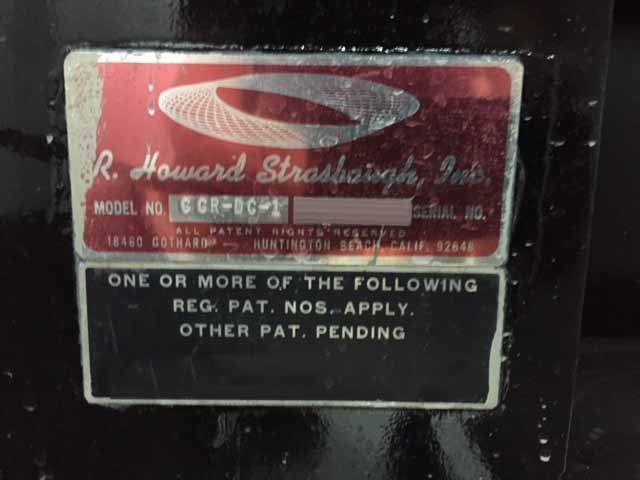

Used STRASBAUGH CCR-DC1 #9203073 for sale

URL successfully copied!

Tap to zoom

STRASBAUGH CCR-DC1 is a high precision, state-of-the-art wafer grinding, lapping & polishing system designed for the production of ultra-smooth surfaces on large area wafers. CCR-DC1 is an industry standard for both the semiconductor and advanced wafer manufacturing markets. STRASBAUGH CCR-DC1 provides full control over the process parameters, highest levels of accuracy and wafer cleanliness. It consists of three main components: a platen stage, a load table, and a lapping/polishing chamber. The platen stage is used to load and align the wafers, while the load table ensures maximum surface contact between the wafer and the grinding/polishing media. The lapping/polishing chamber provides a controlled environment for the grinding and polishing of the wafers. CCR-DC1 uses two grinding/polishing technologies: diamond grinding & polishing and electrochemical polishing. The diamond grinding & polishing uses diamond-coated abrasive wheels to grind and polish wafer surfaces. It is a batch process and is capable of achieving unmatched doping non-uniformity. The electrochemical polishing utilizes an electrolytic solution for removing metal atoms from the surface of the wafer and produces ultra-smooth surfaces. The system also provides the user with a wide range of features and capabilities to best suit the needs of each user. Features such as crash detection, material monitoring, and advanced cleaning cycles are used to ensure the highest level of production. STRASBAUGH CCR-DC1 is also capable of controlling key process parameters such as temperature, pressure, and time, to optimize wafer surface finish. CCR-DC1 is the perfect system for demanding wafer sharpening applications as it offers advanced software, impeccable accuracy, precise control, and superior cleanliness. It is designed to handle a wide variety of applications and provides consistent results in terms of surface finish and wafer properties.

There are no reviews yet