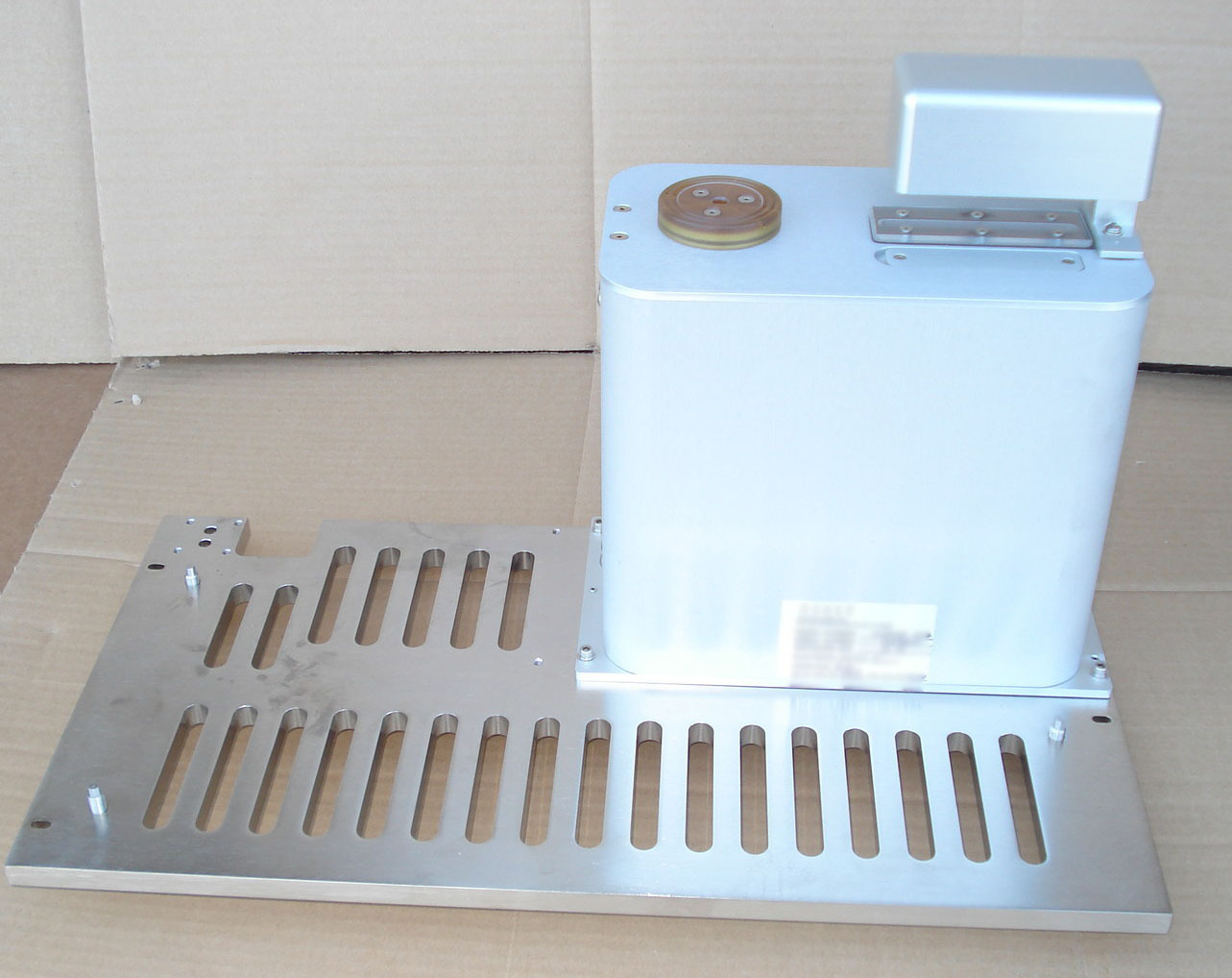

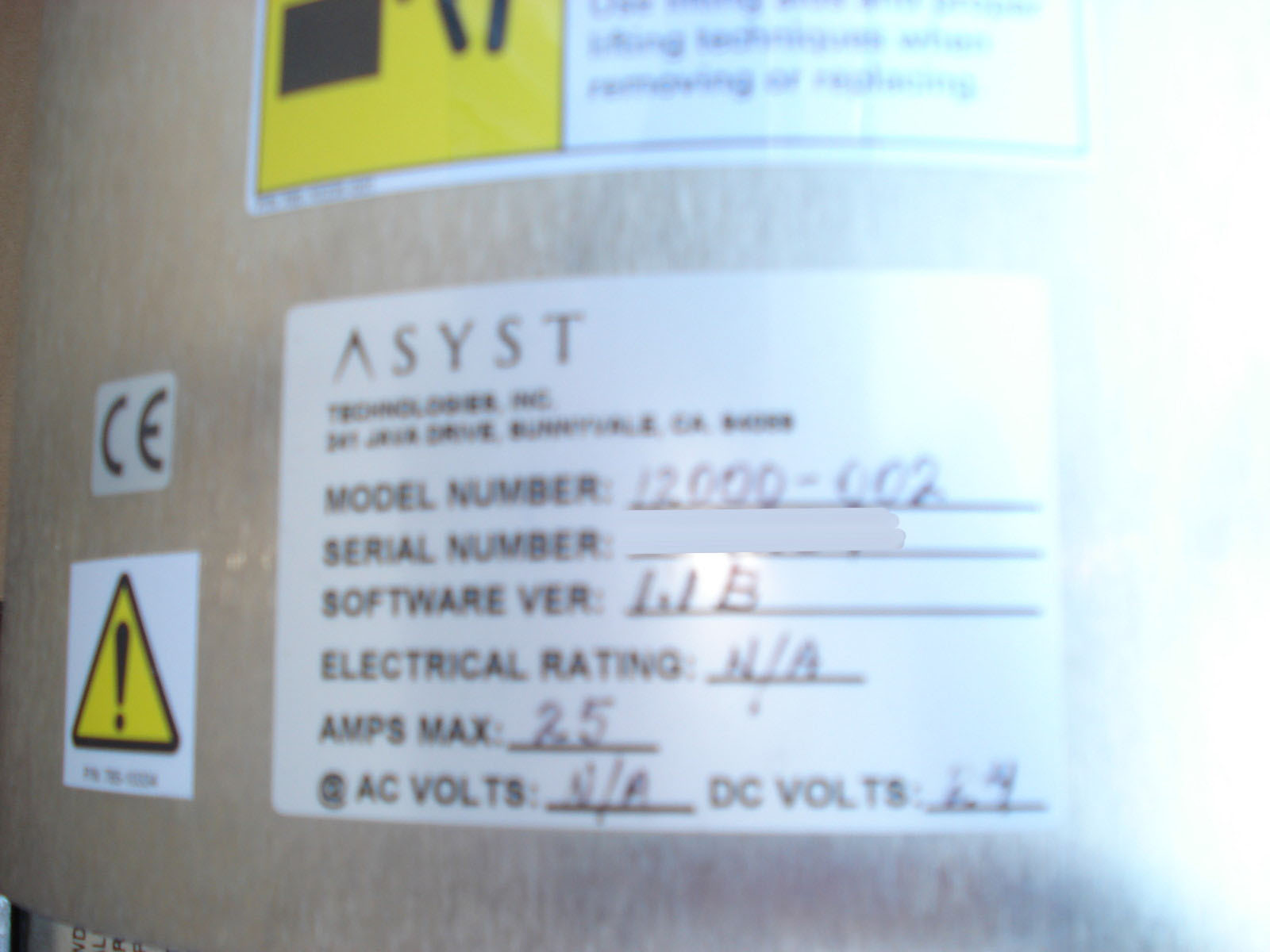

Used ASYST 12000-002 #9013356 for sale

URL successfully copied!

Tap to zoom

ID: 9013356

Wafer handling robot

Includes:

1) ASYST robot control, model 05050-014

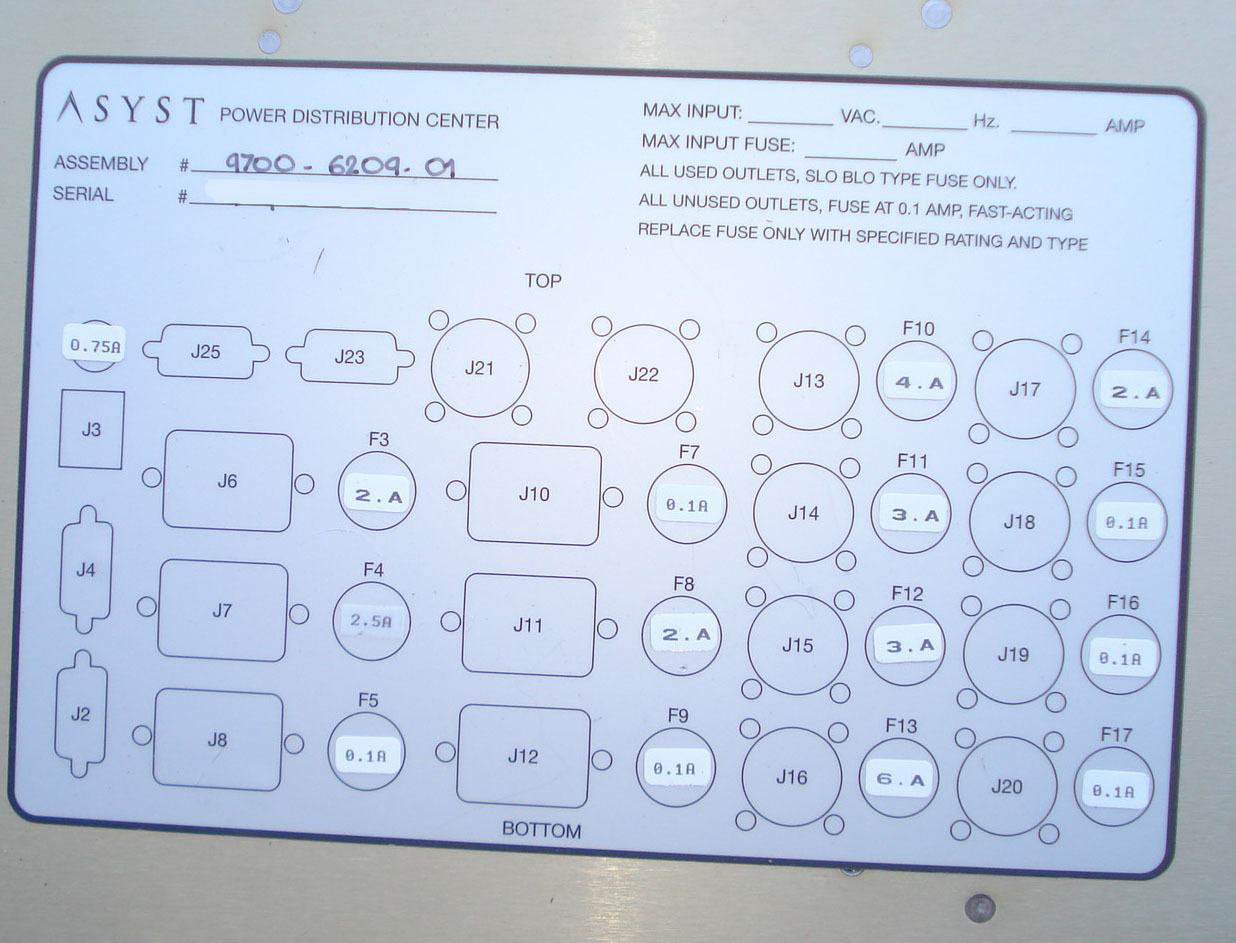

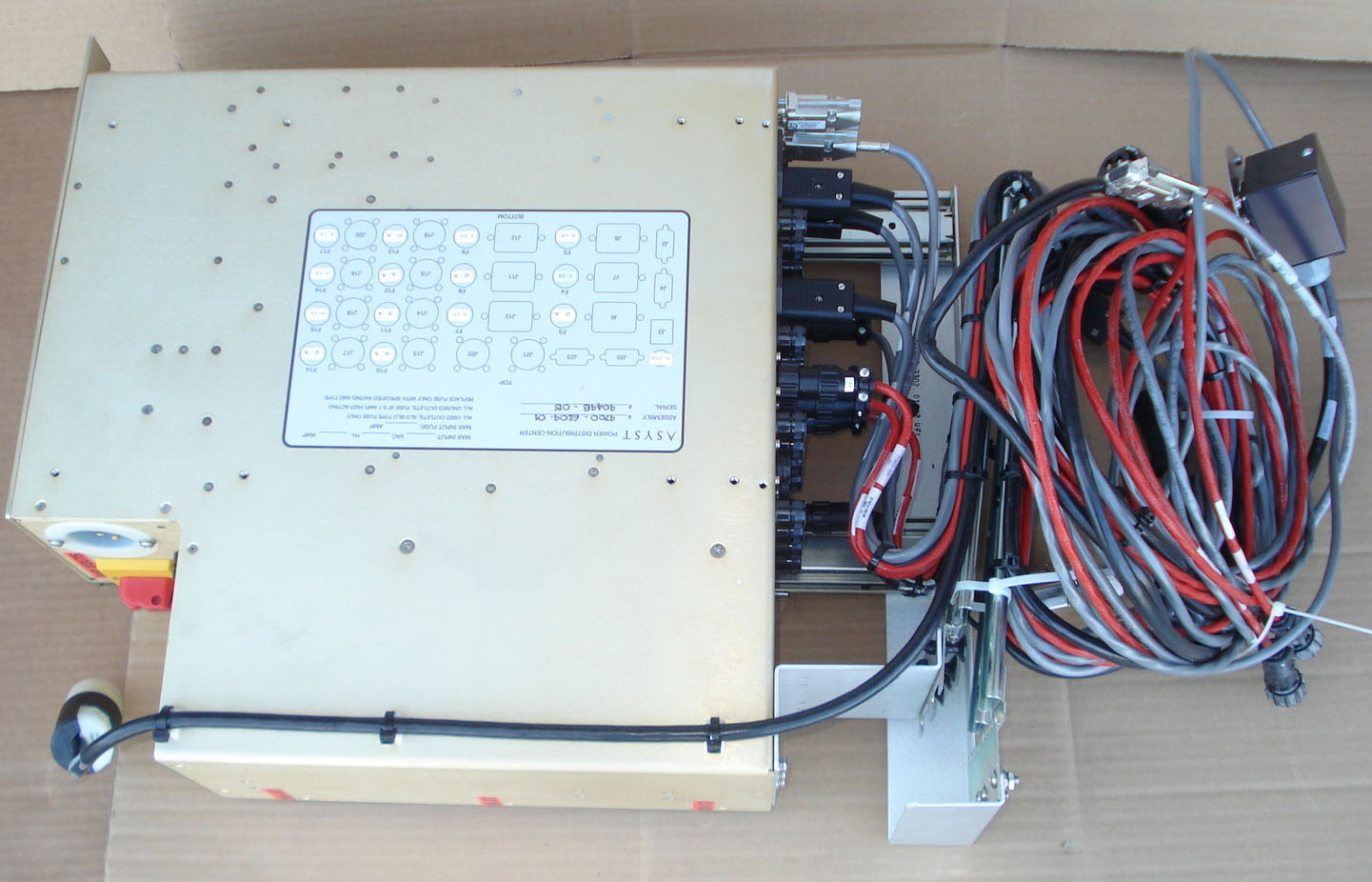

(1) ASYST power distribution center, assembly # 9700-6209-01

(1) ASYST robot pendant controller, model 8045R2-1

Many cables.

ASYST 12000-002 Smart Vacuum Handler is a precision wafer and substrate handling equipment designed for tight control of process parameters in semiconductor and photovoltaic cell fabrication. The automated platform is engineered to perform all the functions necessary for efficient wafer transport, including wafer loading and unloading, wafer singulation, wafer alignment, and wafer clamping. It can be configured with multiple vacuum chambers and port shuttles, and can be interfaced with upstream and downstream tooling to achieve the highest levels of productivity and production quality. 12000-002 utilizes a high accuracy, non-contact Z-axis measurement system that is designed to ensure precise control of wafer thickness, wafer warp, and overall flatness. By working in tandem with the other systems on the platform, the Z-axis measurement unit enables consistent wafer processing results. The machine also extends wafer life and minimizes damages caused by mechanical contact. The wafer and substrate transport is enabled by an eight-axis configuration that provides fast and precise 'pick-and-place' motion. The tool has a wide range of motion, up to 190 mm of traverse, and tightly controlled travel speeds up to 2 m/s. In addition, the platform utilizes individual motion axes to safely accelerate, decelerate or move each wafer using trajectory planning. ASYST 12000-002 features a robust construction and integrated temperature control capabilities. The temperature of the platform is precisely maintained within a range of 20 °C to 40 °C. The temperature can also be adjusted in real-time with process variations, ensuring the utmost safety and reliability of the asset. To ensure reliable wafer handling, the handling gantry is designed for fast, integrated vacuum control. A fully encapsulated vacuum model is used to ensure optimal air flow, minimal noise, and precise tuning of the vacuum levels. The multi-level vacuum equipment also ensures process uniformity across multiple wafers. 12000-002 features advanced programming capabilities that enable efficient integration into a variety of semiconductor production processes. The platform can be programmed using either G-code or a customized control language. This allows for system configuration in specialized processes, enabling the highest levels of automation and throughput. The unit is also equipped with a comprehensive monitoring machine for operation accuracy. Through a combination of mechanical and electronic sensors, the monitoring tool provides real-time feedback on wafer alignment and position. This allows for quick troubleshooting and optimized process control for maximum yield. Overall, ASYST 12000-002 Smart Vacuum Handler is an advanced wafer and substrate handling platform capable of precise control of process parameters in semiconductor production. Its advanced features enable efficient automation and highly reliable wafer transport, ensuring maximum production through efficient integration into a variety of semiconductor processes.

There are no reviews yet