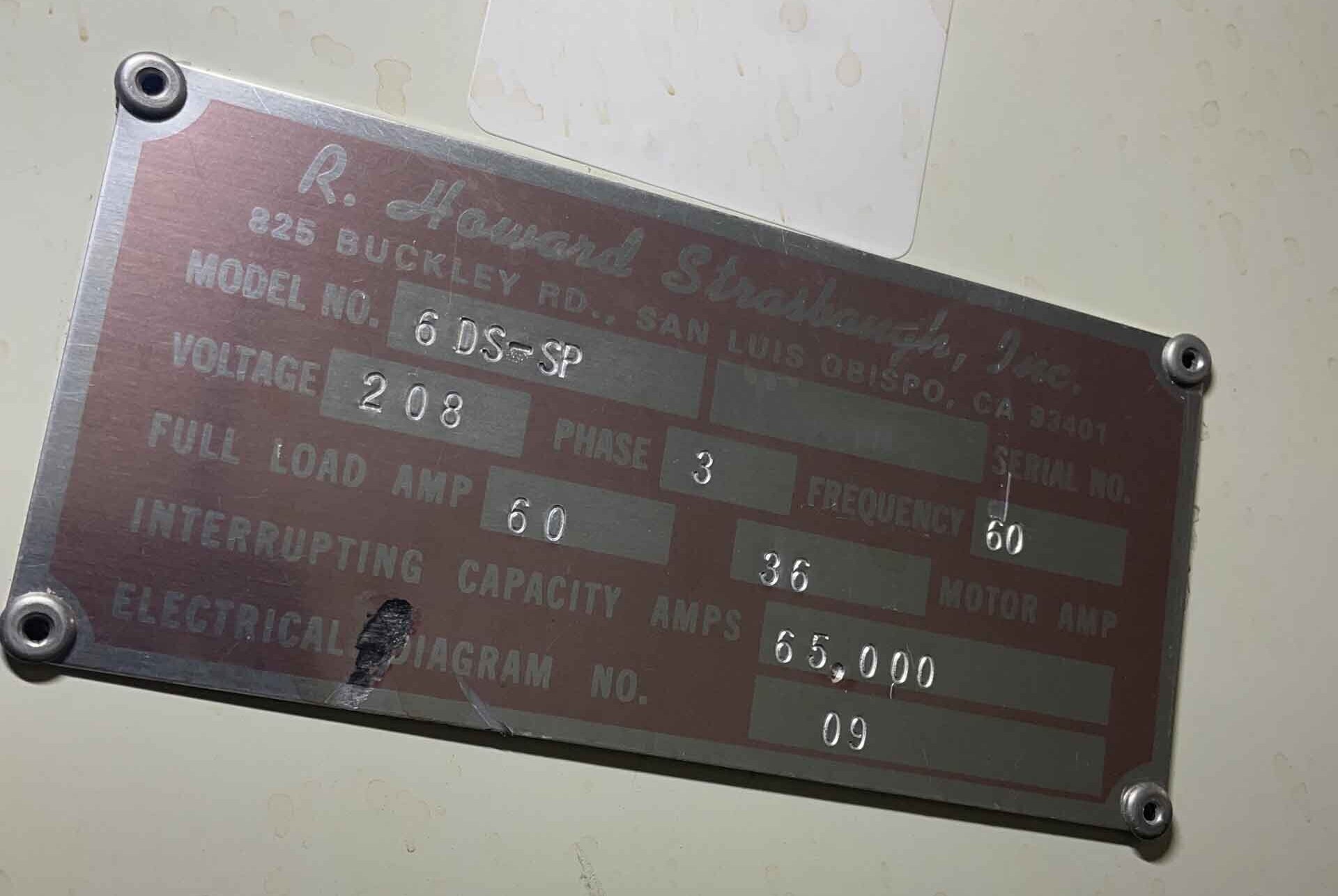

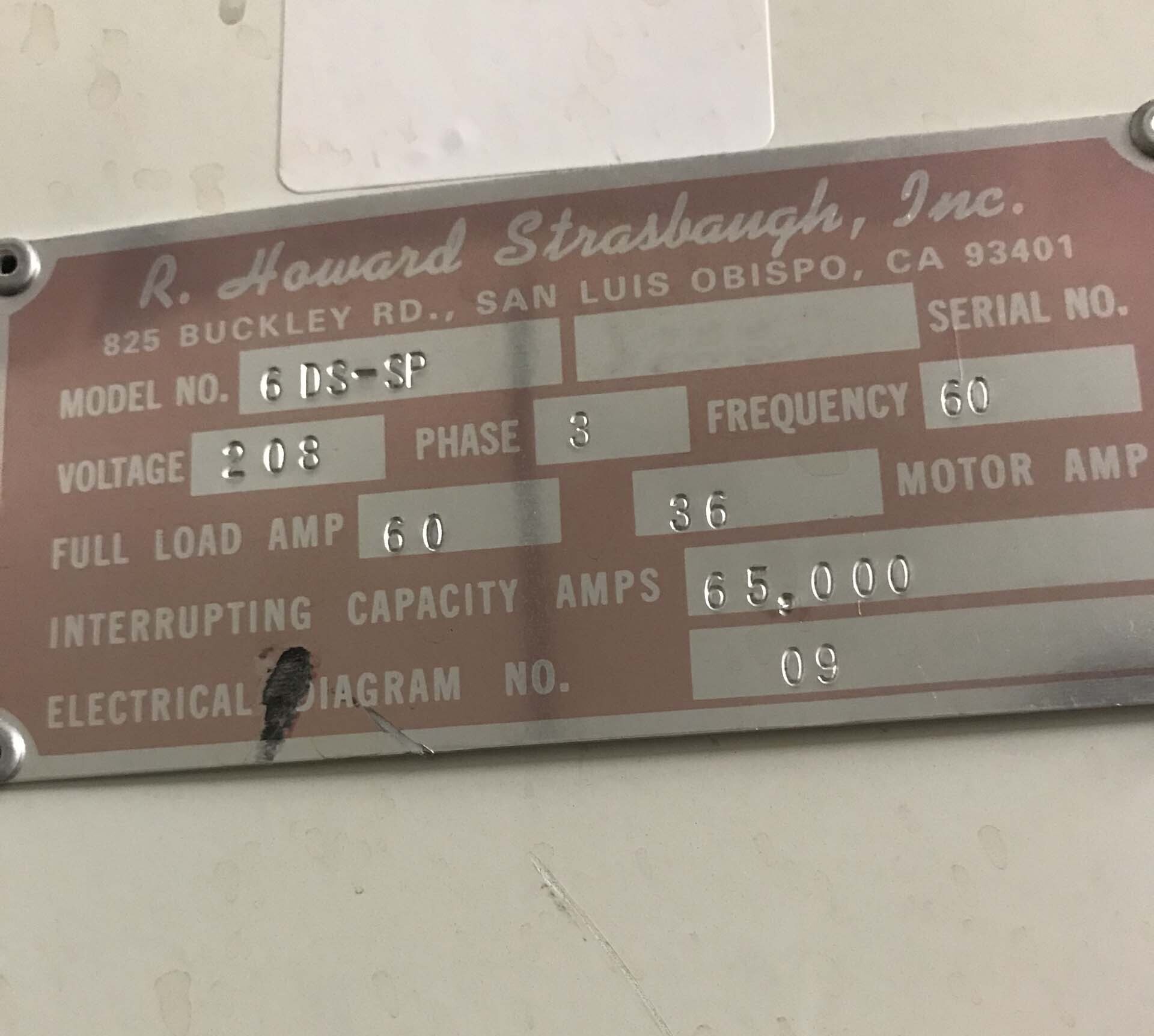

Used STRASBAUGH 6DS-SP #9314675 for sale

URL successfully copied!

Tap to zoom

STRASBAUGH 6DS-SP is a wafer grinding, lapping & polishing equipment designed to provide high quality, surface finish polishing of hard and soft substrates, such as silicon, gallium arsenide, quartz, and sapphire. It is capable of simultaneous grinding, lapping & polishing of 2"-2.5" wafers on any given cycle. The system offers two different platforms for precision wafer preparation: one for small substrates, such as fibers, and one for larger substrates, such as GaAs. STRASBAUGH 6 DS-SP unit is composed of a main control unit as well as various sub-units. The main control unit provides a user-friendly interface which allows for the monitoring and management of the entire machine. The main control also houses the power supply units that provide power to the grinding, lapping & polishing machines. The grinding, lapping & polishing machines are divided into three classes - the grinding class, the lapping class, and the polishing class. The grinding class consists of an automated wafer loading station that includes a two-point tool, allowing for the orientation of wafers, as well as a programmable grinding chamber accommodating up to 0.5" of depth and holding up to 8 wafers at one time. It is designed with a variable frequency drive and allows for up to 35000 rpm. The grinding class is able to grind both sides of the wafer simultaneously and at a variety of different angles. The lapping class consists of auto-loaders that hold up to 8 wafers at a time, and are programmable for both sides of the wafer. A controlled flow of polishing slurry is introduced onto the flat surface of the wafer, allowing for higher controllability and lower cycle times for lapping. The lapping class runs the wafers on a spinning lap wheel to ensure a higher level of flatness. Finally, the polishing class utilizes either an electrochemical polishing or an abrasive polishing process to achieve a higher level of surface finish and reduced defects. It includes a thin, highly conductive layer on the wafer for improved polishing action, as well as programmable auto-loaders that can hold up to 8 wafers at once. 6DS-SP is a state-of-the-art asset that provides controlled, precise grinding, lapping & polishing of wafers for various applications. Its impressive speed, accuracy, model control, and versatility make it an ideal equipment for a variety of wafer needs. The system is relatively easy to operate and makes for a great addition to any lab looking for a complete wafer grinding, lapping & polishing unit.

There are no reviews yet