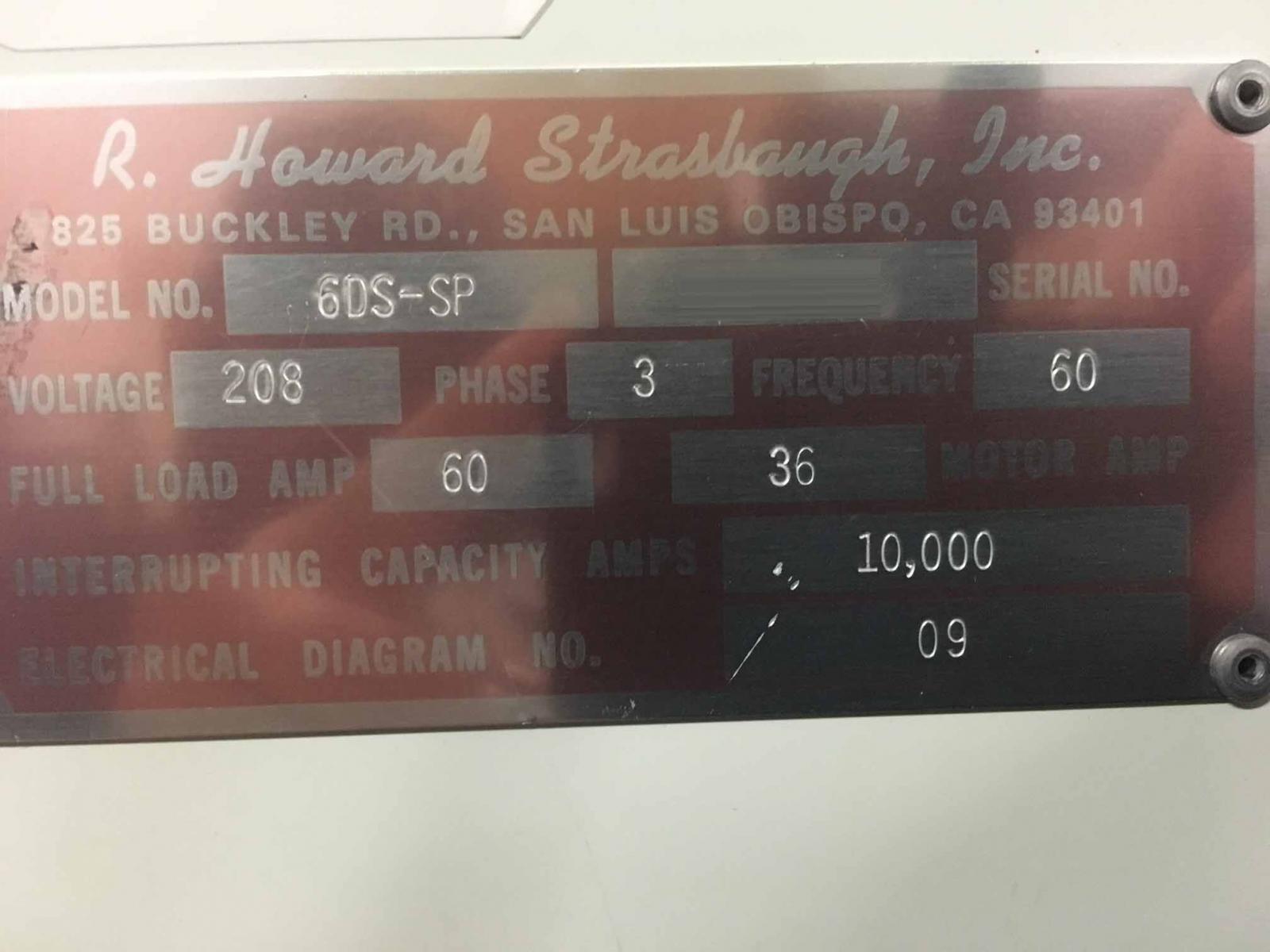

Used STRASBAUGH 6DS-SP #9181741 for sale

URL successfully copied!

Tap to zoom

ID: 9181741

Wafer Size: 8"

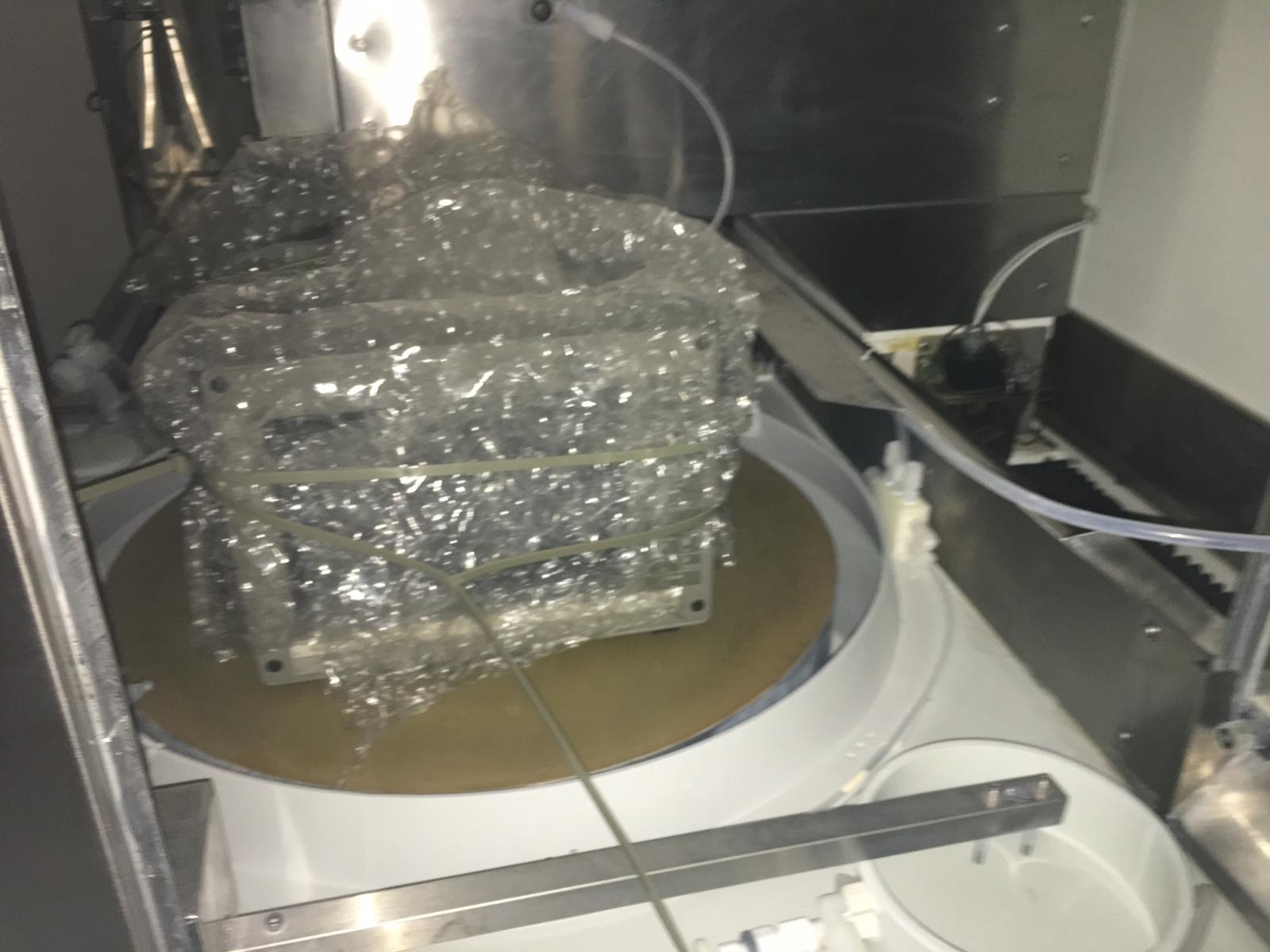

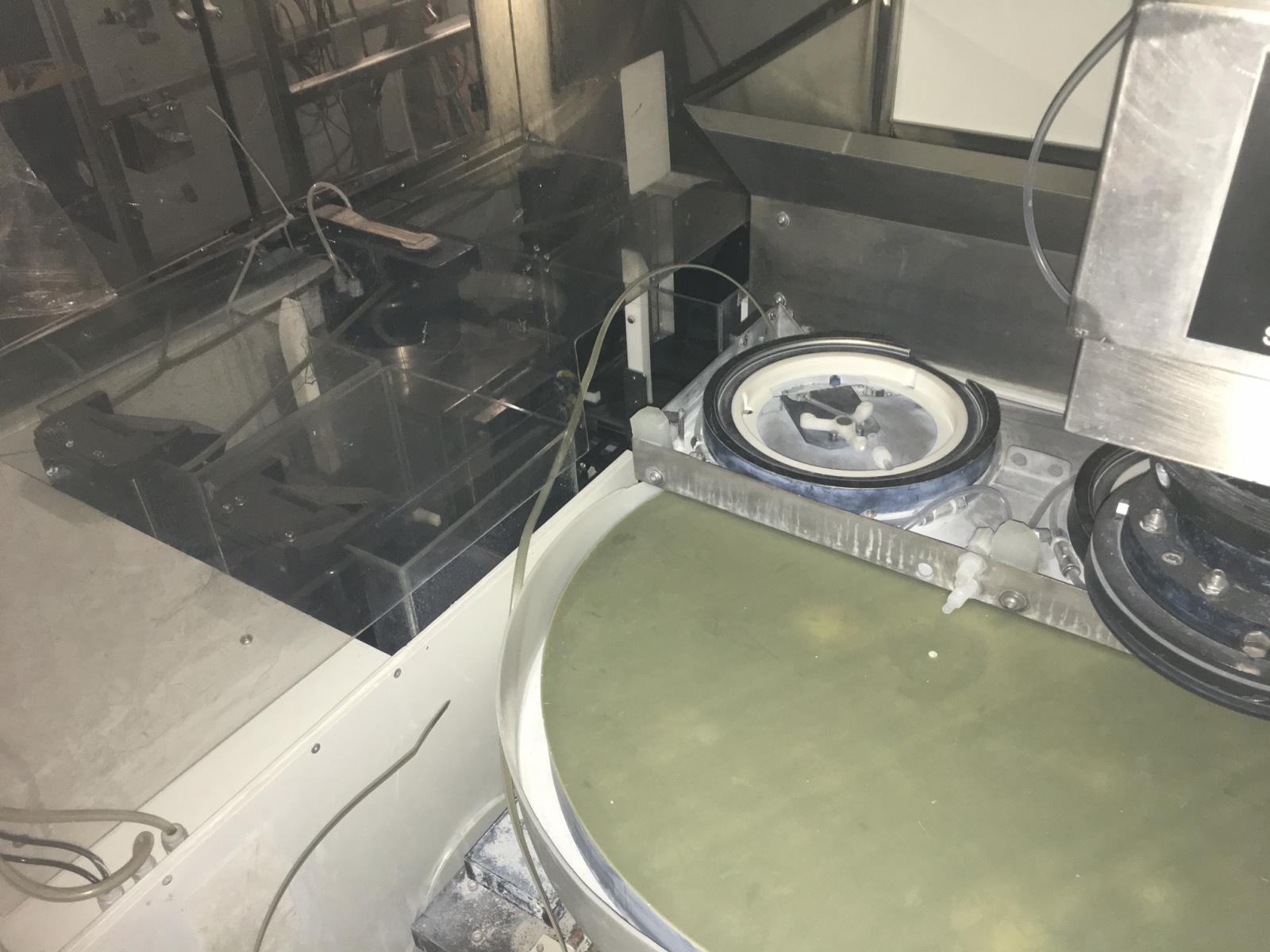

CMP Polisher, 8"

(2) Carriers

Data plate

Aluminum platens and lifters

Spare parts included.

STRASBAUGH 6DS-SP is a fully automated wafer grinding, lapping and polishing equipment offering consistent, cost-efficient processing of a large variety of materials. Designed for maximum throughput within a small footprint, STRASBAUGH 6 DS-SP utilizes robust components, precise computer guidance and advanced process control algorithms to achieve throughput rates of up to 15 wafer per hour. The system is well-suited for applications ranging from laser processing of MEMS materials, semiconductor and solar cells, and optoelectronic components. 6DS-SP includes a manual load station that is integrated with an optional automated wafer mapping scanner for achieving optimal sub-surface uniformity and high-precision measurements down to 0.1 micron. The controlling software is based on the latest generation of high-performance FEI™ (Focused Electrostatics Instruments) technology that is capable of managing the shape, size, and geometry of the wafer as well as the applied polishing process parameters as required. The unit also features a six-axis forced vibration platform that enables small scale processing with reduced thermal gradients. This platform is controlled by an intuitive, user-friendly interface and is capable of motion control to as small as 2 arc-seconds in all axes with the capability of Lap-on-Diamond polishing. 6 DS-SP is also equipped with two-dimensional in-process CCD camera machine for real-time surface and sub-surface material evaluation. This provides real-time data for feedback into the controlling subsystem. This easy-to-operate tool is equipped with a variety of safety features, such as emergency stop buttons, splash-out alarms, and quick-release components for effortless modification of parameters. Additionally, STRASBAUGH 6DS-SP utilizes secure components and is compliant with CE (Conformite Europeenne) safety standards. It also includes software-based automatic process control and monitor functions for improved accuracy and repeatability of the wafer coating process. Overall, STRASBAUGH 6 DS-SP is a robust, high-precision wafer grinding, lapping and polishing asset that offers reliable, cost-effective processing of a multitude of substrates. Through the combination of its advanced process control algorithms, ease of operation, safety features, and support for the latest generation of FEI technology, 6DS-SP is ideally suited for a variety of micro-fabrication applications.

There are no reviews yet