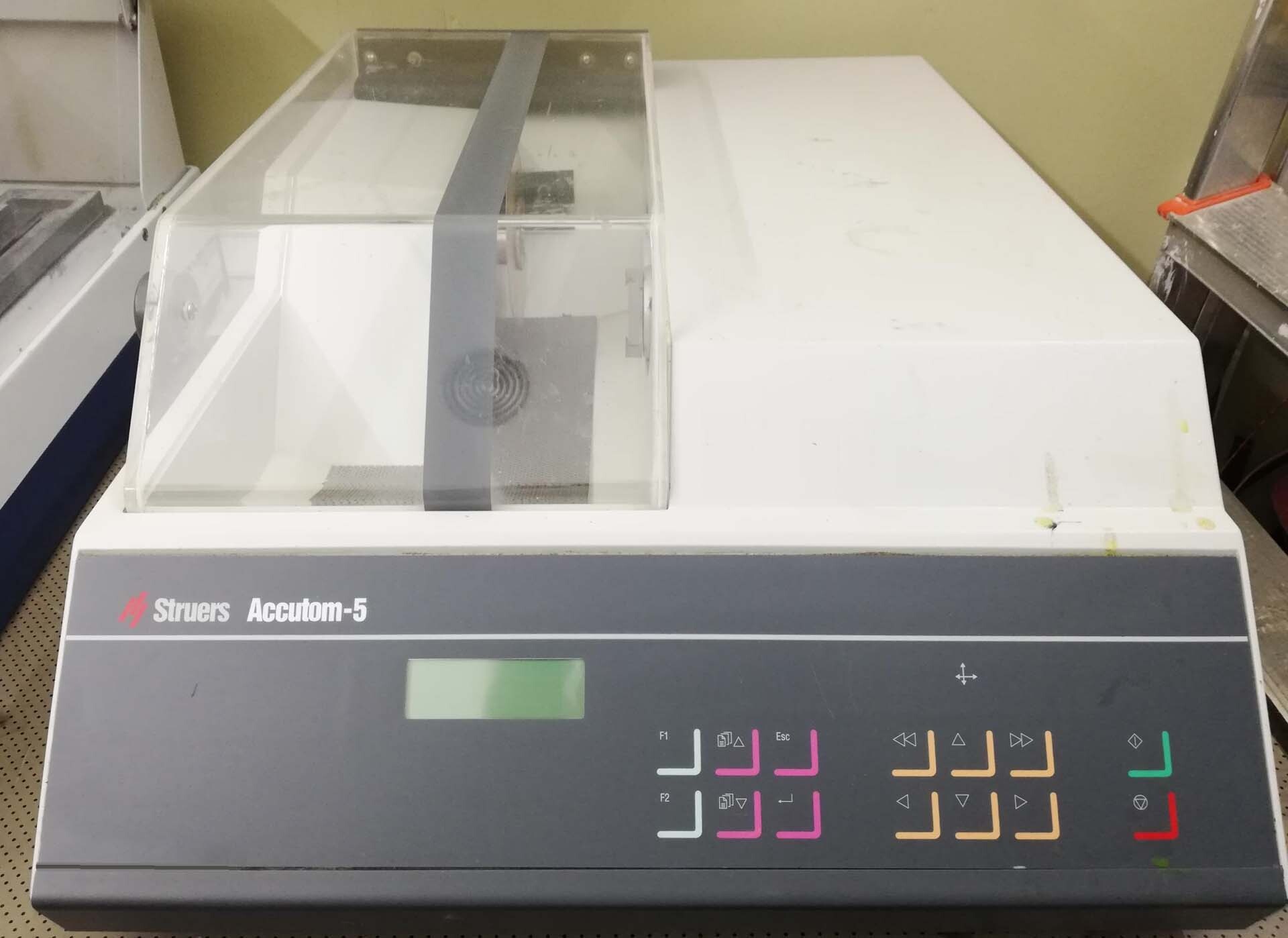

Used STRUERS Accutom-5 #9377664 for sale

URL successfully copied!

Tap to zoom

STRUERS Accutom-5 wafer grinding, lapping & polishing equipment is a versatile, efficient and fully automated sample conditioning system. This unit is used in the preparation of materials for further analysis or for the production of high-end material components. The machine enables users to condition the surface of a variety of materials, ranging from metals and ceramics to polymers and composites. Accutom-5 can process 5 wafers between 20 and 150mm in diameter, with the primary focus on precision surface finishing. The grinding and polishing process involves four different steps. The first step is the grinding process, using diamond grinding discs, which employ a combined mechanical and chemical action to remove surface imperfections rapidly. At the same time, a protective film is produced which helps to preserve the surface during grinding. The second step is lapping, which uses a diamond-impregnated lap to further polish the surface. The diamond-impregnated lap is continuously rotated against the wafer's surface, removing the remaining roughness and irregularities. The third step is a precision polishing process using a diamond paste to produce the highest possible surface quality in terms of dirt, scratches and roughness. Finally, a polisher, which is a variable speed motor with a pressure-driven ring structure, is used to apply a highly uniform pressure across the entire surface of the wafer. This produces a polished and highly uniform surface without the introduction of any scratches or defects. The speed and pressure of the motor can be adjusted to ensure a very high level of accuracy during the entire surface finishing process. All the steps are automated and fully controllable, while a range of automated and manual measurements are available to ensure accurate and repeatable quality of the finished product. STRUERS Accutom-5 tool is an excellent choice for high-end surface finishing and can provide a very cost-effective solution for high-volume production. Thanks to its versatile range of features, accuracy and repeatability, it can meet the demands of a variety of industries.

There are no reviews yet