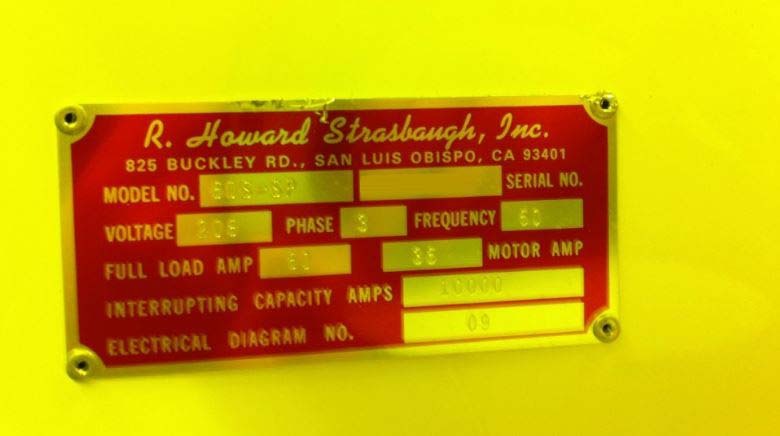

Used STRASBAUGH 6DS-SP #9186494 for sale

URL successfully copied!

Tap to zoom

STRASBAUGH 6DS-SP is a wafer grinding, lapping, and polishing equipment for the production of semiconductor wafers. It is capable of producing wafers to the specified thickness, flatness, surface finish, and other characteristics required for manufacturing high-performance integrated circuits. The core of the system is a multi-axis digital servo-driven unit that is used to accurately and precisely rotate the wafer and control its motion. This machine is integrated with a series of automated tool changers, loading fixtures, and other devices for automatic operation and control. STRASBAUGH 6 DS-SP is a single-side polisher and utilizes a unique combination of diamond grinding and lapping processes. The grinding process involves the removal of surface layers in order to reduce the wafer's thickness and produce flat surfaces. The lapping process polishes the surface of the wafer in order to obtain the specified levels of surface finish. The tool is designed with high-precision components and is capable of producing wafers with production rate up to 5-inch per hour and thickness range from 0.01μ to 0.5μ. It also features a vacuum chucking asset that ensures a strong and secure hold on the wafer when being processed. The model is equipped with a variety of safety systems, including a light curtain interface, a safety interlock for the grinding disk, and a motion control equipment that stops the machinery in case of emergency. It also features a digital readout and a graphical user interface display for easy operation. 6DS-SP is an invaluable tool for manufacturers looking for a high-speed and high-accuracy wafer grinding, lapping, and polishing system. Its unique combination of grinding and polishing steps ensures that the end-product meets all of the requirements for a high-quality integrated circuit.

There are no reviews yet