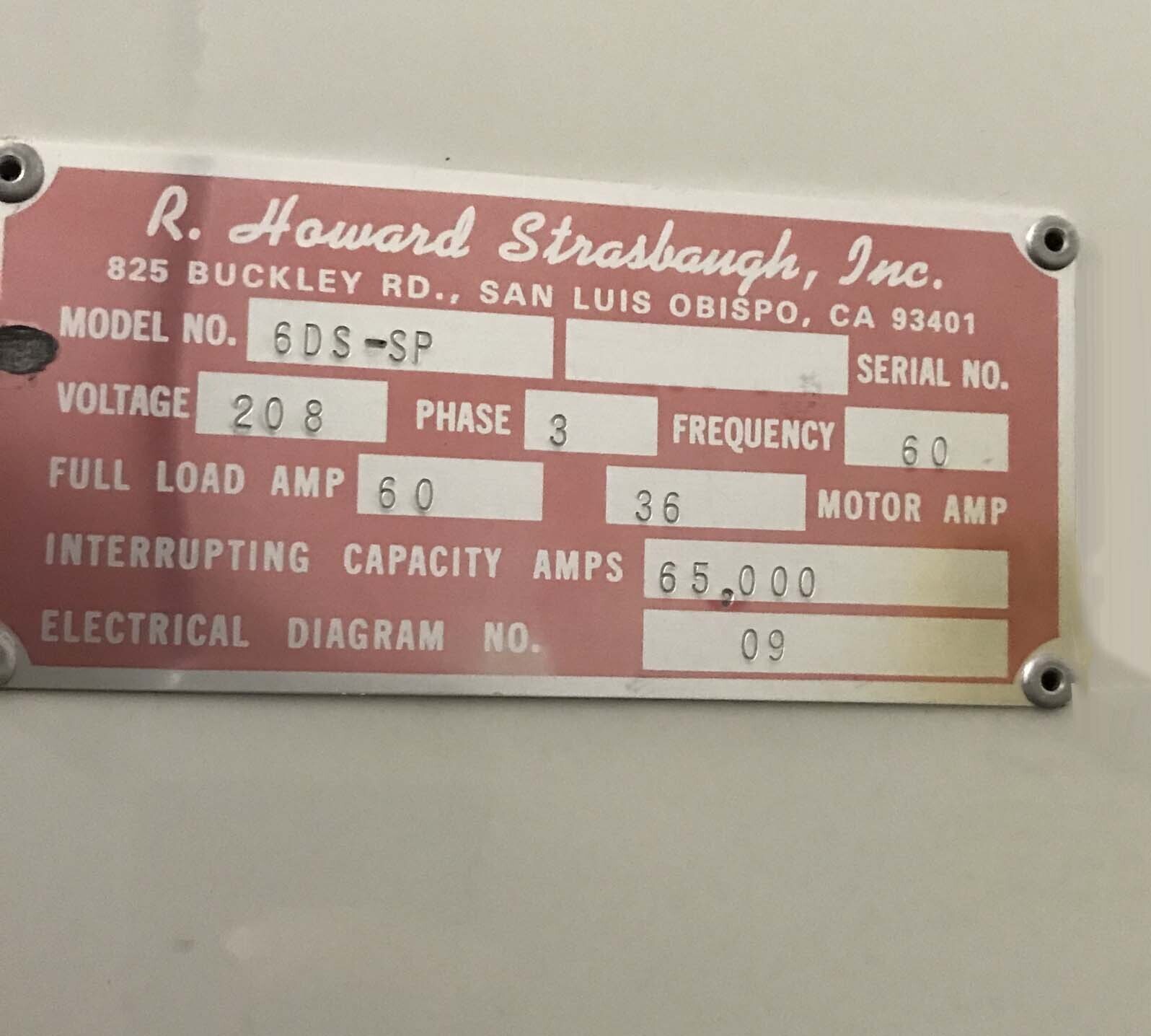

Used STRASBAUGH 6DS-SP #9314673 for sale

URL successfully copied!

Tap to zoom

STRASBAUGH 6DS-SP is a wafer grinding, lapping and polishing equipment designed for semiconductor production applications. STRASBAUGH 6 DS-SP consists of two separate work zones, each of which can process multiple wafers at once. The first zone performs grinding and lapping operations, while the second zone provides precise polishing. 6DS-SP system is designed to produce high-polish finishes on various substrates, including multiple wafer sizes. 6 DS-SP includes a two-zone work platform, a rotor lapping unit, a Rhodius polishing machine, a polishing bed, a swivel head, a manipulator arm, and a water jet brush capacity. The two-zone work platform provides a safe and ergonomic work environment for substrate processing. The rotor lapping tool works to remove substrate bulk by using abrasive lapping pads as well as various lapping and polishing processes to achieve a high-quality mirror-like finish. The Rhodius polishing asset is designed to further enhance the substrate surface finish via a diamond powder and slurry. The polishing bed provides a flat, horizontal surface for easy handling of the substrate. It is also built for fast removal and insertion of substrates. The swivel head allows for efficient wafer processing by enabling quick angular adjustments as well as precise rotational motions for cleaning and polishing. The manipulator arm ensures precise substrate handling, which allows for the accurate alignment of substrates for optimal process efficiency. The water jet brush capability provides a reliable cleaning solution for contaminant removal. STRASBAUGH 6DS-SP model is designed to efficiently process multiple wafers, enabling high throughput. STRASBAUGH 6 DS-SP offers both semi-automatic and manual controls to provide control over substrate processing. The equipment is also designed with a number of safety features, such as safety interlocks, to protect both the operators and the substrates. Overall, 6DS-SP is an advanced wafer grinding, lapping and polishing system designed for semiconductor production applications. It offers several features for efficient substrate processing, and its safety features ensure a safe working environment. By utilizing a variety of processes, 6 DS-SP allows highly polished surfaces to be produced on a variety of substrates.

There are no reviews yet