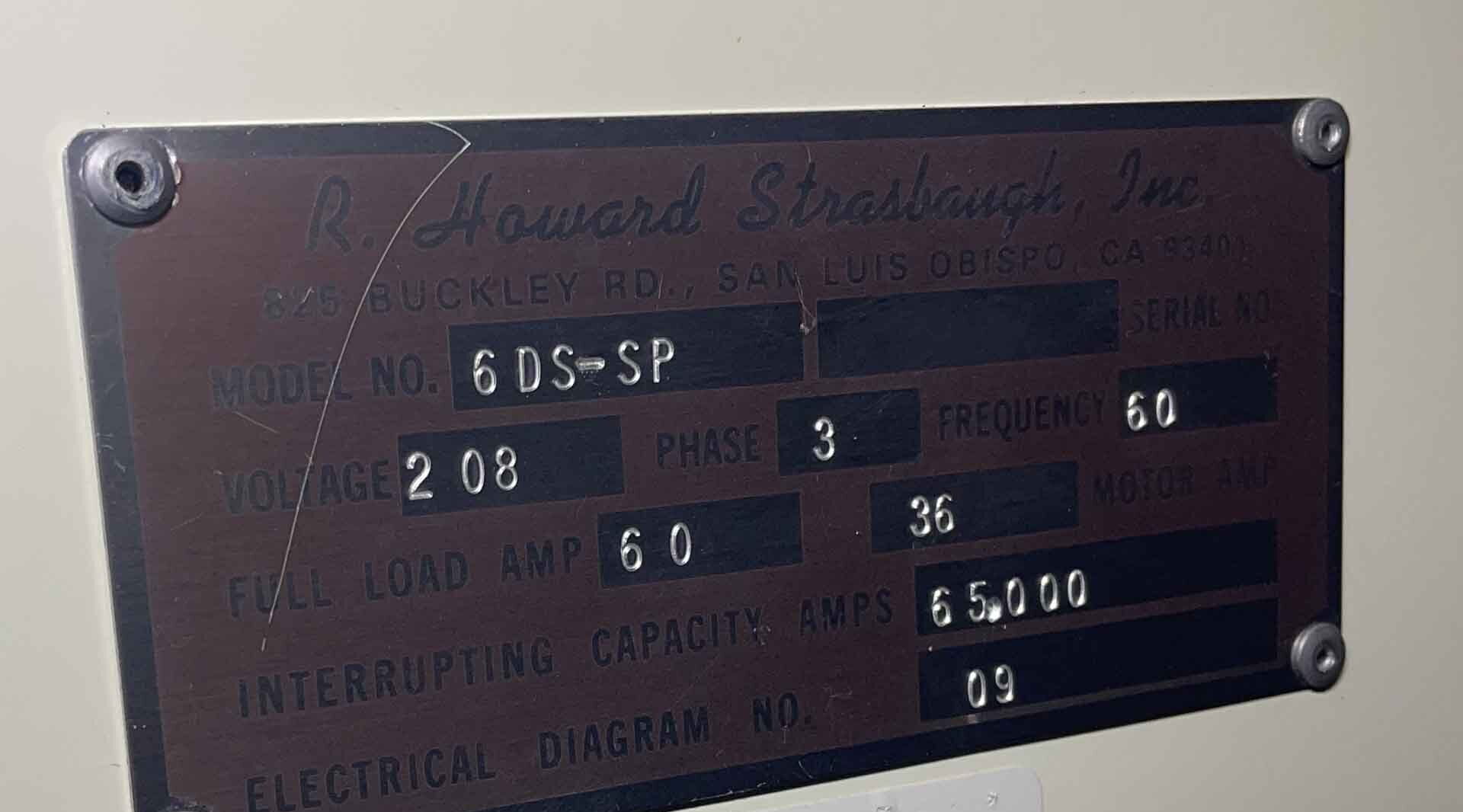

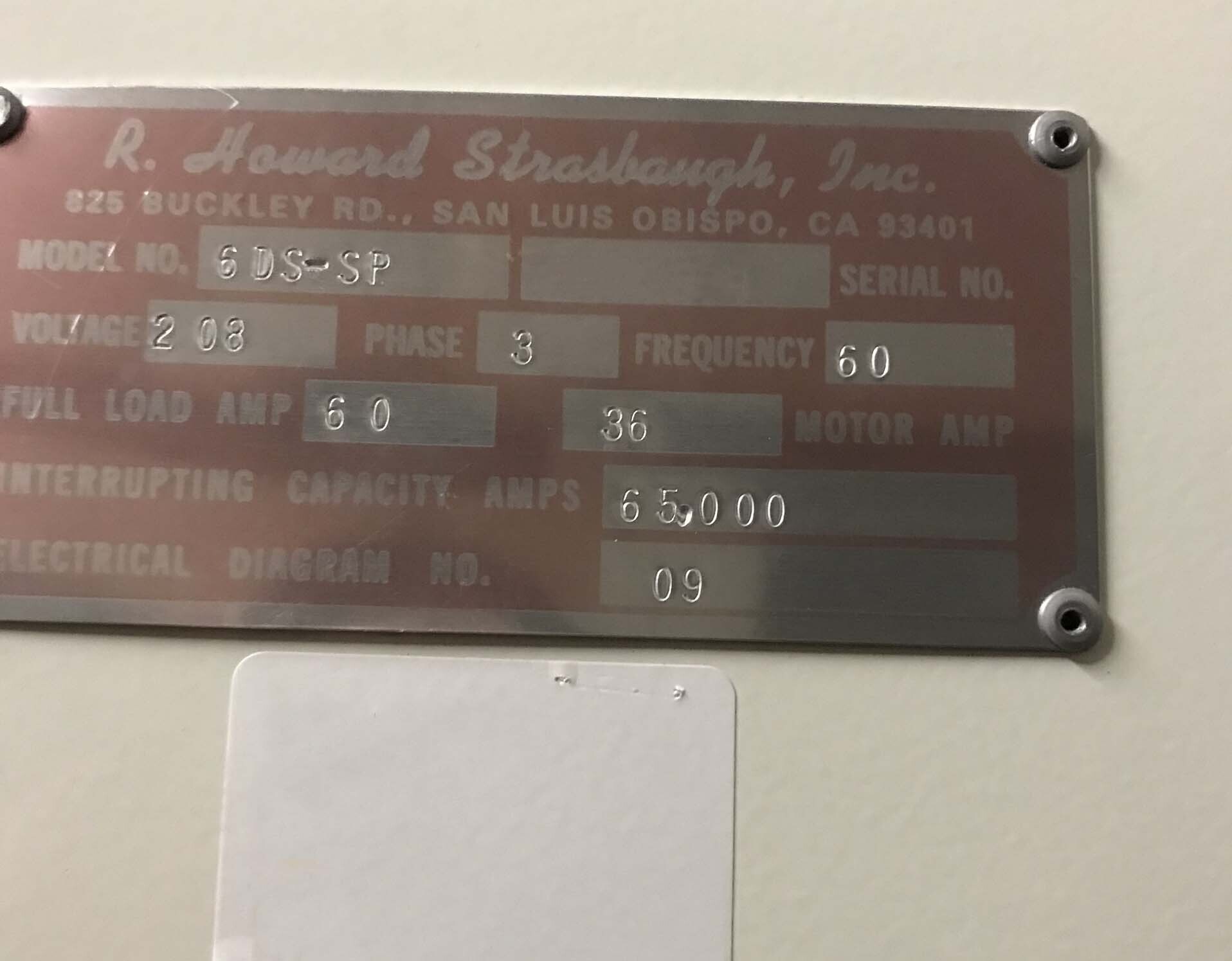

Used STRASBAUGH 6DS-SP #9314026 for sale

URL successfully copied!

Tap to zoom

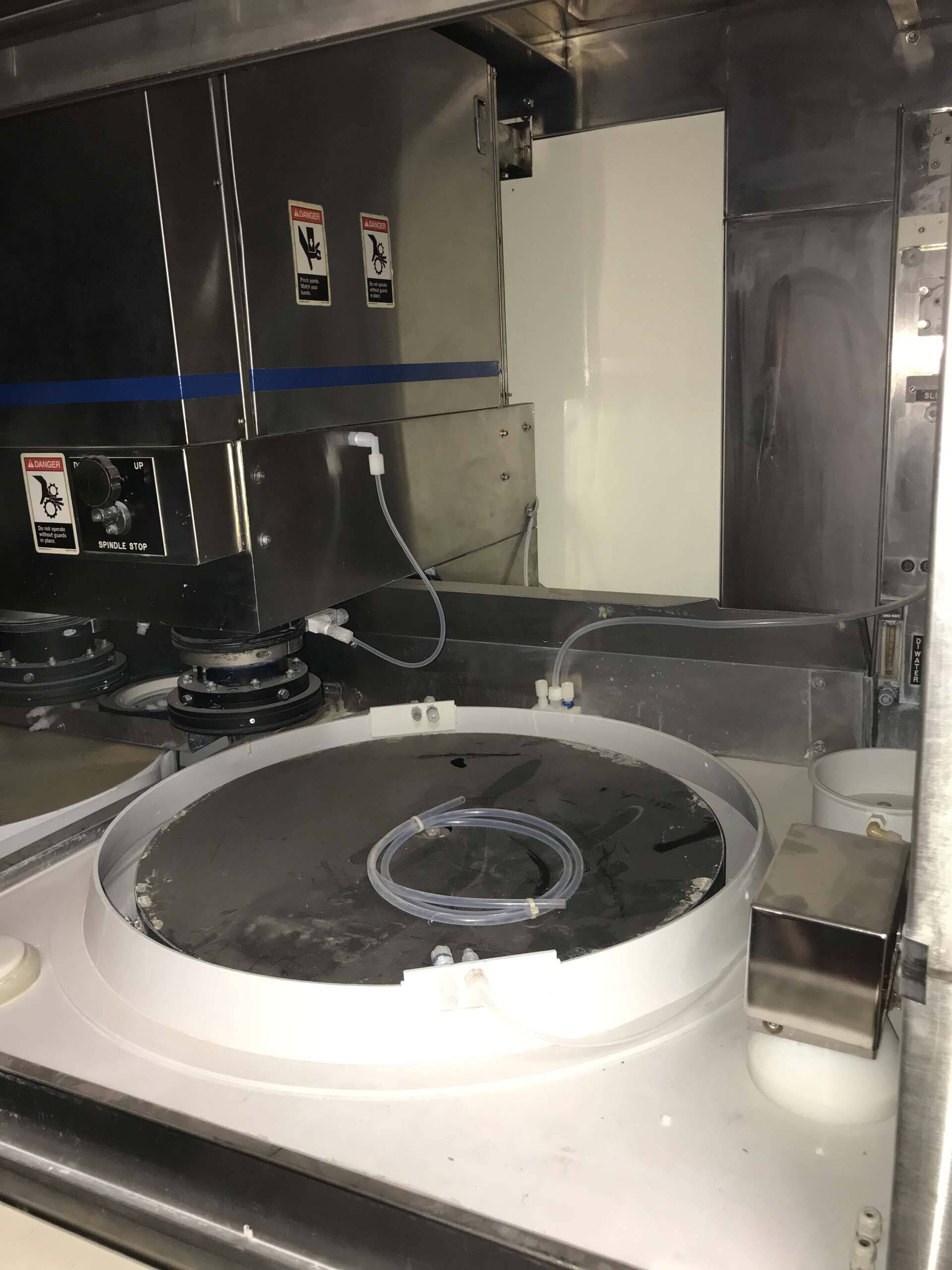

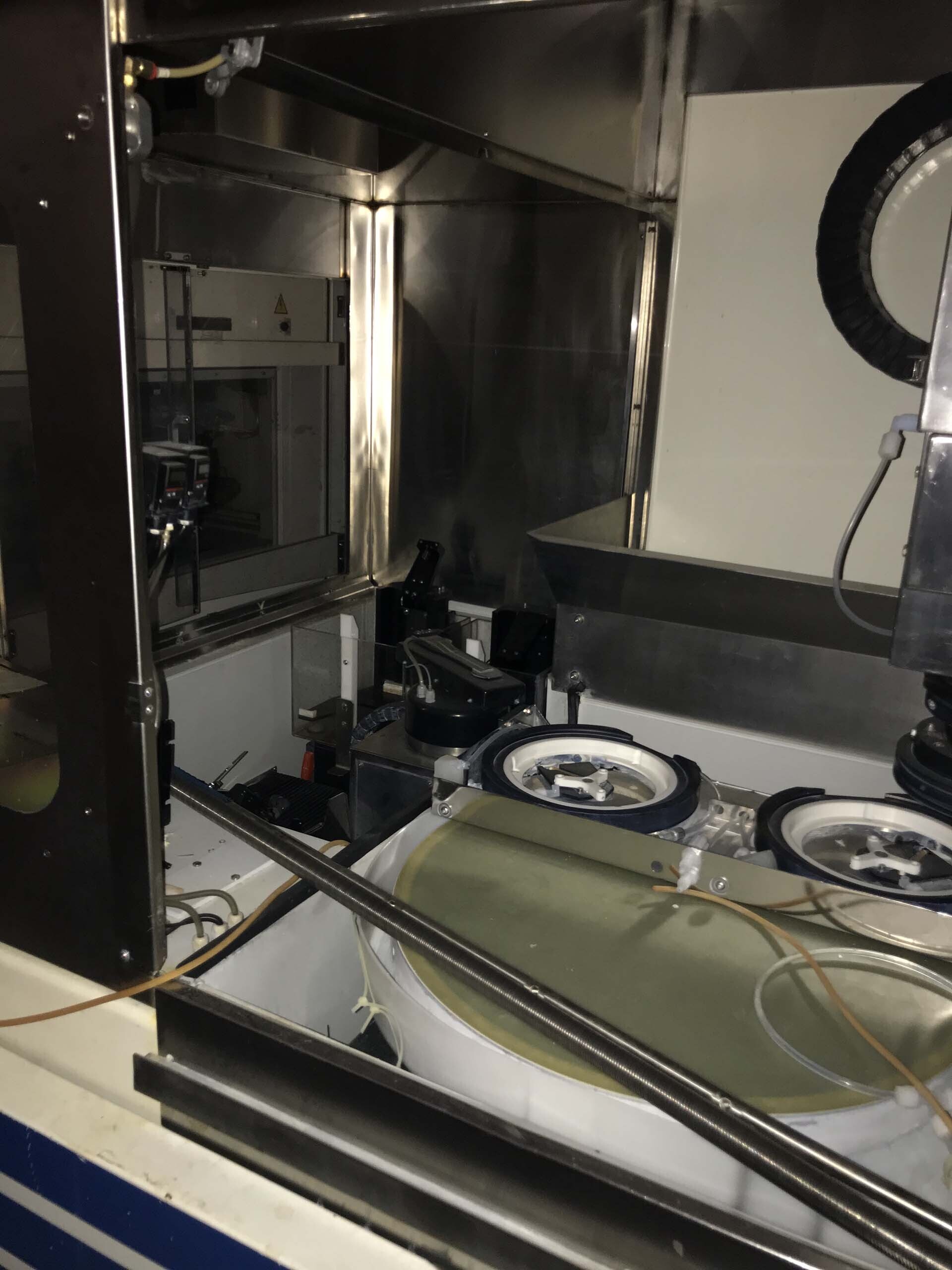

STRASBAUGH 6DS-SP wafer grinding, lapping & polishing equipment is a four-stage, fully automated, continuous-flow system designed to rapidly produce the highest quality optical components. It is a technological marvel of process engineering and automation, blending cutting-edge design with state of the art technologies to produce the best possible lapped, polished, and finished components. STRASBAUGH 6 DS-SP's grinding stages are designed to allow for efficient manufacturing of high-performance optics. The unit optimizes efficiency by allowing different facets of the grinding process to be performed in each of the four stages, ranging from stock removal, detailed surface profiling, fine grinding, lapping, and polishing. The first stage is the stock removal stage, which is used to quickly remove the primary shape of the material. This stage is able to achieve tight tolerances and exceptionally smooth surfaces. The second stage is the surface profiling stage. This stage utilizes diamond impregnated brushing wheels to refine the surface and create intricate detailing. The third stage is the fine grinding stage. This stage utilizes diamond grinding plates and provides excellent control and low surface roughness values. The fourth and final stage is the polishing stage. This stage uses a combination of diamond and a compliant media to achieve extremely tight surface tolerances and the highest levels of surface finish. 6DS-SP wafer grinding, lapping & polishing machine is an absolute powerhouse of a tool thanks to its systematic approach to the process. It is designed to ensure that every component it generates is of the highest quality, with superior surface finish, and precise control of the final specification. With its impressive array of features, it is the ideal choice for any optics manufacturing process.

There are no reviews yet