Used STUDER S21 #9289817 for sale

URL successfully copied!

Tap to zoom

ID: 9289817

Vintage: 1999

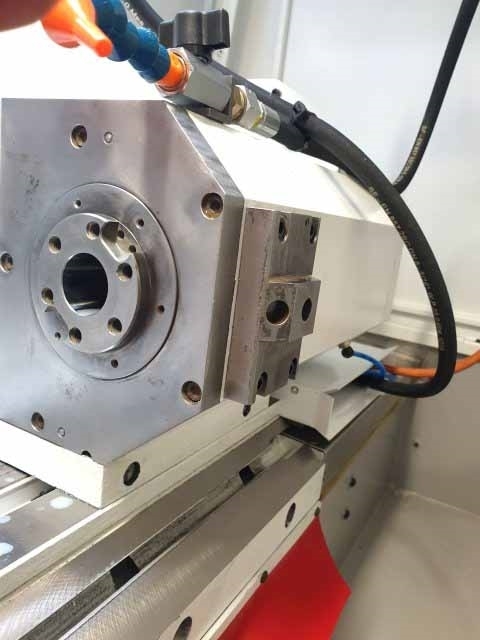

CNC Cylindrical grinding machine

FANUC 16i-TA CNC Machine

Electronic deported crank handle

Status lamp

HEIDENHAIN X / Z Scales

(2) External grinding wheels: Left and right

FISCHER MFV 1245 Internal spindle: 45000 RPM

Electronic variation internal wheel speeds

Tailstock with fine adjustment

Wheel dresser upon workhead

Sensitron (2) contact detection

Spindle cooling unit: CYMAX

Dust extractor: HMB SUCTION TECHNOLOGY

Magnetic chuck: Φ200 mm

(2) External wheel holders

Grinding wheel holder:

Strokes:

X Axis: 254 mm

Z Axis: 483 mm

Universal grinding head

Grinding head (B axis): 157° - 195°

Indexing precision of B axis: 1°

External wheel dimensions: 400 x 40 x 127 mm

Maximum speed: 3200 RPM

Peripheral speed: 50 M/S

Internal grinding spindle: 120 mm Diameter

Part-holder head stock:

Cone: CM4

Rotational speed: 1-1500 RPM

Power: 3 kW

Strokes C axis: 360°

Indexing precision of C axis: 1°

Power supply:

Voltage: 400 V

Frequency: 50 Hz

Installed power: 16 kVA

1999 vintage.

STUDER S21 is a versatile grinding, lapping, and polishing equipment designed for optimal performance and maximum throughput. Boasting high-precision features and superior efficiency, this system is ideal for a variety of industrial applications. In addition, S21 offers a user-friendly interface that is easy to operate. STUDER S21 is equipped with a modern grinding spindle design and a direct drive motor ensuring accuracy and stability when grinding. The spindle is adjustable, allowing operators to adjust the speed to match the application and for finer control over the results. The unit is also equipped with air and liquid cooling functions to prevent over-heating of the machine. S21 is designed to perform a wide range of grinding, lapping, and polishing processes and can handle materials ranging from soft metal alloy materials to hard steel. The tool is equipped with a powerful Load Regulation Adaptation Control (LEC) that automatically monitors and compensates for variable feed pressures. This allows the asset to execute consistent, reliable results every time. The LEC also allows operators to manually adjust and customize operating parameters such as grinding/polishing speed, grinding amount and pressure. To further enhance precision, STUDER S21 is equipped with a high-resolution automatic centering model, which ensures exact material centering. This ensures accuracy and repeatability in the grinding process. S21 is designed for safe and user-friendly operation and is reliable, robust and maintenance-free, allowing for extended production run times. Furthermore, this machine is ideal for use in a variety of work environments and is certified for a dust-free environment. In conclusion, STUDER S21 is a powerful, efficient grinding, lapping and polishing equipment ideal for a wide range of industrial applications. Its high-precision features and user-friendly interface, combined with its Versatility, precision, and maximum throughput, make it an excellent choice for those seeking a reliable and efficient system.

There are no reviews yet