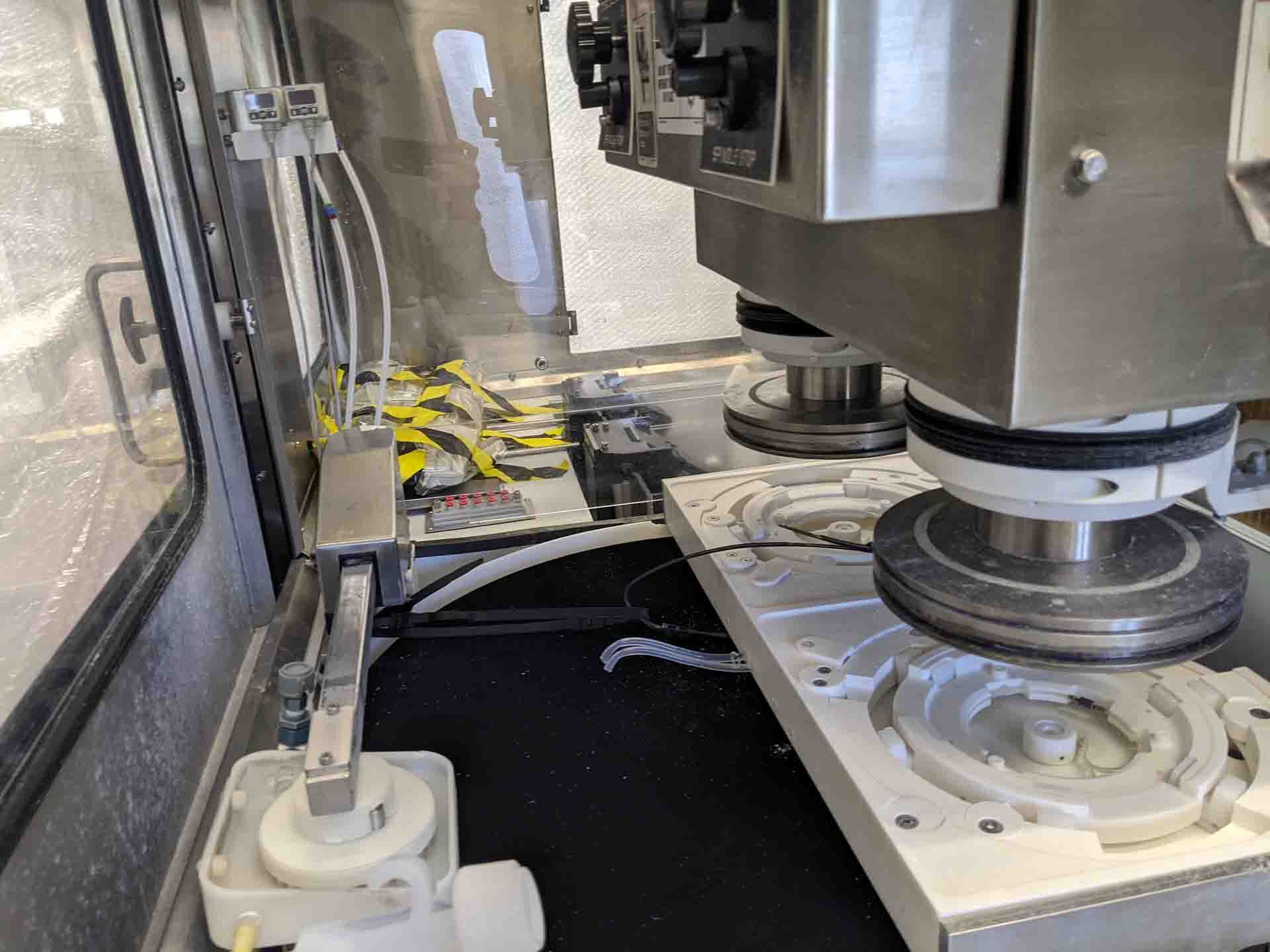

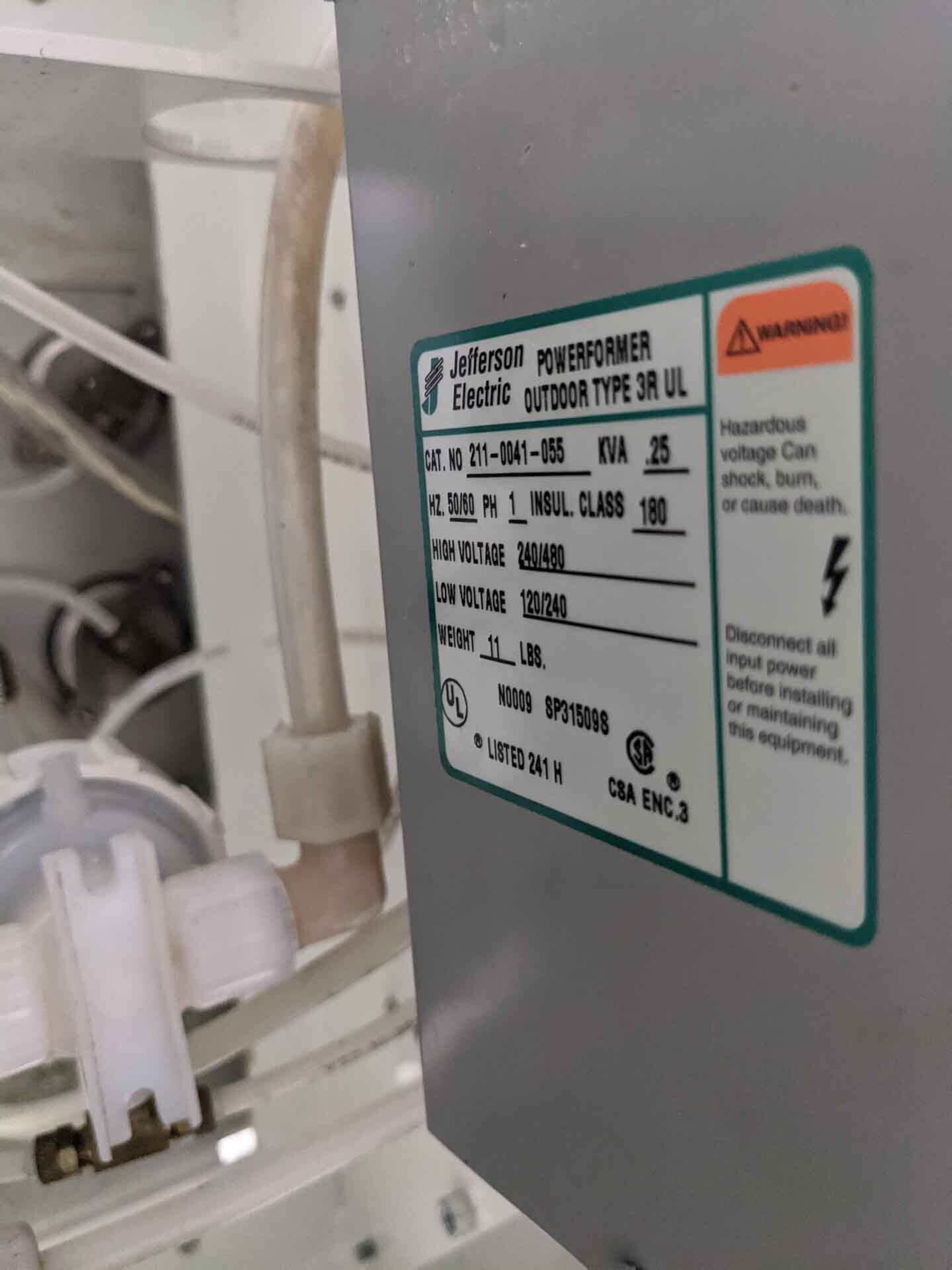

STRASBAUGH 6DS-SP is a multi-functional wafer grinding, lapping and polishing equipment designed for the fabrication of compound semiconductor wafers. This system uses a patented 'Golden Diamond' grinding process to achieve precise and thick uniform layers for optimal polishing performance. The grinding process uses a diamond-impregnated grinding wheel, which is powered by a powerful, yet precise, drive unit. This wheel grinds the top surface of the substrate material in a very controlled manner to form a flat surface. A pneumatic chuck machine holds the substrate and applies a constant force while the grinding wheel is being spun. This ensures that the material is being evenly ground and creates a smooth surface. The lapping and polishing process employs two independent diamond-impregnated lap heads. Each lap head has variable speed and a unique cupping effect enables them to finish the surface to a mirror-like finish. The substrates move back and forth between the two lap heads and are polished in an automated process. This results in a very consistent and polished substrate material. STRASBAUGH 6 DS-SP is equipped with a state-of-the-art technique to precisely control the quality of the finished wafer. A custom-designed visual inspection tool captures and records a high-resolution image of the substrate surface before and after each step to ensure that the best possible polishing performance is achieved. 6DS-SP is an ideal asset for the fabrication of high-end compound semiconductor wafers. It is designed to offer the highest level of performance, precision, and consistency in the fabrication process. The advanced video inspection model ensures that high wafer quality is achieved every time and this equipment is used in several leading-edge semiconductor device manufacturers worldwide.

There are no reviews yet