Used STRASBAUGH 6Y-1 #9218703 for sale

URL successfully copied!

Tap to zoom

ID: 9218703

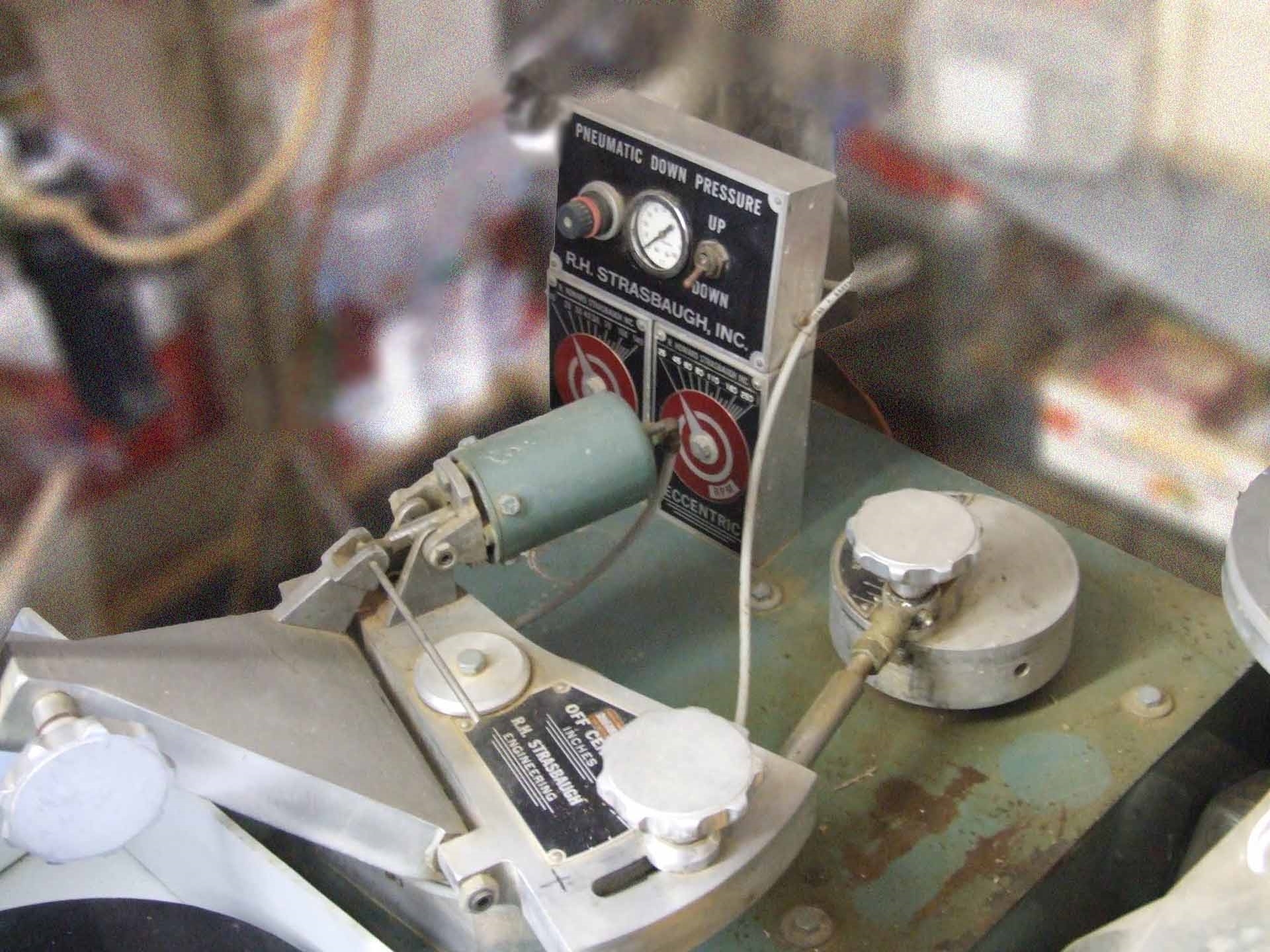

Single head polisher

Diameter table, 16"

Air cylinder for down pressure

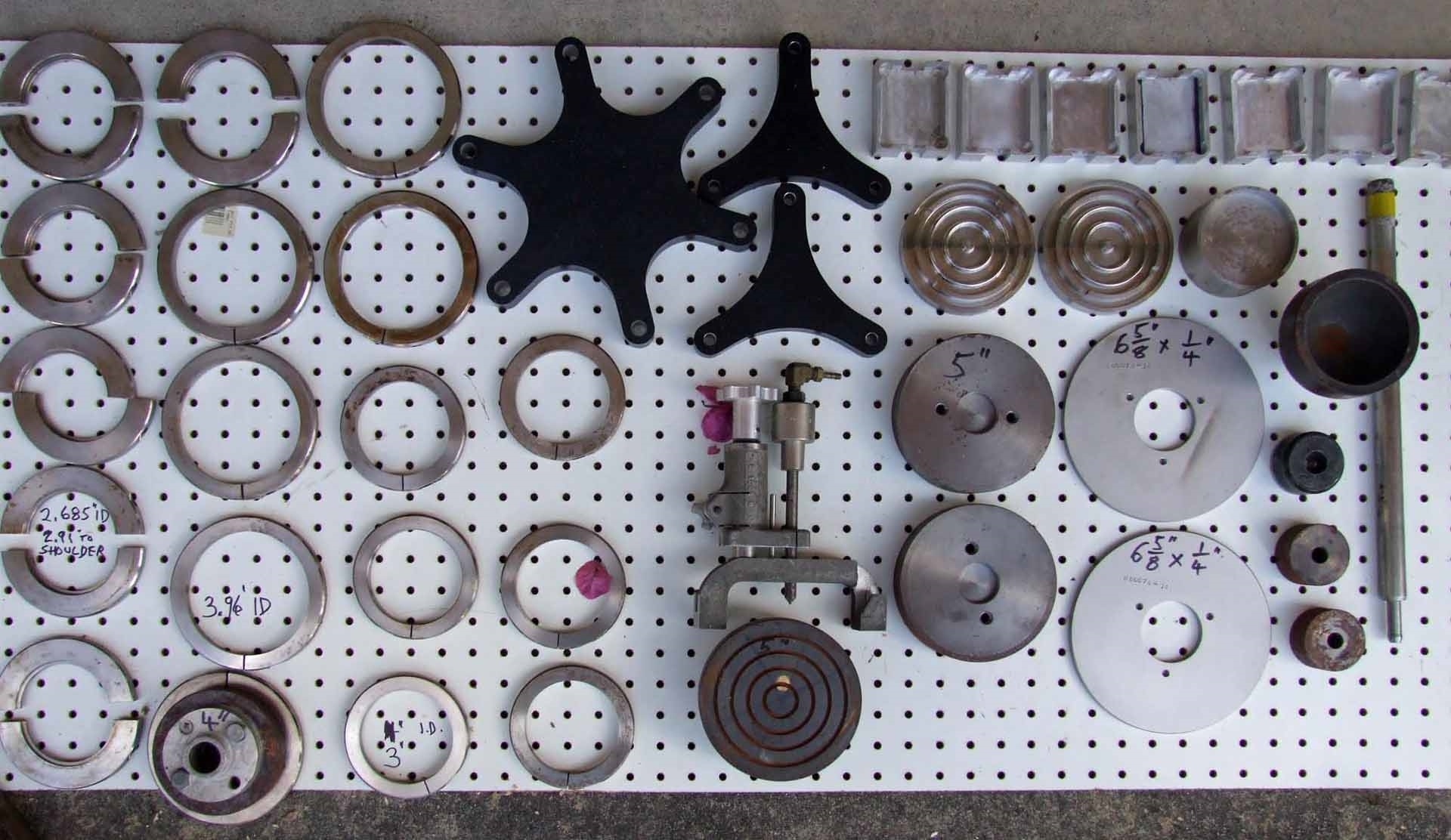

Assorted polishing plates

Aluminum polishing plates, 16"

Miscellaneous lapping / Polishing hardware

Greymills slurry pump

(2) Peristaltic polishing solution pumps

Power supply: 230 VAC.

STRASBAUGH 6Y-1 is a computer-controlled wafer grinding, lapping and polishing equipment designed for precision and high-volume production applications. It is capable of processing wafers up to 450 mm in diameter, and is comprised of a modular design platform which gives customers flexibility and a variety of process capabilities. The system is composed of two separate components, the Lapping and Grinding Unit, and the Polishing Machine. The Lapping and Grinding Tool is capable of high-precision wafer grinding to create tight specifications for templates and substrates. The dual-head asset is able to run simultaneous operations, and utilizes diamond lapped plates to ensure high-accuracy and repeatability. It has a variable speed drive motor, as well as optional peripheral components to extend the range of applications. The Polishing Model consists of a motor-driven spindle, which is mounted in a 300mm enclosed process cabinet. This equipment is designed for repeatable operations, while offering low-profile and low-maintenance maintenance. The spindle is variable speed, and is equipped with a variety of surfaces to ensure high-precision and efficient results. The system also includes an automatic unit indexer, which helps ensure accurate and consistent results. The machine also offers a wide range of post-process improvements and options including high tension or soft-rub polishing, chemical mechanical polishing (CMP), polishing pad processing, and fine-grain diamond polishing. Additional options include a dynamic profile generator and an embedded auto-leveling feature. Overall, 6Y-1 wafer grinding, lapping and polishing systems provides customers with a high-speed, low-maintenance solution for their precision results. With its comprehensive range of process parameters and capabilities, it is perfect for applications that require custom wafers from single or multiple templates in small batches. It is an ideal solution for production runs of any volume due to its flexibility and reliability.

There are no reviews yet