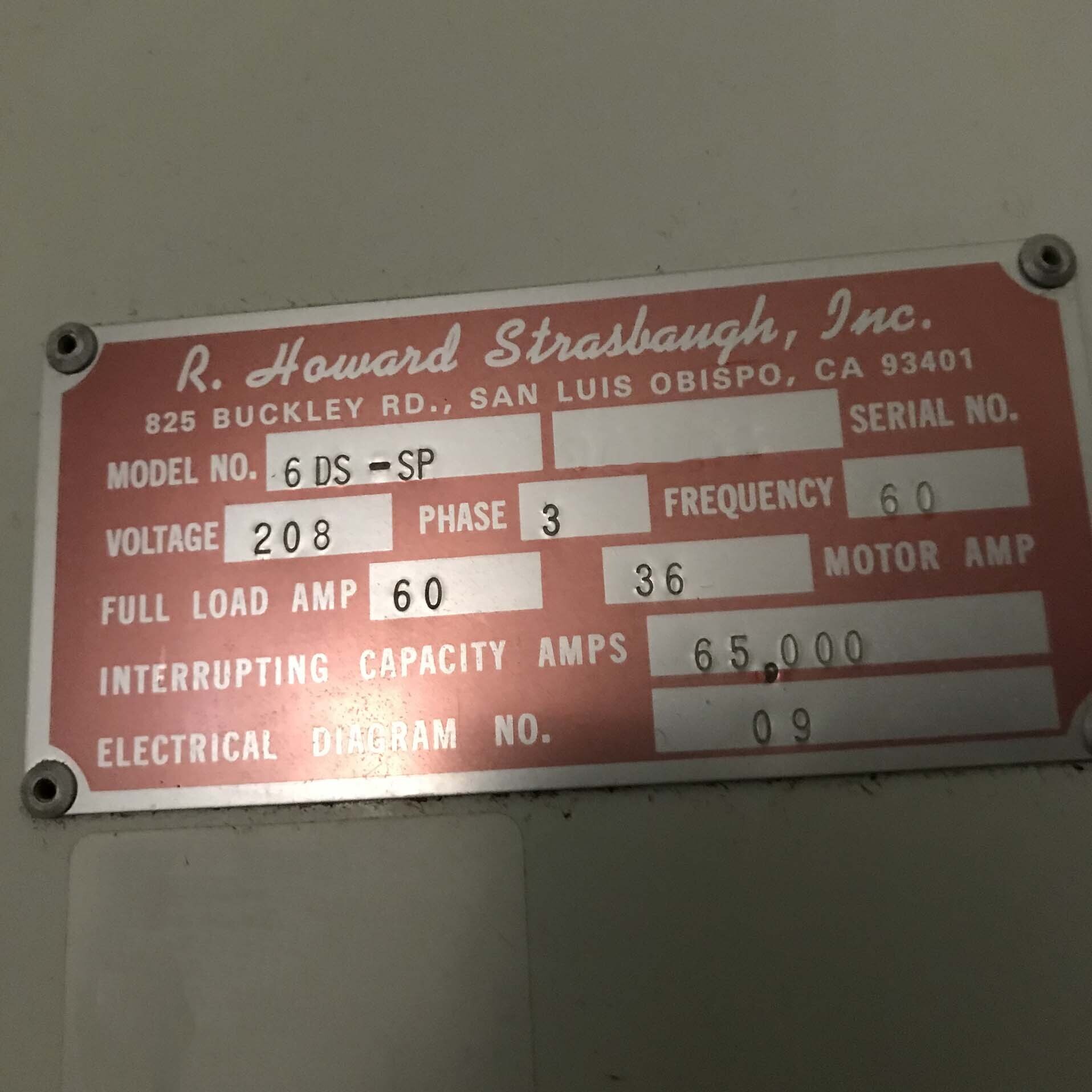

Used STRASBAUGH 6DS-SP #9314680 for sale

URL successfully copied!

Tap to zoom

STRASBAUGH 6DS-SP is an advanced wafer grinding, lapping and polishing equipment designed for precision accuracy and high reliability. With its comprehensive suite of features, the system is capable of repeatable and consistent results for sophisticated wafer processing applications. STRASBAUGH 6 DS-SP has a lightweight, modular frame design, enabling it to be easily configured and integrated into existing process layouts. Its high-precision results are facilitated by the unit's sophisticated wafer handling technology, which accommodates up to 6″ wafers and can be fine-tuned for repeatable results. 6DS-SP is also equipped with powerful grinding, lapping, and polishing motors with torque control, ensuring consistent results without sacrificing precision. In addition, 6 DS-SP includes integrated air bearings with large diameter and extended contact zones, enabling greater accuracy and repeatability when grinding and lapping the wafers. STRASBAUGH 6DS-SP is also optimized for global use with its full complement of electrical and safety specifications. STRASBAUGH 6 DS-SP is capable of producing a range of valuable results. Users can achieve aggressive stock removal rates by leveraging the machine's high-torque motors and air bearings, and high flatness and parallelism up to a quarter micron. The tool is well-suited for last-stage vision flattening, particularly for SOI wafer processing applications. In order to ensure optimal performance, 6DS-SP is equipped with an integrated wafer process control asset. This model features a digital display and touch screen with an intuitive graphical interface. It also provides user-definable process monitoring data acquisition and display functions for real-time process feedback. By leveraging the equipment's advanced features and integrated process control systems, 6 DS-SP provides users with unparalleled accuracy and repeatability for wafer grinding, lapping, and polishing applications. Consequently, the system has become the standard for partners in the semiconductor industry seeking reliable results with minimal operator experience.

There are no reviews yet