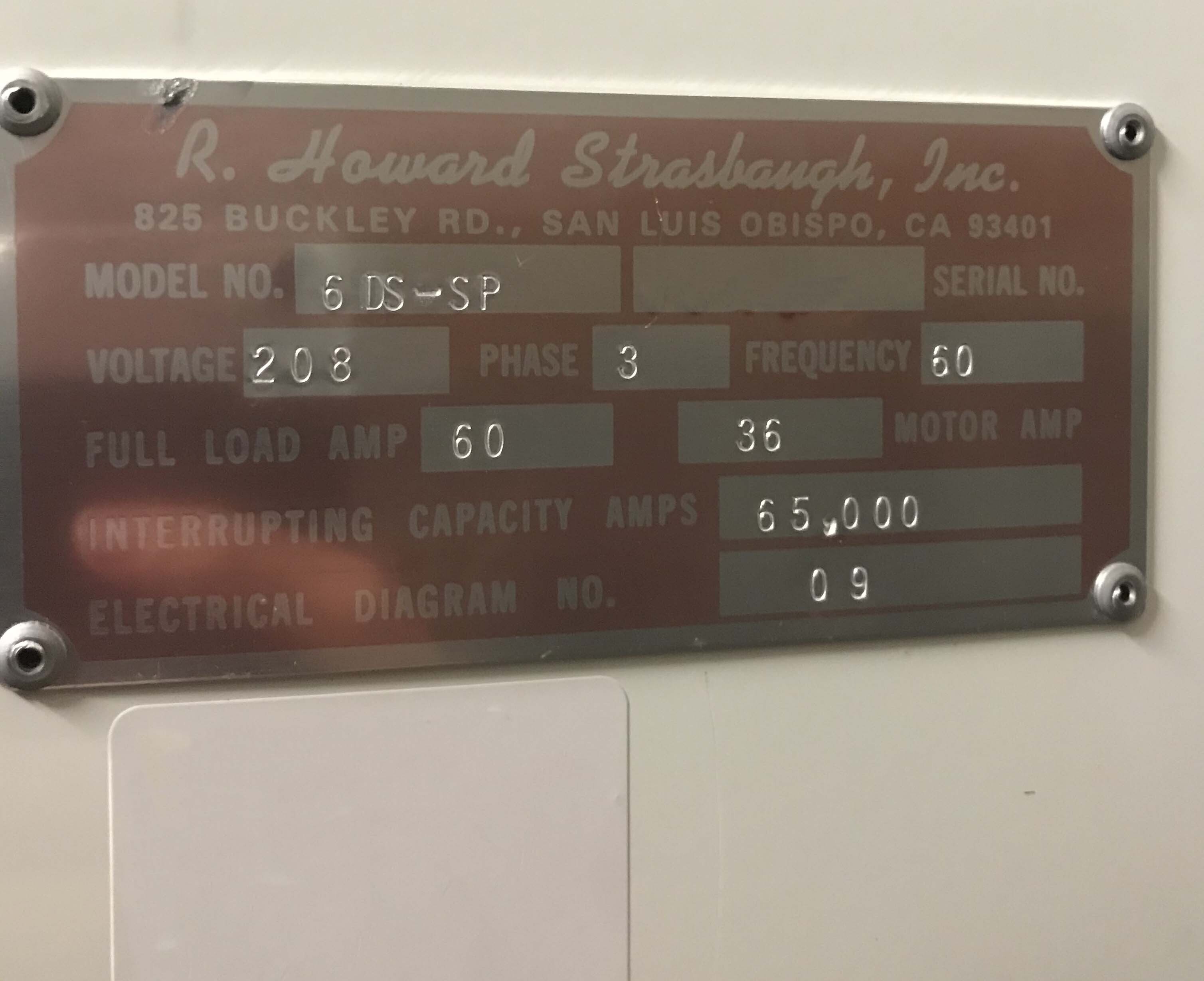

Used STRASBAUGH 6DS-SP #9314688 for sale

URL successfully copied!

Tap to zoom

STRASBAUGH 6DS-SP is a semi-automated wafer grinding, lapping and polishing equipment designed for processing various materials, such as silicon, Gallium Arsenide, and other advanced materials. STRASBAUGH 6 DS-SP employs a range of advanced techniques for material removal, including electrochemical abrasion, as well as ultrasonic lapping and polishing for superior surface planarity and texture. 6DS-SP incorporates two wafer grinding/lapping spindles and one polishing spindle. The grinding spindles use diamond tape and diamond film grinding media to perform abrasion-based material removal. The diamond films are bonded to a flexible spin-on or vacuum-adhered plastic backing by a heat-curing technique. The diamond media can be applied to an etched or laser-drilled pattern to achieve improved texture or surface planarity. 6 DS-SP offers a range of drive speeds up to 2500 rpm, the highest of any machine in its class. This is necessary for maximum machining efficiency and can improve material removal rates. The system features advanced safeguards that protect the grinding surfaces against out-of-tolerance vibration and rocking of the spindles. STRASBAUGH 6DS-SP is designed for easy maintenance, with a crystal clear polycarbonate membrane lid providing dust free environment. The lapping spindles are responsible for the second step in wafer grinding, lapping and polishing; utilizing a slurry of silica sol and diamond particles, lapping is a powerful polishing technique that yields superior surface smoothness. STRASBAUGH 6 DS-SP lapping spindles feature variable link arms for maximum flexibility and control. The link arms offer continuously variable rotating, in-plane, and out-of-plane motions to ensure uniform material removal. 6DS-SP polishing spindle is the third step in the process, allowing for processing at high speeds, polishing to improved surface smoothness, and increased material removal. The unit offers variable pressure for increased precision and control of material removal. The number of platen movements, platen velocities, and platen pressure are also programmable for increased flexibility. 6 DS-SP machine is designed to deliver superior performance, speed and precision while still being economical and easy to maintain. With its versatile spindles and advanced features, this wafer grinding, lapping and polishing tool can be used for processing a variety of materials with consistent results.

There are no reviews yet