Used STRAUSAK Ecoflex 72 #9066972 for sale

URL successfully copied!

Tap to zoom

ID: 9066972

Vintage: 1997

Grinding machine

Grinding wheel diameter 75 - 150 mm

Grinding wheel speeds 1.000 - 8.000 u/min

Center height of table 125 mm

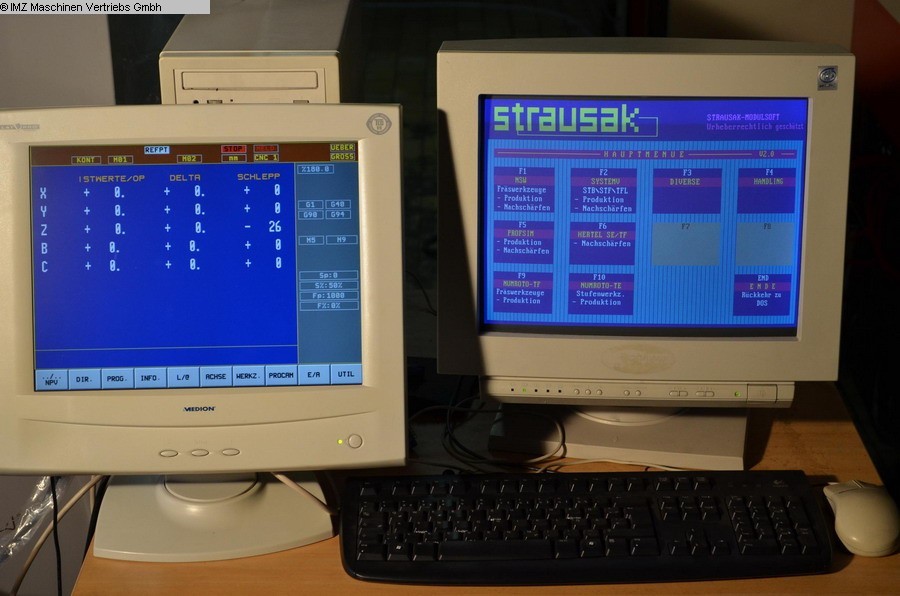

Control num 1062 m

Driving power - grinding spindle 3 kw

Max. Torque 5,73 nm

Fitting taper ISO 50

Axis stroke:

X-axis 350 mm

Y-axis 200 mm

Z-axis 400 mm

B-axis 310º

C-axis 0,001º

Feeds:

Feed speeds x / y / z: 6.000 mm/min

Feed speeds b: 14,28 1/min

Feed speeds C: 37,50 1/min

1997 vintage.

STRAUSAK Ecoflex 72 is a high performance wafer grinding, lapping and polishing equipment designed to meet the requirements of advanced semiconductor fabrication processes. This system is capable of handling wafers up to 300 mm, and features a modular design with a range of wafer chuck sizes, grinding discs, and lapping plates to allow for customized configurations. The unit's closed-loop grinding and lapping technology ensure a high level of accuracy and repeatability for optimal surface treatment and wafer size control. Ecoflex 72 is equipped with a variety of features that make it a preferred choice for high precision wafer grinding. It utilizes a linear direct-drive motor to power its spindle motor, resulting in a more efficient grinding process with superior accuracy. The machine also features a built-in gas assist tool to minimize temperature rise and maintain a more thermal stability throughout the grinding process. This gas assist asset also improves the rigidity of the model as it prevents parts from bending or shifting during the grinding process. STRAUSAK Ecoflex 72 is also designed to provide optimal flexibility to meet the demands of diverse applications. The equipment features a variety of grinding and lapping discs suited for different materials and processes, as well as a range of wafer chuck sizes for accurate and secure handling of wafers. The system also allows for easy recalibration of the grinding and lapping process to achieve the desired results. This unit features a patented laser alignment machine to ensure precise results. This tool accurately measures grinding parameters, including tables, chucks, and discs, and allows for adjustment and recalibration as needed for optimal performance. With this advanced asset, users can easily monitor and control the accuracy and repeatability of the wafer grinding process. Ecoflex 72 also features a unique model of vision and imaging features. This equipment utilizes a combination of high definition cameras and encoders to accurately measure the shape and surface of the wafers before and after being processed. This system also stores the data for efficient analysis of results. In summary, STRAUSAK Ecoflex 72 is a high performance wafer grinding, lapping and polishing unit offering superior accuracy, repeatability, and flexibility for a variety of demand applications. This machine combines advanced components, such as its linear direct-drive motor, gas assist tool, and patented laser alignment asset to achieve optimal grinding and lapping results. The model also features a unique equipment of vision and imaging features to accurately measure the shape and surface of the wafers before and after being processed.

There are no reviews yet