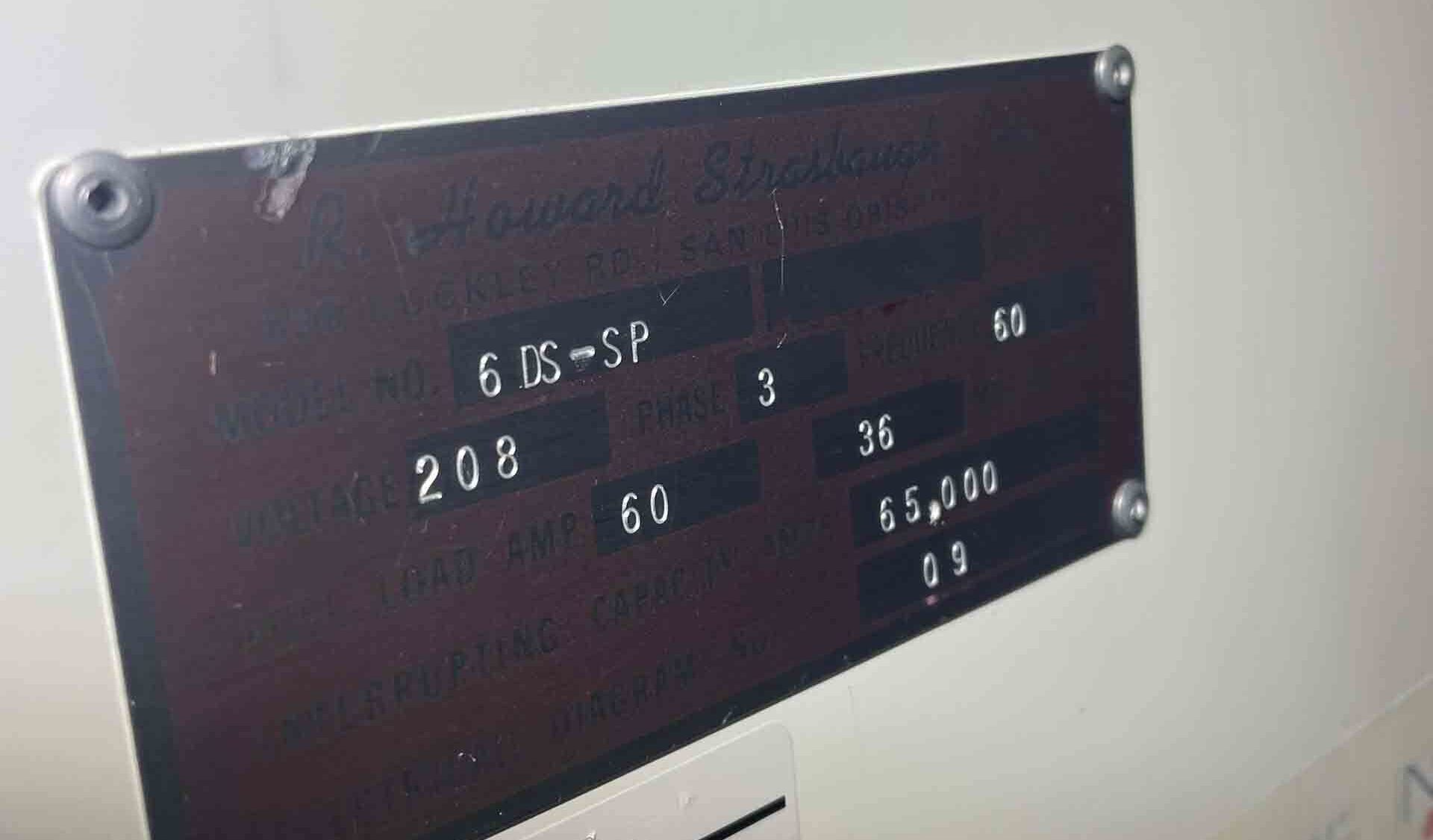

Used STRASBAUGH 6DS-SP #9410927 for sale

URL successfully copied!

Tap to zoom

STRASBAUGH 6DS-SP is a wafer grinding, lapping and polishing (GL&P) equipment, designed to process a variety of materials from brittle to ductile substrates with as little as 1nm of flatness and parallelism. This system is suited for a variety of applications across multiple industries, including semiconductor, medical, and data storage. The unit features a fully automated, multi-axis control and is designed for maximum precision and high-performance, with STRASBAUGH 6 DS-SP achieving an absolute flatness of <1 nm and parallelism of <5 µm. 6DS-SP also features a state-of-the-art, integrated vision machine that enables high-accuracy alignment and measurement during all stages of process development. The tool utilizes a unique process chamber design to allow different materials, such as silicon, glass, quartz and other inorganic substrates, to be processed with both traditional and proprietary processes. Its powerful abrasive slurry, spindle and vacuum systems enable ultra-precise material removal and a combination of mechanical, chemical and thermal processing. The asset is both efficient and safe, featuring an industry-leading safety and environmental monitoring model which monitors air, temperature and humidity. It also includes a video monitoring equipment with an automated workplace cleaning system, and a vibratory feeder to minimize small but essential contamination of the process chamber. 6 DS-SP is designed to process 200mm and 300mm wafers and can be scaled to handle larger wafers as needed. The unit provides flexibility with the sample retention machine, allowing for tape, secure, or non-secure formats. This tool is ideal for R&D, Failure Analysis, and Production GL&P applications and for technologies demanding high precision GL&P with nano-scale accuracies.

There are no reviews yet