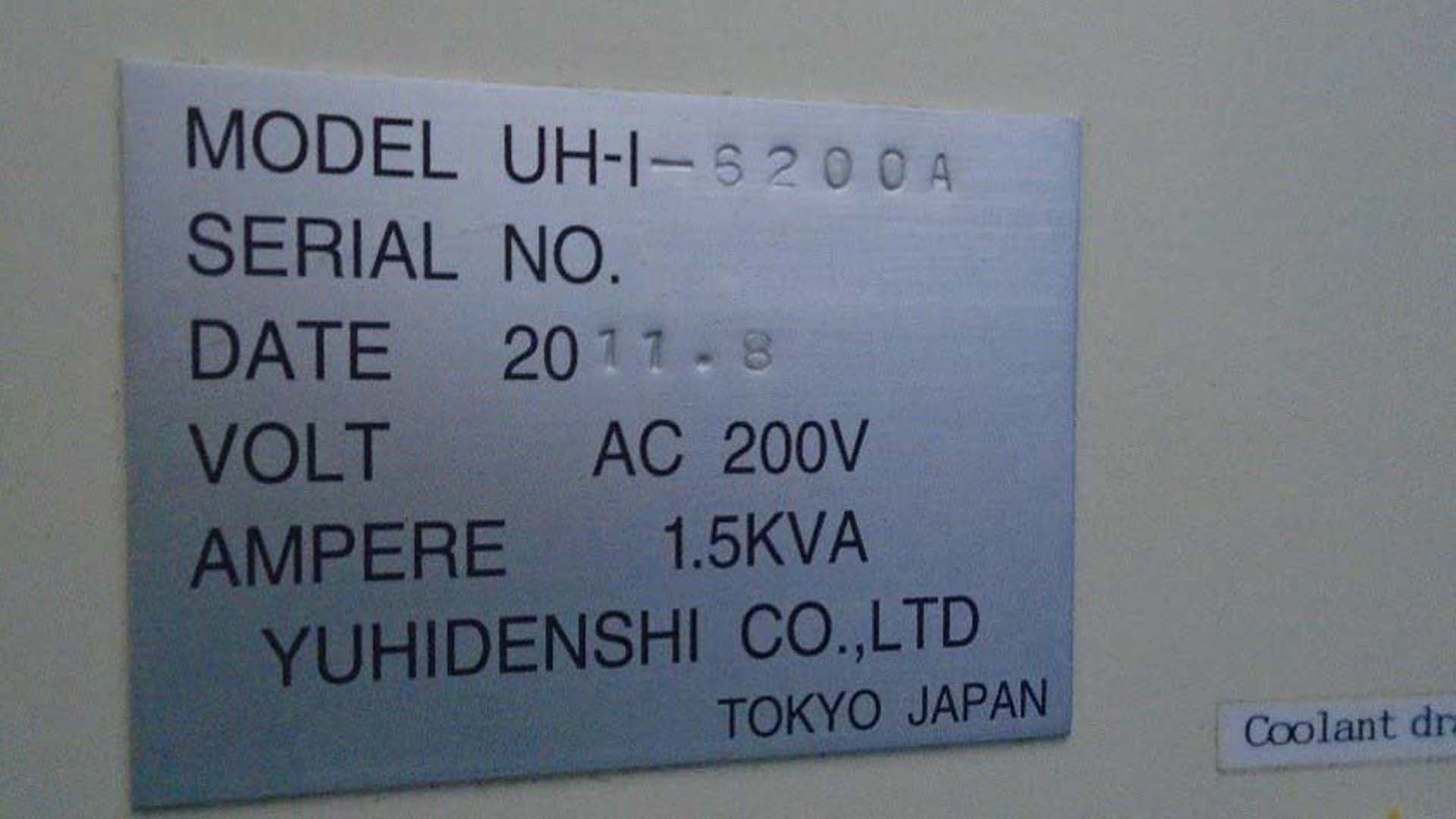

Used YUHIDENSHI UH-I-6200A #9247798 for sale

URL successfully copied!

Tap to zoom

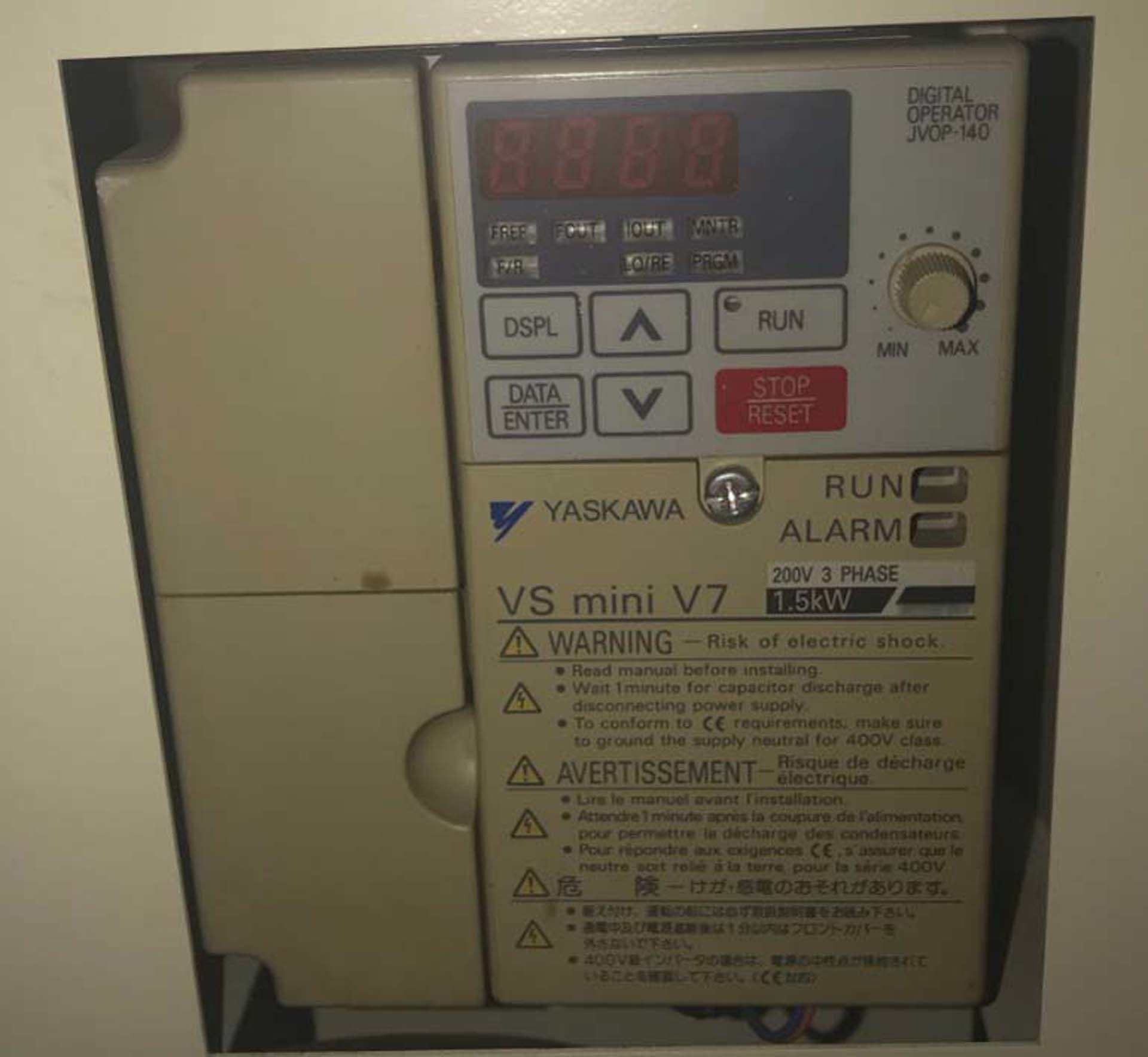

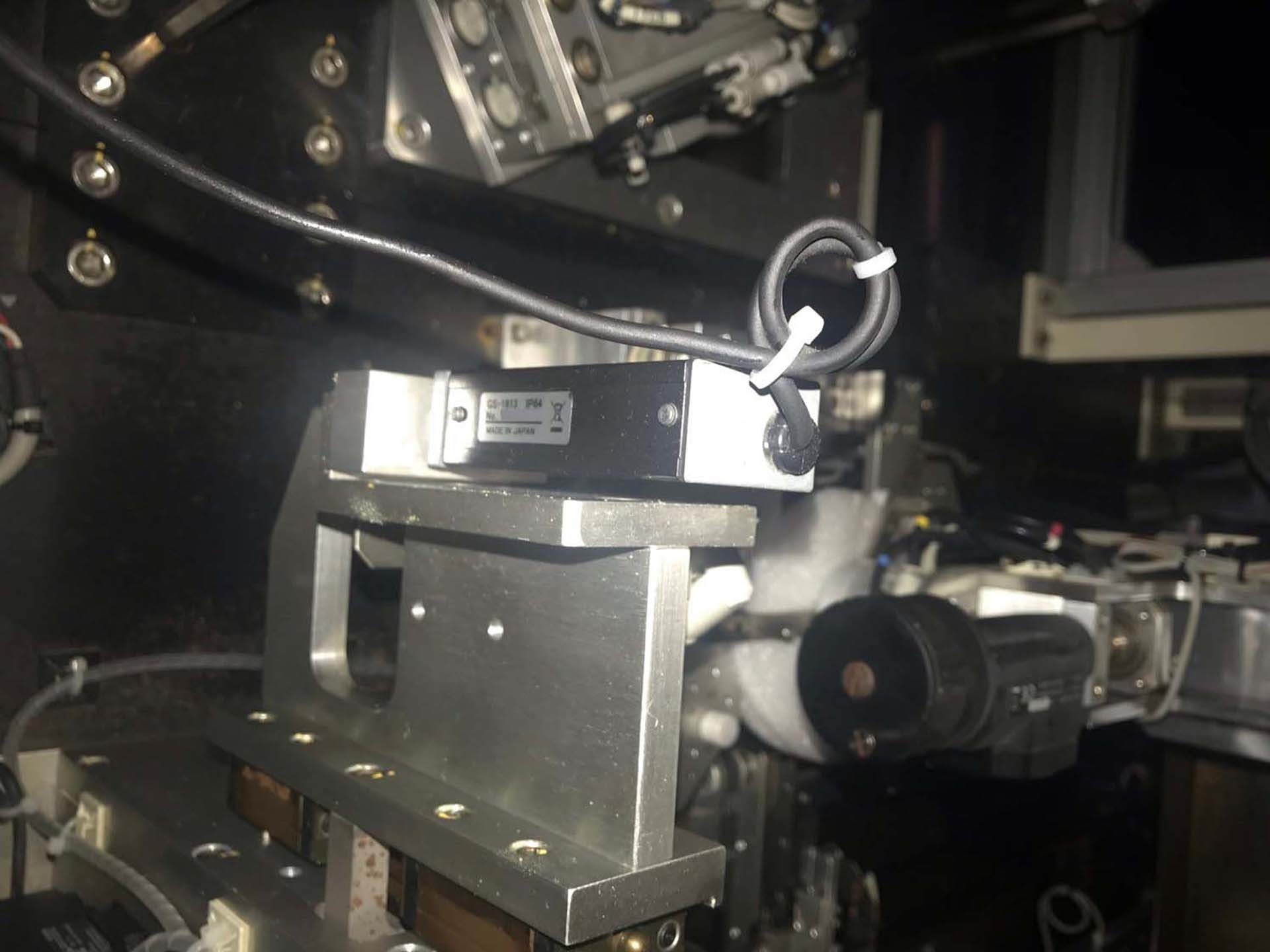

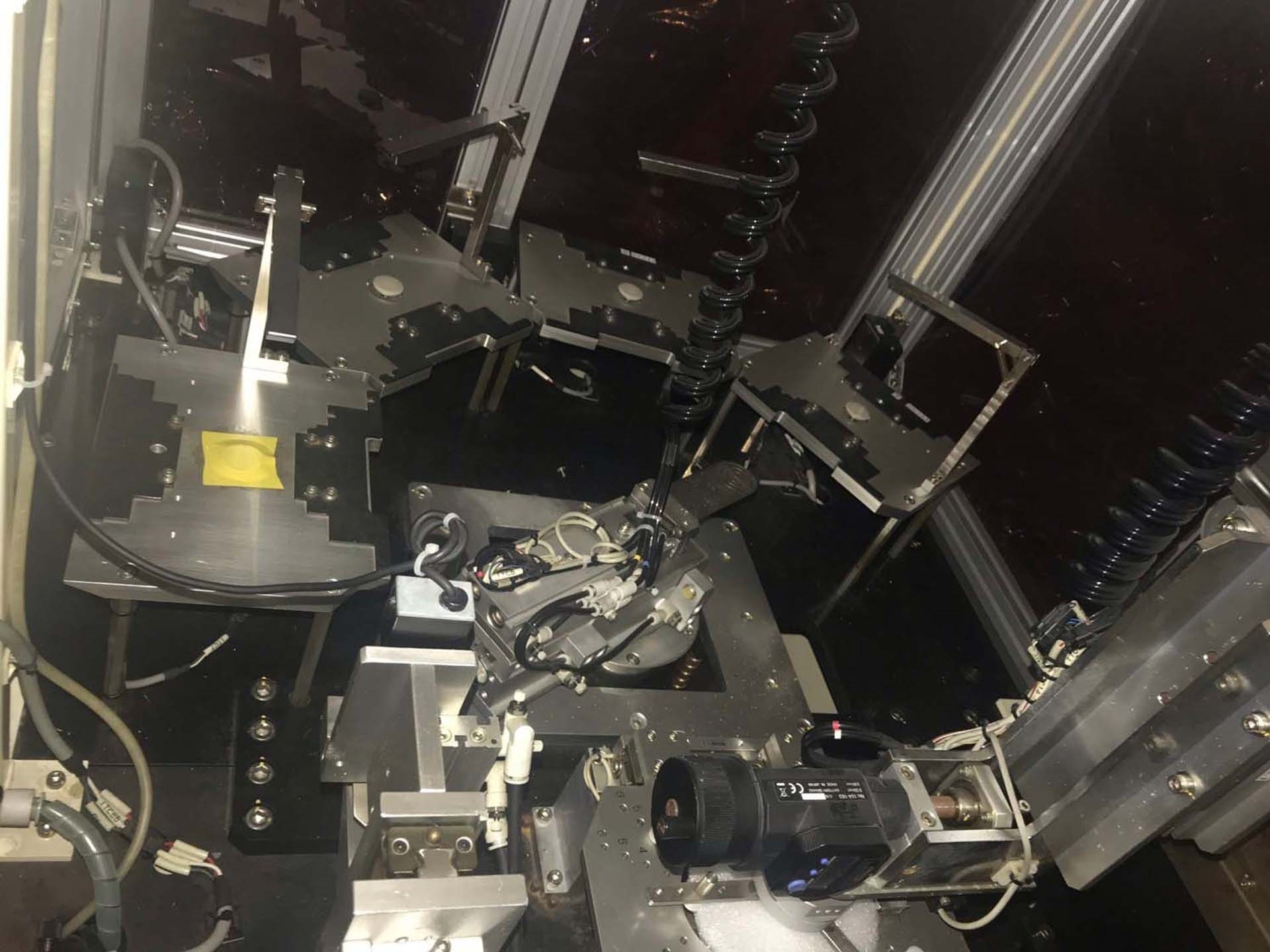

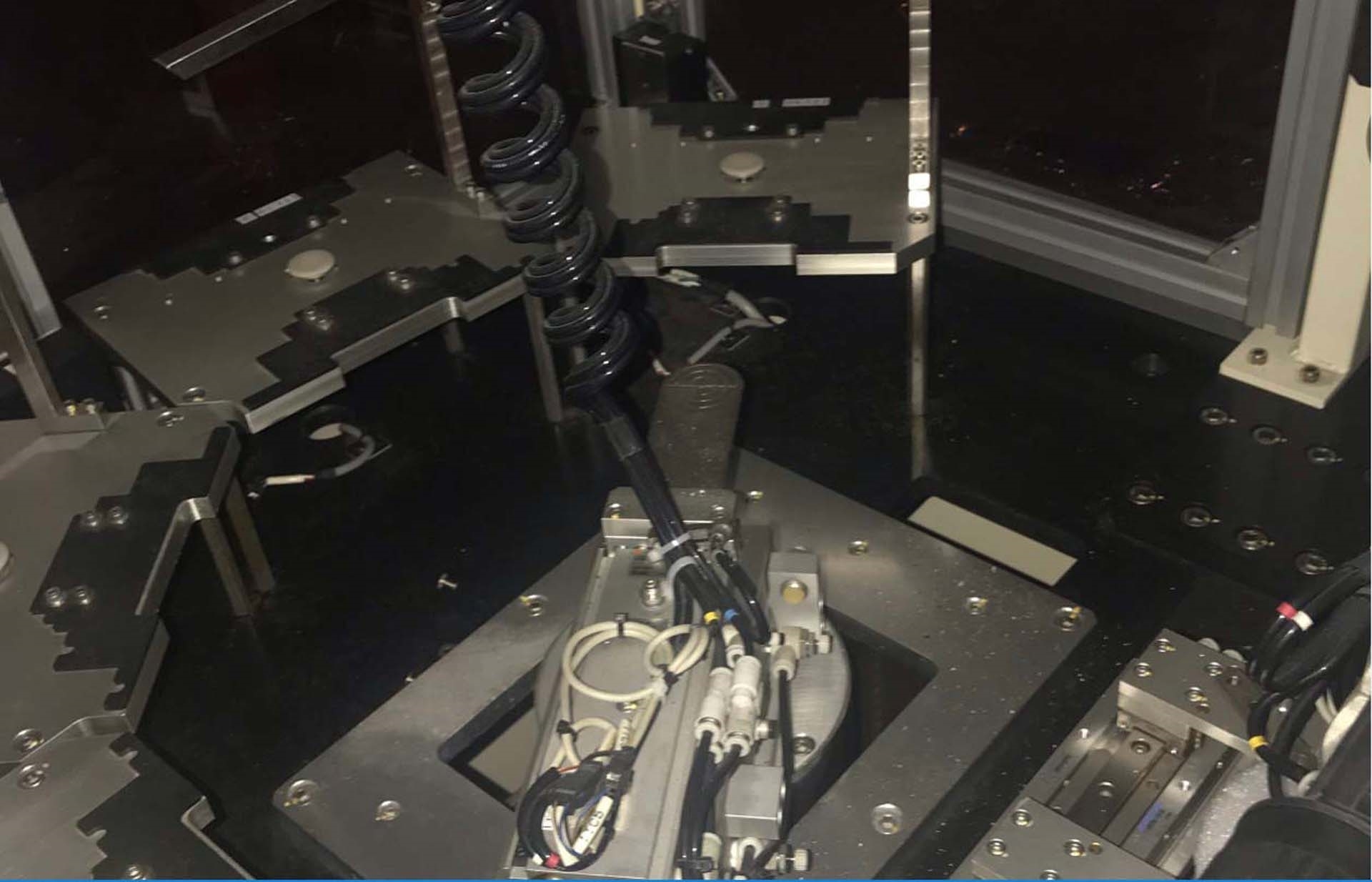

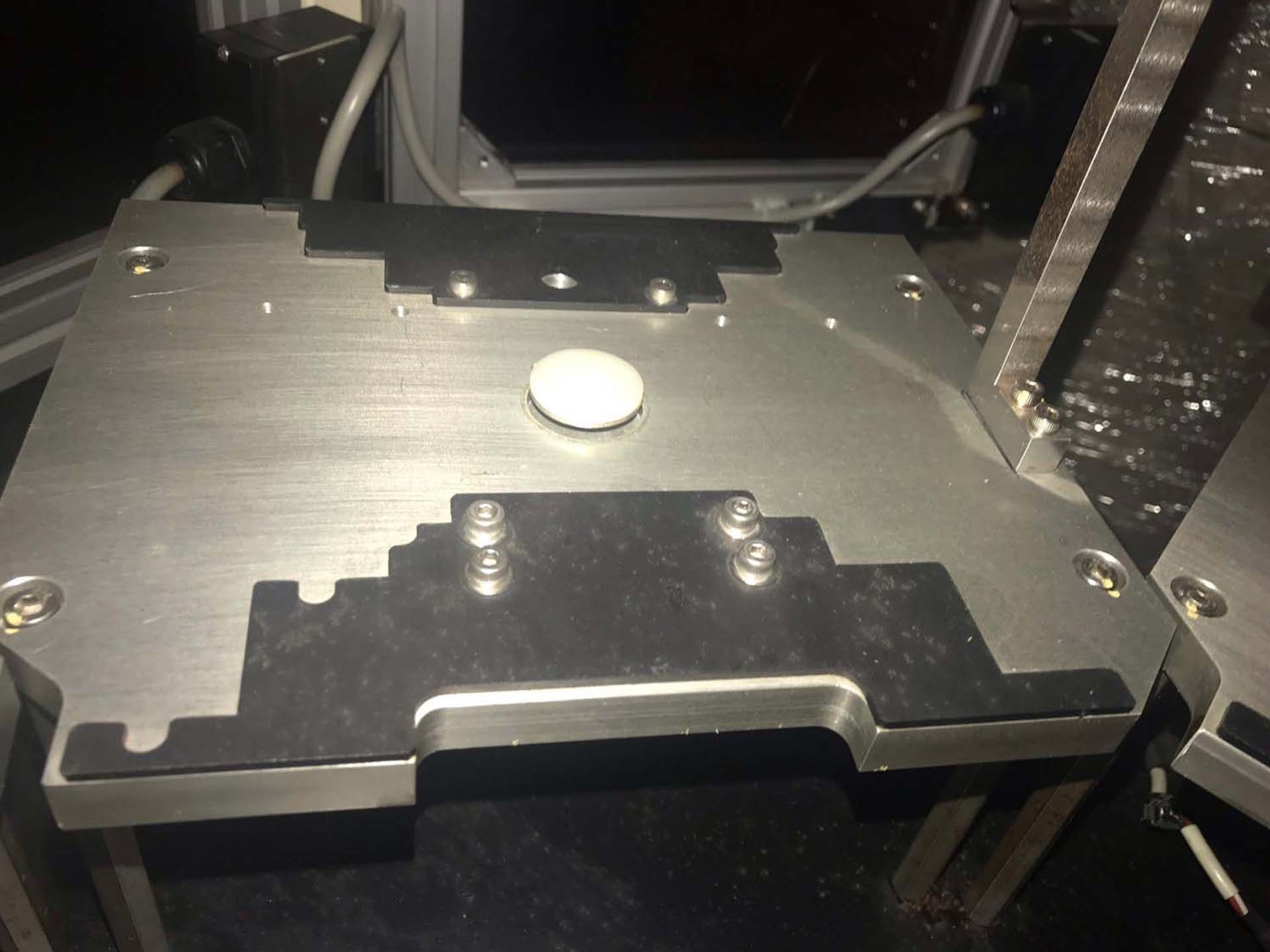

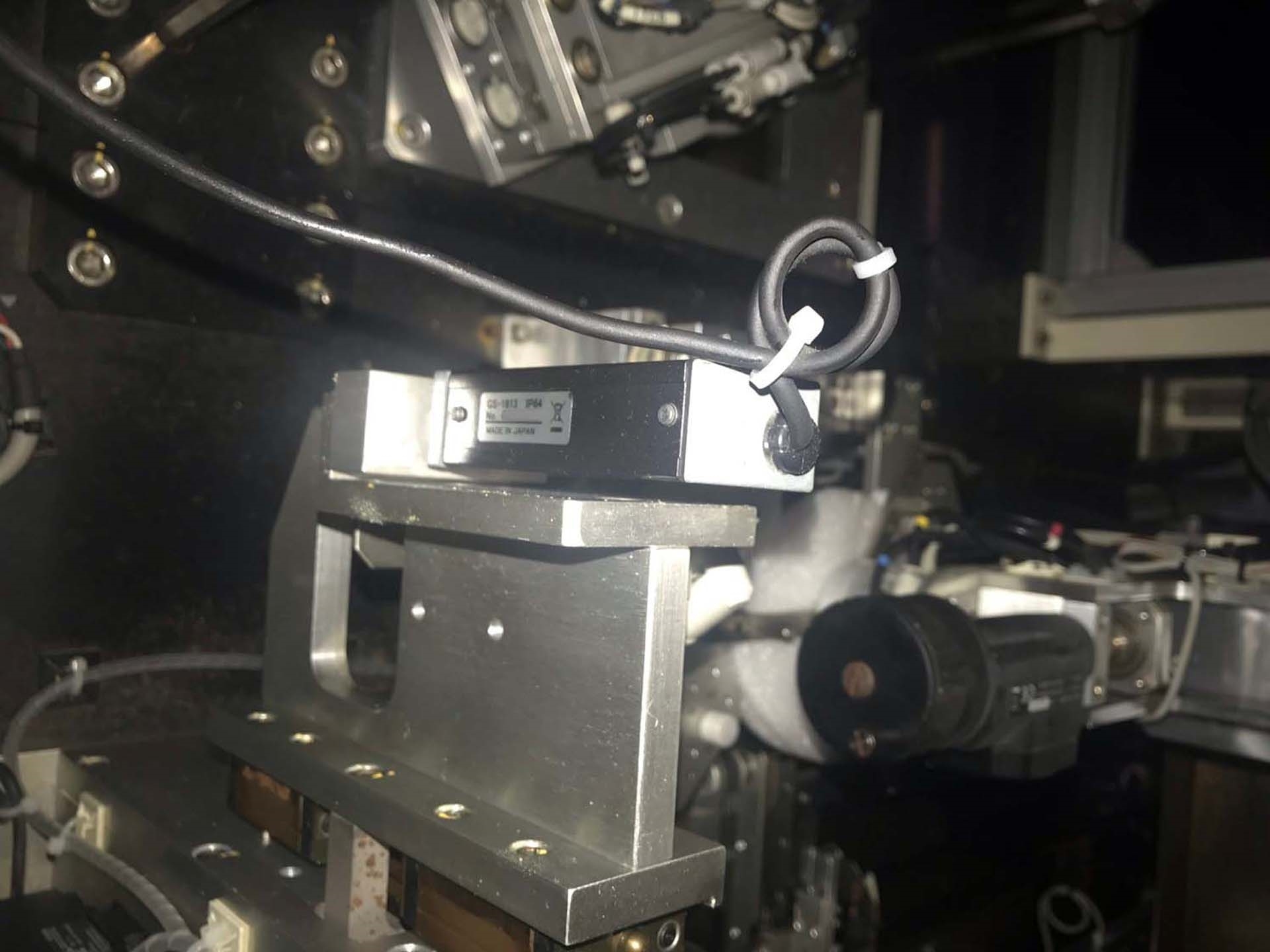

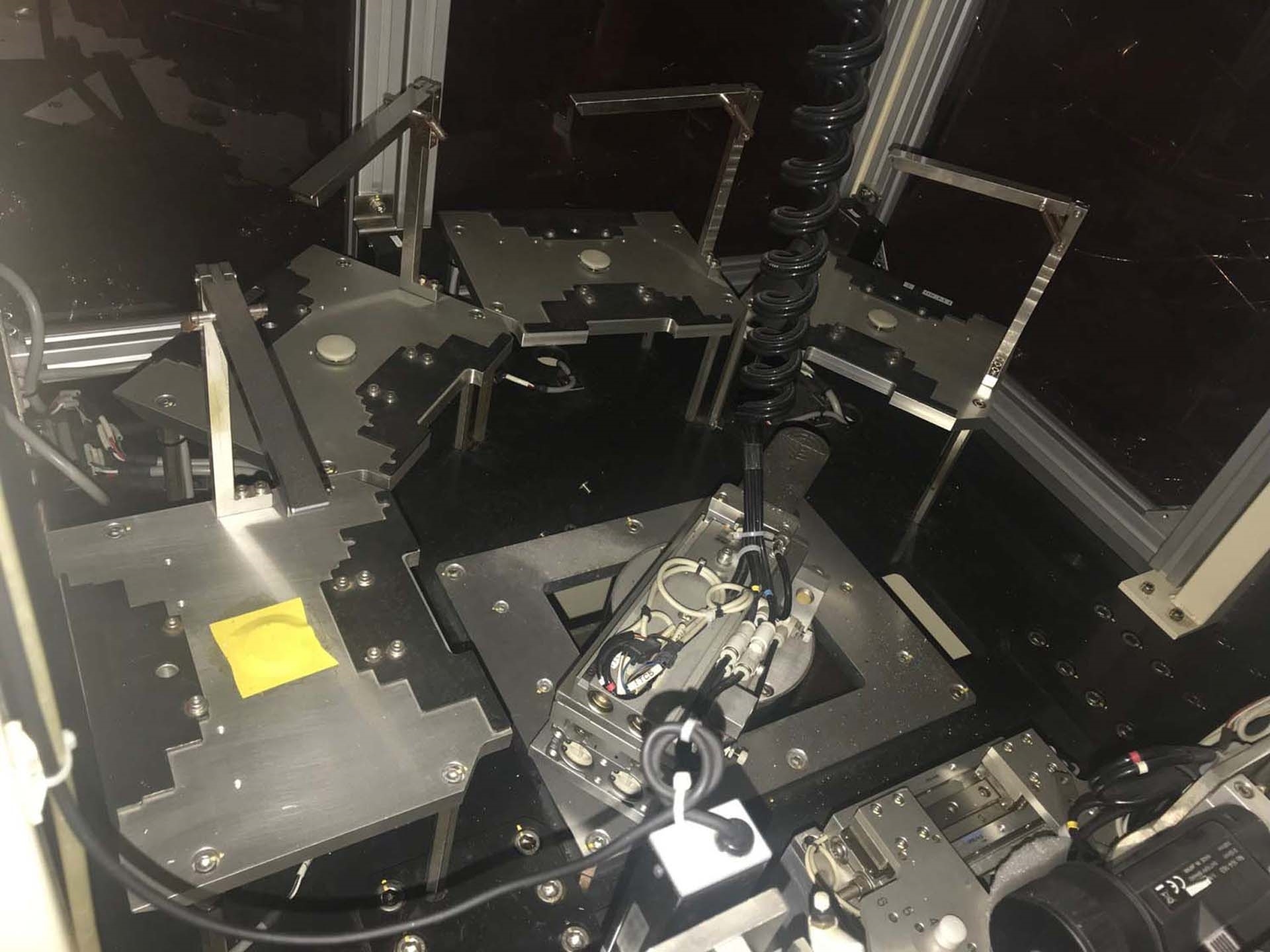

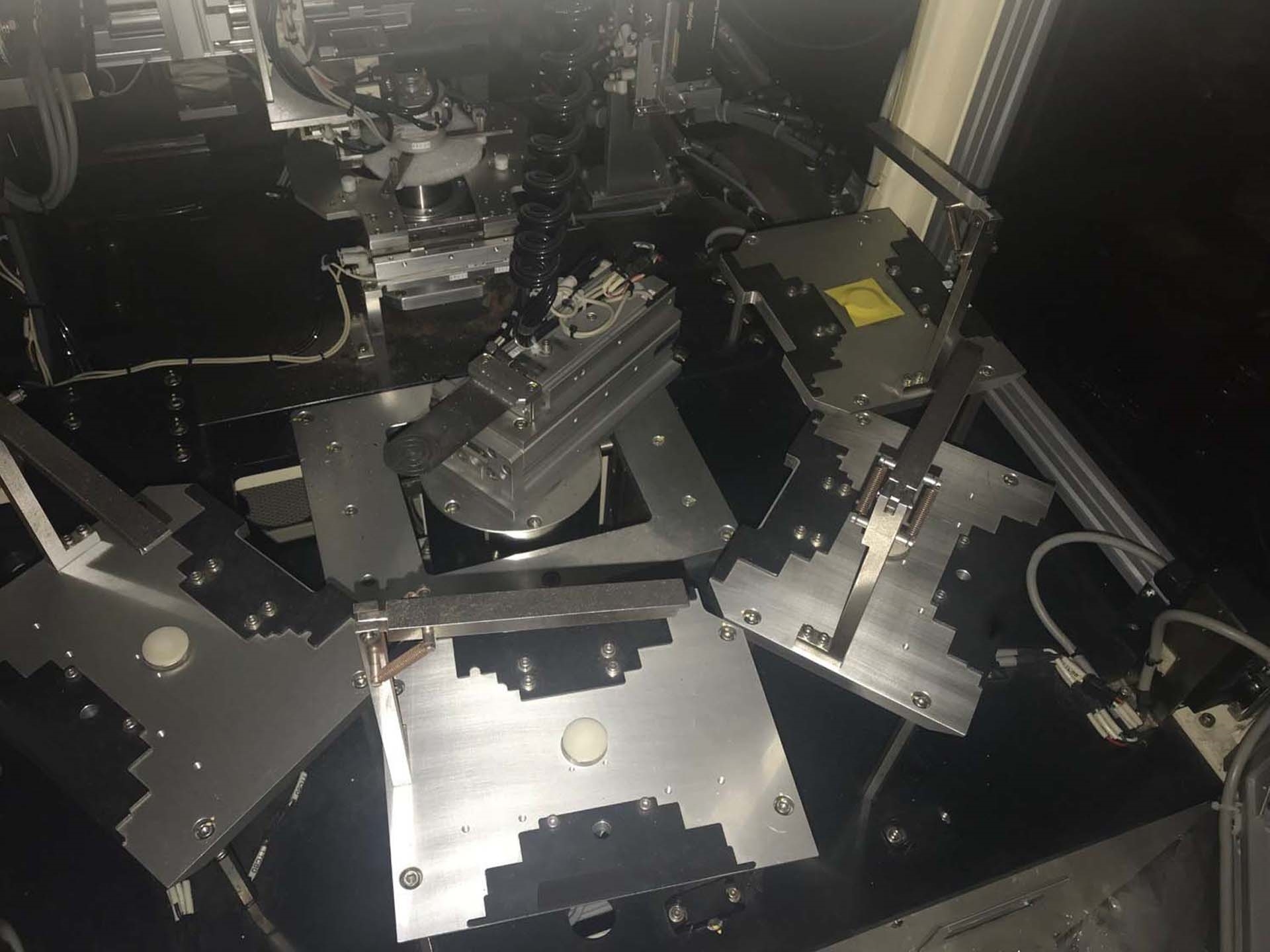

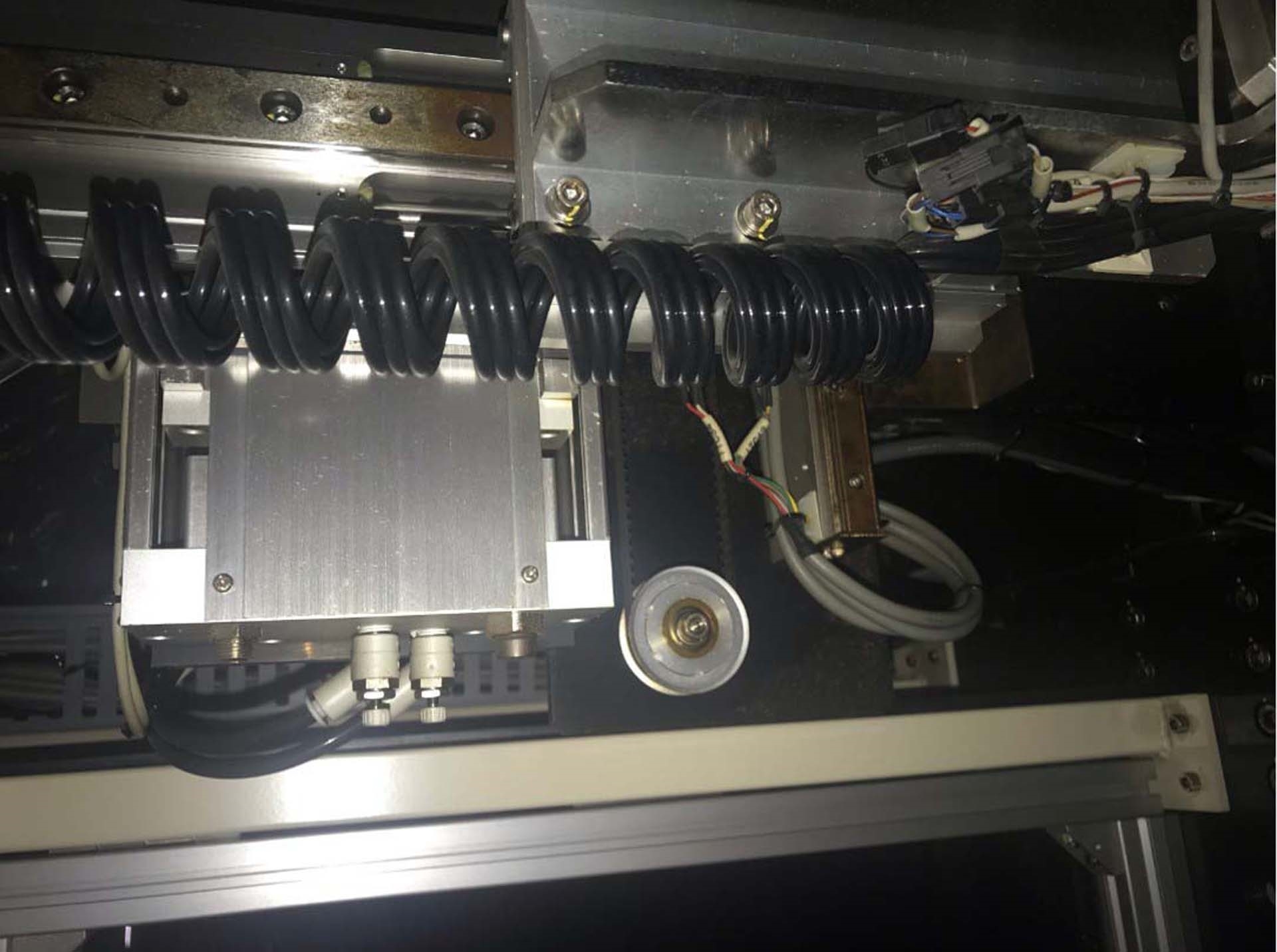

YUHIDENSHI UH-I-6200A Wafer Grinding, Lapping & Polishing Equipment is an automated, high-precision, multi-staged grinding and polishing system designed to provide high-quality wafers with reduced cost and waste. The unit has been designed to meet the exacting requirements of modern semiconductor wafer fabrication. The machine features a highly efficient motor-driven tool which allows for the high grinding speeds necessary for the machining procedure of wafers. This is supplemented by a precise motion positioning mechanism which ensures that the wafer is evenly ground on all sides. The asset utilizes elastomeric foam buffer materials to create a uniform smooth surface. The model features a fully automated process with variable speed grinding, polishing, and lapping steps. The unique design of the equipment ensures that the materials and surfaces are precisely machined. The system also incorporates an advanced dry cleaning unit to remove any remaining material particles or residues. The quality of the lapped surface is directly related to the quality of the polishing process. The fully automated design of UH-I-6200A Wafer Grinding and Lapping Machine utilizes a newly designed low pressure polishing technology, making it possible to achieve extremely precise polishing of the wafer's surface. The tool also features a robustly designed table which is capable of supporting large wafers, enabling higher grinding speeds. It is also designed with a steel-based mineral abrasion asset for the lapping process, which is powered by an electronically controlled motor for precise control of the lapping speed. The model integrates an advanced LED optical microscope to inspect the finished wafer. This allows for continuous monitoring of the finished product, and assures that each wafer produced has met the quality requirements. YUHIDENSHI UH-I-6200A Wafer Grinding, Lapping & Polishing Equipment is designed to provide a comprehensive solution for wafer grinding and lapping. The system provides highly precise and reliable results at extremely high speeds. It is capable of producing wafers with the highest accuracy, while ensuring the lowest cost and waste.

There are no reviews yet