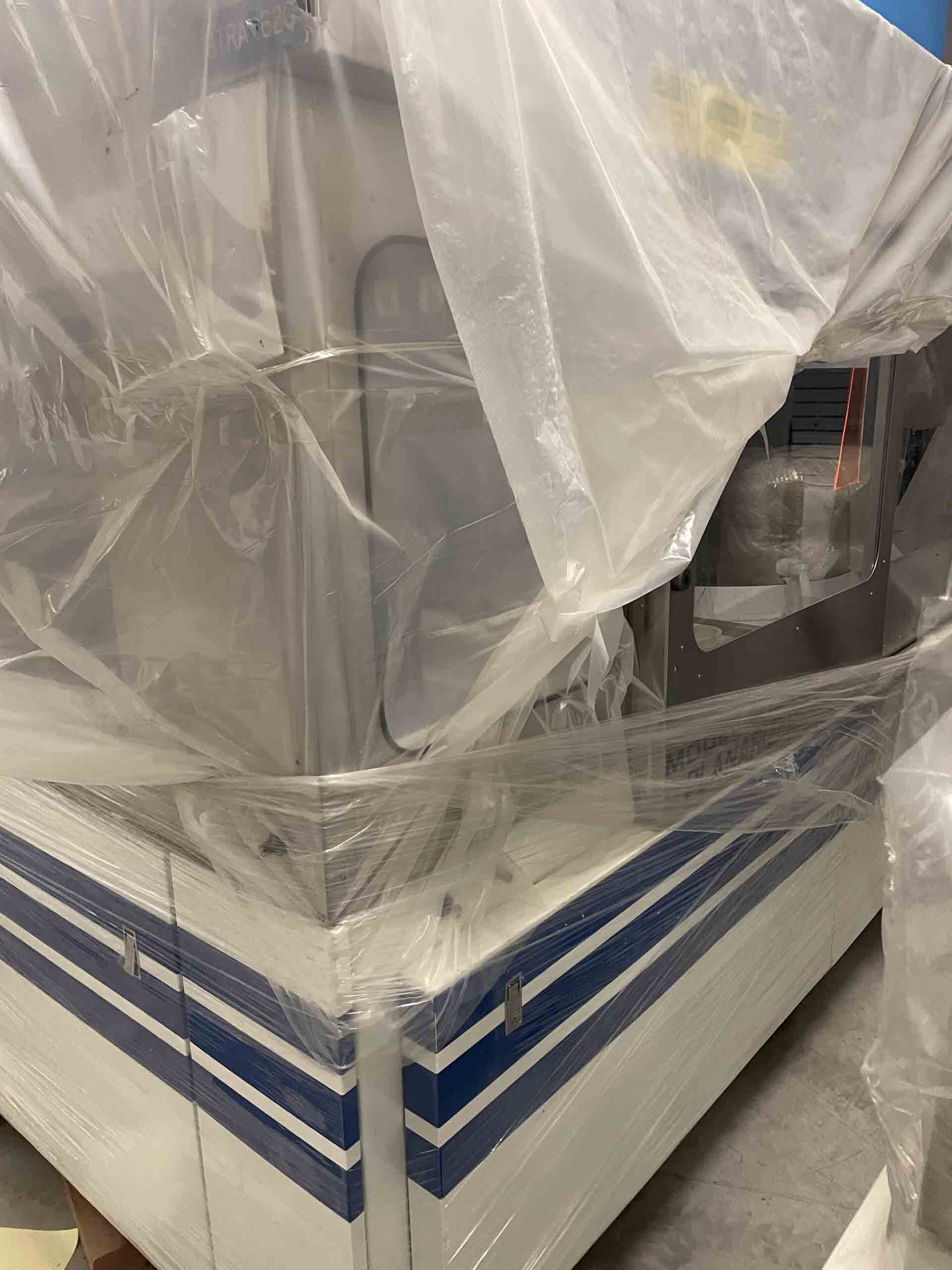

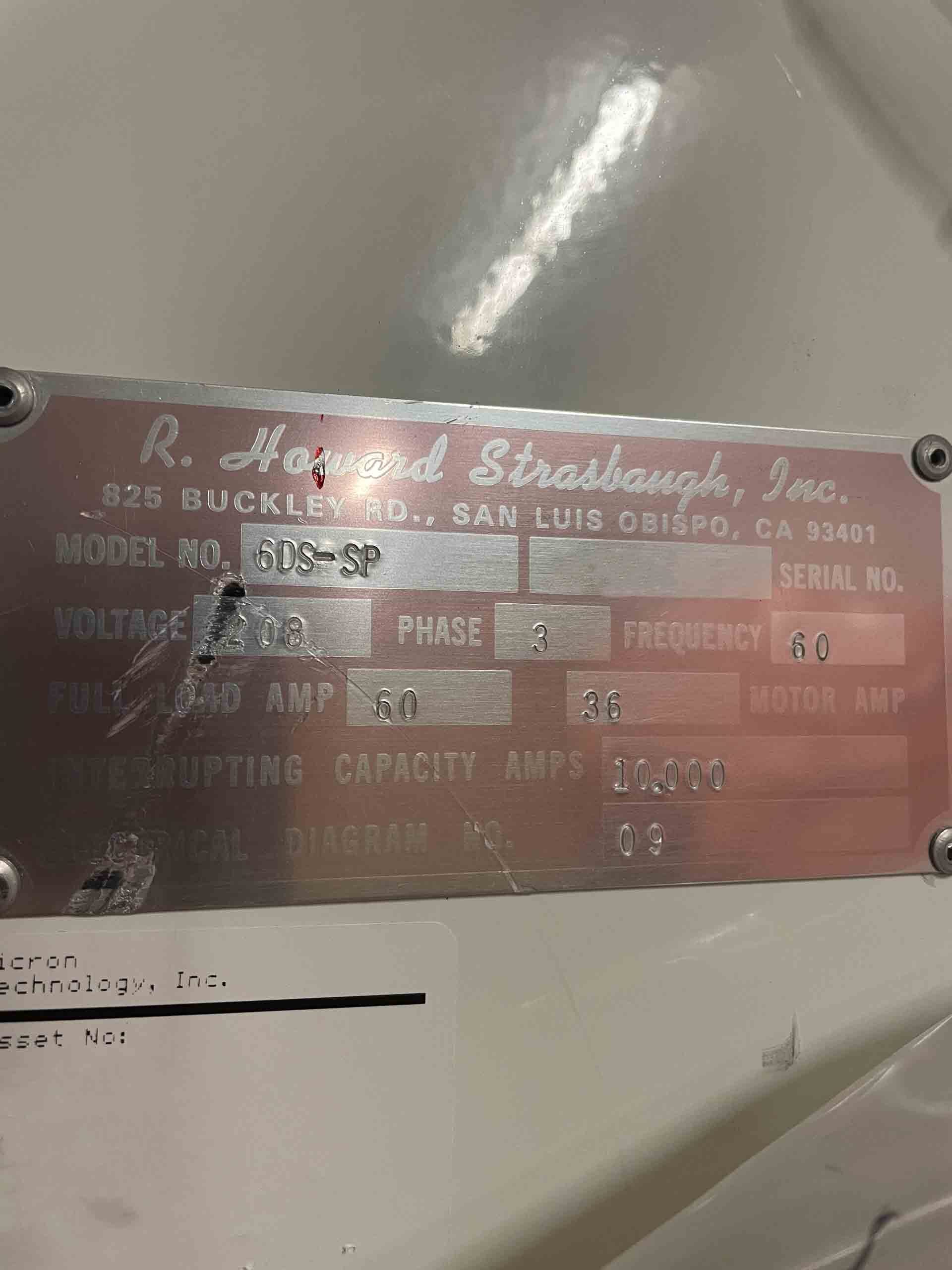

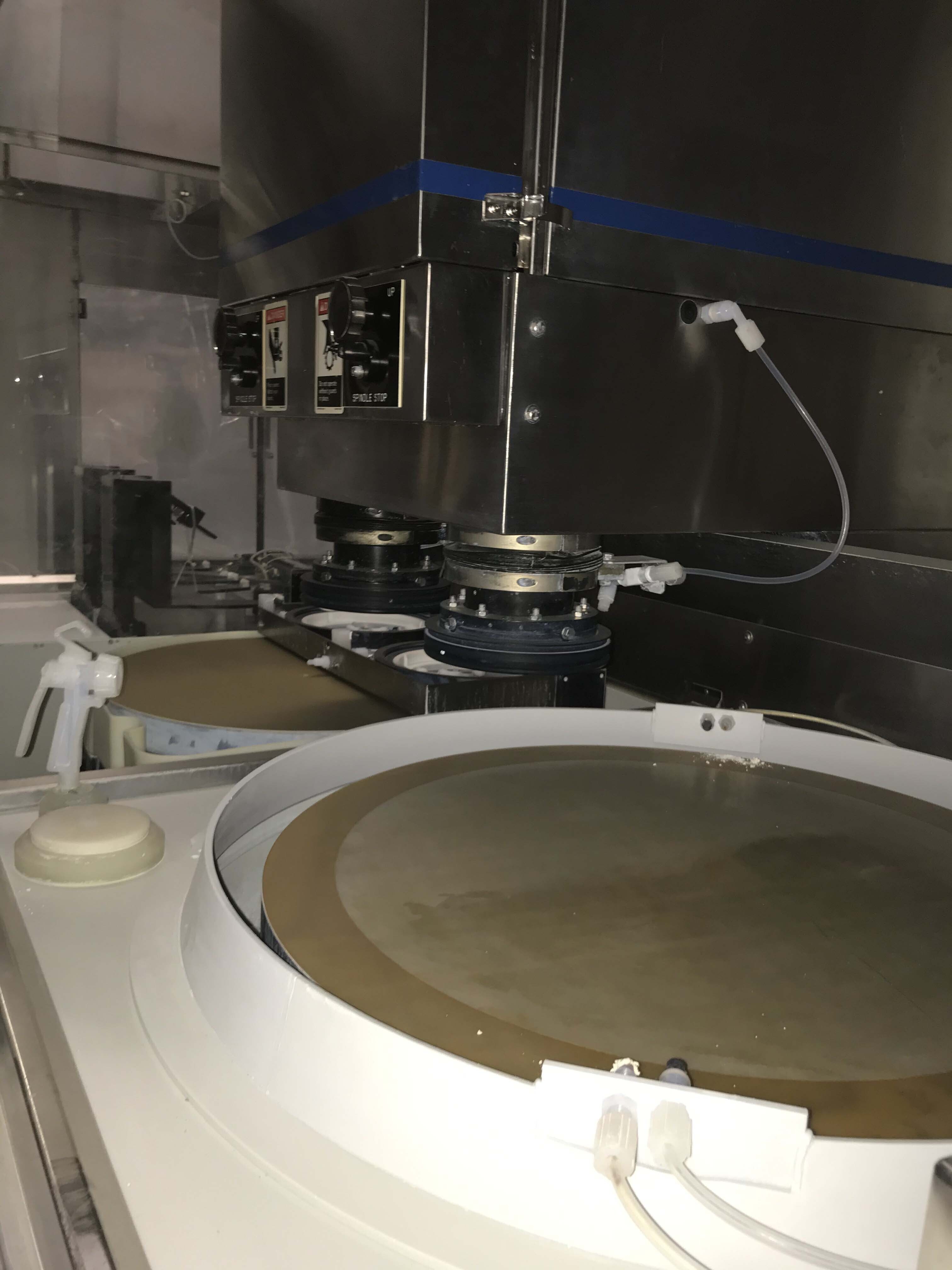

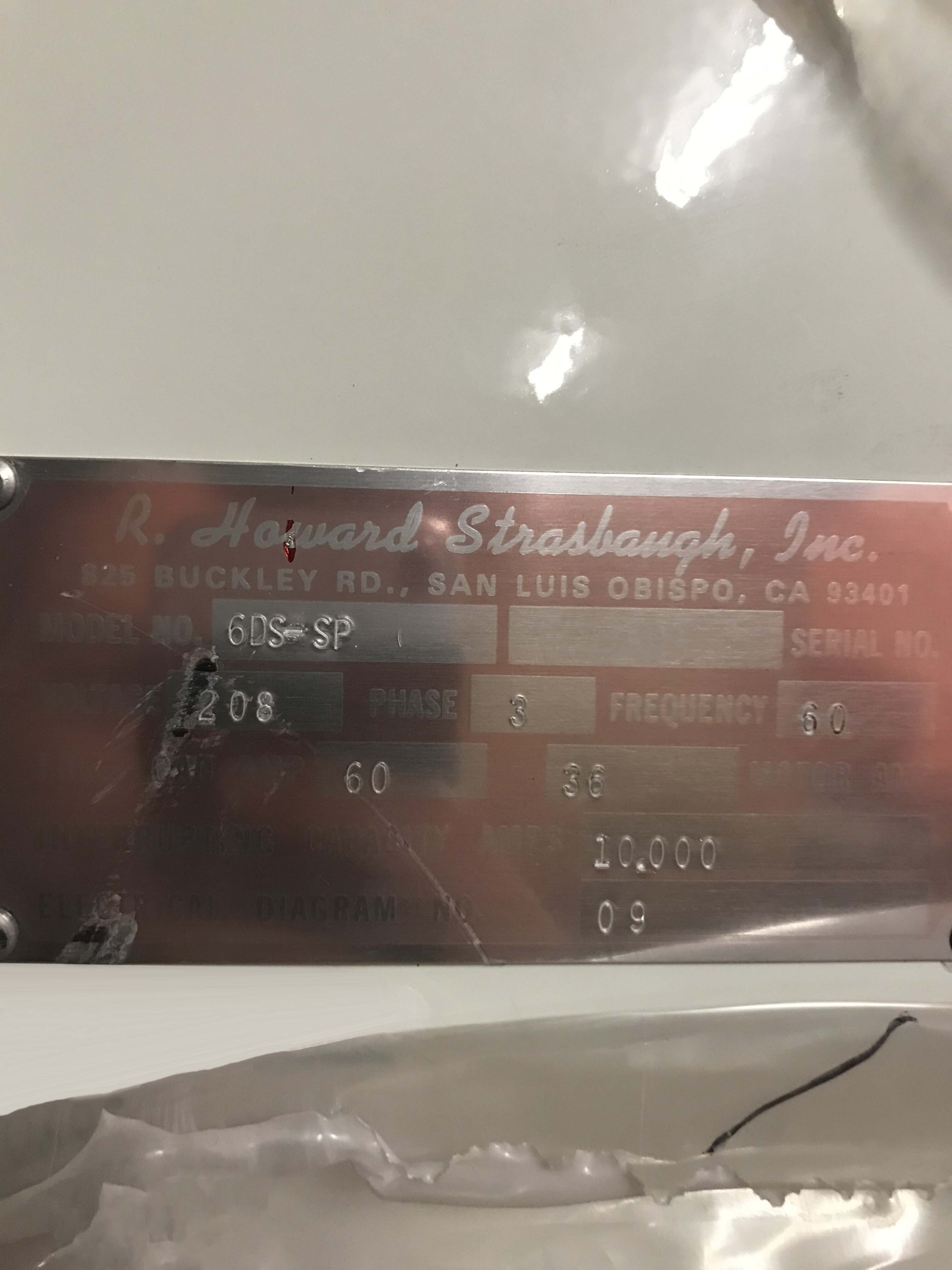

Used STRASBAUGH 6DS-SP #9314687 for sale

URL successfully copied!

Tap to zoom

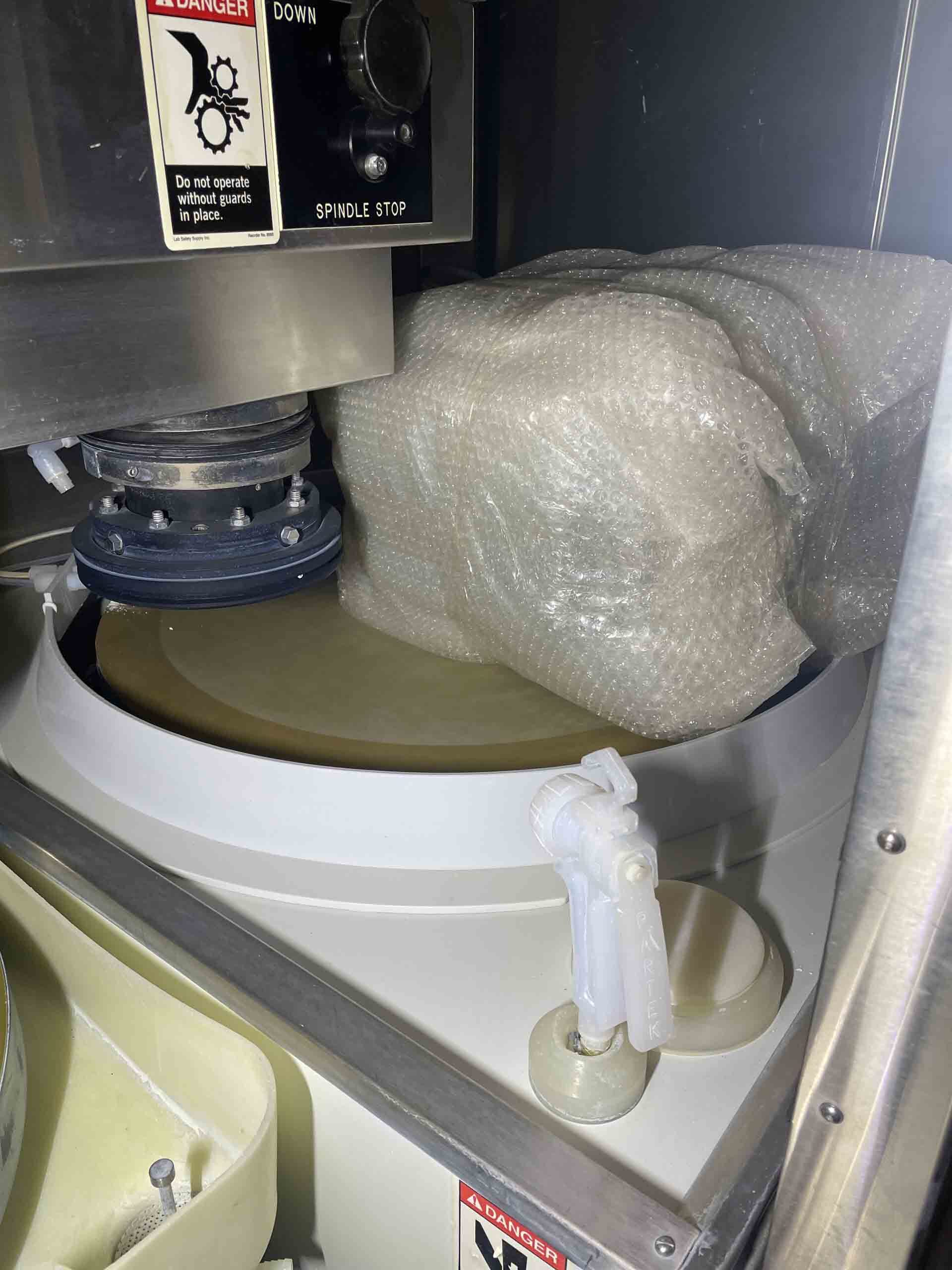

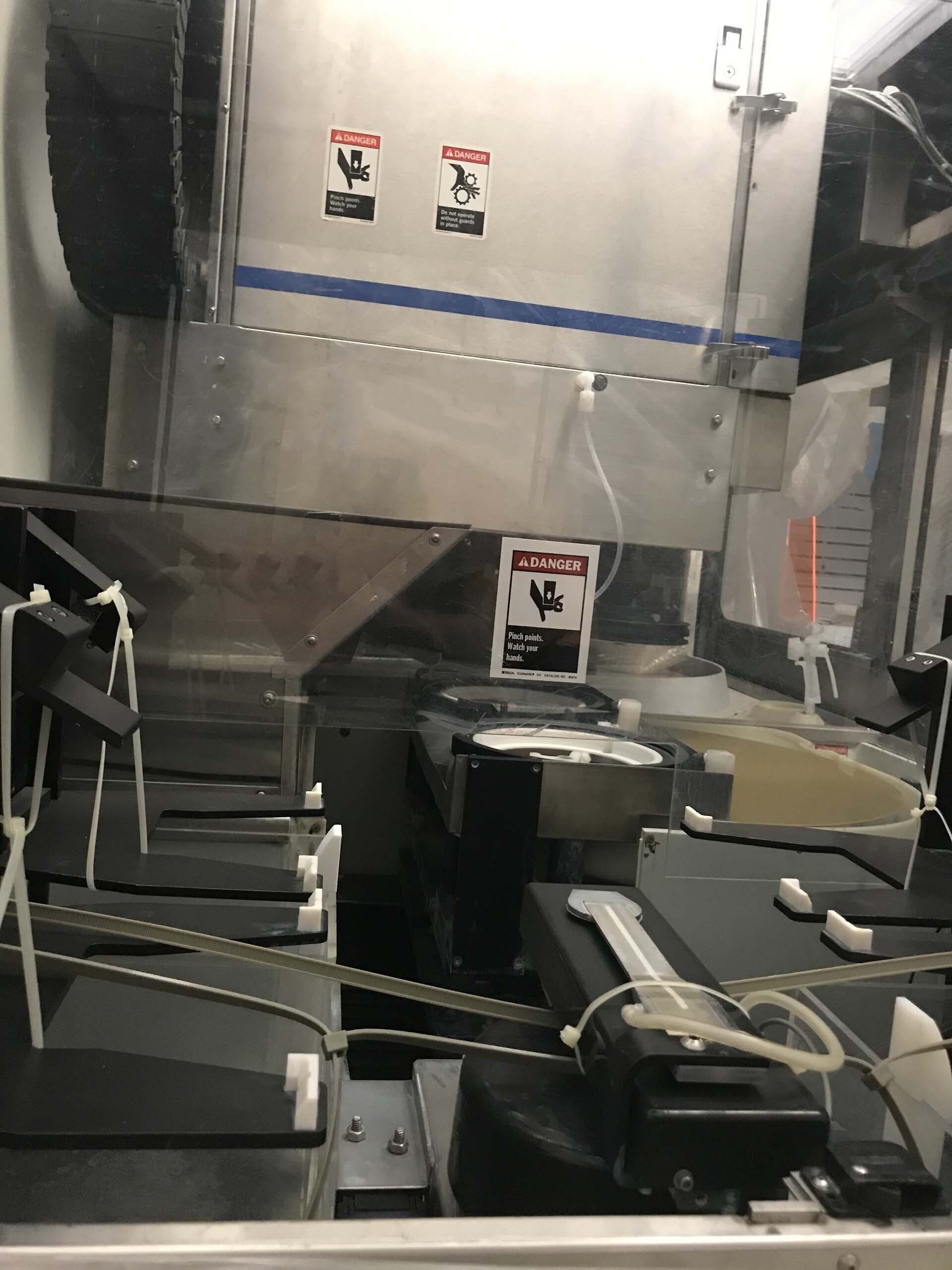

STRASBAUGH 6DS-SP is an advanced wafer grinding, lapping and polishing equipment designed for precise and consistent production of semiconductor wafers and other rigid, flat substrates. The system features a precision load lock for ultra-low contamination loading into the mechanical grind/lapping phase, an ultra-clean, pressure-controlled single-sided mechanical lapping unit, a single-sided, multi-head, dry-chemical polishing machine and a high precision mill/planarizer spindle. The load lock features a HEPA filtered, nitrogen-purged environment for ultra-low environmental contamination. The mechanical grind/lapping tool is capable of producing extremely low surface roughness on rigid surfaces with two-sided grinding, lapping and double-sided lapping. The mechanical asset can also perform single-sided lapping to one sub-micron roughness before the polishing phase. The cleaning station employs brush-and-vacuum action to prevent cross-contamination. STRASBAUGH 6 DS-SP polishing model is designed to achieve a highly consistent, repeatable polishing process with maximum uniformity and control. The equipment utilizes a single-sided, multi-head polishing process with automated, computer-controlled operation. The dry-chemical polishing process is capable of producing a high ultra-precise flatness over the entire substrate surface, and a high-level of uniformity achieved in the polishing tool across the wafer. 6DS-SP is also equipped with a high precision mill/planarizer spindle, which is designed to reduce particulate contamination and prevent the formation of particulates from the material removal process. The mill spindle is precision machined and provides ultra-high-accuracy planarity operations, with a full-motion, real-time video monitoring system for detection and removal of any unwanted burrs. Finally, 6 DS-SP is equipped with an automated handling unit to ensure reliable and efficient production of wafers and other substrates. The loading, unloading, and transferring of substrates can be easily automated and the machine provides a range of safety measures to prevent contamination and damage. The automated handling tool is also designed with intuitive user-friendly software that enables easy and efficient programming and operation of the asset.

There are no reviews yet